Tiling fireplaces and stoves Perhaps, tiling fireplaces and stoves with ceramic tiles is the most popular finishing option. You can choose the desired color and configuration of facing tiles for the fireplace in almost any hardware store. Many of us would like to save money and do the work ourselves. Fortunately, this is quite possible; the most important thing is to approach this issue correctly. First, you should select the desired design and look at photos and videos on this topic. Let's figure out how to cover a fireplace with your own hands.

Fashionable tile solutions for stoves

During the time of all-Union gasification, happy residents of populated areas, who had the opportunity to use clean and fairly environmentally friendly blue fuel, enjoyed technical progress, installed all kinds of gas appliances and destroyed old stoves, forgetting that fashion was returning.

Times have changed. Blue fuel has increased in price. It is still popular and in demand, but the spirit of wood-burning stoves has long been missing for many.

Those who turned out to be smarter and did not touch the creations of their ancestors look at their old tiled, stone or simply made of refractory brick stoves with delight. It was these creations that became the prototypes of modern wood-burning fireplaces and stoves (regular and long-burning), which are now at the peak of popularity.

How to tile a fireplace or stove

To finish a metal fireplace portal, you need to follow several steps in the following order:

- Prepare the walls - remove the old plaster, if any, and smooth out any unevenness.

- Prime the surfaces with a special mixture with additives in the form of marble chips for better adhesion.

- Reinforce the walls with metal mesh, securing the latter with dowels.

- Apply plaster, thus ensuring that there are no horizontal or vertical deviations.

- Perform direct cladding by placing clinker, fireclay or other selected material on glue applied evenly over the entire surface (which prevents the formation of voids and peeling).

Which solution is suitable for masonry

A win-win option would be a ready-to-use composition containing fireclay clay, sand, cement and/or other components. You can also give preference to a dry mixture, which should then be diluted with water in the proportion indicated on the package. In both the first and second cases, you will also need a binder enriched with additives and plasticizers.

The adhesive is selected based on the maximum surface temperature that it must withstand without changing its physical and chemical properties:

- up to 200 °C – intended for surfaces with a low degree of heating;

- 600-800 – for fireproof tiles on the wall behind the fireplace;

- up to 1200 – for lining open hearths and fireboxes.

Be sure to follow the instructions.

How to plaster

To plaster a brick structure, a simple solution is suitable, to create which ordinary clay from quarries is dissolved in water for 2-3 days (and mixed several times during this time). Roll the resulting dough into balls, wait until they dry, and look at their surface. If the structure is homogeneous and there are no cracks, then the mixture is ready for use.

You can also use the factory-made composition, which, as a rule, only needs to be diluted, left for an hour or two and applied in a 3 cm layer. The manufacturer writes detailed instructions on the packaging - all you have to do is follow them.

If you purchased a metal structure, the fireplace portal is also first plastered with any suitable composition.

Tiling a Russian stove

The Russian stove is a symbol of warmth, comfort, hospitality, delicious food - the central place of many folklore and original works. Nowadays, old stoves look like real valuable antique objects, as if they were moved from well-read and beloved pages from childhood.

Many are covered with beautiful plain or patterned tiles that have been well preserved. There are also old brick ones, but still functional. How to revive them with a beautiful finish? What should be taken into account?

Fireplace styling options

In modern homes, it is not only a source of heating, but also an interior decoration, so it is simply necessary that it be decorated aesthetically and tastefully. Let's see in what ways it can be done.

Under Gzhel

Original Russian traditions are still relevant today. It is enough to take white tiles with patterns made in blue tones, and you will see how the room will be transformed: it will become visually larger and more positive. At the same time, you will increase the efficiency of the heating device and improve the level of safety.

Under the stone

The result is a relief surface that quite accurately imitates masonry made from natural cobblestones. It looks impressive and has a homely, spiritual feel - you want to gather around such a fireplace with the whole family. And to create beauty, you just need to pour a mixture of cement, sand, gypsum, perlite and other fillers into a pre-prepared mold that replicates the texture that interests you. The result will be durable enough for many years of use.

Under the brick

The choice for those cases when you need to emphasize the simplicity or even brutality of the room. Thanks to this design solution, the heating device looks as organic as possible in the interior, because with its entire appearance it continues the design of the walls. Ideal for a loft-style room.

Mirror tiles

It looks chic and ultra-modern, fits perfectly into the framework of high-tech, modern, and minimalism. Places the right accents, reflecting the light of a chandelier and sconce, candle flames, visually expands the space, and creates interesting graphic effects. You just need to plant it on a special reinforced glue that can withstand up to 400 °C.

Panel

Images are created on top or on the sides of the firebox: stones, wood, plants, eclectic patterns, recognizable ornaments, if desired, even textile motifs that repeat the texture of the canvas.

Types of stoves, features affecting finishing

The most beautiful and durable material for lining stoves, which does not change its appearance for decades, are heat-resistant tiles specially designed for this purpose.

The facing material and the adhesive for attaching it must withstand high temperatures and temperature changes (if the stove is located in the yard). It is used for both brick and metal stoves.

The surface of the latter heats up very strongly and quickly. The heating rate of metal and tile is different, so decoration is possible using a special frame to which frames or slats for tiles are attached. It is impossible to place the tiles on the metal stove itself.

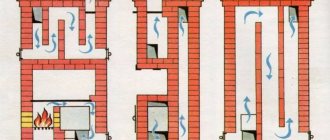

- Brick kilns come in single- and double-circuit types. Single-circuit ones are installed where significant temperature changes are possible (in the yard, in the bathhouse).

- The surface of single-circuit stoves heats up much more, so choosing tiles and heat-resistant adhesive must be done with special care.

- Combined materials are used: for areas of local overheating and for the rest of the area.

It is important that the finishing materials are of particularly high quality. In single-circuit furnaces, they perform a protective, strengthening, binding function, preventing possible deformation and destruction of the furnace.

Double-circuit stoves are considered to be of higher quality. Their outer surface heats up much less than the inner one. There are no local overheating areas. For such ovens, any heat-resistant tiles and suitable adhesives are suitable.

Surface preparation

Cladding a stove or fireplace with ceramic tiles begins with preparing the base surface. If this is not done correctly, the fireplace lining will not last long and will peel off. Therefore, the plane must be properly prepared.

- We inspect the surface. After this, remove the previous coating. To do this, use a metal brush. Nothing should interfere.

- Then we determine what layer of coating should be applied so that it is even. To do this, take the lath and apply it to the surface. Don't forget to use a plumb line, it will show the correct location of the slats.

- If the layer is less than 1 cm, then you can attach the tiles to the surface; if it is more, then you will have to properly level the plane.

- To ensure high-quality fastening of surfaces, we deepen the seams to a depth of 1 cm. To do this, use a chisel and a hammer.

- We deepened the seams, now we need to prime the surface. To do this, it is better to use a deep penetration liquid. Use a brush or spray bottle.

- It is very important that tiling the fireplace is carried out taking into account the thickness of the layer. If your plane does not coincide by 1 cm, it does not matter. If more, then you should definitely apply a construction mesh to the surface. It will enhance the adhesion of surfaces, which will significantly affect the durability of the structure. You can do this even just to strengthen the bonding of the coating.

- Using a hammer, we drive the nails into the masonry. If the solution is strong enough, then we simply take a hammer drill, drill holes and screw in self-tapping screws.

- We hang the mesh on the plane and put washers on the heads of the screws. They will help the mesh to hold on better and not fall off during work.

Choosing tiles for cladding stoves

When imagining their interior with a stove, homeowners already know in what style it should be decorated, what style, what color. To select tiles based on other qualities, it is important to know that the facing material of a solid fuel stove must withstand temperatures of up to 1600 degrees. The combustion temperature of wood is about 800 degrees.

Required characteristics of stove tiles:

- Strength, endurance, heat resistance, wear resistance;

- With a thickness of more than 8 mm, reducing possible deformation when heated;

- Eco-friendly, does not contain toxic substances released when heated;

- Moisture resistant: the water absorption coefficient of stove tiles is no more than 3%.

Material selection criteria

When purchasing, you should pay attention to the following characteristics:

- structure - it is important that it has a low level of porosity;

- environmental cleanliness - it is necessary that when the temperature in the room increases, no fumes with toxic compounds are released;

- general strength, that is, resistance to physical influences;

- thickness not less than 6-8 mm;

- heat resistance - a high-quality coating simply must withstand heating up to 1200-1300 degrees Celsius without deformation.

When a finish has the above properties, it is considered to be of sufficient quality for long-term use. If not, it will begin to crumble and become damaged, as a result of which it will require replacement relatively quickly. And this is far from always simple and generally realistic, since the shade of a new batch of material (especially natural) may differ.

The choice of tiles is also influenced by the following factors:

- Furnace raw material - wood requires heat resistance from the lining at the level of 900 ° C, coal - already 1200 ° C.

- The role of the stove and its installation location - if it performs a decorative function and is placed in a heated room, it can be decorated with anything. If the unit is a full-fledged (and even more so the only) source of heating, its surfaces simply must be heat-resistant, and when installed on a summer veranda, also frost-resistant.

- Weight - the smaller it is, the better (if reliability is not lost), because the less pressure on the supporting elements will be. It is especially important not to overload the floors when the installation point is located on the second rather than on the first floor of the house.

- Moisture resistance, which simply must be high if the premises are not constantly heated. It is important to pay attention to the design, choosing it in accordance with the interior design features. It is permissible to choose the option “to match” or play in contrast, the main thing is that the resulting pair is harmonious.

Technical designations for stove tiles

Stove facing tiles have their own designations in the product labeling:

- “T” indicates that the tile is heat resistant. The numbers 1 and 2, depicted against the background of the flame, indicate the number of its firings;

- “E” with a number is the water absorption rate, which should not be more than 3%. For example, the water absorption of granite suitable for cladding is small - 0.5%;

- “A” or “B” are applied to clinker tiles, indicating the manufacturing technology. Tiles "A" with clear boundaries are made using computer technology. Such products are made more accurately, they absolutely correspond to the specified dimensions. Most often, tiles with a length and width of 25 cm are used for finishing stoves and fireplaces;

The wear resistance of the tile is indicated by the PEI I - V indicator. For finishing the stove, PEI IV or V material is used - durable, finely porous, resistant to mechanical stress.

Alignment

The main requirement for a cladding object is its flat surface. What to use for leveling? Plaster or putty is suitable for this purpose. The main thing is that the composition must be fireproof. Select starting plaster or putty. The alignment technique is simple:

- If the structure is too uneven, then the casting method is used. Using a trowel or ladle, the composition is thrown onto the wall, after which it is leveled using the rule. The methods are quite fast.

- Leveling occurs gradually, moving from bottom to top.

- After leveling, you need to lightly heat the oven so that the composition dries.

- After 24 hours, you can proceed to the next stage - finishing the heating stove with ceramic tiles with your own hands.

Please note that it is not recommended to make the composition very liquid or dry. There should be no lumps, as they have air voids.

Types of stove tiles

Fireclay tiles are very durable, made by hand from refractory clay with the addition of stone ground to flour. Withstands low and high temperatures (about 1300 degrees). Resistant to various acids and other chemicals. It looks massive, much thicker than other species.

Porcelain tiles

Beautiful, high-strength material, is not subject to abrasion and does not change color until the end of its use. Well suited for high-quality finishing of stoves.

Marble tiles

Very beautiful and expensive for finishing stoves. To make this material more affordable, marble-effect tiles are made from granite chips (ceramic tiles, porcelain stoneware). Hardy, heat-resistant, waterproof material. Does not wear off, does not change color.

Klinke

One of the most durable, durable, heat and frost resistant materials. It is made with the addition of highly fired fireclay powder, crushed refractory clay, limestone, slag, and mineral dyes.

Retains its color throughout its entire service life and is not subject to abrasion.

Terracotta tiles

Made from ferrous dense pressed clay. It is not polished and has a rough, slightly porous surface. When fired, it naturally turns into warm orange-red, yellow-brown colors.

- Durable, impact and heat resistant material. Withstands temperatures above 1000 degrees and is not afraid of changes.

- It attaches well to the surface of the oven using various adhesive mixtures.

- Waterproof material with high heat dissipation.

When heated, the expansion of the tile corresponds to the expansion of the brick, which ensures the durability and quality of the stove structure.

Glazed tiles in the Majolica style.

Its production began 5000 years ago in Ancient Egypt and Babylon. The product was subjected to double firing: clay blanks were dried over lower heat.

- Glazed tiles were subjected to more intense heat treatment.

- The glaze and design in Majolica are applied manually, so the price of the product is high, but it is justified by its beauty, uniqueness and durability.

Majolica can be combined with Metlakh tiles - highly fired, durable and stable. Metlakh tiles are also used for finishing stoves.

Hand-painted tiles covered with glaze and enamel - tiles

The word is used only in Russian, comes from "iz" "to cut". Tiles come in different shapes - round, square, in the form of figures, etc. Feature - a box-like base for mounting on a stove or wall - rumpa. The rump can be figured or have regular geometric shapes.

Tile

Afraid of temperature changes. Over time, cracks appear in the glaze. For a better look and longer shelf life, you can use small matte elements.

Skillful use of high-quality, correctly selected materials for lining the stove will increase its service life, ensure safety and high heat transfer.

A beautiful stove made of durable materials is a source of warmth and life in the house, pleasing not only with functionality, but also with appearance.

Preparation of the solution

A fireplace lined with ceramic tiles will last a long time only if you use a high-quality solution. If the fireplace is decorative and does not have a firebox, then everything is simple: you can even attach it to a dry mixture.

If the fireplace is working, then you should approach the issue much more seriously. The surfaces will bond best if the masonry and tile fixing solutions have a common composition. It can be clay or cement.

Clay mortar

This mixture is most optimal for a working fireplace or stove. It can withstand temperature changes and high humidity. Therefore, it does not matter what type of fuel is planned to be used to fire the fireplace.

The clay solution must be plastic

- This solution contains sand and clay. And in order to determine the required percentage composition of the components, you first need to determine the fat content of the clay. To do this, we will make a dozen balls of clay and sand in different proportions. Let them dry completely and simply drop them from a height of one meter onto a hard surface. One that is not deformed or broken and will have the correct composition.

Attention: When making balls, they should be numbered and the data recorded so as not to be confused in the future.

- We pass the clay through a sieve and separate the debris and knead the lumps. The composition must be homogeneous.

- After determining the composition of the solution, we make a batch. To do this, it is best to use a container without stiffeners along the edges and bottom. Pour clay into a container and fill it with water. Let it sit for 24 hours afterwards. It should sour and gain the desired viscosity.

- After this, add sand in the required amount and mix. To do this, use a drill with an attachment. This way we can quickly achieve homogeneity of the mass.

Attention: If you use solid fuel for the furnace, then you should add fireclay powder to the solution in an amount of 10% of the total volume. It will improve the quality of the solution and increase its resistance to high temperatures.

Cement mortar

This mixture is much easier to prepare. However, it should not be used if solid fuel is used to fire the fireplace:

- Sand and cement are used for its preparation. For M300, a composition of 1/3 is used.

- First, pour sand into the container and then add cement in the required amount.

- Dry mix until mixture is uniform. Add water and mix again.

- To make the mass homogeneous, use a drill with an attachment.

Photo of tiles for cladding stoves and fireplaces

Product design

It is not the material, but the style of the room that determines the design. Finding the appropriate ceramic tiles is not difficult.

It is worth noting that for lining large stoves, red clay brick remains the best option. But fireplaces and Dutch ovens offer more possibilities.

- Classic styles use patterned ceramics - majolica, ornamental porcelain and, of course, tiles. This decoration attracts maximum attention and turns the fireplace into the most decorative, central piece of furniture.

- Geometric patterns, especially simple ones, are almost never found. Stove tiles are distinguished by a complex, multi-colored pattern, usually with plant motifs, and always symmetrical. It is possible to create an image, usually in a medieval style: the finish of the stove looks like a painting or fresco.

- In Art Nouveau, preference is also given to patterned tiles with floral designs. But often there is a combination of single-color faience with patterned ones.

- Modern styles use less colorful material. The most elegant options include porcelain stoneware and faience, imitating marble, granite, malachite, and imitation wood is no less common. In techno and futurism, structured single-color tiles are used.

- For rustic styles, clinker and terracotta remain the best option, although the color of the clinker can be very far from natural.

- For rustic and hunting styles, a fireplace faced with “wild stone” is intended.

Dimensions

To make it convenient to work with tiles for lining stoves, their dimensions should not be too large. The optimal size is 25x25 cm, and the thickness is no more than 8 mm. For porcelain stoneware and clinker, no more than 6 mm is sufficient.

Such parameters will ensure sufficient thermal conductivity and strength of the entire installation. In addition, these sizes are much easier to work with.

Larger tiles can be made to order, for example from porcelain stoneware, but they are quite heavy and may not support their own weight, and also require more trimming and sizing. Tiles are also available in smaller sizes, for example, 10x10 cm.

However, it is used much less often for the same reasons as the large one - it is inconvenient to work with.

What is and purpose

Refractory tiles are, according to the definitions given in GOST 28874-2004 and GOST R 52918-2008, a type of molded refractory materials (products), since they are characterized by certain geometric shapes and standard sizes available for all serial products.

The main purpose of tiles made from both natural finishing stones and artificial ceramic materials, regardless of its type, be it ceiling, facade or floor, is decorative, protective cladding of the surfaces of building structures, heating household, industrial equipment, including stoves , fireplace, without which a modern bathhouse, sauna, residential or country house is impossible.

Fireproof materials and their fire resistance

Ceramic heat-resistant tiles are multifunctional products that allow solving several problems facing customers - from builders constructing objects for various purposes to private property owners:

- Create a unique interior in a residential, country house, bathhouse, sauna, using fire-resistant tiles that are suitable/liked in appearance, texture, color, pattern for decorative cladding of the external surfaces of stoves, fireplaces, including fire-resistant cuts and offsets; as well as stationary grills and barbecues located in personal plots.

- To provide protection against overheating of heating equipment, to reduce the possibility of thermal damage to people using it at home and at work.

- Increase the heat capacity of stoves and fireplaces, increase the uniform heat transfer of heating units by creating even, smooth outer surfaces that effectively act as heat shields.

Properties and characteristics

Any types (types) of fire-resistant tile products, regardless of materials, methods of their manufacture, must have the properties required by construction, fire safety, and sanitary standards:

- Fire resistance – the ability to withstand short-term temperature exposure up to 1000 ℃.

- The maximum heating temperature on the outer surface during operation under normal conditions, which, depending on the category and purpose of the furnace equipment, varies in the range from 100 ℃ (moderate heating) to 120 ℃ (high temperature heating). The temperature limits for each type of refractory tile are determined during testing and are indicated in the accompanying technical documentation for each batch of products.

Determination of fire resistance limit

- The absence of toxic substances in the composition, including those formed during high-temperature heating, which is solved by the use of fire-resistant natural raw materials or natural materials without harmful impurities.

- Thermal conductivity, heat capacity, important properties that make it possible not to reduce the heat transfer of furnace equipment made of refractory bricks.

- Low porosity, high density, low water absorption - all these properties are inextricably linked.

- Fracture strength, point impact load.

- Resistance of paint layers and enamel coatings to external influences.

- Resistant to fading of original colors and designs.

Specifications:

How to veneer?

The facing of a stove or fireplace complex is carried out according to a certain principle, you can familiarize yourself with the sequence and features of which below:

- First of all, you will need to remove all dust, remnants of adhesive mortar, and old cladding from the surface of the tile. In order for the surface of the brick portal to be perfectly flat and smooth, it is necessary to plaster it after cleaning. For this, a special cement-based composition is used. If the tile you choose is quite heavy and large, in order to achieve better adhesion to the brickwork, you need to secure a special reinforcement mesh with cells. The basis of such a mesh is fiberglass;

- Next we move on to the finishing work. To do this, we buy and dilute a special adhesive composition in the required proportion with water. It is important that it is ideally suited for the given purposes and can withstand the high temperatures of the upcoming heating. You need to start work from the very bottom row, since it is this row that determines the evenness and clarity of the line and further finishing. We apply the adhesive mass to each tile, then fix it on the surface and hold it by adjusting it for the best fixation. Each row and element must be checked for evenness using a building level.

Gluing tiles is quite simple. This process is no different from laying tiles on the floor in the kitchen or on the walls in the bathroom. The main distinguishing feature is that the adhesive composition, as well as the material itself, must have good strength and heat resistance. High accumulation and low moisture absorption coefficient will also be useful.

Before choosing a suitable material, you need to familiarize yourself in detail with its characteristics, purpose and properties. From this you can figure out if it is suitable for your job and how long it will last. It’s certainly not worth saving on cladding, since it’s better to do it once every year than on a budget and at the same time encounter the first difficulties after just a few fires.

What if the material is chosen incorrectly?

It is important to remember that saving and replacing high-quality material with one of lower quality and not suitable for its characteristics can lead to sad and sometimes unpredictable consequences.

If you have chosen an unsuitable tile, remember that during the operation of heating equipment and strong heat, it can release harmful substances into the air that are dangerous to life and health.

Also, low-quality material will soon begin to crack at a minimum, and at most break off and fall off the surface. In these cases, using the heating unit will become unsafe, and re-construction will take a lot of time and your money.

When choosing a suitable coating, it is important to consider where exactly your stove or fireplace will be located. Indoor and outdoor fireplaces may require opposing materials. In the second case, not only accumulation and heat resistance are important, but also moisture resistance. This is especially important for structures that will be installed outdoors. They will be affected by precipitation and other natural anomalies all year round.

Note that even the most expensive coatings, with good resistance to moisture, will not be able to withstand precipitation for long. Therefore, if you are planning to cover a street structure, equip it, if not with a gazebo or veranda, then at least with a small canopy.

The additional use of special protective impregnations, paint, and varnish compounds is also allowed. All seams between the tiles are rubbed and filled with a special compound. This gives the finished cladding strength and protects it from external factors.

From this video you can learn about the characteristics and features of Terracotta ceramic fireproof tiles:

Choosing artificial stone for finishing

Artificial stone is made from gypsum, synthetic materials, most often with the addition of stone chips. Some of its types are externally indistinguishable from the real thing. High-quality design is achieved with the right choice of materials.

Main criteria:

- price - a good stone is never excessively cheap, but foreign products are always an order of magnitude more expensive than domestic ones;

- goods used for finishing residential premises must have a certificate of conformity and hygiene, and not contain harmful components;

- the longer a manufacturing company exists, the more likely it is that it produces high-quality material;

- the stone should not be too porous - this affects the strength and service life of finishing elements;

- The manufacturer's logo must be indicated on the packaging; the date of manufacture is also important - the optimal strength of the artificial stone is achieved within 28-30 days from the date of manufacture. If the period is shorter, the product is of poor quality, it is better to refuse to purchase it.

Features of working with artificial stone when decorating a fireplace

Decorating a hearth with fake stone has a number of features:

- work is performed at a temperature of at least +6 degrees;

- it is important to use the appropriate adhesive recommended by the manufacturer;

- for cutting use a hacksaw;

- the surface of the product is cleaned, a reinforcing mesh is installed on it;

- then plaster is applied to the mesh, the layer thickness is 0.9-1.5 cm, and dried;

- cladding is done from the corner from top to bottom so that the parts do not get dirty;

- a thick layer of mortar is applied to each part with a trowel, pressed to the place to be decorated, and excess glue is removed;

- it is advisable to use long and short parts in turn, adjusting them with a hacksaw or wire cutters;

- all seams are filled with mortar, dried, and excess is removed;

- After complete drying, the structure is coated with hydrophobic compounds to increase the service life of the coating.