Why do they even put doors on the fireplace?

It is believed that a glass door is a necessity for a modern fireplace.

Everyone sees something different in this. The advantages of a fireplace door seem to be undisputed. So why? Safety.

With a fireplace door, you don't have to be afraid to step away from the fireplace. After all, at any moment a coal can jump out and burn through the flooring. Children may get burned. Smoke may come out, after all... There is an opinion that in general “there are no fireplaces that don’t smoke”... and so on.

Energy efficiency.

A fireplace door prevents the biggest disadvantage of open fireplaces. They keep you warm while they burn. But as soon as active combustion ends. All the heat is “blown out” quite quickly into the pipe. A very large volume of air is “pumped” through an open fireplace, which does not allow it to be used as a full-fledged heating device.

With the installation of the door this problem goes away. At any time, you can cover/close the ash pit and the coals will burn out without sacrificing all the heat that the burning wood provided.

Aesthetics.

It is generally accepted that a fireplace door with glass prevents possible smoke in the fireplace. The fireplace spits less when there are pressure changes and problems with the flow of combustion air. Dark marks of soot do not appear on the arch/covering of the fireplace.

Large fireplace door, fresh from the workshop.

Determining door dimensions

The first step in making a door is to determine its dimensions. This procedure is very important, since a product that is larger or smaller than the required size will interfere with the normal operation of the device. And installing a door that is not the right size will be problematic. As a result, the work will have to be done again.

- To determine the height and width of the door, you will need a small tape measure and a marker (or other device) for marks, as well as a piece of paper and a pen for writing. You need to visually make approximately three marks along the length and width of the fuel chamber and measure the distances. If the length results from the lower left corner to the upper left differ from the same measurements in the right corner, it is necessary to record the smallest dimensions with an error of no more than one millimeter.

- If you want an arched oven door with your own hands, you need to measure the width and two heights: maximum and minimum. After this, determine the nature of the bend of your arch. For both rectangular and arched door types, you should first make a sketch on a sheet of paper, preferably in exact size. This will make it easier for you to transfer the desired shape and measurements to the material from which the door will be made.

The initial stage of creating a door will be establishing the dimensions. This procedure is extremely important, since a product that has inappropriate parameters will interfere with the proper functioning of the device. As a result, installing a door that does not fit will become problematic. Algorithm of actions:

- To determine the dimensions of the stove doors, you will need a tape measure and a marker for notes, paper and a pen. You need to visually make approximately 3 marks along the length and width of the chamber and measure the distance. When the length results differ at the corners, it is necessary to record the smallest parameters with a deviation of no more than 1 mm.

- When the user wants to make a door for an arched stove on his own, he needs to measure the width and 2 heights: the largest and the smallest. Then the bend of the arch is determined. For rectangular and arched types, you should draw a sketch on paper in advance, optimally in the exact size. This will make it easier to transfer the required shape and measurements onto the door material.

We suggest you familiarize yourself with How to make formwork for a foundation with your own hands

Stages of work

The first thing to do is cut out the corner. And then give the desired shape to the structure. In order to carry out this operation, you need to lay the corner on a flat surface, check the correctness of all connections, and then weld all the necessary parts. After finishing the work, you need to inspect the door again for correctness and compliance with the form.

Then you need to mark the inner contour of the frame on a sheet of metal. After finishing the markings and receiving all the measurements, you need to increase them slightly and leave a small allowance on each side. Taking these marks into account, it is necessary to cut out the part using a metal grinder. Since the door is planned with glass, it is necessary to have a piece of heat-resistant material that will be mounted.

Using the same tool, glass is cut to the required dimensions. Next, you need to weld the curtains to the frame. After this, you need to grab them to the common door frame. When this operation is completed, you need to make sure that nothing interferes with the opening and closing of the door. If this condition is met, then final welding can begin. The door handle is attached last.

DIY Methods

When a user plans to make a device on his own, he will need certain knowledge of furnace equipment, its structure and principle of operation. Of course, it will not always be possible to make a high-quality glass product, but it is permissible to try the metal option. Preparations:

- First of all, you need to choose the material for making the product.

- Next, the type and size of the future product are determined. The user's financial budget must be taken into account.

If you don’t have any imagination about the shape and model of the door, you can go online and look for a ready-made solution there. As a result, the user will be able to receive an exclusive product.

Important! To have confidence in the advisability of creating a device yourself, you need to familiarize yourself with all the advantages

Installing a manufactured door in a fireplace or stove with a brick body

- if the door is glass, then the glass is first removed from the frame;

- then the door is applied to the edge of the fireplace in such a way as to cover the entire surface of the firebox;

- a cutting line is drawn on the surface of the brickwork;

- grooves are cut out in the masonry using a grinder;

- a second cut is made from inside the furnace so that part of the masonry can be removed;

- unevenness of the chip is leveled with a chisel;

- the door is fitted into the slot;

- the door is removed and the fastening tape is screwed to it;

- a small volume of oven mixture is mixed (for half an hour of work);

- an asbestos cord is dipped into the stove mixture solution, which is then wrapped around the perimeter of the firebox;

- the combustion door is wrapped with a cord several turns;

- the door is installed back into the hole and secured with dowels;

- noticeable seams must be filled.

The structure is ready.

When installing fireplace doors without brickwork, you will need to drill 4 holes with a diameter of 4 mm. To do this, the attachment points are marked with a marker. The remaining stages of work are similar to those described above.

Glass door installation

Before installing a door with glass in the stove, you should check its ease of opening. If the part moves tightly, it should be developed. This will allow you to use the door as conveniently as possible in the future.

Usually in small heating appliances the temperature does not rise high enough. In addition, the frame is not exposed to open flame. For this reason, expansion of standard furnaces is minimal. Even when a piece of wire is exposed near the door, the wire itself holds in place very tightly.

There is an effective way to fasten the fire door, which prevents it from falling out. It is necessary to rivet special metal plates to it from the bottom and top. It is better to choose products with flared edges. Once all the steps are completed, the plates should be pressed into the brick.

Installation of the combustion door is carried out in stages:

- First, lay the grate.

- After this, plates and wire are attached to the door. As soon as the preparations are completed, the product is installed on the solution.

- Afterwards, the wire and plates are placed on the inner walls of the combustion chamber.

- The other ends of the metal elements are placed on 2 bricks, pressing on top with one brick.

The door angle is checked with a plumb line. Then the last wire is inserted into the door hole. It must be twisted tightly enough so that rings do not form. The wire is then placed in a hole in the first rib of the brick. Then it is pressed on top of the mortar with a brick.

Do-it-yourself fireplace door with glass - manufacturing procedure

You will need for work:

- Silicone sealant.

- 4 window panes to fit the screen.

- Stones for decoration.

- Metal mesh or grate.

- A metal box the size of which matches the base of the screen.

The algorithm for making glass for a fireplace with your own hands is as follows:

- Apply silicone sealant to all 4 panes around the edges.

- Fix the glass at right angles to create a parallelepiped-shaped structure.

- Press the planes firmly against each other and wait until they harden completely.

- Cut off any remaining silicone using a knife or razor blade.

- The screen is ready, now all that remains is to complete the base. Apply sealant to the bottom of the glass box and press the glass to the metal box. The sides of the metal box must be wide enough to accommodate the metal mesh grille.

- Now let's set up the firebox. Place a can of helium fuel in the middle of the box. Place a metal mesh on the sides (it can be laid in separate pieces). Place stones on top of the mesh, remembering to leave gaps between them for ventilation.

The original fireplace of the simplest design is ready!

What you need to prepare

The tools we will need are:

- electric drill or hammer drill;

- angle grinder;

- a hammer weighing up to a kilogram;

- welding machine and electrodes;

- roulette.

The following materials are needed:

- steel corner of the width that suits you;

- metal strip;

- hinges (turned eccentric);

- bolt;

- handle for opening.

You will determine the exact dimensions yourself and adjust the above drawing to fit them.

Material requirements

For fireplace doors, high-strength and heat-resistant thermal glass is used, which has undergone special hardening and processing. It can withstand up to 10,000 C for several thousand hours of direct use.

This glass contains elements such as heat-resistant quartz and transparent crystal ceramics.

Quartz glass is the most popular because it has the smallest expansion when heated. This material is not inferior in strength even to metal products. Using ordinary thermal glass (for the sake of economy) is not advisable, since it cannot withstand temperatures exceeding 1500 C and may crack upon first use. Glass can be of various sizes depending on the parameters of the fireplace, various geometric shapes and curvature.

It is possible to use tinted glass, which will muffle the bright light of the flame. Installed double or laminated glass will contribute to even safer use.

When choosing glass you need to consider:

heat resistance, paying attention to the type of fuel; service life, thickness of the glass screen (at least 3.5 - 4 mm).

Fireproof glass has a disadvantage: it is quite heavy.

. This must be taken into account when choosing door mountings and methods of their operation, creating the most comfortable conditions for handling this device.

Door specifics

If you intend to make a door with glass inserts, you should first of all decide on its style

It is important that it matches the overall decoration of the room and the specifics in your particular case. So, for example, in small rooms it makes sense to make a double-leaf insert or a rising one to save space.

Both of these options are ideal for a corner fireplace. The main point that should not be forgotten is the selection of glass. It must have a heat resistance of at least 800 degrees - it is to this temperature that the flame usually flares up.

The prepared glass is inserted into the metal frame of the door itself, and that, in turn, is attached with hinges to the outer frame, which is fixedly fixed in the opening of the firebox. Wherein:

- a seal is installed on the inside to prevent smoke from entering the room;

- At the bottom of the outer frame, holes are made with adjustable plugs for air access to the firebox;

- Keep in mind that metal tends to expand greatly when heated, so the gap between the transparent insert and the frame is not made too large;

- When starting production, remember that the glass cannot be fixed tightly, because during installation it will need to be removed from the door;

- strips of fiberglass are inserted into the frame to seal it.

Groups of doors in the process of laying

Fire door

The stove design includes doors for various purposes. Each element has its own role. The following doors are separated:

- furnace;

- view;

- blowers;

- cleaning

Furnace

Designed for storing fuel. The combustion door performs the following functions:

- protection of the surrounding area from fire;

- heat transfer from material burning in the firebox to the room;

- preventing sparks from flying out;

- provides combustion with oxygen.

Podduvalnaya

It is installed on the ash chamber, through which the oven is cleaned of ash that spills into the lower compartment. The blower door provides the process with air. By opening or closing it, the flow and rate of fuel combustion are regulated.

Blower doors are made of cast iron or steel, less often glass. They can be of a simple design, or they can be made of cast iron with a relief finish or ornament. They are made in the same style as fireboxes.

Cleaning

They close the hole in the chimney wall and serve to clean it from soot and soot. This is a necessary element in the design of the stove, ensuring its proper operation. Some builders ignore their installation, but an experienced stove builder will never do without cleanout holes. Their presence simplifies stove maintenance and smoke-free operation.

View

To prevent hot air from leaving the stove after combustion of fuel, a damper is installed on the chimney. It is a frame with grooves along which a plate moves, blocking the smoke exhaust channel. The valve is placed in the brickwork of the pipe.

Cleaning Blower Viewing

Characteristics

The designs of all stoves, unlike most fireplaces, require the mandatory closing of the hearth. The furnace door for the stove has several functions:

- protects the room from open fire;

- ensures heat transfer from burning fuel to rooms;

- prevents sparks from entering the room;

- increases the efficiency of the combustion process;

- decorates the structure as a whole.

All elements of furnaces must be fire-resistant, mechanically strong, and prevent the occurrence of fires.

Conventional doors for the combustion chamber allow air to pass through because they are not sealed tightly with a regular handle. Compacted types have a clamping mechanism, which reduces the amount of air entering the interior.

An eye-pleasing feature of some doors is a glass insert mounted in the center; it does not perform any important functions, but it makes it possible to enjoy the sight of a burning fireplace, which many owners really like.

Installing a manufactured door in a fireplace or stove with a brick body

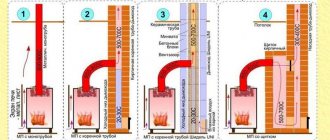

The placement of the stove depends entirely on what exactly the owners expect from it. If it is installed in a small house and will be used as a fireplace for friendly gatherings, you can use the first scheme. This stove is a good option for cooking barbecue on the grill or kebabs.

Brick kiln placement options

The second scheme is for a house of solid square footage. In this case, the front side of the fireplace stove opens into the living room, the stove walls heat both bedrooms, and the heat in the remaining rooms is maintained using heat exchange.

The third scheme with a stove for heating and cooking is a budget housing option for a bachelor or a small family. Pros: a warm bed and the ability to place a dryer in the hallway.

Important: you should take care of the external insulation of the house in advance, because it greatly increases the efficiency of stove heating

- if the door is glass, then the glass is first removed from the frame;

- then the door is applied to the edge of the fireplace in such a way as to cover the entire surface of the firebox;

- a cutting line is drawn on the surface of the brickwork;

- grooves are cut out in the masonry using a grinder;

- a second cut is made from inside the furnace so that part of the masonry can be removed;

- unevenness of the chip is leveled with a chisel;

- the door is fitted into the slot;

- the door is removed and the fastening tape is screwed to it;

- a small volume of oven mixture is mixed (for half an hour of work);

- an asbestos cord is dipped into the stove mixture solution, which is then wrapped around the perimeter of the firebox;

- the combustion door is wrapped with a cord several turns;

- the door is installed back into the hole and secured with dowels;

- noticeable seams must be filled.

The structure is ready.

When installing fireplace doors without brickwork, you will need to drill 4 holes with a diameter of 4 mm. To do this, the attachment points are marked with a marker. The remaining stages of work are similar to those described above.

Preparation, list of tools

Before starting work, you need to determine and mark the place that the new stove will occupy.

The chimney pipe should be no closer than 15 cm from the roof rafters.

If you are doing masonry for the first time, professional stove makers advise you to practice in advance by making a model of the future stove from prepared bricks. Naturally, without a solution. This minimizes possible risks during real masonry, allowing you to learn from your mistakes, which can still be corrected in the layout.

The stove foundation requires preliminary waterproofing; its area must exceed the area of the stove.

When laying a new row, you need to control the absolute verticality of the walls.

To build a brick kiln, the following tools are needed:

- plumb line;

- trowel;

- roulette;

- putty knife;

- Bulgarian;

- knitting wire;

- building level;

- metal strips, corners;

- containers for cement and clay mortar.

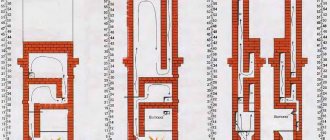

Classification of furnace units

Most often, homemade stoves are made with cooking surfaces.

According to the characteristics of the device they are made:

- chamber;

- duct;

- bell-shaped

In chamber stoves, flue gases enter a special chamber and are completely burned there due to natural circulation. Their design creates a similarity to the burning of an ordinary fire in a confined space. In domestic models, the combustion compartment is connected to the afterburning compartment into a single module called the crucible. Its vaulted shape ensures complete combustion of fuel. An example of such a design is the classic Russian stove.

In a ducted unit, the flue gases first burn out, then gradually cool down and move through the channels located between the partitions. When moving, they give off heat to the furnace body. There is no afterburning inside until the temperature in the combustion chamber reaches 400 degrees. The efficiency of these devices does not exceed 60%.

In a bell-type furnace, combustion products move to the roof of a special bell and linger there, burning out completely. Then the gases sink to the bottom and give off heat to the body. To kindle such a unit, it is enough to warm up only a small area of the hood. Its efficiency can be 75%.

Pros and cons of ready-made stove ideas

Let's look at several reasons why people often choose the old type of heating for their home:

The first undoubted advantage is maintaining heat with a brick oven. Judge for yourself - such a stove keeps heat for at least a day, provided that you need to add firewood once every six hours.

The ability to store heat makes a brick stove very economical, because it does not require a constant source of fuel, moreover, they are much more environmentally friendly than their metal “brothers”.

The surface of such a stove does not heat up to such a high temperature that could leave a burn on the human body; on the contrary, if you lean your hand against it, you can feel pleasant warmth and comfort.

In addition to all of the above, a brick stove has aesthetics; look at the photo of a homemade stove and you will understand everything for yourself.

The downside, perhaps, is that a cold room takes a long time to heat up, but you can heat it up a little earlier or purchase special heaters that will warm the room at least a little while the main power warms up.

Pros and cons of metal stoves

Metal is a durable material, but it is both ductile and malleable, which allows it to be given almost any design. It is able to withstand high loads and temperature changes. There are many methods for processing metals, so various technologies can be used in the manufacture of furnaces.

Another important advantage of a metal stove for a home is the integrity of the structure, so it can be moved and transported without any problems. This is impossible to do with large brick structures.

Due to their low weight, metal units do not require a separate solid foundation, and installation only involves the construction of a chimney. During the non-heating season, the mobile iron product can be moved to a utility room or shed and thereby free up space in the room.

The metal used as the material for manufacturing the unit has high thermal conductivity, as a result of which it heats up quickly, but also cools down similarly. Such heating helps to increase efficiency. In brick stoves, you must first wait until the internal heat exchange begins, and before that, during the heating process, all the resulting heat goes into the chimney.

Almost all the advantages of metal units are based on the characteristics of this material - it is quite dense, non-porous, and does not become damp under the influence of condensation like bricks. They are not at risk of long breaks in work; they do not need booster firing after downtime.

Metal stoves for summer cottages are easier to certify and it is easier to obtain a permit for them from the fire inspectorate, which will save both money and time. There are models on sale that do not require approval at all, but only the installation of an autonomous chimney.

But metal units also have disadvantages:

- They do not “breathe”, since, unlike brick, metal is not a porous material. When a brick oven cools, it absorbs moisture from the air and releases it when heated. As a result, a constant balance of humidity is created in the room, providing a feeling of comfort. Sometimes metal units are faced with brick to achieve a similar effect, but it is not as effective, and the structure loses its lightness and mobility.

- As already mentioned, metal quickly heats up and cools down, so in order to maintain heat in the house, the stove made from it has to be fired constantly, otherwise it will completely cool down in a few hours. This problem can be solved by manufacturing a metal unit that burns for a long time. But in any case, it is a permanent source that creates the risk of fire and fumes, and for this reason it cannot be left unattended for a long time.

- The main disadvantage of metal stoves is their fire hazard. When heated, their walls become heated to such an extent that they can cause ignition of objects, finishing materials, and floor coverings located in close proximity to the fire. Therefore, it is not easy to obtain permission from the Ministry of Emergency Situations to use an iron unit in a residential building - a separate boiler room will have to be equipped for it.

- The service life of a metal stove for home is up to 20 years. With frequent use, even thick metal burns out, as a result of which the walls of the product become thinner. But in just a decade of operation, the stove fully pays for its cost due to reduced fuel costs and the ability to replace the unit without repairs or redevelopment of premises.

Step-by-step instructions with photos for laying a stove

Different stove makers have their own masonry technologies and their own secrets that come with years of experience. Here is information about a fairly simple way to create a stove-fireplace for heating a two-story house; the process will not seem extremely difficult even to novice stove makers.

Foundation laying

The base course of brickwork will serve as the foundation. It is done with any brick; some stove makers even fill this level with crushed stone.

When laying the base row, cement mortar is used.

The foundation is completely filled with mortar, the layer is leveled.

Construction of the furnace body

The first row of stoves is marked. The horizontal line from which they start when marking is the wall of the room.

A grate is placed where the fireplace is planned to be placed. From this row, the bricks are already laid on the kiln mortar.

An important stage of work is the scrupulous alignment of each new row by level.

Laying the second row. The stove wall, located closest to the wall of the room, is reinforced with additional bricks to increase fire safety.

The place where the chimney will be located in the 2nd row remains empty, the rest of the stove is laid completely. A door is installed through which the owners will clean out the ash.

The door is installed on the solution and leveled. For a more reliable fixation, it is secured with wire, which must be laid between the bricks.

Next, the next 3 rows are placed. Then a brick stop for the grate is installed - 2 rows of 1/4 bricks are placed on the sides.

The grate is laid not on a simple brick, but on a refractory brick. To ensure that it lies at the same level as the bricks, holes are cut in the fireclay bricks.

The size of the brick can be easily adjusted - the excess is measured and carefully cut off.

The large door is mounted next to the installed grille.

The large oven door is similarly secured using wire fasteners.

The first row of fireboxes is placed exactly above the fireplace, it is reinforced with metal corners and a strip or thick tin. So that the masonry can lie on them, it is cut using a grinder, then the slots are adjusted manually to the desired size.

The next brick row is laid.

A fireplace grate is laid on the fire-resistant brick along with the brick row.

The door is fixed, the brick is strictly adjusted to it.

The firebox of the new stove and fireplace is ready.

Fire-resistant fireclay bricks are placed above the stove firebox.

The stove body is built.

Creating a chimney

The space left for the chimney is divided into wells. The design requires reinforcement with metal plates.

Brick chimney wells are laid.

Soot cleaners are mounted above the firebox roof.

The wells are divided again, the first rows of walls should be reinforced with strips of metal.

After strengthening, the ceiling of the furnace body is erected. The space associated with the chimney remains empty.

The body cornice is laid out, then the chimneys are laid.

The final stage of work on the first floor. The stove is located at the bottom left, the smoke inside the chimneys moves in a spiral and comes out at the top left. The final separation of the wells is covered with a tin sheet. In order to compensate for the pressure inside the fireplace stove, 2 brick rows are laid on the tin.

There are two chimneys stretching to the second floor of the house - from the fireplace and the stove itself, they are separated from each other. Each chimney requires the installation of a separate damper.

Floor level of the second floor. Waterproofing is installed here, the chimney is again reinforced with metal corners. To save money and avoid building a heating stove on the second floor, the chimney of the stove under construction is again divided. The smoke will snake through it, managing to warm up the room. In order for the chimney to warm up much faster, it is laid in the area of the second floor with a thickness of 1/4 or 1/2 brick.

A hole for the stove chimney is carefully cut out in the roof.

Before placing the chimney on the roof, it is reinforced with metal corners.

If the chimney is located in close proximity to the roof ridge, it must be laid out at least 0.5 meters above the ridge. If further, then the height of the chimney is allowed equal to the height of the ridge, but not lower. In this case, the wind increases the stove draft, lifting the smoke upward.

Even a small stove in the house means coziness and comfort. Larger stoves require increased skill and additional materials, but the principle of their construction is similar to the method described above.

rmnt.ru

19.02.17

Features of metal stoves

The performance characteristics of heating units depend on the metal. Since its thermal conductivity compared to its heat capacity is much higher, this material does not accumulate heat well. The metal quickly absorbs thermal energy, heats up and soon cools down. If you take this property into account, you can assemble a metal fireplace with your own hands in such a way as to achieve high values with a minimum degree of heating.

Homemade metal stoves function differently depending on the design features:

- Chamber. These devices are actually an ordinary “potbelly stove”, the first examples of which appeared a couple of centuries ago, but they required a large amount of fuel. Then their design was improved - they placed a grate with a blower in it, shortened the chimney to 2.5-3 meters and insulated it. The peculiarity of the unit is that it is self-regulating - when the fire is fully fired, the throughput of the chimney pipe is not enough to remove the flue gases, as a result, turbulence occurs in the crucible, completely burning out the combustion products. Only then are the gases able to pass through the pipe. Since their temperature at the chimney outlet is about 100 degrees, there is no condensation. It is cleaned of soot once a year. The efficiency of such furnaces reaches 60%.

- Duct. Instead of a complex labyrinth of gas tubes, they have one elbow. It separates the combustion and afterburning chambers. Through an opening in the burner on the hob or an adjustable air throttle, secondary air is supplied to ensure afterburning of the flue gases. Since this process is carried out in one place, the efficiency is 70-80%. The performance of the stove is high, and the operating efficiency does not depend on the draft force or the size of the chimney. Since the main heat is generated in the afterburning compartment, the unit is used in two modes - flame and continuous combustion. They use different solid fuels, and the power is regulated not by the amount of wood or coal burned, but by tightening the throttle. Chimney cleaning is carried out every few years, provided that the stove is used properly. It is advisable to make the afterburner for it from heat-resistant steel, and in the shape of a trough. The body is made of ordinary steel, having a thickness of at least 4 millimeters, and the cooking surface is made of cast iron or thick 8 - 10 mm steel. It is advisable to make the stove removable, since over time it will need to be replaced as it will burn out.

- Bell bells. Long-burning stoves operate in smoldering mode, which makes it possible to make the heat transfer period longer. It can range from several days when using firewood and from 10 to 30 days for coal. If you use a simplified diagram of such a furnace, the fuel in it will smolder directly at the surface where oxygen enters. During the pyrolysis process, the fuel is split into volatile components, which, rising upward, burn in the bell, providing 60% of the heat. In order to increase this indicator, you can place a gas jacket on the stove, where the gases will burn out. As practice shows, as a result, the efficiency of such a stove can reach 80%, and sometimes more. If the choice is made in favor of this unit design, you need to remember some nuances. Despite the fact that such an iron stove for the home can operate on different solid fuels, the greatest effect from its operation is achieved when it is fired in the type for which it was originally intended. In this case, the fuel used must be dry, and it is not recommended to reload it until the previous load is completely burned. A large amount of toxic condensate always forms in the chimney of long-burning stoves, so it is necessary to create conditions for its safe drainage. To make the body of the unit, you can use a large gas cylinder or a used iron barrel.

- Oil-pyrolysis. These are known as waste stoves. This economical option is very popular among self-taught stove makers. The operating principle of the unit is simple. They pour waste into the tank, then set it on fire and supply oxygen through an air throttle; as a result, the combustion will not be strong, but it will be enough to evaporate the oil fuel. Vapors from the mining flow upward into a compartment in the form of a pipe with perforated walls through which air penetrates. During the combustion process, vapors are sent to an afterburner with a partition that traps nitrogen oxides in a certain temperature zone until they disintegrate and begin to release thermal energy.

Heat-resistant glass

So, we have found that in most cases, consumers prefer to install doors for fireplaces and stoves made of heat-resistant glass (the exception is those appliances that consume coal or mixed fuel). What is the secret of popularity? First of all, the fact that today the production of such glasses has noticeably improved and become more complex. The production process consists of several stages, such as:

- heat treatment;

- treatment with chemicals;

- polishing at high temperature.

Using special glass melting furnaces, manufacturers obtain sheets of material of the required thickness, and their surfaces are treated with special preparations that increase not only fire resistance and strength, but also the service life of the finished products.

After completing all technological stages, the finished fireplace glass acquires a lot of unique positive qualities, including:

- resistance to high temperatures;

- low warm-up rate;

- aesthetic and, so to speak, noble appearance;

- excellent noise absorption;

- ability to withstand significant temperature changes due to low thermal expansion;

- In addition, no visible defects, not even the smallest cracks, appear on the surface of the glass.

Moreover, today, unlike several years ago, heat-resistant glass is produced with crystal and corrugated surfaces, as well as tinted ones (in the latter case, the bright flashes of fire are somewhat muffled).

We have already mentioned above about glasses that can independently remove soot that appears on the surface. Such glasses are called self-cleaning and are distinguished by the fact that they are coated with an almost invisible ball of metal oxide. Due to this, the inner surface of the glass heats up to a higher temperature when fuel burns, and the soot, as a result, burns out almost completely.

How to care for fireplace doors?

We have already noted that metal doors for stoves and fireplaces do not require special care - you just need to paint them with heat-resistant paint. With glass models everything is somewhat more complicated. For example, even self-cleaning models must be periodically cleaned of accumulated soot. This procedure requires a damp cloth and detergent (the same “Mr. Muscle”), but without abrasive components and chlorine. This way you will not damage the glass and the protective layer.

What affects the frequency of cleaning? First of all, this is the type of firewood used (how much resin it contains) and the pulling strength.

This is interesting: Fittings for sliding interior doors

Recommendations for selection

A potential buyer, when choosing doors for stoves, is primarily concerned with their appearance, which is not entirely correct.

The successful shape and beauty of the material is not the only important factor; many other circumstances should be taken into account.

First of all, together with the stove maker you need to accurately calculate the required dimensions of the door, because there are many options in the range, and you need to buy exactly the required product.

The gap between the doors and the brickwork should be small; It cannot be completely excluded, because the material will expand as the temperature rises. During installation, the gaps between the brick and the doors are sealed with sealants made of basalt and mineral wool. As a last resort, asbestos is used, but given the harmful effects of fibers on the human respiratory tract, it is better not to use this material for residential premises.

You should decide in advance on the type of fuel you will use.

The amount of thermal energy released during combustion varies significantly, which should be taken into account

If family members really want to watch the flames, they will have to buy glass doors, being prepared to pay a significant amount for a pleasant purchase.

If there is an abundance of coal fuel in your place of residence, you don’t have much choice. Good coal supplies a large amount of heat when burning, so you need to buy cast iron products.

The most advanced products, which are expensive, have built-in sensors that show the temperature on the surface and the tightness of the internal space of the firebox.

Sources

- https://zen.yandex.ru/media/domspechkoy/samaia-luchshaia-kaminnaia-dverka-so-steklom-podrobno-5c987244d86ddb00b3fa7da4

- https://SdelatBanyu.ru/pechi-i-dymokhody/dvertsy.html

- https://www.tproekt.com/dvertsa-pechi/

- https://ogon.guru/stroitelstvo-svoimi-rukami/pech/voprosi-stroitelstva/dvertsa-so-steklom.html

- https://1-proect.ru/steklyannaya-dver-pechi-svoimi-rukami/

- https://pechnoy.guru/pechi/izgotovlenie-pechi/komplekt-dlp/dvertsa/ustanovka-topochnoj-dvertsy.html

- https://ochg.ru/kaminy/montazh/dvertsa-dlya-kamina.html

- https://pechnoy.guru/pechi/izgotovlenie-pechi/komplekt-dlp/dvertsa/dvertsa-dlya-pechi-svoimi-rukami.html

Types of doors according to manufacturing method

Glass oven door made of heat-resistant material

Various materials are used to make oven doors: metal, cast iron, glass. Cast iron and metal structures have been used for a long time, heat-resistant glass is a new material.

Glass

Glass oven doors have been in use for the last 10 years. Glass sheets are manufactured in several versions:

- Single layer. They have a thickness of 3 mm and are used when burning wood, peat, and plant waste in a firebox.

- Multilayer, 4 mm thick. Installed during the combustion of coal with a high combustion temperature.

Transparent, frosted or embossed glass is installed in the stove doors. Glass doors make it possible to observe the flame. For transparency, you need to wipe the surface with soot-removing products, or buy a material with a coating that prevents its formation.

Metal

Homemade metal door

Ordinary black metal will oxidize when exposed to moisture, this is especially true in a bathhouse. To prevent the formation of rust, metal doors are coated with heat-resistant paint.

The best, although more expensive, option is stainless steel. The product is light in weight and easily attached to a brick structure. The long service life pays off the high purchase price. The modern design makes this stove element a decoration for the interior of the room.

Cast iron

Cast iron design for the firebox and ash pan

The cast iron door for the stove is the best choice. Has the following advantages:

- durability, service life is practically unlimited;

- high heat resistance;

- wear resistance;

- versatility of use.

Cast iron products are used in furnaces that burn coal. The high temperature (up to 8000C) that occurs during combustion does not damage the structure. For the demanding consumer, a complex design of stove doors is developed and combined with glass inserts.

When casting cast iron products for the stove, complex technologies are used; decorating them with ornaments or decorative details complicates the process, making it expensive. Such models are not intended for mass use, but if you wish, you can always find a craftsman to make them.

Material

Metal (often stainless steel or cast iron) is used as the basis for the fire door for a stove with glass. According to the characteristics of experienced craftsmen, cast iron is more preferable: it is distinguished by durability, it is not afraid of high temperatures, it is easy to clean, and it is quite durable. Stainless steel will become very hot when the stove is fired; it is not intended for open fire and will soon warp.

From glass

Glass doors are available in single or double door versions. One oven door usually has a large window to view the fire. There is no difference in functionality. A lot depends on taste here. In two-door ovens, the design is close to ancient forms. It is possible to look at the fire through 1 large glass or 2 small ones. Much will depend on the preferences of buyers and the interior of the room. Advantages of a stove door with glass:

- Glass can withstand the influence of elevated temperatures for a long period of time - this positively distinguishes it from devices made of steel. It is superior in fire resistance to cast iron.

- Fireproof special glass for stoves and fireplaces is approximately 0.4 cm thick and can withstand temperatures up to 2000 degrees.

- Compact dimensions and low weight.

- The main advantage of a glass oven door is the ability to look at the flame. Such an option will outweigh any disadvantages, forcing stove users to purchase stove doors made of a similar material, despite the short period of use and high price compared to solid metal doors.

Flaws:

- The creation of glass doors for a furnace is considered to be a more labor-intensive process than production from a solid sheet. To avoid cracks during use, a little space is left when installing with a seal. The doors will trap sparks from the fire, preventing them from entering the room. Glass inserts are designed so that air blows over the material, preventing soot from lingering on it. Otherwise, the glass will be smoked.

- Fragility of the material. Fire-resistant glass sometimes cracks with minor impacts.

- The price of a device with glass inserts is higher than one made of solid material.

- Glass door ovens are much less efficient than cast iron ovens because heat dissipates through the glass. The larger the material, the less efficient the stove is at heating the room.

Important! Often a stove door with glass is combined with a metal device. In such situations, the frame is made of steel and the door is made of glass.

We suggest you familiarize yourself with Clay mortar for laying a stove: how to prepare it, where to get clay, how to make the composition, clay mortar, how to dilute it correctly

This category involves doors made entirely of metal. The installation process is quite simple and does not have any complications. The products retain heat well and are distinguished by increased fire safety. When the need arises, it is possible to make them yourself with minimal expense. Key advantages of metal products:

- Reasonable price. Compared to a stage on a glass device, it is much smaller, which is why it has a certain prevalence.

- Durability and reliability of such devices. With proper care (regular anti-corrosion treatment using paints that are classified as fire-resistant), they will last a long period of time without causing discomfort to the user.

Important! Despite the fact that such doors have their own consumer, the demand on the market is quite low, since they do not provide the opportunity to look into the flame

Cast iron door

Main advantages:

- Excellent interaction with elevated temperatures.

- Durability and reliability. The cast iron fireplace vent door can withstand any load.

- Beautiful models can be easily created from cast iron.

All this optimally finds its own application in this area; many firebox doors are made directly from cast iron.

Types of fire doors

Today, all doors used in ovens can be divided into several groups, which differ in certain ways. For example, such products are made from a variety of materials:

- One of the most common materials for fire doors is cast iron. Such products have been quite popular for many decades. However, they have such disadvantages as large mass, inconvenience of use, and a significant volume of products.

- The second group includes iron doors. Typically, such products are used when arranging stoves in baths. Iron doors are not used for home stoves because they have a relatively small number of positive characteristics.

- Furnace doors are also made of panoramic glass. Today, such models are most widespread. They are quite light and also provide a full overview of the combustion space.

The last option for the oven door is worth paying special attention to. Their advantages and disadvantages should be described, as well as the types of similar products should be highlighted.

How to install a fireplace door with your own hands - step-by-step diagram

Step 1: Deciding on the sizes

Manufacturers of fireplace doors do not produce them wider than 70 cm - such a design will be too heavy for the fireplace. Therefore, the fireplace door with glass that you are going to buy should ideally not be wider than 50 cm. Focus on the existing opening and select a door a little wider than the opening so that you can insert it more tightly. When the door is purchased, remove the glass from it to avoid unexpected situations during installation. This is usually quite easy to do - the glass is clamped with bolts.

Step 2: Cutting the Grooves

The most dusty and dirty work awaits you, because you will have to cut nothing more than a brick, and even in a closed space. With a high-power grinder, you can reduce the amount of dust if someone else pours water on the cutting line, but if the grinder is less powerful, you will have to cut exclusively dry. In this case, don’t even think about doing without a respirator (or at least a gauze bandage) and safety glasses, otherwise all this dust will settle on your lungs and eyes. Once you've gone through one seam, you can use a hammer and chisel to chip away the brick pieces. Try the door on - if it fits tightly, then we have achieved the desired goal.

Step 3: Insert the door

The heat-resistant baking mixture should be mixed as thoroughly as possible, following the instructions on the package. It is better to knead in small portions so that you can work it out in half an hour. When the solution is ready, soak the asbestos cord in it and wrap it around the perimeter of the door in at least two layers, trying to achieve its uniformity. Once the cord is wound, carefully push the furnace door into place, if necessary, tapping its surface with a rubber hammer.

Additionally, the door must be secured with ceramic dowels - it must have the appropriate connectors. If you notice a gap somewhere around the perimeter, even a small one, it is best to seal it using the same asbestos cord - dip it in the solution and push it into the gap with a screwdriver, and carefully seal the surface with the remainder of the solution.

Fireplaces are becoming increasingly popular again. People install them if there is a technical and financial opportunity. The fireplace has a number of advantages over other heating systems:

- Efficiency.

- Aesthetic appearance. Looking at a blazing fire through a glass door never gets old.

- Making a fireplace with your own hands with the appropriate construction skills is a very real thing.

The topic of today's material is not about arranging a fireplace as such, but about how to make heat-resistant glass with your own hands in order to equip a door in it.

Types of fireplace doors

There are several most popular materials from which doors are made to prevent it from getting too hot near the fireplace. Forged - presented in the form of a lattice with various patterns and ornaments made of steel. A fence of this type does not fully fulfill its function, since sparks can fall through the holes and smoke can leak out.

Such fencing is used for Art Nouveau style, irreplaceable classics, and modern design.

Depending on the stylist’s idea, you can also create interesting combinations of different materials with each other. Ceramic ones are produced by firing clay at a high temperature, this contributes to the material’s sufficient resistance to open fire. Doors of this kind are often installed in ovens if provided for by the designer. This style adds appeal and coziness, and will create harmony in a home that has a rustic feel.

Metal blinds have a fairly attractive design and provide complete safety. Such doors are made of cast iron; it has increased resistance to high temperatures, but for greater reliability, additional coating is also carried out using fire-resistant enamel. These types of doors are used quite rarely; they need to be handled very carefully so as not to end up with a rough room.

Installing a firebox door for a brick stove: 3 different methods Do-it-yourself stove door - advantages and disadvantages, how to choose and install a suitable fireplace door yourself - - Heating Market Do-it-yourself fireplace door with glass, manufacturing algorithm Do-it-yourself stove door: Door for DIY ovens: step-by-step instructions with photos – DIY oven door | All about heating - Mini hotel "Hotel A" Do-it-yourself stove door - advantages and disadvantages, how to choose and install a suitable door for a fireplace yourself - - Heating Market Do-it-yourself stove door - advantages and disadvantages, how to choose and install a suitable door yourself for fireplace — — Heating market

There are options from different types of glass:

- Tempered;

- Borosilicate;

- Kvartsev.

Tempered glass is produced by first heating it to a high temperature, then rapidly cooling it. After such procedures, the glass becomes sufficiently resistant to both high temperatures and various damages that often occur in everyday life. Quartz doors are made of quartz or sand, there are practically no foreign impurities observed. Such a material has a very painstaking and complex manufacturing procedure, but is highly resistant to various temperature changes, therefore it has an acceptable cost, but for many it is too high.

Borosilicate glass is made from substances such as silica and boron oxide. Due to their low melting point, they are not only resistant to very high temperatures and various mechanical damages, but are also quite plastic when compared to ordinary glass. Doors of this kind can decorate and transform almost any interior, adding attractiveness, comfort and color to it, and in combination with forged elements, they will look elegant and stylish.