During the cold period of the heating season, the issue of heating rooms becomes more relevant than ever.

Do-it-yourself bubafonya stove: diagram and drawing

And if in city apartments, as a rule, housing and communal services are responsible for this, then residents of the private sector have to deal with all the problems that arise on their own. For a conventional wood-burning stove, it is necessary to purchase a significant amount of logs, and this often takes a serious toll on consumers’ pockets.

In addition, some need to heat not only residential but also auxiliary premises, such as garages or greenhouses. Therefore, there is a natural desire to find a method for the most economical and efficient heating.

What is a long-burning stove? On what principle is its work based?

First, we need to understand how wood burning actually occurs. In order for wood to ignite, it must first be heated to a temperature of about one and a half hundred degrees from an external heat source. As a rule, this task is performed by setting paper or wood chips on fire with a match. The wood begins to slowly char and, when it reaches about 250 degrees, it decomposes into simple chemical components. The white smoke we see when lighting a fire is the gases and water vapor released by heated wood. And so, having crossed the level of three hundred degrees, the gaseous substances released from the tree ignite, further accelerating the thermochemical reaction.

The decomposition of organic fuel, such as wood, into simple elements is called pyrolysis. And everything would be fine, but ordinary wood combustion does not fully utilize the entire potential contained in the energy carrier. A lot of waste remains, which ultimately does not contribute to savings.

Pyrolysis furnaces, one of the options of which we will consider in this article, use fuel much more efficiently. The main secret is that the combustion of gases released when wood is heated occurs separately from the energy carrier itself. In this case, the primary fuel smolders slowly, which allows for much longer operating time on one stack of logs. In “bubafonya” type stoves and other pyrolysis heating devices, everything burns out almost 100%, leaving behind only a small amount of ash.

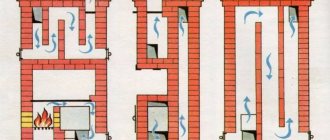

How combustion occurs

Heat into the house, not into the chimney!

Anyone who thinks that burning wood gives us all its heat is deeply mistaken. The efficiency of a standard wood stove does not exceed 50%. The remaining 50% “warms the clouds.” The reason for such large losses is simple: when wood burns, a process of thermal decomposition (pyrolysis) occurs with the formation of flammable gases. In a conventional firebox, they do not have enough time and temperature to ignite and release their energy potential. Therefore, they simply fly into the atmosphere along with carbon dioxide. In pyrolysis boilers, the energy of fuel gases is better used (efficiency 85-90%), since the fuel combustion process here occurs slowly and at high temperatures.

The design of a standard pyrolysis boiler is quite complex and difficult to reproduce without special equipment. In this regard, the Bubafonya long-burning stove is a real find for the home-made master. Its simple design successfully implements the pyrolysis process. The fuel combustion efficiency reaches 90% and is not inferior to factory boilers, the cost of which is tens of times higher.

Such an installation can be successfully used wherever there are no gas networks (garages, greenhouses, country houses), but there is an abundance of firewood and other wood processing waste. Bubafonya does not work well on pure coal, since this fuel sinteres, forming a slag layer that blocks the operation of the furnace. When mixed with firewood, coal behaves better, increasing heat transfer.

The history of the creation of the Bubafonya pyrolysis furnace

“Bubafonya” was first assembled by a folk craftsman named Afanasy Bubyakin, who lives in Kolyma. In fact, it was named in his honor. The master took the Stropuva pyrolysis boiler, made in Lithuania, as the basis for his product. Afanasy simplified the design as much as possible so that it could easily be repeated independently. That is why the homemade pyrolysis oven “Bubafonya” is famous for its fairly high popularity.

It should be noted right away that since a homemade heating device is made from readily available materials, it rarely has an attractive and aesthetic appearance. The main advantage of “bubafoni” is its simplicity, reliability and efficiency.

Below you can see an example of a homemade stove designed by Afanasy Bubyakin, made from an old gas cylinder.

Two “bubafonya” stoves made from cylinders

Build process

Now you need to make a metal “heel” with spacer ribs. They like to make the ribs curved, suggesting some vortex, according to the Coriolis force, and lengthening of its path, which seems unlikely with a slight bend. The plates are simply cut from the same cylinder. The height of the ribs should be about 10% of the width of the metal pancake. In the center, between the ribs, a washer with a hole is sometimes welded, explaining this by the formation of some kind of nozzle. But often, it creates unnecessary interference, according to some users.

The gap that is left between the edge of the heel and the side wall of the firebox should be at least 5% of the size of the pancake. If you plan to frequently use not very dry firewood, the gap is made larger. The heel is welded to the primary supply pipe and thus a piston is obtained. Its thickness has an inverse relationship with diameter and mainly plays the role of a load. A light pancake will not be able to press down the firewood, an active fire will occur and backdraft will occur. Too heavy, it will crush the flame with its weight. For pancakes 30 cm, the normal thickness will be 6-10 mm, and for a barrel ~ 3-4 mm. Intermediate values can be calculated through proportion. An air damper is mounted on top, at the inlet of the pipe, or two if the supply is coaxial. With their help, modes will be adjusted, from maximum to longest.

Next, at the upper edge of the cylinder itself, you need to cut a hole for the smoke exhaust and weld the corresponding section of pipe there. At the point of transition of the horizontal section of the chimney into the vertical chimney, it is advisable to install a container to collect condensate, with a drain valve. All that remains is to install the chimney, the length of which must be at least 5 m, and begin testing. If the described design is assumed to have different dimensions, then the dimensions increase proportionally. For the barrel-based version, you will need to increase the cross-section of all pipes and the size of the gap in the firebox. Increasing the intensity of heat removal from the reddening walls, you need to equip them with a convection heat exchanger, or better yet, blow them with a fan.

Internal structure of the long-burning stove "Bubafonya"

- The main element in the design of the “bubafoni” is its body. As a rule, it has a cylindrical shape: a cylinder, a large fire extinguisher, a barrel or a thick pipe with a welded bottom.

- Chimney for removing waste combustion products. It is made, in most cases, from a metal pipe 11-25 centimeters in diameter, welded to the top of the body.

- Feeder piston. It is a metal circle with ribs welded on the bottom, in the center of which an air duct pipe is fixed. The ribs allow you to create an additional air gap between the piston and the logs, which has a positive effect on the smoldering process and the activity of the release of pyrolysis gases.

- A control valve that allows you to control the supply of oxidizer inside the furnace.

- Cover with hole for air duct. Together with the piston, it forms a secondary combustion chamber, in which ignition of pyrolysis gases occurs.

Schematic diagram of a homemade pyrolysis furnace “Bubafonya”

Frequently asked questions from DIYers

Is it possible to use the Bubafonya stove in residential premises?

You shouldn't do this. With any reboot, reverse draft may occur, and this is dangerous, especially at night.

Can a stove run on raw fuel?

Yes maybe. But the efficiency will drop to a minimum. To increase it, you can make adjustments to the chimney design. It needs to be extended downwards by making an elbow to collect condensate, and install a drain valve on it.

Why might the stove smoke?

If Bubafonya is blowing smoke from the very “birth”, it means that one of the channels is narrowed, the firebox is too wide and the diameter of the gas outlet is small. The outlet may be too low, or the chimney pipe may be too low. When smoke appears later than the start of operation, this indicates clogging of the channels or a failure of the draft.

Making a Bubafonya stove with your own hands is not difficult. The main condition is to adhere to the recommendations of specialists, follow the assembly sequence and carry out ignition correctly.

Advantages and disadvantages of a pyrolysis oven

First of all, the positive qualities of this heating device should be noted:

- "Bubafonya" has a very simple design. Owning a welding machine and basic skills in working with metal, anyone can easily and simply make a stove with their own hands.

- The Bubafonya pyrolysis stove is not at all picky in terms of choosing a solid fuel energy carrier. It will burn properly on wood, coal, sawdust, wood chips and other waste from wood production. In addition, it can be loaded with pellets - inexpensive and environmentally friendly granular fuel.

- Working hours. After one load of wood, a pyrolysis oven can operate continuously and heat the air in the room for up to 24 hours. This indicator, however, can vary significantly, depending on the volume of the chamber, the oxidizer supply rate and other parameters.

But you have to pay for everything, and therefore the simplicity of the internal structure of the Bubafonya stove leads to some disadvantages:

- "Bubafonya" does not have high efficiency indicators. This is due to uneven heating of the cylinder body (barrel) and lower heat transfer. Pyrolysis furnaces of more complex and advanced designs, in turn, can boast excellent efficiency indicators, almost reaching a value of 90%.

- “Bubafonya” is quite inconvenient to clean from combustion residues: the ash and ash have to be removed through the top. However, this homemade heater can be improved by welding a door at the bottom, which makes it easy to rake out all excess from the bottom of the oven.

- Aesthetic unattractiveness. The design is quite rough in appearance and is unlikely to decorate the interior of the room in which it will be installed.

Features of operation

The thermal unit needs increased attention only in the first period after the start of operation. This is necessary to understand all the features of a particular oven. For this:

- After starting, you need to burn several loads of fuel of varying humidity to determine the time of complete combustion. But you can also obtain information about the amount required under different combustion modes.

- It is better to make the chimney dismountable to make it easier to clean.

- There should be a fire extinguisher and a box of sand in the room with the stove.

- It is necessary to regularly inspect the stove to identify burnouts and leaks of combustion products.

Making a stove yourself

The entire process of creating a homemade pyrolysis boiler “Bubafonya” can be divided into five main stages:

- Preparing the room, materials and tools for work

- Installation and assembly of the structure

- Chimney installation

- Laying the foundation for a pyrolysis furnace

Let's look at each of them in more detail.

Drawing of the Bubafonya pyrolysis furnace. Calculation of basic proportions.

The fundamental proportion in the process of constructing a homemade pyrolysis furnace from a gas cylinder is the mathematical ratio of the internal diameter of the housing to its height. In the drawing, the diameter is indicated by the letter D, and the height by H. The ratio of H to D should be in the range from three to five to one. The diameter itself under optimal conditions will be about 30-80 centimeters. You should not choose a housing for a stove smaller than 30 centimeters, since the oxidizer will pass through the combustion chamber too quickly without fully reacting with the fuel. This will significantly reduce the efficiency of the device. A diameter of more than 80 centimeters is undesirable for another reason: in such a boiler, the wood at the edge burns very slowly, and in the center - faster. When the fuel burns out, a hole will form into which the piston will fall, which will lead to the extinction of the “bubafoni”.

Calculation of the proportions of the elements of the Bubafonya pyrolysis furnace

Wall thickness Δ is the second most important calculated value. For optimal heat transfer, a 4-5 mm steel case is perfect. Smaller wall thickness will significantly reduce the service life of the heater and its operating time on one refill.

Dimensions of the piston pressing plate:

The gap c between the piston and the inner surface of the housing is optimally calculated to be 0.05*D. Accordingly, the diameter of the pancake itself will be calculated using the formula d =D-2*H

The height of the pressing ribs made of metal profiles is considered more difficult. Here the relationship between the parameter values is nonlinear. Empirically, for furnace body diameters from 60 to 80 centimeters, we take this number equal to 0.1*D. For smaller “bubafoni” we use the proportion equation, taking into account that with D0=30 cm h0=4 cm.

Example of calculation by proportion. The inner diameter of the cylinder is 40 cm. We calculate the required height of the channels as follows: h=D*h0/D0=4*40/30=5.3 cm

Pancake thickness σ. This parameter is inversely proportional to the internal diameter of the “bubafoni” D. It is necessary that the piston presses on the fuel layer with optimal force. If the pressure is low, the furnace's blowback coefficient will decrease and there will be a risk of the boiler catching fire with subsequent smoke escaping through the air duct. A piston that is too heavy, in turn, will not leave enough air space for the firewood to smolder and the “bubafonya” will go out.

This value can be found using the table below. There are no special requirements for compliance with this parameter; it is enough to adhere to it at least approximately.

| D | σ |

| 30 cm | from 6 to 10 mm |

| 40 cm | from 6 to 8 mm |

| 60 cm | from 4 to 6 mm |

| 80 cm | from 2.5 to 4 mm |

Calculation of the minimum required chimney area. The smallest permissible value of the pipe area S is calculated based on the maximum energy release of the fuel per hour. S(cm2)=1.75*E(kW/hour). In this case, E=m*q where m is the mass of the loaded fuel, which can be found by multiplying the maximum volume of the load V=Hf*(π*D2/4) by its density (we find out from the table below). Coefficient q, in turn, is the specific combustion energy of a unit volume of fuel per hour (we also take it from the reference table).

| Fuel | Density (kg/dm3) | Energy release (kW/hour) |

| Aspen logs | 0,143 | 2,82 |

| Coniferous shavings (sawdust) | 0,137 | 3,20 |

| Alder briquettes | 0,285 | 3,50 |

| Coal | 0,400 | 4,85 |

| Peat | 0,340 | 2,36 |

Calculation of air intake diameter

Knowing the dimensions of the chimney pipe, calculating the diameter of the piston air duct is not difficult. This value, denoted d, is equal to half the square root of the ratio 4S/π.

Preparing the room, materials and tools for work

Since assembling the “bubafoni” requires the use of a welding machine, not every room is suitable for our work. You definitely need high-quality ventilation, an uninterrupted supply of electricity and reliable wiring (welding work can cause overload in the circuit). In addition, installation may take more than one day, so the room must be protected from precipitation and be sufficiently spacious. Good soundproofing of the workplace is also important, since the noise from the grinder, welding and other tools is unlikely to please your neighbors.

Having chosen a suitable location for installation, we begin to prepare the materials.

- The basis for the pyrolysis furnace will be an old gas cylinder. Instead, you can also use a large (about 200 liters) steel or cast iron barrel with strong walls without traces of corrosion, a large used fire extinguisher, or even a metal pipe with a welded bottom made of a steel circle.

- Next we will need blanks for the supporting “legs”. In principle, you can try to do without them, but a “bubafonya” on legs will be much more stable, it is more difficult to accidentally turn it over with an awkward movement. Supports can be made from metal profiles, reinforcement and even sections of steel tubes.

- We can also create “handles” for more convenient carrying of a homemade stove from scraps of fittings. Also, they will not be superfluous on the lid of the “bubafoni”: this will greatly simplify the process of loading firewood and cleaning the boiler from ash.

Various options for homemade stove legs

Legs made of reinforcement

Legs made from pipe sections

Metal profile legs

Auxiliary materials for creating “bubafoni” will be:

- Sheet steel for making a piston;

- Two metal pipes for the chimney and air duct. The optimal diameter of the air supply pipe is about 85-100 mm, and its length should be approximately 150 mm greater than the height of the cylinder. The chimney will require a wider pipe, with a diameter of about 150 mm. As for its length, it must be equal to at least the cross-section of the cylinder;

- Metal profile (channel);

- Crushed stone, concrete and refractory bricks for making the foundation;

The list of necessary tools will be small. We will use:

- Hammer;

- Vise;

- Shovel;

- Mastercom;

- Portable electric welding machine with a set of electrodes;

- Grinder for cutting parts;

- Tape measure, pencil, plumb line and level;

Installation and assembly of the structure. Installation of the chimney.

- First of all, we make a neat cut in the upper part of the balloon. The resulting cap will serve us later as a lid for the furnace.

Blank for the lid of the pyrolysis furnace “Bubafonya”

- We attach homemade legs to the bottom of the cylinder using electric welding. The correctness of their installation can be checked using a level or plumb line.

- The production of the bubafoni piston occurs in three stages:

- First we cut a circle out of steel. Its transverse dimensions should be approximately 3.5-4.5 cm smaller than the internal diameter of the gas cylinder to ensure free exit of the resulting pyrolysis gases into the secondary chamber. We make another hole in the central part of the circle so that the end of the air duct can be tightly inserted.

Blanks for feed piston

- We weld the circle and the metal pipe together.

Air duct welded to the base circle

- We fix channel cuttings to the base of the piston blank by welding.

Metal sections fixed to the back of the piston

The finished product will look something like this:

Pyrolysis furnace piston assembly

- We construct the furnace cover. In the center of the cut off upper part of the old gas cylinder we make markings for the hole. This must be done in such a way that the air duct pipe with the attached supply piston can move freely in it. Using the markings, we make the necessary cutout. On the sides of the improvised lid we weld handles from pieces of reinforcement bent with a vice and a hammer.

Bubafoni lid. Instead of fittings for handles, metal rings were used.

We install a chimney in the upper part of the improvised pyrolysis oven. Using a grinder, we cut out a neat hole according to the dimensions of the pipe blank and fasten it together by welding.

Video: How to cut a straight hole for a chimney using a grinder.

Chimney welded at the top of the cylinder

To ensure better draft, the chimney should consist of two “elbows” connected at right angles. To do this, at the ends of the horizontal pipe coming out of the cylinder and another segment of the same diameter, we use a grinder to make even cuts at an angle of 45 degrees and weld the pipes to each other.

External view of the chimney

In addition, it is highly desirable to provide protection for the chimney in the form of a special reflective cap. This will prevent moisture and precipitation from penetrating inside the furnace with subsequent extinguishing.

External view of the chimney reflector

At this point, the main part of the installation work can be considered complete. The oven is now completely ready for use. We can only, if desired, equip a special foundation for it and begin direct operation.

Laying the foundation for a pyrolysis furnace

Work on arranging the foundation for “bubafoni” will take place in three stages:

- First we need to dig a square hole measuring approximately one and a half by one and a half meters. The optimal depth for the foundation will be approximately 20-30 centimeters.

Pit for the foundation for the furnace

- We pour crushed stone inside and fill it with concrete mortar on top. Level the surface using a trowel. After drying, we check the quality of the resulting plane with a level and further correct it, if necessary.

Stove foundation poured with concrete

- When the concrete is completely dry, we lay several rows of refractory bricks on top of the base. As a rule, two or three brick layers will be enough.

Fire-resistant brick laid on the base of the furnace foundation

DIY chimney

It is better to make the chimney at least 100 mm. Both sizes primarily depend on the expected power and type of fuel. We start by cutting off the lid and making a hole in it. It is important to remember that before opening the gas container with an angle grinder or welding, it must be filled with water. Even an empty cylinder, which may still contain unevaporated gas condensate, can present an unpleasant surprise. It's worth seeing examples online. The container is usually cut along the upper edge, at a distance of 2 cm up or down, although you can choose another place. There is simply a reinforcing strip of metal behind the seam. In the resulting bowl you need to make a hole in place of the tap, about 9 - 11 cm in size. Along the outer edge of the lid, you will need to build an additional metal belt for reliable fixation and some tightness.

Handles for removing it would also be useful. A gap of 2 - 3 mm formed between the pipe and the edge of the hole will act as a secondary air supply. Admittedly, most often this is not enough and you have to install an additional oxygen supply to the firewood. This is achieved by a coaxial supply - along the space between two pipes. This way the air will not mix with the smoke and will reach the ignition point in an already heated state.

Ignition of the Bubafonya stove

We pull out the feed piston with the welded air duct from the inside, having first removed the cap from the cylinder.

We put wooden logs inside. They must be placed horizontally close to each other. Vertical placement of firewood can have quite unpleasant consequences if an unburnt log standing on its edge interferes with the movement of the piston. This will lead to a full-fledged fire breaking out in the primary chamber instead of smoldering. As a result, the correct operating mode of the stove will be disrupted, the wood will burn faster and, in addition to everything, it may begin to smoke through the air duct. Logs cannot be placed above the location of the chimney.

Adding firewood to a pyrolysis oven

Sprinkle chips with sawdust or small branches on top of the wood pile. Soak a piece of old fabric in kindling liquid (kerosene is also great) and place it on a layer of wood chips. An alternative to a rag is paper.

Treating the top layer of the filling with kerosene

We press the filling with the piston and put the oven lid back on.

Installing the piston with cover

We set fire to the wood by throwing a piece of lit rags or paper inside through the air duct. A match for lighting a “bubafoni” is not suitable, since it manages to go out before it falls down.

Ignition of the furnace

After 15-25 minutes, after the filling has ignited well, it is necessary to close the valve on the air duct. This will limit the air supply to the primary combustion chamber and will cause the logs to begin to smolder, releasing pyrolysis gases. Thus, the “bubafonya” will switch to its main operating mode.

Video instruction. Ignition of the Bubafonya stove

Limited air supply and exhaust gases

The next design disadvantage is the limited ability to supply air to the coals. This is due to the diameter of the piston pipe, or as it is also called, the telescope. In the case of a potbelly stove, it is enough to open the ash door wide. Here, we are strictly limited, and the only way out can be forced supercharging, but that’s a different story.

The specificity of long-term smoldering and significant soot content in

exhaust in cold weather can cause increased deposition of unburned carbon in the chimney. This, in turn, will lead to deterioration in draft, decreased efficiency and the need for frequent cleaning of the chimney.

Backdraft

The possibility of reverse thrust occurring in “Bubafoni” should be given special attention. A number of circumstances can lead to this phenomenon:

- Vertical stacking of raw lumps;

- Dense packing of fuel and incorrect size of special ribs;

- Piston jamming as a result of deformation of the furnace walls;

- Small gap between the wall and the “telescope” disk;

- Blockage of the chimney due to its planting.

- The most important element contributing in these cases is the presence of a hot, vertical channel leading into the room.

Recommendations for increasing the efficiency of a homemade stove

The main problem affecting the efficiency indicators of the Bubafoni is the uneven heating of its body and, as a result, the deterioration of the heat exchange process with the environment. It can be partially solved with the help of a fairly simple modification of the design.

To carry out the modification we will need a corrugated sheet of metal profile. It is necessary to make a kind of “jacket” for the stove from it, tightly fixing it on the surface of the cylinder by welding or in another accessible way. Such an improvement will contribute to the formation of upward convection air currents: cold air is drawn in from the bottom of the ribs, and hot air is released from above. In addition, you can additionally cover the entire structure with brick. This step will allow the walls around the stove to accumulate the heat it emits, heating the room more evenly and for longer.

Improved version of "bubafoni". Instead of a corrugated profile, sections of profile pipes were used.

With water jacket

Option for a stove with a water jacket on the chimney.

The capabilities of Bubafoni will increase significantly if you add a water circuit to the stove. To do this, adapt 1 more cylinder to heat the coolant in it. Its diameter is 2.5-3 cm larger; sometimes a square body is adapted for this purpose.

If there is a ready-made heating circuit in the room, the stove is connected to it and the coolant from the water jacket is transported to the heating system using a circulation pump. Such a stove is advantageous in that it can provide heat to several rooms.

The water circuit is installed not only on the stove body, but also on the chimney. The principle of such a system is “pipe in pipe”. The ends of the “jacket” are sealed, and pipes are cut in for the coolant inlet and outlet. The outlet is located at the top, and the return is located at the bottom.

A water pipe can also act as a heat exchanger. A coil is made from it, enclosed in a steel casing so that the heat is distributed more evenly, and sand is poured in. Sometimes brickwork is made around the stove, and the same coil is placed inside.

Fuel quality

It is also important to understand that burning raw wood, even if it turns out to be technologically possible, has a greatly reduced caloric value. Based on the concept of the specific mass calorific value of firewood, with a humidity level of 25–30% accessible to the average person, we get the well-known 3.6–3.3 kW. At a humidity of 50 - 70%, this figure will drop to 1.9 - 0.8 kW, which is at least half as much. Therefore, it is probably better to deal with the issue of dry firewood than to achieve the impossible with wet firewood. Lastly, the question of using such a stove. Since heating does not occur instantly and it is also not easy to put it out quickly, it is inconvenient to use it in the garage. It will have its place in a production facility or greenhouse, where, in addition, there will be fuel for it in the form of plant waste, sawdust and other debris.

Piston pressing block

The distance from the piston to the inner surface of the piston is calculated using the formula 0.5xD. To calculate the diameter of the pancake, accordingly, the formula d = D – 2xH is used. Calculating the height of the pressing ribs from a metal profile is more difficult, because The relationship between the parameter values is nonlinear. Theoretically, for a furnace body with a diameter of 60-80 cm, this parameter is taken as a number of 0.1xD. The Bubafonya stove from a smaller gas cylinder is calculated using a proportional equation, taking into account that with D0 = 30 cm h0 = 4 cm.