Chickens are heat-loving people and rather flimsy. Winter, especially in cold regions, always becomes a serious test for them, and if the chicken coop is not properly insulated, wintering becomes especially difficult. Ice water in the drinking bowl, drafts, constant darkness - you should not expect either eggs or good health from birds that live in such harsh conditions.

Kansei

In the village, our chickens lived in a plank shed, without any insulation; the temperature there was slightly higher than outside. The chickens did not freeze, although the rooster's comb sometimes froze. The downside is that under such conditions, chickens almost never lay eggs in winter, and if they lay eggs and you didn’t keep track, the eggs freeze and burst.

In this article we will tell you how FORUMHOUSE members insulate their poultry houses for the winter.

Shingles

Another way to insulate walls is to use two layers of tiles, which are nailed at an angle of 45 cm. After the masonry is completed, the walls are plastered with clay mixed with sawdust. The solution should have a uniform consistency and harden over time. A minimum layer thickness of 3 cm is used.

When the walls are dry, they may crack - such cracks are filled with a mixture of clay and fine sand in a ratio of 1: 2. Finally, the walls are whitened with quicklime. The whitewashed walls are lined with plastic to prevent chickens from pecking at the plaster.

High heat losses occur not only from the floor, but also from poorly insulated windows. In general, 1-2 small windows are enough, which are best not installed on the north side. In cold weather they should be covered with plastic wrap. The chicken coop door is another conductor of cold. It should be located on the south side and should be insulated with old carpets or foil. If possible, you can also put old carpets and felt on the floor.

Are chickens afraid of frost and can they winter in a greenhouse?

Important! At sub-zero levels, the productivity of chickens will drop sharply, but they will not die and will be able to survive.

If the birds have been acclimatized to the surrounding conditions, then the lowest temperature they can tolerate is – +7 °C.

In this case, the chicken coop should be well ventilated and free of drafts. Some summer residents use a greenhouse as a home for chickens. This is the most suitable place for birds, where they will receive enough light and be able to rummage in the ground all day.

Heaters

In winter, for insulation, simply plug the plug into the socket.

Heating - diesel fuel furnaces. These models do not smoke and are fireproof. For example, to heat a room of 100 m2, you will need a stove with a 2.5 liter storage tank. — One run is enough for 12 hours at -20 ° C.

Heaters are also popular - they run on solid fuel and can even heat several rooms at the same time. Electric heaters are more often used, but they and all electrical wiring must be installed out of the reach of birds - in a special fence or in a niche in the floor.

An economical heating option for winter and autumn is an infrared heater with temperature control, which allows you to save energy. Screen mesh lamps are the easiest way. The power of the light bulbs is adapted to the room.

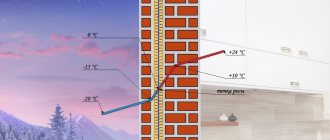

What temperature should the chicken coop be in winter?

Maintaining the temperature inside the building at the same level throughout the winter will allow the hens to lay eggs well all year round.

The most comfortable mode is the temperature in the range – from +10 to +15 0С, but not less than +5

Suitable temperature parameters:

- With the arrival of spring, the egg production of laying hens increases by 40%. To create a spring microclimate in the chicken coop, the temperature is maintained at +18 °C.

- The temperature level in the poultry house should not drop below +10 °C , since as the weather gets colder the birds try to warm up and begin to consume a lot of feed. And most of the nutrients are spent on heating it.

- The most optimal temperature level is +12…+15 °C.

Insulation of windows and doors

The main part of the heat is evaporated from the chicken coop through the cracks in the window and door openings. Therefore, all holes are sealed with foam rubber, fabric, cotton wool and other available materials.

The insulated door should fit snugly against the walls to avoid drafts

To reduce heat loss, install one small window in the room, from which there will be enough lighting. The window is located on the south or east side. For more information about chicken coop lighting, read the article: about the features of the light regime for broiler chickens and egg-laying hens.

Insulation:

- Window. The window structure is equipped with two frames. In summer, the frame is removed and a mesh is installed instead, thanks to which the room is well ventilated. In winter, the window is covered with transparent polyethylene foam and trimmed around with felt material or other insulation.

- Doors . The door is removed from its hinges and insulated from the outside and inside. The inside of the door is upholstered with dense material; film, foam rubber and felt are used for upholstery on the outside. Such insulation will qualitatively protect the poultry house from drafts.

We insulate the ceiling and roof

If a farmer breeds chickens all year round, then the building is built with an attic. This allows you to store bedding, food and much more there.

But drafts moving through the attic remove heat from the house. To retain heat, the roof must be insulated. Insulation and implementation techniques are chosen depending on the structure of the roof. As a rule, the upper part of the building is insulated with mineral wool or penoplex.

Step-by-step description of the process of insulating the roof and attic

Before you begin insulating the poultry house, it is necessary to remove the bad parts of the wooden coverings.

If the boards have areas damaged by rot or mold, these areas are replaced with new parts. Before installation, new boards are treated with an antiseptic.

Step by step description:

- It is customary to insulate the ceiling with mineral wool. It is laid on boards, covered with a vapor barrier film on top and secured on the underside of the frame boards with a construction stapler. For additional protection, a second layer of mineral wool is laid on top using the same principle.

- The entire structure is lined with clapboard. The material is fixed with metal clamps.

- To protect against parasites and rodents, the material is treated with special agents and then painted.

Installation of a chicken coop heating system

A heating system installed inside the poultry house will allow the farmer to collect a large number of fresh eggs every day. For internal heating, batteries, infrared lamps, various types of stoves and potbelly stoves are used.

Stove options: potbelly stove, brick, diesel

A stove installed indoors can become a fire source. Therefore, when installing such a heating system, a protective coating is created that will increase fire safety and protect birds from burns.

Be sure to read:

How to make nests for laying hens with your own hands, step-by-step instructions, photos and videos?

To ensure that the temperature in the chicken coop is always at the desired level, constant human supervision is required. The service life of a potbelly stove is short, since over time it becomes covered with rust.

A diesel heater is the most cost-effective and safe device. Smoke containing harmful substances is not released into the room. The power of the device is selected depending on the size of the room.

Radiator with thermostat

A radiator with a thermostat makes it easy to maintain the air temperature in the chicken coop at the required level. To prevent birds from being injured by an electric battery, it is necessary to make insulation.

The disadvantage of such heating is high electricity bills. This is especially felt if you use a device with high power.

Infrared lamps for heating a chicken coop

Installing infrared lamps will help reduce energy costs several times. The efficiency of the device reaches 98%. The heat emanating from infrared lamps is evenly distributed throughout the room.

The efficiency of infrared lamps reaches 98%, and thermal energy is evenly distributed over the entire area of the room

The lamps are easy to use and easy to install yourself. They are mounted on a wall or ceiling.

Comparative characteristics of heating installations

The pros and cons of heating systems are presented in the table:

| Heater type | Advantages | Flaws |

| Diesel stove |

|

|

| Potbelly stove and brick oven |

|

|

| Radiator with thermostat |

|

|

| Infrared IR lamps |

|

|

Important! All heating elements of the heating device must be insulated with non-combustible material.

This is the first thing to do after choosing a heating device. Electrical wires are sewn into a metal pipe with a diameter of 0.3 cm.

Preparatory activities

At the initial stage, the walls of the room are inspected; any cracks found must be repaired and rotten boards replaced with new elements.

Construction foam should not be used to repair cracks without an additional protective layer, since the material is destroyed under the influence of ultraviolet radiation.

In a wooden shed, it is necessary to consider attachment points for the internal sheathing of timber or metal profiles, which holds the protective layer and finishing.

Since installing thermal insulation does not guarantee maintaining the required temperature in winter, it is necessary to provide places for installing electric heaters.

The equipment is connected to an alternating current network; the wiring must withstand the load without overheating and destruction of the insulating layer. The power is supplied to a switchboard with automatic fuses (the rating is selected in accordance with the power of the connected heaters).

Required Tools

To carry out installation work you will need:

- measuring tool;

- a knife or hacksaw for cutting insulation and vapor barrier film;

- electric drill and cordless screwdriver;

- construction level (hydraulic or laser);

- Phillips screwdriver,

- electric jigsaw for cutting additional sheathing elements.

Some of the necessary tools for the job.

Common heating errors

One of the main mistakes when installing heating in a poultry house is poor preparation of the chicken coop for winter, that is, insufficient insulation. Through cracks, the ceiling and uninsulated windows, heat will escape to the street, nullifying the work of the heater.

When installing a fan heater, you must remember that warm air rises. The warm air stream should be directed downward, otherwise the floor will always be cold.

To protect heating systems from short circuits, circuit breakers should be installed that stop the supply of electricity in the event of a power surge.

In conclusion, we can say that insulating a building for laying hens with old, proven materials: straw, sawdust, peat is the most inexpensive and environmentally friendly insulation option.

Farmers' advice

In rural areas, farmers often use natural materials to insulate poultry houses. Craftsmen advise using sawdust to insulate even walls. The technology is suitable for chicken coops and boards. Even at the construction stage, a timber frame is constructed. It is covered with boards on both sides. The resulting void is filled with sawdust.

If the chicken coop is made of stone, reeds will help to cheaply protect the walls from the cold in winter. It is harvested in the fall on the banks of reservoirs. Reeds are tied with ropes into mats and used to line the walls.

Regardless of insulation, heating is installed inside the poultry house in winter

No matter how well the poultry house is insulated, in winter without heating the chickens will be cold. The easiest way to solve the problem is to hang infrared lamps. They will provide the bird with heating, lighting, and extend daylight hours, thereby improving egg production.

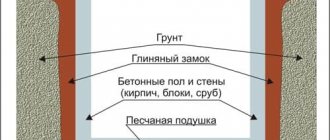

We insulate the walls

It is better to build a home for chickens from natural wood. If the climate in the region is mild, then the building is made of boards. In more severe conditions, logs and timber are used.

Depending on the building materials from which the poultry house is made, the method of work and thermal insulation material are chosen. It can be mineral wool, moss, penoplex and much more.

Insulation is carried out on the outside of the building and on the inside. The outer side of the wall is plastered. If cracks appear on the walls after drying, they are covered with clay mortar and sand.

Mineral wool

Insulating the walls of a chicken coop with mineral wool

When using mineral wool, it is necessary to prepare a sheathing of beams in advance. The beams are laid vertically. The distance between them is left 10 mm less than the width of the insulation.

After installation of the lathing, heat and vapor barrier is made using foil. This must be done, since mineral wool tends to absorb moisture. Then mineral wool is placed in the sheathing and secured to the wall.

Penoplex

Penoplex is made on the basis of polystyrene and is produced in the form of dense slabs measuring 120x60 cm. The structure of the material is fine-celled. When joining parts, no gaps are formed, since each element is equipped with a solid L-shaped edge.

The material has high heat-protective properties and does not emit harmful substances or unpleasant odors. Penoplex is used both in regions with harsh climatic conditions and in hot ones, since the material can withstand temperatures from -50 to +75 °C.

The service life of the insulation is about 50 years. The material is toxic when burned and is used only with plaster, which is its disadvantages.

Other ways to insulate the walls of a chicken coop

Polystyrene foam is another thermal insulation material used to insulate the walls of a barn. This is a lightweight material consisting of foamed polystyrene granules.

Each manufacturer has its own density and strength of the material. Antiperen, which is included in some types of foam, has anti-fire properties.

Polystyrene foam will be an excellent choice for insulating the walls of a chicken coop due to its advantageous price-quality ratio

Therefore, it is better to insulate walls with a material that includes this component:

- The insulation is glued to the wall from the inside or outside of the room. The surface of the wall must be absolutely flat.

- The material is carefully fixed and plastered.

- The thickness of the sheet for the facade should be 5-6 cm.

Be sure to read:

How to build a chicken coop with your own hands for 20 chickens: drawings and design details

Foam plastic has good thermal insulation properties, a long service life, does not require additional waterproofing, and is inexpensive.

Despite all its advantages, this is a fragile material that does not allow air to pass through well. When ignited, it releases harmful substances.

Step-by-step instructions: making a cage for laying hens

The frame of a poultry house is easy to construct from wood - it is an environmentally friendly, durable raw material.

The bars can be easily replaced with a profile designed for drywall, or with corners made of strong metal, but to attach such parts you will need a welding machine.

Step-by-step instruction:

- Mark and cut building materials for the base of the poultry house. Cut wooden blocks 40x40 mm according to the drawing with a hacksaw. Sand the ends with sandpaper.

- Using self-tapping screws, make the skeleton of the poultry house. Install a lattice wooden flooring from a block measuring 2x4 cm - needed for installing the lower pallet. Build a door frame from the same block. To transport a chicken house, you can equip it with furniture legs.

- To make a floor from a grid: according to the sketch, cut a piece from a fine-mesh mesh, bend the front edge like a tray. Strengthen the floor with 2x4 cm blocks, soak them with lime or drying oil. Place the mesh on the bars using self-tapping “bugs”.

- Cover the back and side walls with fine mesh , tightening them with self-tapping screws.

- The front side is covered with a 5x5 cm mesh , placed on self-tapping screws. Equipped with a folding gate on bolts.

- Make the roof from lattice , waterproof plywood or OSB. Secure with self-tapping screws.

- Make a tray-pallet according to the size of the cell bottom from a sheet of tin. Bend the front edge like a handle and place it on a wooden flooring.

Budget three-section cage for rabbits made from profiles

Good day, dear DIYers. Once again I am adding to the topic of rabbit breeding with my photo report on the construction of various devices for this type of animal husbandry. Since rabbits are very fast growing and quickly breeding animals, I always have a very pressing question about their placement. I made both ordinary cages and cages from old cabinets, which I wrote about on this site and posted reports. Today I would like to present to your attention a three-section cage with space for maternity wards for female rabbits or young animals. I will have this cage outside all year round, since I no longer have any space left in the utility rooms. The fact that the cage will consist of mesh partitions is nothing to worry about. For the autumn-winter period, I will cover the walls with silver insulation. This is a proven option that has repeatedly insulated rabbit houses in this way. Well, of course, the queen cells will also be insulated, since newborn rabbits are very delicate animals. The cage I'll show you is fairly inexpensive to make. I spent 915 rubles on its construction and purchase. But this is taking into account the fact that the net was on my farm and I did not spend money on its purchase. And if with a purchased mesh, then in total it will cost 1,570 rubles. As you can see, this is a budget option, because for that kind of money you won’t even buy one cage, let alone a cage with three sections. In online stores they cost from three thousand or more. This is a single section.

To make it I needed the following materials and tools:

profiles for drywall, mesh with a fine mesh for walls and partitions, mesh with large holes for the floor, a sheet of 6 mm plywood, a drill, an angle grinder with cutting and flap discs, a drill, a 4 mm metal drill, a riveter and some others tools that you will probably find in your household if you decide to build this living space.

I bought the profile, the cheapest one. The frame will be made from it.

Best answers

Galina M:

There is no need for a refrigerator if you can’t insulate the entire shed, insulate at least part of it. In villages, chickens winter normally, but only insulated sheds and I agree you can buy an infrared lamp (special for farm animals).

keep it at home

Vladimir:

Anyway, it will be warmer in the refrigerator

Alena Bykova:

Try insulating the shed

Alex U:

can the shed be insulated? lay down straws... cover the walls with something suitable...

Ali Baba:

It’s better if it’s new and already cut up - so that the pieces don’t freeze and each leg is in a separate bag)))))))

rrr:

in a normal barn chickens never freeze

Kotyara:

Insulate the shed with polystyrene foam and screw in a blue lamp... they will be warmer))))))))

Andrey ▒▒▒▒▒▒▒:

If there is no heating, then insulation is useless. Where does the heat come from? 4 frozen chickens will not heat the room. Either provide some heat, or bring chickens into the house.

Sergey Igorevich:

Insulate the barn and put up perches for the chickens; it’s cold on the ground, they need something to sit on...

Olga:

weirdos

Yuri:

Buy them a rooster, it will quickly warm them up)))

Lisa Halanay:

Instead of laying straws in the barn, you should throw a haystack there - the chickens will not freeze in the hay. And why a refrigerator? Make a small pen in your house and let them live until spring. In the warmth and light, even artificial light, chickens lay eggs well in winter.

Doberman Crystal:

I now have three elite chickens imported from China sitting in my apartment in a large exhibition dog cage. If the bird is cold, be sure to bring it somewhere warm; no amount of straw or hay will help. For a couple of months you will live with cheerful cackling)))) For domestic chickens, the favorable winter temperature is +10 degrees. Below it is already dangerous.

Cage sizes for laying hens

For 1 sq. m it is optimal to place 2-8 chickens of meat and egg breed or egg breed.

Birds should be able to freely approach the feeder/drinker without crowding or squeezing their neighbors. To do this, pens are built with a depth of about 50-60 cm, the width is chosen based on the size of the flock - 60-120 cm.

You should not build chicken houses that are too wide - a tray filled with droppings will be very heavy, and the flooring inside the structure will become deformed.

As a rule, the height of the poultry house is 45-50 cm.

Drawing of a cage with 3 tiers

Experienced breeders recommend following the data from the table when constructing poultry houses:

| Number of chickens in the poultry house | 2-3 | 4-5 | 6-8 | 9-12 |

| Depth, m | 0,5-0,6 | 0,5-0,6 | 0,6-0,8 | 0,7-1,0 |

| Width, m | 0,6-1,0 | 1,0-1,4 | 1,4-1,8 | 1,8-2,0 |

| Total height, m | 0,65 | 0,65 | 0,7 | 0,7 |

| Height at the rear wall, m | 0,45 | 0,45 | 0,5 | 0,5 |

| Area for 1 chicken, m² | 0,1-0,3 | 0,1-0,21 | 0,1-0,24 | 0,1-0,22 |

For poultry of the egg-meat breed, the territory should be increased by about 30-40%.

Attention ! Too small a room can result in bird fights, stress for the flock and, as a result, a decrease in egg production.

Materials for making a cage

When building a residential poultry house, laying hens cannot do without:

- pairs of planed wooden blocks 3 m long;

- 5 planed wooden planks 4x5 cm or 4x4 cm, 3 m long;

- galvanized metal grating for the front wall with a mesh of 5x10 cm and a width of 1 m - one roll card (1 lm) or with parameters 0.5x2 m;

- galvanized metal gratings for the ceiling, side walls and floor with a mesh size of 1.5x1.5 or 2.5x2.5 cm and a width of 1 m (roll card 3 lm or with parameters 0.5x2 m);

- self-tapping screws for wood or self-tapping “bugs” for fixing the mesh;

- metal corners for frame screeds or canopies;

- 1.5 mm tin sheet - containers for excrement, or PVC trays;

- PVC pipes or iron sheets - for future drinkers and feeders.