The comfort of a country house built far from gas supply networks is unthinkable without a stove. In the cold season, it gives us pleasant warmth, relieving the air of dampness.

The market today offers customers all kinds of designs of metal “stove stoves”. Despite this, many summer residents prefer the classic version - a heating stove made of brick. Its advantages are obvious: due to its large weight, it accumulates a lot of heat and releases it for a long time, warming the room well.

The service life of a brick structure significantly exceeds that of a metal one. Minimal costs for materials and simplicity of arrangement attract the attention of home craftsmen to a simple stove for a summer residence.

Our article will help you test yourself as a stove maker. In it we will look at several options for simple wood-burning stoves and give practical recommendations for their installation.

You will be convinced that there is nothing complicated in the drawings of these structures. Having learned to read “orders” - brick layout diagrams, you can build a full-fledged heat-generating device with your own hands.

Seams in stove masonry

When applying the mortar to the masonry not with your hand, but with a trowel (21), it is recommended to moisten the surface of the brick with water.

Place a mound of mortar on the brick and quickly level it. Place a moistened or soaked brick on the mortar, press it tightly, rub it in and remove the excess. The mortar is applied to the bonded edge with a trowel or the brick itself. Refractory brick is only rinsed with water. Seams in stove masonry are made in different ways. If the masonry is supposed to be plastered, the seams are hollowed out, i.e. they are not filled with mortar to a depth of 5... 10 mm. When plastering, the solution flows into the seams and adheres better to the surface of the stove.

If the masonry is not plastered, the seams are completely filled with mortar and they remain in the same plane with the wall surface. This type of masonry is called undercut. If you want to give the surface of the stove a more beautiful appearance with the help of seams, separating the bricks from each other with seams, then the seams are given a convex or concave shape, making masonry for jointing.

In this case, a tool is used - a jointer, which is made of roofing steel, giving it the desired shape, which has the reverse image of the seam.

The jointing technique consists of cutting the extruded mortar into an undercut, applying the jointing to the seam and running it over the mortar (22).

The mortar should be such that with slight pressure on the brick during laying, the excess is easily squeezed out of the seams.

Figure 23 shows the main parts of a brick. The brick is laid flat in half a brick or flush on an edge in a quarter of a brick and upright (24).

This suggests that the furnace walls and channels can be laid out in different thicknesses. A half-brick masonry is considered normal, a quarter-brick masonry or thin masonry is considered (25, a). The most common laying is flat or flush (25, b). The same thickness of masonry can be obtained from two-fours laid on an edge (25, c). Laying three-quarter bricks is done in half a brick and a quarter of a brick, i.e. on an edge (25, g).

When it is necessary to completely cover the seams, the masonry is laid from two-fours on an edge, but so that one row of masonry is 5...6 cm higher than the other (25, d).

When laying the first row of the furnace, its shape and dimensions are checked using a rule, a square, a meter or a cord stretched across the corners of the masonry (26). The first row is first laid out dry and only after that on the solution, carefully observing the dressing of the seams. Each laid out row must be checked horizontally with a rule with a level, vertically with a rule with a level or plumb line, and for rectangularity with a square or a cord along the diagonals (27). Identified inaccuracies are corrected. Frequent inspections are time-consuming, so to improve productivity, guide posts or racks with movable formwork, which are installed strictly vertically, have been proposed.

The box can be made for several rows of masonry. In this case, the last row of masonry, for example the third, must be strictly on the same level with the top of the box.

Furnace designs

Proper completion of the laying of a wood-burning stove for a summer residence

At this point, the laying of the outdoor stove is almost complete, but there are a few technological aspects remaining. Grate bars and grates should be located 7-14 mm below the combustion opening. A gap of at least 5-10 mm should be left between the grate and the masonry of wood-burning stoves along the entire perimeter, filling it with ash or sand so that the expanding metal does not damage the masonry when heated. When laying the grates, it is recommended to tilt them towards the door by 2-3 cm, which will ensure that unburned fuel rolls off the back wall onto the grate. The grate slots must be placed along the firebox (from the door to the rear wall).

Cast iron stoves used in kitchen fireplaces are best laid level on a thin layer of clay mortar.

Proper laying of the furnace implies that the structure must be dried naturally, or, in extreme cases, artificially. During the drying process, all valves must be open around the clock. The pipe can only be closed during a thunderstorm. This drying process takes approximately 10-12 days.

Artificial drying is faster. To do this, it is necessary to heat the stove with a gradual increase in the amount of dry fuel: shavings, straw, wood chips, finely chopped firewood. It is forbidden to dry the stove by burning a large amount of wood at once, since the water in the brick, turning into steam, can destroy the masonry.

The first addition of fuel should not exceed 20-25% of the amount required for normal combustion. For the second furnace, the volume of fuel can be increased to 30-40%, for the third - to 60-70%, etc. up to the full norm. After each firebox, all stove devices must be open, and the temperature of its outer surface should not exceed 50-60 °C.

Laying a stove for a summer residence and drying is considered complete when damp spots no longer form on the surface of the stove and there are no traces of condensation on the valve.

Masonry process technology

We lay the very first row first without applying mortar to the brick.

Having reached the corner bricks and making sure that the real picture coincides with the sketched project, we proceed to the complete addition of the row. We do not let go of the level - the first rows must be laid out clearly horizontally. Using a construction tape measure, we compare the dimensions of the stove in width, length and diagonals. Both diagonal straight lines must be the same; if this is not the case, then you will have to knock down the corner bricks until the dimensions are equal. Then the inside of the oven is laid out for the first row. We start the second row with corner bricks, the position of which we constantly check with a level. And then, as in the first row, we lay out two lengths and two widths, then the inside. We constantly refer to the drawing and compare the layout for correctness. Having already two rows, we drive nails, about 100 mm long, into the corner parts of the mortar between the rows.

Using a plumb line, we transfer to the ceiling the location of the corners of the laid out second row. We hammer a nail into these transferred points on the ceiling. We tie a nylon thread to each of them and secure it to the corners of the masonry. The result was a good lightweight formwork made from nylon thread. Using this method, the layout will go much faster and will not take much time to check the level. If, when checking the plumb line of the threads, any deviation becomes noticeable, then this can be very easily removed by adjusting the nails in the ceiling.

Now we lay out row by row, not forgetting to remove excess solution. After laying out every five rows, moisten the inner walls of the oven with a damp sponge. We try to achieve the narrowest possible seams in the masonry. According to brick construction technology, each vertical seam must be covered on top with a clear middle of the brick in the next row. This rule should be followed at all times. To avoid mistakes, look at the drawing more often. Do not use even slightly damaged bricks. This will lead to the fact that when the oven is heated to maximum temperature, such a brick, which does not have good integrity, will crack and fall apart into small pieces.

It is advisable to lay out the firebox itself from fireclay bricks, as it is more fire-resistant. But the bricks of the firebox and the outer wall of the furnace should not touch each other. There should be a gap of no less than 0.5 cm between them. This is due to different degrees of expansion of the material when heated.

Installing doors

In order to properly install the furnace door or vent door, it is necessary to first attach the existing part to the laid wall and check how tightly it is in contact. If there are any defects, they must be eliminated before applying the solution. Then we screw a double wire, up to 60 cm long, to each corner. The bricks are treated with mortar, and the mounted door is checked with a level for the correct position relative to two perpendicular axes. Twisted wire is inserted into the joints of the brickwork on four sides.

The remaining bricks after laying the stove can be used to build paths with your own hands.

You can make formwork for the foundation of the furnace using the instructions.

Slab installation

To install the slab, the bricks are first laid “dry”.

We find a brick that would have a gap of 5 mm, necessary for expansion when heated from all sides of the slab. And then we lay out everything thoroughly. We pour the solution into this gap, and lay an asbestos wire along the entire perimeter. The laid slab is compacted to the correct vertical position. Laying a stove is a very interesting and exciting activity, but it requires good dexterity and a minimum amount of knowledge from the master. A self-made stove will bring coziness and warmth into the interior of your home and create a more homely atmosphere. And guests and visitors will tirelessly praise the owner of the home for such a handmade work.

Do-it-yourself brick stoves for your home

Although private homes now mostly have gas or electric heating systems, many owners would not mind having a simple but reliable stove in their household, which will always help out in the cold and rid the home of humidity. In addition, such a device, lined with tiles or high-quality bricks, looks great in the interior of a dacha or country house. There are different types of ovens - exclusively for heating, for heating and cooking, universal with an oven and a device for drying fruit. In this example, we did not show how complex structures with a vault are built, but limited ourselves to an example where the construction of a small stove with a heating panel is simulated.

DIY small brick oven

For work we will need 250 whole bricks, 6 pieces cut to ¾, 43 halves, 20 pieces cut to ¼. In total we will have 22 rows of bricks laid out. You should also purchase 3 valves, a combustion and blower door, and a cast iron hob. You will see that bricks with small chips and cracks (low quality) can be laid inside, and on the outside we line the oven with facing material. But first you need to lay a foundation under the stove, because the mass of such a structure is several tons, which is a fairly significant load on the foundation. It is best to pour a reinforced concrete pad, which has an area 15% larger than the area of the base. In our case, we will build a simple brick oven with our own hands, which is suitable for heating the room and for cooking. We lay out the first continuous row of material according to the pattern you chose. It should be as even as possible, because the reliability and beauty of our building depends on this. In this example, we will not use mortar, making only educational dry masonry for speed and clarity. When laying the second or third row, you need to lay out the ash pan. The doors of the ash chamber and cleaning compartments are installed immediately. Standard products have fastening ears; a wire is passed through them and inserted into the seam. Until the solution dries, the doors are fixed with temporary stops (bricks or other material). On the fourth row, places are laid for cast-iron cleaning doors (we have bricks there, placed on edge). The sixth row is laid out. The beginning of 2 vertical channels is formed. In the place where the grates are installed, samples were made on the brick using a grinder. We install grate bars. The 7th row is laid. Our grates are free-standing (installation takes place without mortar), and they should be easy to remove. The resulting voids must be filled with sand. Place the smoke damper on the back of the stove

In our question of how to make a brick oven with your own hands, we have reached an important stage. Installing the combustion door

This can be done on a corner or on a wire with nails. On the eighth row we form a connection between the vertical channels of the heating shield. In the place where the cleaning door is installed, we again temporarily place half a brick on the edge. We put the cast iron stove in place. It is advisable to cut a niche under it with a thermal gap, which is then covered with sand to allow the metal to expand. 22 rows will be enough to create a good DIY brick wood stove for your home with excellent heat dissipation. We begin laying a three-channel heating panel with vertical chimneys. In the future, our rows (even and odd) are copied. We connect the 2nd and 3rd vertical channels. We put another valve at the top. We complete the construction by laying a chimney. The work is finished, we managed to make a simple but quite effective brick oven for our home with our own hands.

One of the most important stages in building a fireplace in a house is its cladding. We will show you how to perform this task efficiently yourself in the master class.

The most important stage of home renovation is leveling the walls, which is often done with plasterboard. We will show you how to cover walls with plasterboard with your own hands in a master class.

In apartments where it is impossible to install a real fireplace, an imitation would be a good option. We will show you how to make a decorative fireplace out of cardboard in the master class.

A brick stove is not only a heating method, but also an element of cozy home design. We will show you how to build a brick oven with your own hands in the master class.

Types of adhesives and solutions for lining furnaces

The facing adhesive can be one-component - for laying tiles without cutting joints, and two-component - respectively, for laying tiles with cutting joints. Based on their properties, adhesives are divided into heat-resistant and heat-resistant.

The term “heat-resistant” describes compositions that can withstand thermal cycles with temperature fluctuations of no less than 150⁰C. Only compositions that can withstand prolonged heating of 500⁰C are called heat-resistant. For stove cladding, only heat-resistant adhesives are used; for fireplaces, heat-resistant adhesives are acceptable.

For fireplace linings, domestically produced compositions have been tested in practice - Moment-Crystal, Vetonit Weber, Plitonit SuperKamin and others. Among the recognizable import brands is Ceresit-SM. For a decorative fireplace that is lit only periodically, these compositions are quite suitable, but heat-resistant compositions are required for stoves. For example, a two-component composition K-77 with a primer of the same name, which has a high load-bearing capacity. Complete hardening of the composition occurs after three to four weeks, and it is unacceptable to start the accelerating firebox before the curing period of the glue has expired. When this facing composition gains strength, the room temperature should be within 18-28⁰C. There are special compositions for terracotta and majolica. The market offers quite a lot of heat-resistant and heat-resistant compounds, and you should carefully study the scope of application and follow the recommendations indicated on the packaging.

It is also possible to lay tiles on clay mortars filled with quartz sand or sawdust.

When using clays, it is important to choose the correct proportion depending on the fat content of the clays, so that the solution is sufficiently plastic, but does not subsequently crack. Filler/clay proportions for fatty clays 4:1, for normal clays 3:1, for lean clays 2.5:1

In addition to fillers, fireclay powders are added to clay solutions to increase resistance to high temperatures and changes, this is especially justified in the case of a coal furnace. Some craftsmen add salt additives to the solution - up to one glass of table salt per bucket of water. Salt retains water in the mortar mixture, and there is less risk of cracks. The usual ratio of clay and water in solution is 4:1, but selection is carried out experimentally and also depends on the fat content of the clays used. One of the recipes, which is considered classic, includes cement. One part clay, three parts sand, one part chalk and one part cement. The amount of water is selected according to the type of clay. This composition provides not only good adhesion to bricks and tiles, but also higher strength compared to clay mortar.

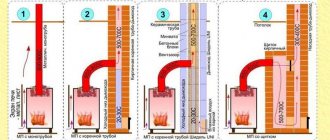

Installation of indentations and cutting furnaces

In places where the wooden structures

of interfloor and attic floors

approach

smoke ducts in stone walls

or

the main and top pipes of heating stoves

, it is necessary to arrange

cuttings

, i.e. thicken walls or pipes.

Retreat

(

cutting

) is the air space between the outer surface

of the furnace, chimney or smoke duct

, on the one hand,

and the combustible wall, partition

or other building structure, on the other hand.

Furnaces and main chimneys

SHOULD NOT be placed close

to wooden walls

.

Between the wooden wall and the pipe,

a gap (

indent

) of at least

13 cm

(

0.5 bricks

) is left over the entire height, and

the wall must be insulated with two layers of felt

impregnated with clay mortar, and then upholstered with roofing steel.

Indentation

in this case it should be open on the sides.

For chimneys of stoves and hearths

with

long-term combustion,

the indentation size must be

at least 25 cm

(

1 brick

).

Leave an air gap ( indentation

) to the entire height

of the stove or chimney

.

the indentation

is closed on the sides, the wooden wall

should be covered with boards and then lined with brickwork

in 1/4 brick

(cold quarter), on felt impregnated with clay mortar.

Holes must be left at the bottom and top

of the indentation and

sockets and grilles

measuring at least

13x13 cm

.

When using

backfill made of flammable materials

(sawdust, peat, etc.)

in attic floors, near the chimneys

one row above the surface of the backfill.

Distances from the upper planes of furnace floors

to combustible (or fire-protected)

ceilings of premises

must be no less than those indicated in Table 1.

TABLE 1: DISTANCE FROM THE TOP OF OVEN COVERS TO COMBUSTIBLE CEILINGS, MM

| p/p | Furnaces | Ceilings | |

| Not protected from fire | Fireproof | ||

| 1 | 2 | 3 | 4 |

| 1 | Heat-intensive | 350 | 250 |

| 2 | Non-heat-intensive | 1000 | 700 |

| Note:1. The thickness of the upper ceilings of the furnaces must be at least three rows of bricks. With a smaller thickness, the distances between the top of the stoves and the ceilings increase accordingly. 2. Ceilings can be protected from fire with 8 mm thick asbestos card or 25 mm thick plaster. The protection should be 150 mm wider than the ceilings on each side. | |||

The gap between the top of a thick-walled oven

and

the ceiling

can be closed on all sides

with brick walls

.

In this case, the thickness of the upper ceiling of the furnace

must be at least

4 rows of brickwork

, and

the combustible ceiling

must be protected from fire.

Space between chimneys

and

roof structures made of non-combustible and low-combustible materials

should

be covered with non-combustible roofing materials

.

Space between floors

(

in front of the roof

)

of a heat-intensive stove

and

a ceiling made of flammable and slow-burning materials

may be covered on all sides

with brick walls

.

In this case,

the thickness of the furnace ceiling to four rows of brickwork

.

The cutting thickness of brick stoves

with short-term combustion

is taken

to be 1 brick

(from the surface

of the stove elements to the wooden structures

, and

the wooden parts in these places

must be covered with asbestos cardboard or felt in 2 layers,

impregnated with clay mortar

).

In the absence of asbestos or felt, the cutting thickness

must

be increased to 1.5 bricks

.

In kitchen and heating fires

with a fire duration of more than 3 hours. the cutting thickness

must be increased to

1.5 bricks

, and the wooden parts in these places should be covered with two layers of felt

impregnated with clay mortar or asbestos cardboard

.

In the absence of felt or asbestos, the cutting thickness

should be

increased to 2 bricks

.

Cuttings

should also be installed

near ventilation ducts

passing next

to smoke ducts

, because due to an oversight, smoke from the stove may be released into the ventilation duct.

NOTE: Gaps between slab and groove

must be filled

with clay mortar mixed with asbestos

.

A diagram of the cutting

for a chimney in the ceiling of a house

is shown in Fig. 11.

Horizontal cuts at chimneys and furnaces

DO NOT lean on beams and floor boards, especially those structures that give rise to sediment (chopped, cobblestone, adobe).

ATTENTION! When making cuts in floors

independent settlement

of furnaces and pipes

.

Supporting cuttings

on structural

elements of the floor

is NOT ALLOWED.

Laying vertical grooves near wooden walls and partitions

should

be carried out using clay, lime or cement mortar

, and DO NOT allow them to be tied to the masonry

of a stove or chimney

.

The cutting height should be greater than the thickness of the ceiling by the amount of possible settlement of the building

and

70 mm above the layer of combustible backfill

.

Horizontal cuts

in the floor plane SHOULD be carried out simultaneously with the main laying of the furnaces.

diagrams indentation

(

cuts

)

for hearths and walls or partitions

made of flammable and low-combustible materials are shown in Fig. 12.

For walls or partitions

made

from flammable and slow-burning materials,

the derogation should be taken in accordance with Table 1 (see below), and

for factory-made furnaces

should be taken according to the manufacturer’s documentation.

Dimensions indentation

(

cuts

)

of furnaces and smoke ducts, taking into account the thickness of the furnace wall,

should be taken equal to:

- 500 mm

- to building structures made

of combustible materials

; - 380 mm

- to a wall or partition

made of non-combustible materials

, adjacent at an angle to the front of the stove and protected from fire from the floor to a level

250 mm above the top of the fire door

: plaster

25 mm

on a metal mesh - or metal sheet on asbestos cardboard 8 mm

.

Dimensions of cuts ( SNiP 2.01.01-82

) should be accepted in accordance with the mandatory requirements for deviations given in Table 2.

TABLE 2: DIMENSIONS OF THE OVEN AND CHIMNEY PIPE TO WALLS AND PARTITIONS

| p/p | Furnace wall thickness, mm | Distance from the outer surface of the stove or smoke duct (pipe) to the wall or partition, mm | ||

| Retreat | not protected from fire | protected from fire | ||

| 1 | 2 | 3 | 4 | 5 |

| 1 | 120 | Open | 260 | 200 |

| 2 | 120 | Closed | 320 | 260 |

| 3 | 65 | Open | 320 | 260 |

| 4 | 65 | Closed | 500 | 380 |

| Notes:1. For walls with a fire resistance rating of 1 hour or more and a flame spread limit of 0 cm, the distance from the outer surface of the stove or smoke duct (pipe) to the partition wall is not standardized. 2. In buildings of children's institutions, dormitories and public catering establishments, the fire resistance limit of the wall (partition) within the setback should be at least 1 hour. 3. Protection of the ceiling, floor, walls and partitions should be done at a distance of at least 150 mm exceeding the dimensions of the oven. | ||||

Within the walls

To cover

the setback

, openings should be provided above the floor and at the top

with gratings with a clear cross-sectional area of

at least 150 cm2

each .

Floor in closed retreat

should be made of non-combustible materials and located

70 mm above the floor of the room

.

Laying the floor close to the main pipe or smoke ducts

located

in stone walls

is NOT ALLOWED.

The sheathing and floor

should only be brought to the

cutting

, and

the floor above it should be made of fireproof materials

: concrete, metlakh tiles, roofing iron, etc.

ATTENTION! IT IS NOT ALLOWED to connect any kind of ash pits of furnaces with the underground.

(with floors on joists) for the purpose of its ventilation during the firing of stoves.

Distance between the top of the furnace floor

, made

of three rows of bricks

, and

a ceiling made of flammable or low-combustible materials

, protected by plaster on a steel mesh or steel sheet on

asbestos cardboard 10 mm thick

, you should take:

- 250 mm

-

for ovens with intermittent firing

, - 700 mm

-

for long-burning

, - and with an unprotected ceiling,

350

and

1000 mm

respectively .

For furnaces

having

an overlap of two rows of bricks

, the indicated distances should be increased

by 1.5 times.

Distance between the top of the metal stove

and

the overlap

should be taken:

- with thermally insulated ceiling

and protected ceiling -

800 mm

, - and for a stove with a non-insulated ceiling

and an unprotected ceiling -

1200 mm

.

When installing a stove

between combustible partitions

or

in the opening of a wooden wall

between the stove and these structures, make an indent of at least

1/2 brick

,

sealing it with a brick cutting wall

.

The wood from the cutting side is insulated with asbestos or felt

impregnated with clay mortar.

Cut thickness

(from the surface of the

stove elements to the wooden parts

)

in stoves with short-term combustion

should be at least

1 brick

, and

in stoves with long-term combustion

- at least

1.5 bricks

.

Vertical cutting of furnaces and pipes

installed

in the openings of combustible partitions

, are carried out to the entire height of the furnace or pipe.

The width of the grooves

is taken to be no less than the thickness of the partitions, and the thickness is in accordance with the data given in Table 3.

TABLE 3: CUT-OUTS FOR OVEN DEVICE TYPES

| p/p | Types of furnace devices | Combustible structures | |

| Not protected from fire, mm | Fire protected, mm | ||

| 1 | 2 | 3 | 4 |

| Heating furnaces of intermittent operation with combustion duration: | |||

| 1 | - up to 3 hours | 380 | 250 |

| 2 | - more than 3 hours | 510 | 380 |

| 3 | Gas-heated furnaces with a flow rate of more than 2 m3/hour | 380 | 250 |

| 4 | Long-burning heating stoves. Apartment kitchen stoves running on solid fuel. Residential gas water heaters | 250 | 250 |

| 5 | Combination cookers with built-in boilers and separate apartment-type boilers | 380 | 250 |

| Note: Metal chimneys are not allowed to be laid through combustible ceilings. | |||

In the walls of a closed space above the stove

should be provided

at different levels with gratings

each having a clear cross-sectional area of

at least 150 cm2

.

Retreat

left open or sealed on both sides with bricks or other fireproof materials.

ATTENTION! Side walls of a closed retreat

tying with the main masonry of the stove is NOT ALLOWED.

The floor in the air gap is lined with bricks one row higher

room floor level.

Indent width

and the method

of insulating walls and partitions in retreats

is taken in accordance with the data given in Table 4.

TABLE 4: METHODS OF INSULATING WALLS AND PARTITIONS IN OVEN SETTINGS.

| p/p | Heating stoves | Types of derogation | Distances between stoves and combustible walls or partitions, mm | Methods for protecting combustible structures |

| 1 | 2 | 3 | 4 | 5 |

| 1 | Apartment-type stoves with walls 1/2 brick thick with a combustion duration of up to 3 hours. | Open or closed on one side | 130 | Lime or lime-cement plaster 25 mm thick; asbestos cardboard |

| 2 | Same | Closed on both sides | 130 | Brick cladding with a thickness of 1/4 brick on clay mortar or asbestos-vermiculite slabs with a thickness of 40 mm |

| 3 | The same with walls 1/4 brick thick | Open on both sides | 320 | Lime-gypsum plaster 25 mm thick; asbestos-vermiculite slabs 40 mm thick |

| 4 | Heating stoves for long burning | Open | 260 | Same |

| 5 | Stoves and stoves with walls 1/2 brick thick with a fire duration of more than 3 hours. | Open | 260 | The same, or cladding with a thickness of 1/4 brick on clay mortar |

| 6 | Same | Closed | 260 | Brick cladding 1/2 brick thick |

| Metal stoves: | ||||

| 7 | - without lining | Open | 1000 | Plaster 25 mm thick |

| 8 | - with lining | Open | 700 | Same |

In attics and roofs

between chimneys and wooden parts of buildings

(

rafters, sheathing,

etc.),

cutting

is NOT done, but a free gap of at least

13 cm

.

For flammable roofs

(shingles, tar paper, etc.) the free gap must be at least

25 cm

.

The free space between the pipe and the wooden roof structures

should be covered with fireproof roofing material (roofing steel, special asbestos cement sheets, etc.).

Distance from the outer surfaces of chimneys to rafters, battens

and other

roofing parts made of flammable and low-combustible materials

should be provided in the light:

- from brick or concrete chimneys

- at least

130 mm

, - from ceramic pipes

without insulation -

250 mm

, - and for thermal insulation with heat transfer resistance - 0.3 m2 *t C/W with non-flammable or difficult to combustible materials - 130 mm

.

When laying wooden beams in the wall

at least

one brick

away from

smoke or ventilation ducts , and their ends must be wrapped in

two layers of felt impregnated with clay mortar

.

If it is impossible to carry the beam from the channels to the specified distance, it must be shortened and cut into the crossbar. Between the crossbars and the chimney ducts, it is necessary to arrange the cutting in accordance with the previously stated rules.

When laying steel beams in a wall

Brickwork with a thickness of

at least 0.5 bricks

.

Types of furnaces

Currently, the most popular options are heating and cooking stoves designed for space heating and cooking. The design of such a stove can have a hob or a full-fledged oven.

A heating stove, which performs only one function - heating the room, has a simpler design and is built in a shorter time. The cost of installing such a stove will be minimal.

Fireplaces are classified as a separate category of stoves. Fireplace configurations can be varied - from the simplest to the most complex design developments. As a rule, the high cost of fireplaces is due to the use of a large number of expensive finishing materials.

Readers found these materials useful:

- “Shvedka” stove - a method of arrangement with a bell-type firebox and a stove bench

- Independent construction of a Dutch oven according to diagrams and drawings

Laying lintels for firebox and oven doors

One of three methods is used here:

Method No. 1 : the door is covered with bricks - poking a little with an overlap of half a brick on the door frame on each side.

Method No. 2 : the door is covered with three bricks with specially cut pins at 45 degrees, with the side bricks overlapped onto the door frame by a quarter-part of the brick.

Method number 3 : the door is covered with an arched lintel using wedge bricks; these bricks can be made independently.

Types of tile layouts may vary

- Vertical seams match. This layout is for tiles of the same size. If rectangular tiles are installed, then the layout can be both vertical and horizontal, while you can lay out colored contrasting zones and insert panels - it looks linear and neat

- Bandaging, or displacement along vertical seams. Used in geometrically complex areas so that trimmed fragments are not noticeable

- Diagonally. Artistic and complex layout, allowing for rare designs. Very original, but you will need about 10-15% more tiles, a lot of trimming and waste

- Tiles of different sizes are laid out in checkers, carpets, highlighting fragments and contrasting zones, panels and decorative elements are possible

Features of masonry of an outdoor fireplace

The laying of an outdoor hearth is similar to a fireplace. To prevent the outer surfaces from heating up, use vermiculite or kaolin wool in a layer of 100-150 mm. Or 250mm, which depends on the purpose of the fireplace. Also, such thermal insulation is necessary for maximum heat accumulation by the surfaces inside + to create the highest temperature in the firebox of a barbecue, tandoor oven, barbecue, etc.

Share on social media networks

0

Tweet

Standard set of tools for making furnace linings

- For cutting and fitting – tile cutter or grinder

- For straightening tiles - hammers with a rubber head

- For drilling - drill

- The solutions are mixed with a construction mixer or a drill with a whisk attachment.

- Rubber and notched spatulas for applying adhesives

- To control the verticality and horizontality of the cladding - a plumb line and a building level. More convenient are rack levels with bubble ampoules not only on the long sides, but also on the ends

Consumables - dowels or staples, crosses for tiles (plastic crosses must be removed from the seams), special grouting compounds for stove linings on a mineral or silicone basis, designed for high temperatures.

Only metal meshes are used for furnace lining; fiberglass meshes are unacceptable. The reason is that the mesh distributes not only mechanical impact, but also thermal impact. Therefore, a reinforcing metal wire mesh with a cell of 25 * 25 mm - 50 * 50 mm and a steel cross-section of 1.2-2 mm is used. For a standard layer of glue or primer of 3 mm, this is optimal. But even if the thickness of the glue applied according to the instructions is greater - 4 or 5 mm, it is not recommended to use wire mesh thicker than 2 mm, since the linear expansion of steel is significant, and this creates a danger that when the oven is heated, the tile cladding may begin to peel off.

How to lay stove bricks correctly

To successfully build a functional outdoor stove, be sure to follow the following masonry rules:

- First fold each level like a construction set, without mortar. Trying on will allow you to accurately cut the stones in the right places and fit them to each other.

- The ceramic brick is soaked for 2-3 minutes in a container of water, then placed in place. The refractory stone is only rinsed from dust.

- The maximum thickness of a masonry joint on a clay-sand mortar is 5 mm. Exceeding threatens the formation of cracks.

- Do not tie a fire-resistant wall with a regular one. Insert sheets of basalt cardboard into the gaps between different types of bricks.

- Check the horizontality of each tier with a building level, and the verticality with a plumb line.

Remove any mortar protruding outwards with a trowel, and wipe the internal surfaces with a damp cloth. If you lack experience, do not try to chop stones with a pick; it is better to use a grinder with a cutting wheel for concrete.

The tile installation technology is different

- With cutting of joints - removing mortar from masonry joints to a depth of about a centimeter

- No seams

Cladding using the method of cutting seams is considered the best - metal elements, hardware and dowels are not introduced into the masonry bricks, which pose a risk of cracking of the brick during thermal expansion, because the walls of the furnace can heat up by more than +500⁰C. The mesh is attached only with thin staples. In addition, when facing along cut seams, mechanical impacts on the furnace body will be minimized. But the labor costs for this method are, on the contrary, maximum.

It is dangerous to get cracks in the masonry while knocking the mortar out of the seams, especially in cases where the stove has been heated many times and the mortar seams have sintered to a stone state. Carefully cutting seams to a depth of 8-10 mm is not an easy and painstaking job and requires attention and experience.

Seam cutting sequence:

- First, soften the mortar joints a little with water, without strong impregnation - apply a damp cloth (rags, burlap) to the walls of the oven and leave this “soap” for an hour or two.

- Knock the mortar out of the seam with a narrow chisel (called a cross-section), which is used to cut a groove. The hammer is struck lightly, no force is used.

- When the softened layers run out, make new “lotions” and repeat the whole process until the seam is released by at least 8 mm, and preferably 1 cm.

- Remove all fragments and crumbs of the extracted solution, remove dust from the surfaces

- Apply the first layer of soil to the masonry surface. When facing with joint cutting, a two-component adhesive composition is used, and the primer component is applied first, completely filling the joints. The thickness of application depends on the composition used and is carried out in accordance with the instructions for use or instructions

- Next, install the mesh over wet plastic soil, and at a pace until the soil sets. For this reason, they do not cover the entire stove with soil at once, but work in 1-2 m2 sections.

Fastening the mesh along the cut seams:

- As soon as soil is applied to the first grip with an area of about 1-1.6 m2, the mesh is pressed into it and temporary fixation is made into pre-drilled holes, using dowels with plastic sleeves - three dowels at the top and three at the bottom. The dowels are driven not into the seam, but into the brick - this is a mandatory requirement. The holes in the bricks should be smaller than the length of the sleeves so that their edges protrude from the holes and can be removed with pliers.

- After tacking the mesh, permanent fasteners are installed - wire staples, sticking them into the seams filled with soil at intervals of 25-30 cm, after two or three rows of brickwork.

- After the soil hardens, remove the dowels and fill the remaining holes in the brick with soil.

- Then you need to wait until the soil is completely dry, including the holes - during this time the layer in which the mesh is pressed will have the necessary strength for further work.

When the mesh is attached to the masonry without cutting the seams, fastening is possible only with steel dowels. Plastic is not suitable for the outer walls of the oven, as it will melt when heated. In addition, hardware creates risks of cracking of brickwork due to the significant difference in the thermal linear expansion of metal compared to brick.

Which one to build?

First, let's see what kind of stove it is possible to build outdoors, taking into account the fact that it will not be heated intensively and irregularly, but will be exposed to climatic influences, freeze in winter, and it will be difficult to provide it with a high chimney. But the danger from the spread of carbon monoxide from an outdoor stove is reduced to the minimum possible, although it is not completely eliminated, especially in a gazebo, under a canopy and in calm weather. Don't forget about this: there is no stove that can be heated at random without fear of fumes. You can get burned just sitting by the fire.

Keeping these circumstances in mind, the choice of outdoor stove design is not so wide. The simplest garden stove is the well-known rough or rough stove. She can look terrifying, pos. 1 in Fig., but it can be heated with any fuel and it works properly, almost regardless of the quality of the materials used and the work: when building a rough structure, you can use broken simple red working bricks or stones from the surrounding area using ordinary cement-sand masonry mortar, i.e. .To. microcracks in the masonry have almost no effect on the technical performance of this stove. See, for example, the video below of how a 5-year-old child built a rough stove, which his family successfully uses and which can also be used for smoking. Which, by the way, not every oven allows, see below.

Video: a simple stove, a rough one, a design accessible to a child

An outdoor oven at a weekend cottage is often a barbecue roaster, pos. 2. Although, as we will see later, in fact this is not a barbecue at all. Such a stove takes about the same amount or less bricks as a rough one (about 200 pcs.), and you can use red working brick in the same way, but masonry mortar, due to the, so to speak, subtlety of the structure, is already needed for the stove for the street (see .further, about technology and materials).

Based on the brazier, the so-called. Finnish outdoor brick oven, which is a hearth, brazier or barbecue attached to a rough stove, pos. 3. In fact, the only Finnish thing about such a stove is that the Finns were the first to think of producing them in the form of a set - construction instructions with detailed instructions and procedures, dry mixture for preparing masonry mortar, embedded parts, fittings. Now domestic kits for building an outdoor brick oven are sold in the Russian Federation. Sometimes the set also includes bricks; if necessary, hemmed/trimmed and numbered. A kit for an outdoor Finnish stove is inexpensive, and even a completely inexperienced person can build a stove from it, which is why the Finnish outdoor stoves from the kit are very popular, see for example. track. video clip.

Video: Finnish outdoor stove

https://youtube.com/watch?v=1qCvXhB7jSk

Even less common in areas is an outdoor fireplace, pos. 5. The reason is limited functionality: you can admire the flames and cook something as if on a simple fireplace, although the material and labor intensity of an outdoor fireplace is quite high. A Russian stove is built on the street (item 6) even less often. The culinary qualities of products and dishes from a Russian oven are well known, but a small Russian oven requires 2500 bricks, a large one - 3500, the design is very complex and it is not easy to protect it from bad weather. For the same reasons, Neapolitan (item 7) and Sicilian ovens for pizza and pastries are not very common in private households; In addition, these are quite highly specialized devices.

Tile installation

Surface preparation is standard - if the stove has old plaster or finishing, it is knocked down with a chisel and cleaned with metal brushes, and then dusted. Then the joints are done - if it is decided to install the tiles on a grid with jointing. Prepare the adhesive composition according to the instructions. Pour the dry mixtures into the water, portionwise, with constant stirring. The speed of the drill or mixer is adjusted so that the glue does not foam; air is not needed in the structure. Leave the glue for as many minutes as indicated in the preparation instructions - usually up to 15 minutes. Start facing from the bottom. Apply glue or primer (if cladding is done using jointing) for four tiles horizontally. Fix the reinforcing mesh. Along cut seams - on wire staples, without cutting - on dowels. The adhesive is applied with a notched trowel, the first tile is pressed and slightly rotated to secure it tightly. Crosses are used to calibrate seams, but not all craftsmen recommend crosses, and some designs involve the illusion of unevenness of the seams - to imitate ancient masonry. Verify the horizontality of the tiles using a level, then the vertical. The first row is the most responsible

Deviations are corrected carefully by moving the tiles with light blows with a rubber hammer. Seams for different types of tiles can be from 8 to 12 mm, except for clinker ones, the thermal expansion of which is so insignificant that a neat seam of only 3 mm is possible

All tiles of the first grip are verified with a level and plumb line. The first three rows of tiles after laying should be left until the adhesive composition sets. Plastic adhesive may not hold heavy tiles, and the trim will slide off from its own weight. Furnace linings do not require high speeds. Pauses between grips are about three hours, depending on the properties of the glue or solution used. For fitting and trimming, use tile cutters or a grinder. They usually try to hide the cut tiles adjacent to the wall or in other inconspicuous areas. After the glue has completely set - after 24 hours, remove the crosses and clean the seams from glue deposits.

Grout the seams only after the glue has completely cured, according to the instructions for the composition, otherwise you may end up with microcracks in the grout or the tiles peeling off. Mineral grouting is done manually - with a spatula, or with a mounting gun if the seam is made convex. Grouting with silicone compounds is very sticky and is only possible with the use of mounting guns.

The first fire is possible only after the glue has completely cured, from a week to a month, depending on the composition used.

Additional tips for choosing material

Brick comparison chart

You should buy brown clay materials for stove masonry. They successfully withstand sudden temperature changes, and if the stove has not been used for a long time, the masonry will not crack.

You should not choose silicate, cast or pressed bricks - their structure will not withstand the load.

Fireclay brick is most suitable for laying a furnace, as it can withstand temperatures up to 1350C. It can also be used to construct the entire structure, or you can use it to lay out only the inner mile.

The use of brick grade ShA 8 yellow with specks or ShA from 22 to 45 is an excellent solution for laying a stove, but not for rooms with high humidity levels, since its operation is only possible at 60% humidity.

In rooms such as a bathhouse, it is best to use the following types of bricks:

- ceramic;

- refractory;

- clinker.

Taking into account all of the above, you can achieve an impeccable result.

Preparatory process

Each oven, especially one built independently, is unique.

Therefore, before you start laying bricks, study the structure of your house well and create your own project. If in doubt, you can resort to a ready-made drawing suitable for the specific layout of the house. The main thing is that the furnace is built exactly in the place where the greatest heat transfer is achieved. When creating a project, you should consider how correctly the chimney will exit through the roof and whether it will damage the roof structures. Having sketched out your drawing, you will confidently imagine the structure of the future furnace from the inside, and you will be able to look at the layout of the bricks. The created project will help to more realistically visualize the future structure, and therefore will be able to provide complete information about how harmoniously this stove will fit into the overall design of the room.

Before installing the stove, take care of calculating the heating of a private house.

Take a break from laying the stove by reading about the most unusual houses in the world in the article.

Materials for laying the furnace

Under no circumstances should you lay the same foundation for the walls and for the stove. Since the load on the foundation is different, this can lead to cracks and splits. In the worst case, a fire may occur.

The foundation for the furnace is laid from gravel, small brick chips or rubble stone. In size, the foundation should protrude beyond the boundaries of the stove itself by 5-7 cm along each side. The most important thing about the brick used is its correct geometric shape. In other words, all corners must be clear and even, maintaining a right angle on all sides. Each brick should be carefully checked for cracks, and it is best to use a well-burnt brick. For interior masonry, only red brick is suitable.

The brick is fastened with cement mortar. Before adding the kiln with mortar, it is recommended to lay the entire brick as it will lie already bonded without mortar. For clearer boundaries, it is advisable to use formwork - this way you can protect yourself from unevenness and distortions. The very first few rows should be laid out perfectly even and smooth. The quality of the masonry of the rest of the furnace will depend on them. After laying out the first two rows, waterproofing is carried out by laying two layers of roofing material.

The mortar for the main furnace is made from sand and clay. Only the foundation and the pipe on the outer sides are laid with cement mortar. Of course, it is better to take fatter clay and use cleaner sand.

Advice. It is impossible to accurately determine the proportions of clay and sand, since the fat content of the clay and the purity of the sand are different everywhere. But before mixing the solution, try sifting the sand and leaving the clay in a plywood box for a couple of days. Mix the solution by constant testing. If there is more sand than required, the seam will quickly crumble. And if there is an excess of clay, the greasy seams will quickly crack and shrink greatly.

The solution should reach the consistency of sour cream. To check whether the ratio of ingredients is correct, fashion a small ball and throw it from a height of one meter. Also, try to burn it well. If in both cases the ball remains intact and unharmed, then the proportions are correct. The density of the mortar should also differ in its plasticity, which allows you to remove excess mortar between the bricks. The level of plasticity is affected by the water content in the solution.

Advantages and disadvantages

Designs with a built-in heat exchanger have many advantages:

- The system is energy efficient and economical. Brickwork will not require serious financial investments, the costs for pipes and radiators will be in any case, and the heat exchanger is an order of magnitude cheaper than ready-made boilers. When operating a stove, the cost of heating the house will be several thousand rubles for the purchase of firewood for the winter period.

- The design of a brick stove hides unsightly elements; if desired, a fireplace or decor can be added to the system.

- Heating of the room does not depend on the location of the structure; radiators can be installed anywhere

- A brick stove takes a long time to cool down; the water circuit will remain hot for several hours after the wood burns out.

Some publications list the advantages of the water circuit system as the possibility of installing it in a ready-made furnace, which is possible in principle, but in practice this option is associated with a large number of problems that have to be solved.

Disassembling and subsequent reassembly of the stove is the most necessary thing that will have to be done. The cost of correcting an incorrectly installed register is comparable to the cost of a new stove, so contact professionals for such work.

The disadvantage of this design is a continuation of its advantages; in order to make a stove with heat exchangers yourself, experience is required, both in laying bricks and in installing heating systems. If experience comes with age and the amount of material studied, then when building a furnace with a water circuit, its disadvantages should be taken into account:

The fireplace is a fire hazard; it is necessary to take measures to prevent fire from reaching flammable objects; The stove takes up a significant area of the house, design the rooms in advance, include a large heating system in the design of the room; The temperature near the stove will always be higher than in the rest of the room; The heating process of the oven cannot be stopped instantly. If you are using a closed loop system with a circulation pump, turning off the electricity (even briefly for a few minutes) and stopping the pump will cause the water in the heat exchanger to boil. To avoid this, provide a combined system for water movement in the circuit. If the heating system is not used regularly, the water must be drained, which leads to premature wear of the entire structure. Otherwise, the water will freeze, which will lead to the destruction of the entire complex of devices. You cannot light the stove without water in the circuit.

This will lead to the destruction of the register and the reconstruction of the stove in order to use the stove in the summer without “turning on” the battery using the original design of the installation of heat exchangers. There is a risk of carbon monoxide poisoning, as with all solid fuel heating products, special attention must be paid to the correct manufacture of the chimney.

Making a heating system in your home based on a stove with a heat exchanger and batteries is an economically viable solution, but the design and construction must be approached competently, taking into account all the nuances of the work.

Types of stoves

Building a stove is a simple matter, but before you start, you need to decide on the type of structure. It is selected depending on the required options, the availability of free space in the house, as well as other parameters. Afterwards, a diagram of the stove is created with the required dimensions and notes - it is according to this diagram that the subsequent laying of the stove will take place.

Heating. Its name fully describes its purpose. This is a run-of-the-mill stove that is the easiest to put together. It is characterized by the simplest design compared to the following subtypes. Often equipped with a bed.

Heating stove for a summer residence

Heating and cooking. In this category of stoves for the home, a secondary option is added - cooking in pots or pans. This design will not replace a full-fledged stove, but it will cope with the task of saving gas. Heating and cooking stove Combined. This is a multifunctional unit, which is located in the kitchen of the house, and is equipped with an oven or a fully working stove for cooking. Furnace designs of this type are quite complex and are recommended for construction exclusively by craftsmen. Stoves and fireplaces. Building such a stove with your own hands is also not difficult, but there are certain requirements for its appearance. The facade should be beautiful and neat; its task, in addition to heating, is also to decorate the house. Fireplaces take up much less space and are easy to light, which is why their popularity is growing.

Brick stove-fireplace

These are not all types of stoves, but the most common ones are listed. Next we will talk about how to fold a heating discharge furnace.

What does simple mean?

It is further understood that a simple oven, which can be quickly made with your own hands, should satisfy the requirement. requirements:

- A person building such a stove does not need to have a deep understanding of the stove business. Ideally, he doesn't need to understand anything about it at all;

- The stove must operate on low-quality waste fuel with a thermal efficiency (this is analogous to the efficiency of heat engines) of at least 35-40%;

- A brick kiln should not require long-term drying after construction and “accelerating” fireboxes to reach the rated thermal power;

- It should consist of no more than 115-120 bricks, so that all the necessary materials can be brought at one time in the trunk of a car or on a trailer to it;

- Stove fittings (doors, hobs, burners) should be the most common (so that you can use used ones) and/or cheap;

- The masonry of a brick kiln should not contain complex joints, sawn (cut with a grinder) bricks, transitions from red brick to fireclay and steel mortgages.

Rehearsal for the future oven

Gaining experience in this craft is quite easy. To do this, you will have to make small bricks yourself, for example, five times smaller than standard ones, and build a stove five times smaller. Wait until the solution sets and try to heat it.

In this way, you can check the level of acquired skills. Then you can disassemble the stove and try to assemble another model, thereby training your hand on different models and their features.

The main attribute of any stove is the pipe. Folding the pipe is one of the main points in laying the entire furnace, so you must strictly follow all instructions.

Stages of construction of the furnace structure

After determining the location of the furnace, it is necessary to make a high-quality and reliable foundation on which the rest of the furnace will be built in the future.

Therefore, the foundation is the basis of almost every furnace, and the durability and reliability of the furnace design largely depends on the foundation.

After erecting the foundation, it is necessary to begin constructing the ash pit; this is a special chamber that supplies air to the combustion chamber, and also an accumulation of burnt fuel is formed in this chamber. Therefore, it is periodically necessary to clean this chamber from soot and ash.

The size of the firebox must be taken into account based on the size of the stove structure itself. Next, you need to make an ash pan; this is a special chamber where all the ash accumulates, which must be periodically removed. Its installation height largely depends on what fuel the stove will operate on.

The final stage in the construction of any stove will be the chimney, which is designed to remove carbon monoxide and smoke from the stove. During its manufacture, it is necessary to install a special partition, the so-called valve, which must be opened when the stove is burning, and closed after it goes out.

This is how you make a brick oven using wood with your own hands. Upon completion of the construction of the structure, it must be left for several days to dry completely.

The process of constructing the structure itself is of no small importance. The fact is that the stove must be built in stages; after each row of brick laying, it is necessary to measure all the necessary parameters with a level, and if necessary, eliminate inaccuracies.

All work must be done slowly, carefully and carefully. A brick stove for a bathhouse is built with your own hands in almost the same way; the operating principle is almost the same, but there are minor differences.

The difference is that the sauna stove must be additionally equipped with a special place for storing stones, as well as a container for heating the hearth.

Tandoor or Russian oven

Tandoor is an ancient construction of a dome-shaped adobe hearth. Distributed in different regions: from Central Asia and Northern China to Africa and Latin America. It combines high heat capacity with fuel efficiency, because in the historical homeland of these stoves there has never been an excess of firewood.

Ancient tandoor

A distinctive feature of the tandoor is its single-chamber design with a high round arch. The operating temperature in the firebox is higher than in a Russian stove. Therefore, the thermal regime during cooking is more intense, which affects the range of dishes. The cuisine is famous for its wealth of recipes based on simmering: porridges, grain dishes, various soups and decoctions.

Interior design for a small kitchen

A small kitchen requires good design. Functionality is what matters here. A good way to enhance the interior of a small cooking room is to connect it to the living room. Kitchen design should start with the layout. For a small kitchen you should choose furniture that has several functions. The peninsula will do a great job arranging a room. It has been proven to be an excellent solution for small areas. Allows you to make the most of a small room's surface while taking up little space, so you can conveniently prepare meals and eat them together. In turn, the space under the peninsula will be useful for storing kitchen knickknacks and installing an outlet.

General requirements and safety

Small Firebrick Stove

Let's start with the basics that will be useful to any novice stove maker. It will not be possible to understand everything at once, since laying a stove is a very complex and responsible process.

It is much more difficult to build than a brick wall. Therefore, today we will look at the simplest option that even a beginner can implement.

So let's start with terminology. It will be useful for you to understand the material that we will present below. Without knowing the names of the structural elements, even an experienced builder will not understand the information correctly.

Schematic structure of a brick kiln

| Part of the stove, photo | Description |

| There is nothing complicated here - this is a solid foundation on which the entire structure will stand. It is made in the form of a monolithic concrete slab of the required size and shape. |

| The furnace walls provide a framework that supports the internal structure of the furnace. Their outer side transfers heat into the rooms, and it does not do this at once, but accumulates and then gradually cools down. |

| This is a combustion chamber in which combustion products and flue gases are formed, which transfer thermal energy to the walls of the furnace. The upper part of the firebox is called the arch, and the lower part is called the bottom. |

| The grate is a metal grate installed inside the firebox, through which ash spills down and air rises to maintain combustion in the furnace. |

| The chamber under the firebox, into which the passage from the grate leads, is called a blower or ash pan. Through it, air is sucked into the furnace from the room and ash is removed. A cleaning or hatch leads into the ash pan - this part is made of metal and has holes for air to penetrate inside. The system is equipped with a shutter to prevent spillage of hot ash. |

| Smoke circulations are passages through which hot gases pass through the furnace, heating its outer surfaces. Through them, smoke is discharged through the chimney outside the room. Everything is clear with the chimney. |

| Upper surface of the oven. It can be made simply of brick, or have a metal or ceramic hob. |

| This is the name of the cavity inside the furnace, which is not connected by direct passages to gas exchange paths. |

Also in the oven there is:

- Damper - a damper that blocks the smoke channel;

- Doors for firebox and blower;

- Trenches - beams that replace the foundation slab, can be made of different materials.