Buildings of any type with a steam room require a heating structure capable of heating the air to high temperatures. However, purchasing a finished product entails considerable financial expenses, so individual developers very often make sauna stoves from iron with their own hands. It is metal that is a good conductor between the combustion chamber and the environment.

The photo shows a homemade iron structure.

Initial information

Self-made structures made of steel, when compared with their brick counterparts, are distinguished by the speed of construction and increased heat transfer. To carry out the work, it is enough to find a pipe whose diameter will be approximately 50 centimeters. Such products are especially relevant for small objects.

Requirements

Approximately the following pipe needs to be prepared.

- The heating structure must be located in a place where reliable fire protection is provided for materials subject to easy ignition.

- The area occupied by this object should not exceed 0.15 percent of the useful square footage of the heated room, since it is not very comfortable to carry out water procedures in a cramped environment.

- The side surfaces of the structure must be covered with heat-insulating materials so that the risk of burns is minimized.

- When installing, you should take care of the correct location of the stove, because the heat emanating from it should spread in different directions, thereby ensuring high-quality heating.

Basic elements

When making an iron stove for a bathhouse with your own hands, every novice craftsman must familiarize himself with the main components that make up the structure.

Any of the fragments listed below performs some function, so it is important to study all the details in full.

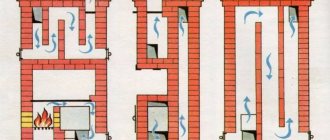

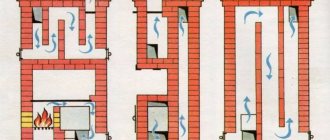

The structure of a sauna stove with water supply.

- The firebox is the main chamber where organic fuel is usually burned to heat the walls and then the surrounding air.

- The ash pit is located below the previous chamber, ensuring the collection of ash, which is formed as a result of the combustion of organic substances.

- The stone container allows you to lay cobblestones of jadeite, gabbro-diabase, crimson quartzite or other high-temperature resistant analogues.

- The pipe is a hollow product that is necessary to remove combustion products from the main chamber.

- The grate is an element inside the firebox that makes it possible to hold a layer of solid substance intended to produce thermal energy.

- Blower and firebox doors allow you to control the flame by covering it, which leads to a decrease or increase in oxygen inside.

- A pipe valve is usually made in the form of a control element that moves perpendicular to the working medium.

Shown is a homemade grate made from rebar.

Attention! If the building combines a washing compartment and a steam room, then the hot water tank is installed directly on the stove. However, in such a bathhouse it is also possible to have stands above the stones.

What is a grate?

The cast iron grate for the stove ensures the most complete combustion of fuel. The element is placed between the ash compartment and the firebox and looks like a grate. During combustion, air enters through the grate from below. The movement of the air flow - from bottom to top, allows the fuel to burn completely. And after combustion, the ash does not accumulate in the firebox, but spills through the same grate into the ash pan. At the same time, it also serves as a kind of protective layer for the grate itself, since it does not allow it to become hot. The photo shows grates.

The products perform several important functions at once:

- separate the firebox from the ash pan - the temperature in these two compartments is different;

- ensures the passage of air flows from bottom to top - draft;

- the same rising air flow dries firewood and coal;

- the entire system of the ash pan, grate and stove door allows you to regulate the fire.

Ready-made devices - Harvia, Bavaria, products from Castor, of course, are equipped with this element. And, even when it comes to a do-it-yourself design - for a bathhouse, for example, it is recommended to purchase this part. All well-known manufacturers of furnace units - Termofor, Castor - offer grates of any size for sale. It’s also quite possible to make a grate yourself, but getting the material for it – cast iron – is much more difficult to work with.

What is a grate for?

This important element of the furnace combustion chamber allows you to get the maximum effect from fuel combustion. The structure of modern stoves is constantly being modified and improved, and only the main structural element of the firebox remains unchanged. The combustion equipment retains its grate configuration.

The platform supports any type of solid fuel (firewood, coal and briquettes). Through the through openings, air is sucked in from below, which creates effective draft inside the combustion chamber. Combustion products (ash) fall into the ash pan (ash pan), freeing up space for the top layer of fuel. The grate promotes uniform combustion of fuel, thereby achieving maximum thermal energy transfer from the fuel placed in the combustion chamber.

Buying tips

For high-quality combustion, not only the size of the grate is important, but also the weight of the fuel that it can withstand in one laying. The rods should not deform or wear out.

The grate must have a sufficient number of holes - at least 40% of the area of the part itself. If this figure is lower, then there will not be enough oxygen to maintain the fire, and the ash will remain on the grate and clog the stove.

If the gaps in the grate have a large area, then the remaining fuel will fall from the combustion chamber into the ash pan. Fuel consumption will become uneconomical.

Optimal lattice option

Types of grate

The grate is made from elements of different shapes, but only from cast iron and steel. Other materials do not withstand frequent calcination or are too expensive. Depending on the design, grate bars are divided into several types:

- tile grating;

- beam grate

- basket;

- mobile grid.

Tile grate

One of the most common types of grate is the tiled grate. The main feature of this design is the observance of strictly fixed dimensions. This grille is designed for an installation site of a certain size. A mandatory condition must be met - the presence of a gap between the outer perimeter of the grate and the walls of the firebox of at least 5 mm. If this size is not maintained, the cast iron grate may expand greatly when heated and damage the firebox.

Beam grate

The grate consists of a set of individual grate elements. On opposite sides of the installation site, grooves are made into which cast iron bars are placed. Such a system is not entirely convenient for cleaning grates, and today these designs are practically not found. However, it should be noted that when using an antique stove, this is an acceptable option for installing a grate.

Basket

The basket is the same lattice, only with high sides. This type of grate was used in open fireboxes, but now such equipment is practically not used

Mobile grid

The movable system allows you to avoid manual control of the grate. Automated long-burning furnaces are equipped with designs of this type.

Grate - grate

Without grate stoves for baths

OVEN FOR BATH SERIES “DRY”

Sauna stoves “Sukhovey” belong to the group of metal stoves made in a bent-welded manner. The furnace body can be made of black carbon steel ST-3, 4-6 mm thick, or heat-resistant stainless steel, 2 mm thick. All stoves have a pre-furnace tunnel for the possibility of firing from the dressing room, which completely eliminates the possibility of smoke entering the bathhouse. All Sukhovey stoves are lined with special casings that add aesthetics to the stove, increase heat transfer, create proper air circulation in the bathhouse - from floor to ceiling, and protect against burns. The entire structure of the stove is covered with heat-resistant enamel that can withstand temperatures up to 600 0C. The casing of the stoves can be made of mirror stainless steel, giving the stove a delightful appearance for life. “Sukhovey” stoves can operate in the “Finnish sauna” (dry steam), “Russian bath” (wet steam) mode.

Sauna stoves “Sukhovey” PS series are stoves made in the best traditions of the Russian bath. The internal design of the furnace firebox includes a cast iron grate and an ash pan. The basic model of this series is the PS-1 oven, which is simple and easy to use. Takes up little space. Ideal for a bathhouse with a volume of 16 m3. Model PS-1-B is an analogue of PS-1, but in its design it has a 5-liter tank for circulating running water and heating it from the furnace firebox. This model is suitable for those people who would like to organize a shower in their bathhouse. PS-3-40 is a stove equipped with a built-in tank for heating water with a capacity of 40 liters. The tank is located at the rear wall of the furnace firebox, which ensures rapid heating of the water. These models are also designed for baths with a volume of 16 m3. PS-4 is an analogue of PS-1, but has a much larger size and therefore is used for heating baths up to 25 m3. For all PS stoves, the approximate bath heating time is 40-90 minutes.

When developing the design of the stove, we achieved maximum heat transfer from burning wood to the steam room. This was achieved through the development of the surface of the furnace walls. The total surface area of the heat transfer walls of the PSN furnace is 228 dm 3. And not only this - the understanding that in the process of a chemical reaction of fuel combustion, 60.70% of the total heat release occurs due to radiant energy, 15.20 - transfer by gas flow, 10.15 - heat transfer. Knowledge of all this forced us to design the furnace firebox in such a way as to make maximum use of the above properties of the combustion reaction.

There is a misconception that a stove without a grate is not a stove. This is not entirely true. Bulleryan grateless stoves have been known all over the world for decades. From our experience: the PSN “Sukhovey” sauna stove can be heated 15-20 times, based on one steaming procedure per week - that’s 15-20 weeks, i.e. approximately once every six months there is a need to clean the firebox from ash. This has been tested and proven. Since so little ash remains in the firebox, it means that all the fuel burns out 100% and only twice a year you face the unpleasant operation of cleaning the stove. RATE. Do you want a grate?! Please - in PS ovens.

What does two modes mean? We add firewood, open the air supply damper completely, you can even open the oven door slightly. Depending on the volume of the bath, we heat the steam room in 15.40 minutes to the required temperature. After this, experimentally, depending on the volume and the set temperature, we limit the air supply to the furnace with a damper, thus activating the gas generation mode. And we steamed for 2.4 hours without paying attention to the stove - it automatically maintains the temperature in the bathhouse.

The controlled process of fuel combustion, through a gate in the door of the combustion tunnel, in combination with intensive heat extraction from the stove body, makes it possible to heat the bathhouse at lower temperatures in the firebox compared to conventional stoves. This dramatically reduces wood consumption, reduces the burning of oxygen in the room and increases the service life of the stove. The system of passages inside the housing ensures uniform heating of its walls.

PSN “Sukhovey” stoves are produced with a firebox made of St3 steel with a thickness of 4.6 mm, with a firebox made of stainless heat-resistant steel.

Sauna stove “Sukhovey” PSN-0

Small, grateless sauna stove. The volume of the heated steam room is up to 8 cubic meters. m.

The oven has a compartment for storing stones with a capacity of 25 kg.

How to choose a grate and install it yourself

The choice of grate depends on several reasons:

- Type of fuel;

- size of the firebox opening;

- furnace operating mode.

For example, if the stove is heated with wood, then the size of the firebox opening is 350×260 mm, the operating mode is year-round. The most suitable option would be a factory-made grate with a rectangular configuration with sides of 300 and 252 mm, made of cast iron. It will be very easy to install the grate with your own hands.

Drawing conclusions

The optimal choice of grate for a fireplace or potbelly stove is cast iron, as it is durable and has a large margin of safety. Another advantage is the possibility of installation in metal and brick ovens . The main criterion when choosing a grate type is the area of the gaps and the mass of the fuel to be installed .

Installation of monolithic models is somewhat simpler, while stacked models are the best choice for gratings with non-standard dimensions. When installing, be sure to leave gaps for the possibility of metal expansion .

Similar articles:

Adhesive for stoves and fireplaces Doors for stoves and fireplaces

The use of heat-resistant adhesive for lining fireplaces and stoves Cast iron hobs for stoves

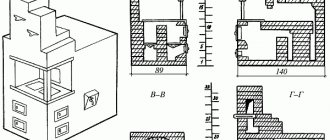

Due to the fact that many works on cars, and others, are delayed or postponed into winter, it was decided to build a potbelly stove, with one hand itching to cook. This scheme was taken as a basis.

How to make grate bars with your own hands

The grates that are permanently installed in the furnace eventually burn out and become unusable. If the opening for the grate was made individually, then you can only install a grate of a certain size. A simple way to make a grate with your own hands is to weld a grate frame from a steel angle. To do this you need to prepare tools and materials.

Tool

List of required tools:

- welding machine;

- angle machine;

- sander;

- drill;

- vice;

- hammer;

- tape measure and ruler;

- square;

- pencil.

Materials

- corner 40×40×2840 mm;

- steel strip 100×40 mm.

Step-by-step instructions for making a grate

Before you make grate bars with your own hands, you need to clarify the initial data. The firebox opening subframe is made from a 50×50 mm corner with an internal perimeter of 265×335 mm. Therefore, the grate frame should be made with dimensions of 260x330 mm along the outer perimeter. Having prepared tools and materials, the following work is carried out:

- Using a corner machine, a corner 1180 mm long is cut.

- The side of the corner 40x40 mm is successively marked with a pencil into segments: 260, 330, 260 and 330 mm.

- Perpendicular lines are drawn in marking areas. From the top point, lay 20 mm in both directions. The sides of the equilateral triangle will be the cut lines.

- Using a corner machine, triangular fragments of the corner are cut out.

- Alternately clamping the steel workpiece in a vice, bend it into a frame with a hammer.

- The sides of the folds are connected by welding. The right angles of the frame are checked with a square.

- The remaining section of the corner is divided by a corner machine into 5 sections, each 322 mm long.

- The corners are welded into the frame with the feathers facing outward with 10 mm gaps between them.

- A grinder is used to remove all burrs and metal deposits after welding.

- A piece of strip is welded to one of the sides of the frame, having previously made a hole ø 6 mm in it with a drill. This is done so that when cleaning the grate it can be easily removed from the subframe.

- The finished grate is lowered into the subframe.

It is necessary to comply with safety regulations during work on assembling the grate. The master must have special clothing and shoes, especially for welding work.

The proposed manufacturing method is not suitable for everyone. You must have skills in handling welding equipment and power tools. As a last resort, a grate of this design can be ordered at any mechanic shop. It won't cost much, and the order will be completed quickly.

You can go another way. Instead of corners, cast iron grates 330 mm long are placed in the frame. To do this, appropriate grooves are made under the beam elements in the vertical corner of the frame. Despite the fact that the grate may initially seem difficult to implement, making it with your own hands is not difficult.

Author: geras, February 15, 2011 in General

Drying the oven

Drying a Russian stove lasts approximately 30 days. This requirement cannot be waived. If you decide to flood the stove without waiting for the allotted time to dry, then, most likely, cracks will appear in the seams, and no amount of putty will be able to repair the damage - you will have to redo everything.

Recommendations for properly drying the oven:

- After laying out the furnace, during the first 14 days, all valves and hatches must be opened for cleaning so that the entire structure can dry naturally. Alternatively, you can put a 200-watt incandescent lamp in the firebox and turn it on constantly so that the air in it can circulate freely.

- This is followed by 14 days of forced drying, during which the firebox door and cleanout hatches will need to be closed, only the dampers should remain open. During active drying, on the first and second days you need to burn 3-4 kg of wood. After this, every day you need to add another 1-1.5 kg of firewood.

- At the drying stage, before moving on to heating, keep an eye on the metal elements of the stove - if moisture stops condensing on them, this will indicate that the stove is almost completely dry.

- After another two weeks, you can try to heat the stove at full power. After a full day of heating, the next day all seams should be carefully checked for damage, especially near the firebox. The slightest cracks are not covered immediately, but at the end of the season.

- If the stove has not been heated for a long time, its startup should continue for 3-4 days.

- Sometimes a cooled stove at the beginning of the heating season does not want to flare up, or smokes. In this case, you need to open all the lower hatches for cleaning and put a lump of crumpled newspaper in each of them. A few minutes after setting the newspapers on fire, a draft should appear; the main thing is not to forget to close the cleaning hatches after that.

In conclusion

In this article we learned in detail how to make a Russian stove with your own hands. It turns out that this is not a difficult process, and anyone can handle it.