Homemade sauna stoves are devices for heating air, steam, water for bath procedures, made independently. Basically, most of these devices are made of metal or brick. Next, we will understand the variety of technologies used to assemble sauna stoves in order to choose the appropriate option for each home in terms of size and materials used.

What homemade stoves for a bath can be like Source vbanepar.ru

Advantages and disadvantages of homemade sauna stoves

Most often, a metal or brick stove is chosen for a bathhouse, and in order to make the right choice, their advantages and disadvantages are taken into account.

Among the “advantages” of metal sauna stoves, it is worth highlighting the following:

- quick heating of the steam room (stone or brick gives off less heat than metal: a couple of hours after the start of kindling, and sometimes even earlier, you can go steam);

- compact design (this allows you to get more space in the main bath room);

- durability (subject to high-quality assembly, the stove will last from five to fifteen years);

- ease of use (compact metal stoves can be transported from one place to another);

- ease of manufacture (unlike, for example, the brick version);

- profitability (materials for the production of baths are inexpensive).

The advantages of a brick kiln include:

- soft steam, which is typical for spacious brick ovens;

- long-term preservation of steam and heat;

Soft steam from a brick stove Source wikimedia.org

- ease of use (there is no need to take fire protection measures before operating such a stove);

- aesthetic appeal (a brick stove looks very presentable, unlike its metal counterparts);

- ease of construction.

A simple stove for a sauna Source neoenerg.ru

However, for both types of homemade sauna stoves, the following negative points must be taken into account:

| Metal | Brick |

| Rapid cooling, which forces you to regularly add solid fuel | Heavy weight |

| The stove walls heat up too much, which reduces fire safety | Lack of mobility (all brick stoves are stationary) |

| In most cases, only suitable for small bath spaces | It is necessary to build a foundation for the furnace |

| Limited number of forms and modifications | The need to allocate a fairly large space in the bathhouse for installing a brick stove |

| Possibility of deformation from strong heat | Need to spend more money on buying building materials |

| Too dry air | Even one mistake in the brickwork can make the stove of poor quality (it will not hold high temperatures well) |

| Emission of infrared radiation | Low preparation speed for steaming (all preparatory work can be completed within an hour, and then it will take up to five to six hours for kindling). |

| Uneven distribution of heated air | — |

| The chimney needs to be cleaned constantly | — |

The chimney of a metal stove needs to be constantly cleaned Source kamin.lutsk.ua

Features, types of metal and brick stoves

Simple in shape, metal sauna stoves may differ slightly in design. The classic, easiest to make option is the potbelly stove. Essentially it is a metal box with a door and a pipe. However, this form is considered uneconomical: fuel consumption is high and heat transfer is low. The thickness of the metal for a modern, more economical type of sauna stove should not be too large, the optimal one is 4-5 mm.

Some owners make a combined stove for their bathhouse, the core of which consists of metal sheets, and the outside of the structure is lined with bricks. Thus, they achieve a reduction in fire hazard and an improvement in the uniformity of heating of the surrounding air. The basis for installing such a furnace can be a concrete slab lined with ceramic tiles, refractory bricks or a metal sheet.

Among the small variety of types of metal sauna stoves, three main types stand out: closed, open and combined stoves. The first type is distinguished by a completely closed combustion zone and small size. Open stoves contain in their design places for laying out heating stones that do not close.

Closed oven Source tildacdn.com

Typically, the firebox of a homemade iron stove for a bath is placed in the waiting room, and the part with heating stones is located directly in the steam room. To properly operate an open stove, it is necessary to ensure maximum contact of stones with the outer surface of the firebox.

As for combination stoves, they have the additional ability to heat the air in the room. This can be done by equipping the structure with a network of pipes, which are attached to the stove through a pipe and are then brought out so that they cover the entire perimeter of the bathhouse complex. When the fuel in the stove burns, the energy generated heats the air, after which it begins to circulate through the pipe system. In this case, the supply of heated air is carried out by moving a special grille in the form of a valve.

Brick stoves themselves are safer than metal stoves, and also more convenient. The reason lies in the gradual and uniform heating of the air surrounding the stove. The location for the construction of such a stove must be chosen carefully. The heating element should be located near the wall of the room, but no closer than twenty centimeters from it.

Brick oven Source wmpics.pics

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

Installation Rules

The requirements and recommendations for installing the furnace are the same as for other metal units.

- These relatively lightweight structures can be installed on a concrete screed without a foundation.

- If the floor is wooden along the joists, you need to pour or lay out a solid foundation from blocks.

- To reduce infrared radiation from hot metal and reduce the risk of burns, you can line a pipe sauna stove with bricks or simply separate it with a brick screen.

- The distance from the stove to the walls must be at least 20 cm.

- At the point where the chimney passes through the ceilings, a cut-out is arranged in the form of a metal box filled with non-flammable material, for example, stone wool.

The ceiling around the pipe is covered with a sheet of iron Source izhevsk.ru

- A metal sheet is also placed on the floor before the firebox to prevent accidental fire from sparks and embers.

How metal sauna stoves are made

To make a homemade metal sauna stove, you will need:

- five- to eight-millimeter steel sheet (several pieces will be needed, and the size and quantity will depend on the dimensions of the firebox of the stove being manufactured);

- water tap;

- ruler or tape measure;

- Bulgarian;

- a thin metal pipe with a thickness of 5 mm to 10 mm and a length of about two meters;

- grate;

- metal scissors;

- hinges and latches (depend on the number and shape of stove doors);

- four metal squares with a side length of 10 mm, or doors for three functional compartments of the stove: for the firebox, heater and blower;

- welding machine.

First of all, the firebox is made. To do this, nine square pieces of metal measuring 50 × 50 cm are measured on a metal sheet and a box is welded from them. There should be another one inside (a separating plate), while the upper part of the firebox is needed to burn fuel, and the lower part is needed to collect ash and ash. In each of these parts, holes for the doors are cut so that they are located on top of each other. After attaching the doors, proceed to the next stage.

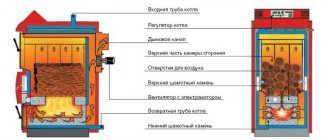

One of the options for a stove for a bath (drawing) Source vbanepar.ru

Next, two pieces are cut from a two-meter pipe: one for the firebox (90 cm), the second for the tank (60 cm), and the first of them is welded to the firebox. After this, make a rectangular hole in a larger section of the pipe with dimensions of 20 × 50 cm for the blower and securely attach the door to it. A grate (grid) is welded onto the resulting product.

Remember! To heat a room of 14 m², it is enough to have a heater with dimensions of 30 × 40 × 30 cm.

To make a heater (that part of the stove that will contain heated stones), they take several more pieces of the plate and make a container out of them, then thick iron rods (thickness - at least ten millimeters) are welded on top of the prepared firebox. Be sure to make a hole for the door and carefully weld it onto the hinges. It is worth paying attention to the fact that the structure must be strong, because these rods or metal plates need to hold a fairly large weight of stones.

Important! To fill the heater, they usually take diabase or soapstone, but refuse to use granite (it crumbles after strong heating) and stones containing mica (it helps release carbon dioxide) or the inclusion of silicon.

A heater on a stove, welded from rods Source hozsektor.ru

Another important structural element of a homemade stove is a water tank. Above the manufactured heater, first of all, another metal plate (thickness - at least 8 mm) with a pre-made hole for the chimney is welded. After this, the pipe prepared for the smoke exit is also carefully welded to the edges of the round hole.

At the final stage, they do one more thing - in the area of the rear wall of the structure, and attach a water tap. A pipe for the tank is then welded to it. It is important to make the water tank small so that you can easily weld it on top of the stove, above the heater or next to it.

In the resulting product, after welding all the structural parts together, each node will perform its functions. So, at the very bottom (above the ash container), that is, in the firebox, fuel (for example, harvested firewood) is burned, then the heat moves through the stove to the stone section, strongly heating the stones. In this case, these stone blocks can be changed or added through the door in the heater (if it is a closed type), and the smoke comes out through the chimney.

One of the options for placing a water tank and heater on a sauna stove Source baniwood.ru

The water tank is equipped with an additional lid or other auxiliary parts that will allow you to periodically fill the container with new cold liquid. Thus, they create the simplest homemade iron sauna stove with a water tank and a heater.

Metal for sauna stove

As for the metal from which a homemade stove is made, cast iron material is usually chosen, because it is much more difficult to fasten (if there are no difficulties with fastenings, cast iron is well suited for the firebox door).

Iron plates are used, but they must take into account that when such a stove operates, the temperature in the combustion chamber rises to four hundred and fifty degrees Celsius. Thin metal under such loads begins to deform and burn through. When choosing a stainless metal with a sheet thickness of 10 mm or more, you can avoid this problem, but another one will appear - the warm-up time will increase significantly, and with it, fuel consumption.

Structural steel for furnace Source steelsukraine.com.ua

If a non-professional nevertheless decides to make a stove with his own hands, be sure to take into account the advice of experts who recommend using stainless high-alloy steel grade 08x17T. It is practically not subject to corrosion and destruction by high temperatures. An example of a product that is made of just such steel is AISI 430. It will not change its shape even when heated to a temperature of + 850 °C.

The furnace compartment, called the firebox, is exposed to the highest temperature and is in direct contact with the flame. That is why steel grade 10 is chosen for this structural part (manufactured according to the GOST 1050-88 standard); for convection parts, 08PS or 08YU is suitable (manufactured according to the rules of GOST 19904-90). Structural sheet steel is considered ideal for the body of a sauna stove.

Briefly about the main thing

Most of today's bathhouse lovers prefer to equip them with light metal stoves that occupy a minimum of space and do not require the construction of a foundation. When remodeling the bathhouse, they can easily be moved to another place. The most effective, economical and easiest to manufacture are structures made from thick-walled large-diameter steel pipes. They can be installed both vertically and horizontally, depending on your own preferences, size and layout of the steam room. When placed vertically, a minimum amount of additional materials is required, since the firebox, heater and boiler are compactly placed one above the other in one pipe.

How to make a brick stove for a bath

A bath stove can also be made from bricks. Unlike the installation of a metal sauna stove, the brick version requires the construction of a foundation, since the device will be stationary.

Refractory brick for the stove Source prom.st

The fuel combustion chamber is lined with refractory bricks, while the external (visible) parts are decorated with burnt red. Masonry mortar is made from a mixture of sand and clay. It is the clay component that will firmly hold the brickwork. The most common version of a homemade sauna stove is a design with a base of 890 by 1020 mm. To do this, standard brick blocks are laid in a base 3.5 by 4 bricks wide. When choosing a stove with base dimensions of 1020 × 1290 mm, blocks are laid in a stove foundation measuring 4 by 5 bricks. The dimensions of a conventional stove, including the chimney, are usually 168-210 cm.

Important! Cement is not used in the manufacture of sauna stoves, as it crumbles when the masonry is heated.

Video description

To see how a 3x3.5 brick stove is laid, see this video:

When choosing a brick for a sauna stove, be sure to pay attention to the absence of cracks and chips, as well as mica film. The standard version is suitable, having the following dimensions: 25 × 250 × 65 mm (permissible deviation - 2 mm). If thin thread-like cracks and very slight grooves are observed on the brick, such a building material is considered to be of high quality and suitable for construction. To make the stove level, the bricks must be the same size.

Before starting the manufacture of a homemade stove, after preparing the bricks, sand mixture and a grinder with a diamond disc for cutting building materials, pre-lay (without mortar) the bottom (zero) layer. After the issue with the size and layout of the furnace base has been resolved, the first layer of bricks is put back, since first of all it is necessary to make waterproofing, securing it to the foundation.

After this, the sand and clay are cleaned of stones and other foreign matter. The clay is soaked for several days. The best material for such work is a clay mass mined in the area of one and a half meters from the surface of the earth.

Mortar of clay and sand Source 2proraba.com

Important! Always choose the clay that is part of the brick that will be strengthened with its help (for example, for fireclay bricks, it would be ideal to use fireclay clay for mortar).

Unlike making an iron stove for a bathhouse, a brick stove requires a bonding agent. To get a good solution, combine clay with water and sand, after which everything is thoroughly mixed. If the clay has a high fat content, it can be diluted in a ratio of 1 to 2, that is, one part clay to two parts sand.

You can check whether the solution came out correctly as follows. Take a wooden stick and dip it into the solution. After this, they carefully look at the sand-clay layer that has stuck to the piece of wood: if its thickness is 2 mm, they begin the intended work.

Prepare for installation:

- bricks;

- emery wheel;

- order;

- pliers;

- broom and dustpan;

- container for soaking bricks and water.

In order to remove unnecessary air bubbles from the brick, as well as to prevent dehydration of the solution and wash away dust, it is pre-soaked, that is, immersed in water for a while immediately before laying begins.

This is how bricks are soaked Source kronotech.ru

Rules for successful masonry

The efficient operation of the furnace largely depends on how well the masonry technology was followed. This is influenced by the quality of the bricks, the method of doing the work, the binding solution and the degree of moisture of the material. The result of proper masonry will be a solid structure. An unsatisfactory result is considered to be a structure made without bandaging the joints, separated by vertical lines of seams.

During the work, one important requirement must be met: it is necessary to prevent the gases formed during combustion from escaping to the outside. In addition, air entering the furnace structure is also not welcome.

Careful selection and adjustment of the material will help make the masonry beautiful and durable. It is important that the bricks are split and hewn. Before starting work, the cobblestones need to be soaked in water, lowered into a container for 10 seconds, then laid in a row on a layer of clay.

Craftsmen advise applying the mortar by hand, and using a trowel only when doing external masonry.

The brick laying process is as follows:

- take the block in one hand, grab the clay with the other and apply a thin layer to the brick;

- level the surface;

- place the product in a specific place;

- while pressing on the cobblestone, perform forward and backward movements;

- remove excess mortar on both sides of the masonry with your hands;

- with the next brick, repeat the above steps, in this case it is necessary to apply the solution also to the end of the block, with which it will be pressed against the first one.

Features and important nuances of constructing a stove for a bath

In order to properly make a homemade stove for a wood-burning sauna with a water tank or build a brick one, you need to know in advance some rules that should be followed when working on this useful device:

- They think in advance about exactly what plan the stove will be made in order to prepare all the necessary tools and materials in sufficient quantity.

- To produce a metal furnace, you can also use an unnecessary iron barrel, which eliminates the common problem of unsoldering the seams of the product.

- After completing the welding work (if any), be sure to check each seam made for integrity.

- A container for laying stones can be provided for both metal and brick sauna stoves.

- When selecting bricks, clay, sand or metal sheets for making a bathhouse, you should always give preference to high-quality materials. In some cases, the material is improved independently: for example, sand is sifted to include large fractions, and other components are cleared of debris.

Materials

To carry out the work, the following materials are required:

- the pipe itself, which will be needed to create a firebox and a water tank, its diameter should be from 500 to 600 mm (530 mm is considered optimal), wall thickness - from 8 to 16 mm, length - from 1.2 to 1.5 m;

- a pipe that will later become a container for stones - its diameter is approximately 400 mm;

- chimney pipe – diameter 120-150 mm, thickness 2-4 mm;

- metal sheets in the amount of several pieces, dimensions approximately 600 by 800 mm, thickness about 8-12 mm;

- hanging hinges made of metal;

- a small part of a threaded water pipe, diameter 1/2-3/4 inches, length 50-80 mm and a water tap with a thread inside of the same diameter;

- pieces of rods from reinforcement - length approximately 500 mm, diameter from 12 to 18 mm, ready-made cast iron grates for solid fuels are suitable;

- cement composition;

- bricks;

- sand.

Required tools:

- apparatus for welding elements;

- any strong metal carver;

- electrodes;

- mortise tap;

- rolled metal for legs;

- asbestos cord;

- door handles.

Video description

One of the options for assembling a bathhouse using the example of a layout is shown in this video:

- When making a stove, they always remember that the stove is being made for loved ones, relatives, and friends, so they always check the safety of using the selected building materials.

- The quality of steaming in a built sauna depends, among other things, on the regularity and thoroughness of cleaning the stove.

- If an already unnecessary gas cylinder is used for a sauna stove, the doors are carefully cut out from it, then additional money is avoided on these structural elements.

- Homemade sauna stoves can have a vertical or horizontal firebox.

- When purchasing doors for the firebox and ash pans, compare their size in advance with the dimensions of the future stove (they also think about it in advance and purchase fasteners in the required quantity).

- If the stove is made without a heating water tank, you just need to equip the chimney with a steel heat exchanger and run pipes to the water used for showering, then the thermal energy generated in the firebox is used more fully.

Drawings of a metal stove for a bath Source oboiman.ru

- The air flow, when passing through a stove made of a thick pipe, a metal barrel or an unused cylinder, flows around it, thus improving heat transfer.

- A very hot metal stove is additionally separated from the rest of the space by brick walls, then the level of fire safety is acceptable.