A stove in the garden will help out in many cases.

DIY garden stove

When you come to your dacha to relax, you don’t really want to stand at the stove in the kitchen to feed the whole family or invited guests. Cooking outdoors in good summer weather is much more pleasant, so you can’t do without such an assistant. But a garden stove can be built with your own hands if you carefully select the right model, understand its installation and purchase the necessary materials.

Furnaces may have several functions, or may be limited to one or two. To focus your attention on one of them, you need to consider their different types.

Stove for a cauldron

This version of the garden stove is designed for cooking in a cauldron or on a built-in stove. It has a simple masonry scheme, and can be done independently if you have certain skills.

Stove with built-in cauldron

You can, of course, just hang a cauldron over a fire and cook food, but such a stove, designed for a cauldron, will help distribute the fire evenly under it, and the dish will turn out exactly as it should be according to the recipe, and not with a burnt taste. In addition, a carefully constructed and decorated building will add a special warm note to the landscape of the site and become a decorative element.

- The first thing to start working on a stove is site planning. To do this, you need to know the dimensions of the building - in this case they are 1010 × 1114 × 800 millimeters.

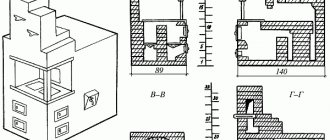

Schematic diagram of a stove with a cauldron

- Next, based on the diagram, the necessary materials are purchased: brick (preferably fireproof); mortar of fireclay dry mixture and sand for masonry; doors for the blower, firebox and cleaning chamber, grate and hob made of steel with a thickness of at least 3 mm.

- A well-designed site is a reliable basis for such a stove. Since it does not have the same weight as heating and cooking buildings, it is not necessary to make a capital foundation for it. The area under the stove should be raised above the soil surface by 10-15 centimeters. The base is made using formwork, and it is advisable to reinforce the structure with five-millimeter metal wire.

- The main feature of the internal design of a cauldron stove is its shape - it resembles a truncated cone. This is done to ensure that the surface of the cauldron is heated evenly.

An important feature of the stove is the channels for uniform heating of the cauldron

- On a prepared and fully set site, you can begin laying the masonry. In this case, the bricks are bandaged in the corners, so that even rows begin with half a brick, and odd rows with a whole brick. The firebox is laid out from halves of bricks, which are cut at an angle - this is done in order to achieve a semicircular shape.

- The diagram above clearly shows that starting from the first row, a hole for the blower chamber is marked, and a door is installed on it, which is secured with metal wire.

- A grate is installed on the third row, and the laying of the walls continues.

- On the fourth row, at the back of the building, a hole is left to remove smoke and a firebox door is installed, securing it in the same way as the blower.

- Fifth row - external and internal walls are laid.

- Sixth row - the masonry around the fire door is completed.

- From the seventh to the eleventh row, work proceeds according to the scheme and the inside of the firebox is laid out.

- On the twelfth row, the structure is strengthened with a metal corner, a plate is installed on top of it, in which a round hole is made in advance the size of the cauldron.

The hole can be made with a grinder, short cuts, or using a gas cutter. Then the hole needs to be leveled, since the cauldron must fit tightly into it at two-thirds of its height.

Such a stove will help you cook not only in a cauldron, but also use the stove for boiling water or frying vegetables or meat products in a frying pan. To do this, you need to provide a lid to cover the hole for the cauldron.

Best models

A small wood-burning stove for a summer cottage can be made from several types of materials. Let's look at the 5 best models from leading heating device manufacturing companies.

Made of brick

Mini-stoves for wood-burning cottages made of brick cannot be found on sale. We will not analyze this topic in detail; if you are interested in such designs, the best models can be found by reading the information in the article “Do-it-yourself mini-oven.”

Let's look at the best industrial models made of steel and cast iron.

Made of cast iron

Based on customer reviews, a rating of the 5 best stoves and fireplaces has been compiled.

| Model name | Main characteristics and dimensions (L, W, D in mm) | Approximate price in rubles |

| Model "COLMAR" | Dimensions – 820/547/355. Maximum power – 7 kW. A chimney with a cross-section of 150 mm is connected from above. The maximum volume of premises is 160 m3. Weight 75 kg. Fuel - pallets, firewood. | From 58000 |

| , model "Kerpen II" | Maximum power 6 kW. Weight 58 kg. Room volume – 124 m3. The outlet of the chimney pipe, with a cross-section of 120 mm, is located on the rear wall. Efficiency level – 78%. Door with glass. Equipped with a hob. Dimensions – 885/285/320. | 17000 |

| Model "Bestfire Chelsea" | Room volume – up to 200 m3. The chimney comes out of the rear wall, diameter – 120 mm. Equipped with a hob and a door with fireproof glass. Efficiency – 80%. Dimensions – 820/500/480. Weight 78 kg. | 20000 |

| Fireplace "Oscar" | Power 7 kW. Location – wall. The chimney, with a cross-section of 130 mm, comes out of the rear panel. Weight 70 kg. Dimensions – 610/470/410. | 25800 |

| Mobile wood stove. Model "EcoStove Ingrid" | Room – 150 m3. Power 9 kW. Dimensions – 840/400/380. Door made of fireproof glass. | 24000 |

Of steel

| Model | Main characteristics. | Average price. |

| "Gnome 3" | Dimensions – 640/363/502. Power 5 kW. Weight 37 kg. | 9000 |

| Heating stove "Potbelly stove UMK" | Power 5 kW. Weight 35 kg. Dimensions – 675/310/580. The cross-section of the chimney pipe is 100 mm. Room volume – up to 80 m3. | From 3000 |

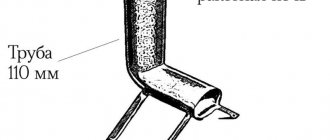

| Heating garden stove "Ermak" | Equipped with a cast iron hob. Room volume – up to 80 m3. Dimensions 540/320/480. The diameter of the chimney coming out of the top of the stove is 115 mm. Power 5 kW. Weight 15 kg. | 4800 |

| , model “Pechurka Plus” | Equipped with a hob. Dimensions 505/450/450. The cross-section of the chimney pipe is 115 mm. Weight 29 kg. The maximum volume of the room is 50m3. Power 5 kW. | 6700 |

| Model "Sava" | Dimensions – 480/380/660 allow you to load long firewood into the firebox. Weight 52 kg. The ventilation pipe cross-section is 115 mm. Room volume up to 70 m3. Power 6 kW. | 9700 |

BBQ oven

A very simple barbecue oven

This version of a stove for a summer residence is quite simple in design, and its construction is accessible even to a novice craftsman. To do this, you need to study the diagram, find a place for the stove, purchase materials and carry out the work with great care. The structure should be erected slowly, measuring the evenness of the horizontal and vertical sides.

"Ordering" the stove

The dimensions of the furnace shown in the diagram are 1500x1500x750. The order is given before the start of the firebox, which is lined with fireclay bricks inside. Covering large distances is done using metal strips, on which rows of bricks are laid on top. The chimney cap and chimney pipe, like the entire structure, can be made of brick, or they can be made of metal. The second option, of course, is easier to install; the only thing you need to do is take the dimensions and order it from a master tinsmith.

For this not too massive structure, there is also no need to build a foundation, which is required for large home stoves. A well-equipped cemented area is quite suitable for it.

For construction, you need to purchase the same materials as for the first version of the stove with a cauldron, and the amount of brick can be calculated according to the dimensions indicated in the diagram.

Installation

The process of installing a long-burning stove for heating a dacha is simpler than installing a radiator-type heating system. However, this work should also be entrusted to specialists. The slightest mistake when installing the device can result in serious problems during its operation.

Fortunately, the services of professional installers are not expensive at all. Our specialists will not only install a furnace to heat your home, but will also check its functionality and also clean up after themselves - you won’t need to do anything at all.

Complex brick oven

Multifunctional garden stove

A garden stove, which has many functions, will help out in any case and will help you prepare different dishes - from barbecue to smoked products. An oven built into the stove will be able to bake bread or a pie, thereby allowing you to avoid leaving the dacha for a long time to go to the nearest shopping center - you just have to stock up on all the necessary products when going out of town.

This design is heavier and has built-in elements and additional extensions. Therefore, to build it, you must first think about building a foundation. You don’t need to make it too massive and make a deep pit for it, but you can’t do without it if you want the stove to last for many years and not fall apart in the event of slight soil subsidence.

“Ordering” a garden stove with an expanded set of functions

The diagram shows an option that is slightly different from the photo, but also has a stove and barbecue grill. The figure clearly shows what each of the rows of a complex furnace looks like. Based on the proposed drawing and following the recommendations, it is quite possible to do the work yourself.

About the manufacturers

Our catalog presents wood heating stoves from the best manufacturers:

- TERMOFOR. This is the most famous Russian company engaged in the production of heating equipment. Each long-burning heating stove for a summer residence from this manufacturer is a truly reliable device, the performance of which fully corresponds to the declared indicators. In addition, TERMOFOR stoves have an excellent design

- Breneran (Buleryan). Equipment manufactured under this brand meets the highest international quality standards and can satisfy your most stringent requirements.

- Zharstal. Simple, inexpensive and high-performance furnaces from this manufacturer are becoming more and more popular every year

- STROPUVA. Ultra-modern and extremely reliable, these furnaces (boilers) are extremely easy to use and extremely efficient.

Do you want to know more about the products we offer? Or are you ready to buy a heating stove at a more than reasonable price? Call us!

Oven with tandoor

An interesting option is a tandoor oven

The complex may include a unique element that can completely replace many of the functions of a garden stove - this is a tandoor. Not a very familiar word, but most likely many have seen how oriental flatbreads are baked. But this oven can also become a roaster for cooking barbecue, vegetables or fish, and allows you to prepare pilaf or pizza. In addition, you can also make a smokehouse out of it. For each dish, there are various devices that are installed on or in this stove. Everything cooked using the tandoor has a special taste, so it is perfect for those who love either oriental dishes or just delicious food. If you look at this stove in cross-section, it looks something like this.

Sectional view of a tandoor oven

The tandoor can be built into a brick barbecue complex, which is located in a gazebo, or it can be installed separately. This oven looks like a large jug inside. It has a vent and a grate in its lower part - they make it possible to obtain coals from the firewood, with the help of which various dishes are prepared.

If the furnace is built separately from the complex, then a shallow reinforced cement podium needs to be prepared for it. When it is ready, you can begin laying it, which is quite complicated, since the tandoor has a semicircular shape, tapering at the top. It is this configuration that is necessary to retain the heat inside for a long time.

If additional walls will be laid around it later, this must be foreseen when laying the foundation, and space must be left for them, or better yet, the first row must be made common.

Stove diagram with tandoor

To lay the tandoor, they use clay mortar, and begin by laying out a brick base. If you work according to the presented scheme, the oven will gradually narrow towards the top and converge into a circle. In order for everything to work out as planned and a beautiful vault to be built, the bottom layer of brick is cut off.

After completing the work, the inner surface of the tandoor is well cleaned of any mortar that has protruded from the seams.

On the outside, the seams between the bricks are traditionally filled with dry ground clay, and the inside surface of the tandoor is coated with a solution that consists of soaked clay mixed with very finely chopped grass. Next, the stove is left to dry, after which it must be carefully fired. This is done first using plain paper, but newspapers should not be used, since printing ink consists of substances that are not entirely useful for the human body. After warming the tandoor with paper, you can gradually add dry firewood to it.

In the east, the tandoor is coated with a layer of clay on top and decorated with various ornaments. If you plan to build a stove with a tandoor in its design, smooth walls are placed around the jug, and the distance between the walls of the tandoor and the smooth walls is insulated using a mixture of clay and vermiculite. The top of the oven is placed in the same way as a regular barbecue oven. In autumn and winter, the tandoor must be closed from above, since precipitation and dirt can damage the interior decoration.

The process of building a small stove

At the initial stage, preparatory work is always carried out. The quality of construction of a small brick stove for a summer cottage largely depends on them.

Project selection

When contacting professionals, you can choose one of the ready-made stove designs. Highly qualified specialists will also, if necessary, develop individual drawings taking into account the customer’s wishes. When choosing a specific option, consider:

- heated area;

- number of heated rooms;

- winter air temperature outside;

- purpose of a small stove;

- heater heating frequency;

- construction costs.

When choosing a furnace design, construction costs are taken into account Source ark-eng.ru

What to consider during construction and operation

After choosing any of the models of garden stoves and deciding to build it, in order for everything to be successful, you need to understand some of the nuances of its construction and care.

- The foundation of the furnace must be raised to a certain height so that the furnace structure is not affected by melt water or flooded by heavy rains.

- Since clay mortars do not respond very well to natural influences (humidity, precipitation, direct sunlight, etc.), it is better to use cement mortar to seal external joints.

- The best option would be to place a garden stove under the roof in a closed gazebo - this arrangement will allow it to be used in winter, as well as in any weather.

- A gazebo for a garden stove should be spacious, so that you can install a table in it and seat guests.

- On the site, the gazebo and stove should be located away from the gas pipeline and power lines, but closer to the water supply so that water can be piped inside the gazebo.

The first thing you need to do when planning a building is to find or draw up a project. How convenient it will be to prepare your favorite dishes will depend on it. Therefore, when dealing with this important matter, you need to think through all the nuances of the functionality of the future stove.

Video description

The video will help you understand how to install one of the options for a small brick stove for a country house:

- On the 16th row, a continuous masonry is made above the cooking chamber and the smoke exhaust channel continues to be laid out.

- When installing the 17th row, a door is installed through which the chimney will be cleaned.

- During the laying out of the 18th row, the final fastening of the door is performed to clean the chimney.

- The laying of rows 19-22 is carried out according to the scheme depending on the selected furnace design.

- When installing rows 23-27, a wind niche is created. At the same stage, the oven itself is installed. It is first wrapped with asbestos rope. It allows you to improve the accumulation of thermal energy.

- When laying the 28th row, a second cleaning door is installed.

- During the laying of the 29th row, a chimney valve is installed.

- On the 30th row, the previously selected pattern is laid out.

- When installing 31 rows, a second chimney valve is placed.

Finally, the 32nd row is laid out, which serves as the basis for the chimney. Usually it is also mounted from brick. However, some homeowners choose to install a metal chimney.

Negative qualities

Cast iron stoves are not without their drawbacks. Among them the following are noted:

- Fragility. This applies to almost all similar products. The material has a high fragility factor and therefore requires careful handling. He is afraid of strong blows and falls.

- Large mass. For example, a 9 kW oven weighs approximately 70 kg. In a private home, to install such a device, you need to make a reliable foundation.

- Instability to sudden temperature changes. When lighting the stove, no damage occurs, since the device heats up and cools down gradually. But if cold water accidentally hits a hot surface, the cast iron may crack.

- Price. Of course, the cost is much higher than other analogues. However, this is justified: the product is highly reliable and designed for long-term operation.

- Fire safety. Storing flammable materials near such a stove is prohibited. They can catch fire from the high temperature of the walls of the unit.

- Nuances of operation. The room in which the cast iron stove is installed should not have high humidity. Because of this, rust may appear. Any damage requires immediate repair. Models from foreign manufacturers are heated only with pellets or peat, so there is no need to put long logs in them.

Foundation

Under a large complex, you will have to make a reliable foundation , with a depth below the freezing point of the soil (it is different for each region, you can check it with familiar builders). The foundation must be reinforced. On soils with heaving soils, it should have a trapezoidal shape.

If the garden stove is small, then an ordinary slab 10-15 cm thick is sufficient. To construct it, the fertile layer is removed, a hole 40-60 cm deep is dug, 10-15 cm of sand is filled in, compacted, after 30-40 cm of gravel. The formwork is being exposed. Reinforcing mesh is placed in it and everything is filled with concrete. It is better if the foundation is 50-100 mm above ground level.

Materials

Considering that the oven will be located in the open air, the choice of materials should be approached very responsibly. It is best to use refractory fireclay brick, but if the complex is large, then it is possible to use solid red brick . When purchasing a brick, check its dimensions. It is important that it matches the dimensions of the brick in the project.

It has always been believed that for laying bricks it is better to use clay with the addition of sand. The amount of sand depends on the clay and here you need to look at the condition of the mixture. The clay must first be soaked in water for 2-3 days, then knead it well with your feet, adding a little sand. The solution is considered the most suitable if the bun made from it, falling from a height of 1 meter, does not crack or crumble, but simply flattens.

For the generation under 30, this is the same as the rocket fuel formula for my mother. Therefore, we leave the clay in a basin for the children to enjoy, and we ourselves buy in the store a special building mixture for outdoor stoves or just stoves, if there is a canopy over it.

Technical features

Like any construction, the construction of a furnace begins with the construction of a foundation. You need to know a number of features that will help you avoid mistakes.

Stove maker from St. Petersburg:

– There are no light brick kilns. Even a low 630x630 mm 1/4 brick with lining will weigh about 700-800 kg.

Even such a relatively “light” device cannot be installed on every floor.

Installation of stoves, fireplaces and chimneys weighing over 750 kg must be carried out on a separate foundation.

According to Alexey Telegin, the foundation should provide:

1. Uniform distribution of load on the ground in accordance with the bearing capacity of the soil;

2. Stability and protection of building and furnace structures from external influences during house movements, shrinkage and soil heaving.

Any foundation (its depth, dimensions and reinforcement) is calculated based on the load acting on it, as well as the bearing capacity of the soil.

The load on the furnace foundation (given its large mass) is very different from the load acting on the main foundation. If you build the foundation in one piece, it turns out that at the site where the furnace is erected, the loads are added up, which can lead to undesirable consequences.

For buildings subject to shrinkage and movement, it is necessary to build a separate foundation for the stove, not connected to the foundation of the house.

MasterOk:

– The foundations are made independent, and if two foundations are adjacent to each other, a soft insert is installed between them.

The simplest soft insert between two foundations can be made of a foam plastic board 5 cm thick.

This will protect the foundation from any lateral loads and the destructive properties of frost heaving of the soil. It’s not without reason that they say that a separate foundation for a stove is folk wisdom.

If a single foundation is laid, the uneven load must be taken into account in the calculation. And in order to compensate for it, additional reinforcement is laid in the “body” of the foundation, in the place where the furnace is planned to be installed.

Water heating circuit

To get rid of one of the main disadvantages of a conventional stove - uneven heating of rooms, you need to:

1. Install a heat exchanger (register) filled with water into the oven;

2. Connect a circulation pump to the system, which will circulate heated water through the heating system - radiators or heated floors.

This system operates on the principle of a solid fuel boiler and a closed heating system.

In this case, the stone stove is multifunctional: it simultaneously performs the function of water and stove heating, which ensures uniform distribution of heat throughout the rooms.

Vadim Kornev:

– It is better to place a stove with a water circuit against one of the walls of the house to facilitate the wiring of batteries. The presence of a circulation pump, as well as an expansion tank, is required. Such devices are quite safe if the heating element is professionally welded and there is always water in the circuit.

Interesting is the practical experience of building heating for a country house based on a stone stove with a water circuit by a specialist from our portal Vasily Katriychuk :

– I installed a water tank in my stove. The total capacity of the system including the pipes to the riser was 65 liters. When it is heated, the water in the tank is simultaneously heated, after which, with the help of a circulation pump, the coolant is driven into the heated floors and radiators of the heating system.

When installing such a heating system, it is necessary to provide all safety measures. In the event of a power outage, the circulation pump will stop working, but the stove will still continue to heat the water (it cannot be turned off instantly). As a result, the water may boil and the pipes will burst. To prevent this from happening, a security group is installed in the system. And if the coolant boils, excess water is discharged.

The operating pressure in the heating system ranges from 0.6 to 2 atmospheres. The safety group will operate at a pressure of 3 atmospheres.

Vasily Katriychuk:

– In case of a power outage, you can provide a backup electricity supply system - an individual inverter or a gas generator.

In addition to providing the home with heat, a water-contour furnace prepares hot water for the domestic hot water system. And in order not to heat the stove in the summer, you can additionally install an electric boiler for the hot water system.

Let's figure out whether the house becomes dirty from a working stove and how much one stack of firewood is enough.

Vasily Katriychuk:

– I lay firewood twice – in the afternoon and in the evening. Thanks to the large firebox, I can even put logs in my wood stove. This extends the burning time on one tab. And since the heating stove is built according to all the rules, it is very economical, does not smoke, and the ash must be removed once every three days.

The register can be installed in the oven in two ways:

1. Install the heat exchanger into the already folded stove. This is expensive and you will have to partially disassemble the device. Also, the volume of coolant in the register will limit the size of the furnace;

2. Design and build the furnace under a carefully calculated heat exchanger. This method will allow you to achieve the ideal combination of oven and register, which will ensure their efficient operation.

Vasily Katriychuk:

– In my case, the water tank is installed in the firebox through removable doors.

To remove the tank at any time (for repair or maintenance), a gap of 3-4 mm is left between the walls of the heat exchanger and the walls of the furnace.

The gap is also necessary to compensate for the thermal expansion of the steel heat exchanger.