Today you can count more than a dozen different types and designs of stone ovens for cooking, but the Pompeian oven occupies a special place among them.

Pompeii oven

Compact, efficient and beautiful - it will not only allow you to cook delicious food, but will also look stylish on any country plot. How to lay out a Pompeian oven with your own hands, and what technical nuances should be taken into account, we will discuss in this article.

A standard Pompeii stove is characterized by certain proportions that must be observed regardless of the shape and size of the structure. Thus, the height of the entrance is approximately equal to 50% of the total height of the dome. This allows you to optimize the work process as much as possible, create normal traction and reduce heat losses.

Device and elements

Externally, the “Italian stove” resembles a “Russian stove”, but unlike the second one, it is not capable of heating the room.

The design ensures a stable and high temperature inside the stove. Usually a classic Pompeian oven is built from brick or clay, but sometimes other materials are used, most often concrete cinder block. The design of this system consists of four components:

- Foundation;

- Tabletop;

- Pedestal;

- Bake.

The Pompeian furnace was built in order of four main components:

- Floor;

- Entrance arch;

- Dome;

- Chimney;

Construction of the Pompeian furnace

Since the history of this kitchen system is very long, it developed along two different paths, which subsequently led to the appearance of two types of Pompeii stoves: Tuscan and Neapolitan.

Photo of a Pompeian oven of two types:

Pompeian ovens of different types

Tuscan designs have a high dome and a round vault, while Neapolitan designs are made exclusively with a low vault - due to the fact that they are intended exclusively for preparing large-sized pizzas and high-quality frying.

How much will it cost?

A DIY Pompeian stove is a fairly expensive design, even if you decide to carry out all the work yourself. This is due to the high cost of the materials from which it is made. Since the design of a tandoor consists of several components, it is easiest to calculate the cost of each of them.

The price consists of purchased materials, and does not include construction waste and materials that can be found near the house (clay and sand):

- A bag of cement – 250 rubles;

- Cinder blocks will cost about 300 rubles;

- Fireclay bricks in the amount of 350 pieces will cost 17,000 rubles;

- Thermal insulation will cost 500 rubles;

- A cutting disc for stone costs about 250 rubles;

- Polyethylene for waterproofing will cost about 200 rubles.

In total, the construction of the entire structure, provided that fireclay bricks are used to lay the dome, will cost approximately 18,500 rubles .

Device

The design of the Neapolitan stove is easy. Making a Pompeii stove yourself is not difficult. The components of this stove are:

- The base of the Pompeian furnace (foundation).

- A table that is necessary for comfortable cooking of any dish.

- A hemispherical vault or otherwise called a dome. Another component of the furnace is the under. Under (the bottom of the oven or its floor) is the place where the fire is lit and the pizza or other dish is cooked.

- The fourth part is the chimney pipe.

- Outer casing.

- Thermally insulated layer.

These are the main components of a Pompeian oven that do not require professional intervention for their construction.

Construction Materials

Fireproof Bricks

The so-called fire brick is used in pizza ovens due to its ability to withstand high temperatures. These bricks are made from fire clay with high alumina content.

Refractory solution

In some places where it is difficult or impossible to use refractory bricks, refractory mortar is hammered in. However, it should be taken into account that the maximum use of refractory mortar should not be more than 6 mm. A higher value leads to cracking of the furnace body. Avoid using fireproofing mortar to fill oven holes or empty spaces. It is suitable for external use only. It is used on the furnace dome in places where there is no direct contact with fire. If you do not want to buy pre-mixed fireproof mortars, you can use the following recipe:

3 parts sand 1 part Portland cement 1 part lime 1 part fire clay

Cement

Additional Information: Concrete for Wood Stove

Cement is a powdery substance made from fired clay and lime that is used as a binder in construction projects. Cement is mixed with other components in various proportions to form various mixtures such as mortars and concretes.

Advantages and disadvantages

Among the main advantages of using a Pompeian stove:

- High heating speed. You can add food within half an hour after kindling. Within an hour, the temperature inside the oven reaches 370 °C.

- High heat dissipation. Heat accumulates inside the housing and the ability to cook remains for several hours after the fuel is burned.

- Compact dimensions and the ability to be erected on any site.

Among the main disadvantages of Pompeian furnaces, the complexity and high cost of construction, as well as the need to build a reliable foundation, stand out first.

The main cooking styles are:

Cooking in the oven

Roasting:

Pompeian brick oven heat of 350 degrees or higher is used to bake pizza, pizza-like flatbreads and some types of appetizers, all of which take just a couple of minutes to cook. The goal of this type of cooking is to completely fill the floor and dome with heat, create a large "bed" of coals, and maintain a large fire as the flames reach the top of the dome. There are two ways to tell when your oven is ready to bake your pizza. Firstly, when the oven dome itself has cleared up and there is no visible black soot. At this point you should move the heat to the side, continuing to keep the heat high as the flame reaches the middle of the oven. Alternatively, if you are using an infrared thermometer, the oven floor should be between 350-400 degrees. Pizzas are baked right on the floor next to the fire. Leave the oven fully open and add wood every 15-20 minutes to maintain a high flame.

Baking:

Bake (250 degrees and below) is used for baking breads, desserts, small cuts of roasted meats, beans and legumes, and pasta dishes at regular oven temperatures. After the Pompeii oven is fully fired, carefully remove the hot coals and clean the oven. Your Russian oven can now cook accurately and consistently with the heat stored in the oven dome and floor, maintaining a constant temperature for a long time. Using this type of cooking, you can bake either one full batch of bread, or several baths of different types of bread, but in smaller quantities. Close the oven door tightly to trap heat inside.

Roasting:

A Russian brick oven or Pompeian oven makes an excellent grill. By raking a layer of hot coals to the front of the oven and placing a rack in the oven, you can enjoy grilling gorgeous meats.

Also, try experimenting with different pots and pans. A grill pan preheated in the oven gives your cuts of meat a beautiful seared pattern, while a terra cotta plate and steel plate make fried potatoes taste completely different than deep frying.

If a Russian brick stove or a Pompeian brick stove was laid out for you by a good, competent stove maker, then such a stove will take a central place not only in everyday life, but also on those days when you have friends over. A skillful hostess will be able to offer something new and unforgettably delicious for every such meeting! Experiment! And we will build a good Russian stove!

Ordinary masonry of the stove

After preparing the base and familiarizing yourself with the drawings, you can move on

It is important to strictly follow the order indicating the correct position of the bricks and installation of stove fittings

With stove and bed

If you plan to bake a stove with your own hands, then the simple procedure looks like this:

- Make a continuous and even row.

- Lay out the internal compartments, design the cleaning channels and ash pan chamber.

- Place the door of the blower and cleaning chamber. Secure them with steel wire, placing the ends in the seams.

- Close the vault, block the entrances to the channels, form holes and decorate the ceiling of the bottom channel from the inside.

- Fix the grate in a large firebox. Carry out the internal masonry without mortar; it is better to use fireclay, cutting it in half in thickness. Place the door on the small firebox.

- Install the hot water tank.

- Place the grate on the small firebox and the door on the large firebox. Stretch the right wall with a strip of steel. There is no need for mortar behind a large firebox.

- Install and secure the small firebox door. Continue to output internal channels.

- This row is combined with the previous one.

- Lay out the bottom of the furnace, combine the combustion vaults. Bring the channel holes into the chamber and close the water heating tank.

- At the edge of the masonry, secure a 5x5 cm metal corner between the fireboxes. Cover the space of the large firebox behind the stove with a grate. There is no need to secure it.

- Form the chimney and the walls of the furnace. Install a damper on the left.

- Continue the algorithm.

- Form an entrance to the chimney. It will be opened by a valve (vertical). Remove the walls of the furnace and make a hole for the damper.

- Begin to narrow the masonry, blocking the roof of the chamber. Proceed with the removal of the chimney.

- Reinforce the walls with strips of metal.

- Secure the back wall with a strip of metal. Narrow the chamber vault further and prepare to lay the vault. Above the niche with the slab, lay a corner and a strip of metal - the basis for the masonry that creates the ceiling.

- Lay out the outer walls and roof of the furnace in the shape of a dome. You can install a template or weld an arch from strips of metal.

- Strengthen the wall above the entrance to the chamber with a strip of metal and surround the roof of the furnace with walls.

- Pour sand and compact it.

- Proceed to the base of the bed. Lay a sand embankment and narrow the slit in front.

- Narrow the overpipe and install a panel with a circular hole to change the direction of the smoke.

- Install the cleaning window door.

- Install the draft control valve.

- Continue to cover the space.

- Work according to the algorithm.

- Combine the overpipe and chimney on rows 27-29. Lay out the chimney before starting to form the groove. In the place where the chimney passes the attic floor, use cement mortar.

When the pipe is brought to the roof, make an otter - an extension above the roof in the form of an overlap. Close the gaps between the roof and the chimney with waterproofing.

The Russian stove with a fireplace and a stove bench is multifunctional. It gives warmth, they cook food on it, and they rest on top. Any things will dry on it instantly.

With a stove for a cauldron

Both the components and the masonry resemble a Russian stove with a fireplace and a stove bench. Refusal of the latter is beneficial due to the reduction in dimensions and a stove on which a large cauldron will fit. The order is:

- Make a level and continuous base.

- Install an ash chamber.

- Secure the cleanout doors.

- Place the grate.

- Form a flood chamber.

- Start lining the firebox.

- Start building the walls.

- Align the corners.

- Align under.

- Form a hailo.

- Place the stove.

- Build a combustion chamber.

- Close the smoke duct.

- Form the roof of a large firebox.

- Build walls.

- Continue the previous row.

- Connect the walls with the arches.

- Continue the row.

- Insulate the furnace.

- Take care of the general overlap.

- Continue the algorithm.

- Set the valves.

- Install cleanout doors.

- Continue the previous row.

- Follow the algorithm.

- Close the channel.

- Form a chimney.

- Install the valves.

All that remains is to build the pipe to the ceiling. Cover it with 2x1.5 bricks. To insulate the ceiling, non-combustible material is used - metal, asbestos.

You can build a stove with a firebox and a stove bench. In this case, the length of the combustion chamber is increased or an extension is built, inside of which there will be smoke channels.

Are you planning to build a Russian stove for yourself?

Not really

Technical characteristics of furnaces

The main similarity between Pompeii and Russian stoves is the ratio of the sizes of the stove arch and dome. For both types of ovens, the widest part of the arch is equal to the height of the arch of the inner chamber. The height of the vault usually ranges from 60 to 80 percent of the entire stove dome. The optimal width of the internal base of the firebox is about 1 meter. A wider chamber will heat up worse and retain heat poorly, and a small firebox is not convenient to use and will not allow you to cook dinner for a large number of people.

The Pompeian stove differs primarily in the location of its chimney. It is located at the top, immediately behind the entrance arch. Thanks to this, hot air moves through the chamber from bottom to top, quickly and evenly baking the dish. The height of the chimney is selected depending on where the stove is located. If the stove is located under a canopy, then the pipe must be extended beyond the roof, otherwise the entire space under the canopy will be filled with smoke.

The Pompeian stove can be lit with straw or wood, for example, alder, cherry, apple tree

Light the stove with straw and wood. Alder, cherry, apple, oak, and ash produce the least amount of smoke. The stove should not be heated with fuel pellets, coniferous wood or damp wood. When such fuel burns, a lot of soot is formed, which will spoil both the taste of the finished dish and the appearance of the stove itself.

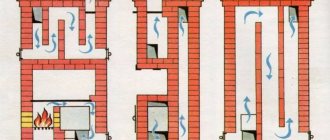

Operating principle

Pompeian stoves of all types work on the following principle: cold air enters from below and is drawn towards the fire. When heated, it rises from the horizontal hearth, goes around the arch and, reflecting from it, falls into the central zone, exactly where the cooking takes place.

How does a Pompeii oven work?

After this, it is pulled out into the chimney. The entire surface of the inner chamber is used for heating. Convection flow, uniform combustion and distribution of thermal energy occur due to the structural design and position of the chimney.

It is recommended to fire a Pompeii stove with non-smoking wood, such as cherry, alder or olive. Coniferous species negatively affect the condition of the dome and the quality of food.

Points to pay attention to before starting construction

Before you begin to study the step-by-step instructions, it is important that you have a clear idea of the end result. The article describes the technology for manufacturing a small portable pizza oven that will move on a small cart

This option is ideal for those who do not have construction experience, but really want to bake pizza at home in a wood-burning oven.

How much free space do you have for your oven? Would you like to be able to move it or should it be stationary? Be sure to answer these questions before starting assembly. Ovens designed for restaurants can have a total hearth area of 1,900 to 2,700 inches. We recommend that you first measure the area where construction is planned.

You need to determine the size of your stove in advance. Depending on where you live, make sure you don't need a building permit.

Cost: Of course, the larger the oven, the higher the cost. If this is your first time undertaking this type of construction, then using our instructions you can build a stove from reclaimed wood and recycled materials for less than $100. But if your oven is for a restaurant or commercial use, the price could rise to $10,000.

Tools and Materials: Our build plan requires a minimum set of tools and materials. If you plan to build a more substantial brick kiln, you will already need firebricks, fireclay, fireproof fabric and other materials.

It’s worth preparing all the tools and materials in advance - if you plan to make the oven small, you won’t have to spend a lot

A small oven will require these tools.

- Hammer.

- Nails or screws (for cart).

- Wheels/rollers (for trolley).

- Gloves.

- Bag or bucket.

- Plywood.

- A bag of cement.

- A bag of vermiculite.

- Water.

Required skills: Before starting work, you need to objectively assess your skills. With the proper patience, anyone can master the skills necessary to make such a stove. But if you do not have independent experience in making such products, then it is better to start with a simple stove design, which we describe in our instructions. If your plans are for a more ambitious project, then you should consider bringing in an experienced friend or relative who can help if problems arise.

This stove allows you to cook different dishes. So, if you decide to build your own stove in your yard, great! Follow our instructions carefully and get started!

Construction Materials

Fireproof Bricks

The so-called fire brick is used in pizza ovens due to its ability to withstand high temperatures. These bricks are made from fire clay with high alumina content.

Refractory solution

In some places where it is difficult or impossible to use refractory bricks, refractory mortar is hammered in. However, it should be taken into account that the maximum use of refractory mortar should not be more than 6 mm. A higher value leads to cracking of the furnace body. Avoid using fireproofing mortar to fill oven holes or empty spaces. It is suitable for external use only. It is used on the furnace dome in places where there is no direct contact with fire. If you do not want to buy pre-mixed fireproof mortars, you can use the following recipe:

3 parts sand 1 part Portland cement 1 part lime 1 part fire clay

Cement

Additional Information: Concrete for Wood Stove

Cement is a powdery substance made from fired clay and lime that is used as a binder in construction projects. Cement is mixed with other components in various proportions to form various mixtures such as mortars and concretes.

Basic rules for arranging a Pompeian oven

Following step-by-step instructions and a diagram for laying a Pompeian stove, even a beginner can handle the work. But in order to avoid mistakes, it is necessary to adhere to the following basic rules when performing work:

- The furnace inlet must have a spherical shape. In this case, the width of this entrance should be equal to the height of the dome. Whatever shape and size you plan to make the stove, be sure to adhere to these proportions.

- Thanks to the spherical design of the inlet, maximum heat is maintained in the furnace and smoke is collected.

- For the Pompeian stove, use only straw or firewood (pellets are allowed only during the first test firing). Quite high demands are placed on firewood. It is better not to use coniferous wood, as the resins released during the combustion process can negatively affect the further operation of the stove, and even the taste of food.

- You can only build the base and chimney from ordinary bricks. And the dome itself must be made exclusively from fireclay (fireproof) bricks. If the Pompeii oven is being built outdoors, then it would not be a bad idea to build a small canopy. Although it is lined with hydrophobic material, constant precipitation can negatively affect its technical characteristics and strength.

- The chimney is located on the front of the stove, especially in cold climates.

Conclusion

In order to delight your household and your guests with delicious pizza, as well as pleasant gatherings near a warm fire, every enterprising owner can build a Pompeii pizza oven in his own garden with his own hands. This structure can be made of brick, and if you want to save money, it can be built from clay material. The main thing is that the entire system is manufactured in accordance with technology and basic rules.

What kind of Pompeian stove will you make?

From brick From clay

What is a Pompeian oven?

A Pompeian or Roman oven (Italian, dome, Neapolitan, etc.) is a culinary stone, wood-burning, dome-type oven, not intended for heating, used exclusively for cooking. Often used by pizzerias to bake pizza. Powered by wood. It has a dome, which provides the exceptional characteristics of this Italian stove. Allows you to prepare pizza, bread and other famous dishes. Italy is considered the birthplace of the Pompeian stove. In the Roman city of Pompeii, historians found a perfectly preserved oven, hence its name. This type of stove has been known to the world for about 3000 years.

Features of the Italian stove:

- The dome ensures rational distribution of thermal energy and its minimal losses. Because of this element, heat is not wasted and is retained inside the oven for a long time.

- The small dimensions allow the stove structure to be placed in a place convenient for the owner. The structure is mobile.

- Unlike the Russian stove, the Pompeian stove has an oval arch and is significantly lighter.

- Such stove structures have a lot of weight, which primarily determines the heat capacity and economic efficiency of the stove.

- It runs on wood and is not intended for space heating.

- Heats up quickly - in about 30-60 minutes the oven is fully ready for use.

Types of Pompeii ovens:

- Tuscan ovens are miniature in size. The dome is a regular hemisphere; the height of the dome is equal to the radius of the stove. The Tuscan type of oven is designed for baking pizza and other foods.

- Neapolitan stoves are also a special case of the Pompeian stove; the main difference is the lack of a clear geometric shape and parameters. Has a small dome. Since these types of ovens are often larger than the Tuscan design, they can cook pizza much faster.

Essential elements:

- Under is the place where firewood is placed.

- A vault is a hemisphere made of bricks.

- The firebox is the place where food is prepared.

- The chimney is built from baked solid bricks. It can be laid directly from bricks or from metal and ceramic blanks and pipes.

Popular models

VITCAS CASA

Mini wood-fired pizza for the garden. Easy to assemble and install at the dacha.

- The cost is approximately 500 - 600 euros.

- Dimensions: external: 550 x 670(depth) x 520(width), internal: 370 mm x 600 mm.

- Weight: 150 kg.

- Maximum 2 pizzas at a time

- Country of origin: Italy

VITCAS Pompeii

For a small pizzeria.

- Cost approximately 1200 euros.

- Dimensions: external: 1000 x 1120 (depth) x 440 mm (width) mm, internal: 800 x 400 mm.

- Maximum: 4 pizzas at a time.

- Country of origin: Italy.

SPECIAL PIZZERIA BOCCA 120

For a large pizzeria.

- Cooking surface - diameter 110 cm.

- Warm-up time: 60 minutes.

- Maximum: 6 pizzas at a time.

- Cost from 430,000 rubles.

- Country of origin: Italy.

Terrecotte GOTI 80

For a small pizzeria.

- Cost from 270,000 rubles.

- Hob - diameter 78 cm.

- Warm-up time: 30 minutes.

- Maximum: 4 pizzas at a time.

- Country of origin: Italy.

Pavesi JOY 90

For the average pizzeria.

- Cost from 380,000 rubles.

- Dimensions: 120x135x176 cm.

- Cooking surface - diameter 90 cm.

- Warm-up time: 30 minutes.

- Maximum: 4 pizzas at a time.

- Weight - 300 kg.

- Country of origin: Italy.

VALORIANI VESUVIO GR 100

For the average pizzeria.

- Dimensions: 116x130x58 cm.

- Cooking surface - 100x100 cm.

- Warm-up time: 30 minutes.

- Maximum: 5 pizzas at a time.

- Weight - 550 kg.

- Country of origin: Italy.

- Cost from 470,000 rubles.

Design Features

Thanks to the special internal structure of the oven, it heats up quickly and retains heat for a long time. Historians claim that the Pompeian oven appeared on the Iberian Peninsula and was initially used specifically for preparing an open cheese pie, where the structure was not needed to heat the room.

Decoration of a Pompeii oven

Later it spread throughout the world. It is also called Neapolitan, Italian oven, tandoor.

The Pompeian oven will not only be an ideal design for preparing pizza, pies and bread, but will also decorate any countryside area. In combination with a gazebo or barbecue, it becomes a real landscape decoration, becoming a favorite vacation spot for the whole family.

Stove in the yard

Basically, such a stove is installed in suburban areas on the street, in a barbecue area, in an outdoor garden, but if desired and some technical modifications are made, a Pompeii stove can be built in the house. To do this, of course, you will have to provide not only a reliable, solid foundation, but also a chimney.

In this article we will look at the classic option for building an Italian oven in the open air. Before proceeding with the step-by-step instructions, I would like to warn you that laying a Pompeian stove is a very difficult and expensive undertaking.

But if you do everything correctly, then such an oven will delight you for decades, giving you an authentic look to your dacha and helping you prepare delicious homemade baked goods. Thanks to our clear and simple instructions, even a beginner can master the laying of a Pompeian stove with his own hands.

The structure of the Pompeian stove is somewhat similar to the design of the ancient Slavic stove.

Construction of a Pompeii furnace

But, unlike a traditional Russian stove, it heats up much faster. You can cook pies in it literally 30 minutes after heating, while a Russian oven will take at least 3-4 hours before reaching the optimal temperature for cooking.

This heating rate in the Pompeii furnace is achieved due to the lower thermal mass. The layer of brick that is heated is only 12 cm. Within 45 minutes after kindling, the temperature in this oven reaches 260 degrees, and after an hour - 370 degrees.

How is the temperature distributed in a Pompeian oven?

| In 30 minutes | In 45 minutes | In 60 minutes | In 90 minutes | |

| Outer part of the vault | 150 | 260 | 370 | 370 |

| Inner part of the vault | 315 | 370 | 370 | 370 |

The peculiarity and main advantage of the Pompeian oven is that you can cook almost any dish in it in a short time. Thanks to the high temperature that is reached inside the vault, pizza and bread are perfectly baked in it. Smoke adds a special piquancy to baked goods.

Convection

Oven convection is defined as heated air circulating through the oven. As shown in the picture below, cold air is drawn into the oven through the access hole (when the outside door is closed) or through the opening in the brick oven (when the door is open). When cold air is drawn into a brick oven, it is quickly heated by the fire and stored in the oven. This heated air is evenly distributed throughout your dish. As the air continues to heat up, it moves to the back of the brick kiln and rises. The heated air now passes through the food again as it exits the chimney. This "draw" causes a constant flow of heat to pass through the dish in the oven, causing convection. As you develop your skills with a brick Pompeian stove, you will learn how to control the amount of air entering the stove; and the amount of air leaving the stove by controlling the flue.

With a Pompeii oven, you can also use convection when cooking with the door closed. Once the pompeii is heated properly and the fire is removed, you can place an insulated door in the oven to retain heat. When you place the dough in a hot brick oven, convection will move through the moisture in the dough. When hot air comes into contact with the dough, heat is transferred.

Essential elements

Foundation. It is indispensable when constructing such a structure. Instead of such a base, a reinforced concrete slab can be used, which is laid on a gravel bed.

Stand. It sits on a bed of gravel, allowing you to raise the structure to a comfortable height, making cooking easier. The stand itself is a square box with brick or concrete walls.

Table. We are talking about a flat surface installed directly on the stand. In essence, this is reinforced concrete, the thickness of which is about 20 cm. Such an element must withstand the weight of the furnace and provide high-quality thermal insulation of the hearth.

Base

The base of the structure is laid with cinder blocks, the average height of which is 80 cm. When the foundation is raised above ground level, the height can be reduced. The base is laid out in the form of the letters H or P. The width of the sides is 120 cm.

Operating procedure:

- The blocks are stacked one on top of the other and fastened together with reinforcement through holes. No cement layer is required.

- The level controls the horizontal and vertical planes.

- Cement mortar is poured into the holes of the blocks. Drying time - 3 days.

Additional recommendations for creating a stove

The design of the Pompeii furnace is already known to you; now you can become more familiar with the methodology of the work. When making the foundation, you can make it in the form of a reinforced concrete slab, the thickness of which will vary from 100 to 200 mm. When purchasing cinder blocks for a stove stand, you must be guided by the following dimensions: 200 x 200 x 400 mm.

When creating a plan, it is recommended to think about the dimensions of the pedestal; it can have a square shape with a side of the structure of 1200 mm. The height of this part can be 800 mm. When creating a second layer of thermal insulation, you can use a cement mixture with the addition of perlite. Sometimes this ingredient is replaced with expanded clay or vermiculite.

When a Pompeii brick oven is built, it is imperative to prepare a hole for the foundation, the dimensions of which will be 1500 x 1500 mm. If we compare with the dimensions of the pedestal, then on each side along the perimeter it is necessary to leave 150 mm. What are the dimensions of the Pompeii oven, the drawing will allow you to determine. As soon as the hole is prepared, you need to lay crushed stone on one and make a sand cushion, the thickness of which will be 200 mm. The boards will allow you to assemble the formwork, and to make it easier to pour the mortar onto the sand, you need to cover it with plastic film. A reinforcing mesh is laid on top using rods, the thickness of which varies from 8 to 12 mm.

Option made from clay (without brick)

Making a Pompeii oven from clay, without using bricks, is a simple process. The foundation and tabletop are made in the same way as in the case of the classical design, but the model is made from coarse sand (screenings). A clay dome is laid on top of it.

Pompeii made of clay

Device

It is best to use special clay; you can purchase it at a construction warehouse. How to properly make an Italian design from clay is well shown in this video:

A Pompeii clay oven is installed with your own hands in the same order as when constructed from other materials. After the dome is installed, a chimney is made - any materials can be used for its construction, including ordinary brick.

Expert opinion

Nikolay Davydov

Stove maker with 15 years of experience

As in the case of a brick Pompeian stove, waterproofing and thermal insulation are required, which will ensure a long service life, as well as cladding, which will protect the structure from irritating factors (rain, hail, snow).

The Pompeii clay pizza oven is a simple design to construct - anyone can make one like this.

Design features of the Pompeii furnace

The Pompeian stove has one distinctive feature, which is the shape of a hemisphere. The fire is lit from one side, so the heat rises up and down into the center of the hearth, creating the right temperature for cooking pizza. The vault may be Neapolitan or Tuscan.

The first type involves a design in which the height of the dome is 80% of the diameter of the furnace. The second type is an option in which the diameter of the structure and the height of the dome are identical. The Pompeian stove is quite simple in design. If we compare with channel structures, then the ones described are much simpler to manufacture, they consist of:

- foundation;

- arch;

- outer body;

- table;

- chimney;

- thermal insulation.

Construction technology

Building a Pompeii stove with your own hands begins with choosing the type of structure and location on the site.

A Pompeian stove can be of any size. In the classic version, its internal diameter is 80-110 cm. A smaller size is considered inconvenient, and a larger one is considered uneconomical. The height of the entrance arch is taken to be 0.6 of this size.

Main stages

Foundation. It must be thorough. A reinforced concrete slab with a thickness of 100-200 mm is suitable for these purposes. It is laid on waterproofing made of 2 layers of roofing material.

Pedestal. It is erected over a slab of brick, cinder block or gas block, or natural stone. It resembles a U-shaped or H-shaped box, and is later used to store firewood or utensils. The optimal design is considered to be 0.8 m high with a side length of 1.2 m.

During the laying process, thermal insulation is made so that the heat from the oven hearth is not transferred to the stove. Otherwise it will collapse.

The cinder blocks are connected with construction wire, after which the holes are filled with mortar. Drying time is about 3 days.

The structure of the pedestal of the Pompeian furnace

Tabletop. It is poured into formwork with a minimum height of 150 mm. The bottom is covered with roofing felt or thick film. Then a mesh of reinforcement is laid in increments of 50 mm. The cantilever sections are reinforced with rods. The form is filled with concrete, and on top - a heat-insulating layer of lightweight concrete with the addition of expanded clay or perlite sand. The surface is leveled.

The top layer can be made of insulating calcium silicate slabs. The structure is covered with polyethylene and aged for at least 3 weeks. An under-dried countertop may crack or collapse during further use.

Work zone

Bottom of the oven. Made from refractory fireclay bricks or plinth. The tabletop is placed on the base and the position of the dome is marked. Fireclay bricks are laid along the contour on the mortar in the form of a herringbone. A bead is formed for the base of the entrance.

Dome. To form a dome with an arch, you will need a template made of cardboard or plywood and a wet, clay mixture.

Working area of the Pompeian furnace

Work begins with the creation of the entrance pharynx. The gap when laying bricks is left minimal. Then the dome is arranged according to the template, in the direction from the stove entrance to the rear. In each subsequent row, the distance between the bricks increases. To create the required gap, wooden wedges are inserted. The top of the dome ends with a lock of 2-4 shaped elements, after which the outer arch is formed using a plywood template.

A protective coating of 2 layers is applied on the outside. First comes thermal insulation plaster with vermiculite 6-10 mm thick. Then - a moisture-resistant decorative coating or finishing with a layer of 2-4 mm. The arch is decorated with facing bricks.

Chimney. The chimney pipe can be made of brick and mortar, or use a ready-made steel or ceramic pipe with a diameter of 150-170 mm. The chimney is in front on the arch. The height is determined by the design of the furnace.

We build it ourselves

If we take a strict approach to the issue of baking pizza, then no factory equipment can give a truly “real” result. This means that lovers of Neapolitan or Diabola will have to build a pizza oven with their own hands.

Foundation

The total mass of the finished structure is quite large. Even installing any brick oven outdoors requires a solid foundation in the form of a foundation. Our Italian stove will rest on a solid reinforced foundation with a crushed stone cushion.

To dig a pit you need to know the dimensions of the future furnace. As with any other construction, you will need a drawing. The layout of the furnace is quite simple, so the drawing shows only the dimensions of the structure. The pit should have linear dimensions slightly larger than the dimensions of the furnace podium.

Good to know: Is it worth using a gas heater in the country, which model to choose

A pillow is installed at a depth of 40 cm. To do this, a layer of crushed stone is poured and compacted tightly. Then, the rest of the foundation is filled with mortar, for the preparation of which cement and sand are used. This is an ordinary solution with a ratio of 1 and 4, which fills the space limited by the formwork. A reinforcing mesh should be placed on the surface of the pillow and throughout the entire layer of mortar.

After raising the foundation to the desired level, you need to check the horizon and leave it for several days for the solution to dry completely. To ensure that moisture evaporates evenly over the entire depth and cracks do not form, the new foundation is covered with a film.

Stand and table top

It is too early to design the firebox, as it will be located low and inconvenient to work with. In addition, you can create a functional addition to the stove - a compartment for storing firewood. A stand will be formed on the surface of the foundation. It plays a load-bearing role and determines the height of the furnace. When building independently, the height is selected according to your height. The walls of the stand are formed of strong concrete blocks; there is no front wall. A kind of niche is formed for storing firewood.

Creating walls

The height of the table top is usually 10 cm. This layer of mortar should have two layers of reinforcing mesh. There is a gap of 5 cm between them. After pouring, the tabletop is covered with film and dries for several days. Now you have a base that can support a wood-burning pizza oven.

Walls and dome

To build any wood-burning stove, you need to stock up on refractory bricks. The inner surface of the firebox, where the highest temperature is observed, is lined with fireclay bricks. Clay mortar with good adhesion can be purchased at the store in the form of a dry mixture. Preparing the solution yourself will take a lot of time, since you will first have to select a type of clay suitable for its fat content, grind it and mix it with sand.

At the first stage, the arch of the vault is laid out. It is necessary to prepare a wooden template that will hold the arch until the solution hardens.

Creating an arch of the desired shape

After this, we begin the construction of the dome. A row of bricks is laid out around the circumference on the tabletop. To form a dome, many craftsmen advise making a wooden internal frame.

Appearance of the finished structure

But there is a more convenient and practical way. Sand is poured into the space limited by the first row of bricks. A pile of compacted sand is given the desired shape. It can be used to lay out the dome, and then the sand can be removed through the firebox inlet.

Creating a firebox shape using sand

The wood-burning pizza oven body is plastered with clay mortar. Clay can withstand temperature and will prevent heat from escaping from the firebox through possible cracks.

Good to know: Tiled stoves-fireplaces, a new wave of popularity of antique finishes

Chimney

The design of the chimney in a Pompeian stove is quite simple, but at the same time it has one feature. The pipe protrudes forward, towards the entrance to the firebox. Since the stove model is outdoor, there is no need to build a high channel. It is enough just to ensure that the smoke escapes outside.

Construction work has been completed

Having completed all stages of construction, the oven should be left for several days. Despite the fact that the solution dries quickly on the outside, moisture will remain throughout its entire depth for a long time.

First firing

Before lighting the stove for the first time, you must make sure that all materials are completely dry and the concrete or mortar has set. The longer you let the concrete dry, the stronger it becomes. You can wrap the structure in salophan or a damp cloth to prolong drying time.

During the first ignition, the water remaining in the masonry turns into steam, and can lead to cracks at this stage

For this reason, it is important to let the oven sit until it is completely dry. Heating of the oven itself must be done gradually

This also applies to brick and stone ovens. When starting the fire for the first time, you need to light a small fire and gradually increase the load of wood. Try not to use large firewood as this can cause the heat to build up quickly. The initial kindling should be spread over a 6 hour period. After you first fire up the fireplace, it should be carefully inspected for signs of cracks in weak points. In subsequent burns, you can use larger logs and heat the oven to its full potential.

Kindling after completion of work

After completion of the work and removal of the auxiliary frames, testing of the furnace begins. It is carried out in 5 stages:

- 2 kg of straw and 1.5 kg of paper are placed in the oven. All this is set on fire and left until completely burned.

- Next, take 2.5 kg of straw and 0.5 kg of brushwood. Likewise - until complete combustion. 4 kg of wood chips are burned.

- Logs are laid and burned.

- The furnace is being tested as usual.

If all stages have been completed successfully, you can begin operating the furnace.

When baking pizza, you don't need a base - it's placed in the oven, and the smell of smoke adds a unique aroma. If meat is being cooked, the coals are raked to the side and a metal grate is inserted through the arch. The meat is located on it. Thanks to its properties and purpose for cooking, dishes turn out juicy, with a bright taste and aroma.

Project selection

Taking into account the configuration of the dome, two types of Pompeian oven are distinguished. The first type is called Tuscan. Its dome height and radius have the same values. The Neapolitan dome has a height 20% less than the radius.

This oven is used for preparing various types of dishes.

The Tuscan stove is considered universal due to its higher arch. It perfectly cooks meat, stews, soups and pies. Neapolitan design has a narrow specialization. It is ideal for preparing various baked goods. Experts recommend choosing the Tuscan option.

As for the dimensions, the internal diameter of the oven should not be less than 110 cm. Otherwise, it will be inconvenient to cook in it.

A Tuscan oven can have different sizes, but its proportions must remain the same. For example, the height of the arch should be 60% of the dome, the width of the hole for storing fuel should also be calculated based on the total height of the structure.

The chimney should be placed at the front of the stove

This is especially important for our climatic conditions. After choosing a project and determining the location of the entire structure, you can begin purchasing materials and subsequent construction

Classification

Baking requires a special type of oven with a bread chamber. Despite the same principle of making bread, ovens differ significantly from each other in a number of ways.

- Based on the heating method, furnace surfaces are divided into two types. Direct heat transfer is characterized by the fact that the surface is heated by the action of a flame. This type includes a wood- or gas-fired baking oven. Indirect exhaust furnaces use a specific medium as a coolant. Examples include electric, convection, and oil bakery ovens.

- Classification by type of heat channel implies the existence of furnaces made of materials with high heat capacity and low heat capacity. The first type includes brick structures, and the second type includes mechanical ones.

- In the distribution by type of fuel used, 4 groups are formed. Electric ovens are designed as compact devices in which you can bake 1-2 loaves of bread. Typically, such an oven is small in size and located in the kitchen of a house or apartment. Liquid fuel ovens operate on a more global scale, are massive and allow bread to be baked in large batches. This is a great option for small businesses. Wood-burning or gas structures can act as an extension to a stove or fireplace, or as a separate unit.

Industrial bread production

Based on the method of placing products in the chamber, each model can also be classified into one of the groups. The storey placement method is represented by several shelves located in the chamber at a certain height. In order for the bread to be baked throughout its entire volume without the formation of burnt areas, it is necessary to swap trays located on different floors. Tunnel models do not make it possible to move bread to zones with different temperatures, but they allow you to bake products in huge batches. Such specimens can be found at factories that supply the needs of an entire city district. The rotary type of ovens rotates the trays around a vertical axis. In the horizontal plane in the chamber, the heating temperature is slightly different, so this rotation ensures uniform baking. The cradle oven is represented by pallets that can be moved vertically. Unique cradles allow you to place baked goods in a zone with a higher or lower temperature, at the discretion of the technologist.

Good to know: What is a fireplace stove and how two different devices are combined

Features and characteristics of pizza ovens

Pizza is one of the most famous culinary dishes in the world.

Its history begins around the seventeenth century, at which time special chefs appeared who prepared culinary dishes for peasants in Italy. Subsequently, the dish received the status of the national dish of Italy.

Today in every city you can find several pizzerias that attract people with a wide variety of recipes with an incredibly wide range of all kinds of ingredients and toppings.

As a rule, the entire cooking process takes place in front of visitors, which has a positive effect on the process of waiting for a flavorful dish and encourages visitors to buy flavorful pizza. Therefore, furnaces are indispensable equipment.

A pizza oven is highly professional heating equipment used by Italian restaurants, pizzerias, and fast food outlets to prepare pizza.

Despite its narrowly targeted name, it is widely used for baking baked goods, frying eggs, and finishing semi-finished products.

A special feature of this type of equipment is a stone tray that accumulates heat and maintains a constant high temperature (up to +500°C) inside the chamber. The pizza preparation process takes place directly on this hearth, which takes no more than 7 minutes.

Pizza ovens can be divided into two main categories:

- Homemade. Used in everyday life, intended to meet family needs;

- Professional. It is used in catering establishments. It is characterized by increased productivity, design complexity and high cost. They are designed to allow you to cook several pizzas at once.

The standard equipment of the furnace includes:

- an oven that can accommodate up to four standard-sized pancakes;

- heat flow intensity regulator with a temperature in the range of 100-500°C;

- safety thermostat that turns off all heating elements if overheating is likely.

Doors with a viewing window made of tempered glass and internal lighting allow you to keep an eye on the cooking process and control its readiness. Having a thermometer will make it possible to accurately set the temperature inside the chamber. The units are made partly from stainless and galvanized steel.

Pizza ovens are today used in such establishments as:

- canteens;

- restaurants;

- bakeries;

- cafe.

Choosing a stove is not an easy task and requires taking into account several important factors.

If you are betting on the originality and authenticity of the product being produced, then the best solution would be a wood-burning brick oven.

This equipment came to us from antiquity. It ensures the preparation of pizza with the highest taste and excellent aroma.

Hearth and conveyor ovens allow you to prepare a mass product, but are characterized by higher productivity than their wood-burning counterparts.

The choice of equipment is also influenced by the capacity of the device, its overall dimensions, the type of energy supply (electricity, gas, firewood), the number of cameras, and, of course, cost.

https://youtube.com/watch?v=ofuQaJkhYec

First of all, in order to choose the right pizza oven, you should understand why it is needed.

Of course, in the primary version it is clear why, of course, to bake pizza.

But as I hope you have already understood, you can bake it in different ways, and as a result, you will end up with a different taste of the prepared pizza.

So, if your establishment will have seating, work for visitors, you will have a large bar counter, and you want to additionally make baking pizza in the oven an element of the surroundings, then this is definitely a wood-burning pizza oven.

Moreover, thanks to the different sizes of wood-burning pizza ovens, you can choose the ideal option specifically for your establishment.

Hearth pizza ovens, unlike conveyor ovens, cost significantly less, so they can be recommended as an initial option for a small pizzeria or pizza delivery.

Conveyor pizza ovens can be recommended if the budget is not very limited, and you also plan to recruit unqualified personnel for the work, since baking in conveyor pizza ovens is the simplest and does not require any professional knowledge and skills.

How does it work?

It is important to understand the furnace structure before moving on to the construction phase.

The operating efficiency of the equipment depends on the technical features. Temperature changes in the oven are regulated independently due to cyclic changes in gases, which is a characteristic feature and is perfect for baking baked goods and pizza. The dome of the structure is one of the main elements in the organization of work, accumulating heat energy emanating from the fire. During the combustion of solid fuel, two gas flows interact in the dome cavity:

- The first is convection. The flow is directed from the firebox.

- The second is reflected. Gas streams reflected from the walls of the dome itself.