Many private houses and apartments are equipped with automatic and semi-automatic gas heating appliances. A boiler is a reliable assistant for heating a room in winter. Even if it was serviced before the heating season, there is still a possibility of it breaking down. Let's look at the reasons why a gas boiler goes out or doesn't light up and how to restore the boiler's functionality if it lights up and goes out.

Reasons for the lack of flame in boilers with automatic ignition and ways to eliminate them

The ignition unit is damaged

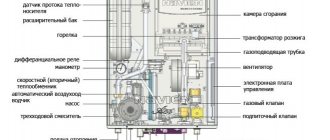

The photo shows the electrical part of the Ariston turbocharged boiler.

To determine the condition of the ignition unit, you can use an electronic tester in ohmmeter mode. The probes are connected to the output of the ignition electrode contacts (or to the electrodes themselves) located on the block. The unit is operational if the tester readings are within the range of 650 - 750 Ohms.

Checking the automatic ignition unit of the Ariston boiler.

In a damaged unit, the tester will detect an open circuit (1 will be displayed on the display) or a short circuit (0 will be displayed). The identified faulty part is replaced with a similar one.

Flame control electrode dirty

During the combustion of fuel, soot is formed, which gets on the working surface of the electrode and disrupts its proper operation. Clean the surface of the electrode with fine-grain sandpaper. If it doesn't help:

- move the temperature control knob to the heating off position;

- wait until the circulation pump and smoke exhauster turn off;

- on the instrument panel, press the switch off button;

- unplug from the socket and turn 180 degrees the plug of the device;

- insert the plug back into the socket;

- turn on the boiler.

Smooth shutdown of heating equipment extends its service life.

The operation of the flame control unit, due to its operating principle, depends on the phasing of the supply network (phase and zero connection points). Therefore, rephasing helps him restore the sensitivity of the gas ions.

Low mains voltage

The ignition unit and electronic gas valve may not work properly due to insufficient voltage in the network. To maintain a stable level of supply voltage, it is advisable to connect the boiler through a voltage stabilizer. It will provide protection for the electronic elements of the gas boiler during power surges.

Gas valve malfunction

The valve may be blocked by debris that has entered through the gas burners. In the device, the inductance coil designed to control the valve position may burn out. To check it, on a completely de-energized boiler, an ohmmeter is connected to the terminals. The coil is considered working when the reading is 80 - 90 Ohms.

Checking the gas valve coil.

To clean the gas regulator, the side part of the housing is unscrewed where the valve is located. Garbage is removed and his work area is cleaned.

Reassemble in reverse order. Often, to assemble a gas regulator, fasteners with a common head profile are used: an asterisk with a pin. To work with such hardware, you need to purchase a screwdriver with a blade of the required size and profile or sharpen a screwdriver with a flat tip.

Goals and objectives of SAUG

- Providing operational personnel with timely, reliable and sufficient information about the progress of the technological process and the condition of the main equipment

- Bringing the technological process of controlling the burner devices of the boiler unit into compliance with current regulatory documents

- Implementation of algorithms for automatically checking the tightness of gas equipment and igniting burner devices

- Coordination of operation algorithms of burner devices

Reasons for the lack of spark and flame in boilers with semi-automatic ignition - methods for eliminating them

Most of these models are equipped with Eurosit 630 automatic transmission.

Photo of the Eurosit 630 automation.

One of the reasons why a gas boiler with automatic “Eurosit 630” does not light up or goes out may be:

The piezo element is faulty

The piezoelectric element is a reliable part of the gas boiler automation system and breaks down in rare cases. It is installed next to the coolant temperature control knob, but can be mounted separately.

To check the functionality, it is enough to disconnect the wire along which the generated voltage moves from the electrode and bring it to the valve body at a distance of 4-8 mm.

Piezoelectric element wire disconnected from the electrode.

Press the piezoelectric element's start button several times. If a spark appears between the wire and the housing, it means that the generator is working and you should pay attention to the electrode itself, the ceramic housing of which must be dry and intact.

The electrode mounting nut should only be tightened by hand.

The emergency electrical circuit is broken

The emergency protection system for a gas boiler consists of:

- connecting wires;

- bimetallic sensors installed in the chimney and heating supply line, triggered at a temperature of 75-85 degrees Celsius;

Traction sensor

Definition

The autonomous operation of the gas boiler is carried out thanks to an electronic control system. It provides control using sensors, collecting technical indicators from different parts of the structure. If these indicators deviate from the norm, the control system changes the boiler operating mode or stops its operation.

A gas boiler draft sensor is a monitoring device that determines the presence and degree of draft in the chimney, and also transmits the corresponding signals to the electronic boiler control system.

It is the main device that protects the health and lives of people from the accumulation of carbon dioxide indoors.

What is it needed for

- The main functions of the draft sensor are to determine the draft force and completeness of gas combustion, as well as ensure safety during operation of the gas boiler by sending a signal to the control system about insufficient draft.

- If the process of removing carbon monoxide is disrupted, it accumulates in the room, which negatively affects human health, and, with a large volume of accumulated combustion products, poses a serious threat to human life.

- The draft sensor detects and prevents incorrect operation of heating equipment.

Where is it located?

Installing a draft sensor in gas boilers is a prerequisite for their operation. This is approved by the relevant legislative act.

As a rule, the installation location of the sensor is the smoke hood or a section of the boiler body near the ventilation duct.

The draft sensor is not installed by the manufacturer directly into the flue or is separated from it by a special thermal insulating material. This type of installation eliminates overheating of the draft sensor due to direct contact with a hot surface.

The draft sensor, like the chimney, requires periodic inspection and cleaning.

Device and principle of operation

The main principle of operation of a gas boiler draft sensor is the closing and opening of contacts.

It works according to the laws of physics, thereby controlling the temperature of the burned fuel. When the temperature indicator shifts into an unacceptable zone, the draft sensor transmits a corresponding signal to the electronic control unit of the boiler.

The type of sensor directly depends on the type and design of the gas boiler in which it is installed.

Boiler with natural draft and open combustion chamber

The main element is a plate consisting of two metals that have different deformation characteristics due to heating, as well as two contacts that are brought together and separated by these plates. As a rule, one of these plates is fixedly fixed to the sensor body, and the second is deformed due to thermal effects.

The sensor must match the fuel type. If the boiler operates on compressed natural gas, the sensor must operate in the temperature range from 95 to 950 °C, if on liquefied gas - from 75 to 1500 °C.

If the traction force becomes less, burnt gases accumulate. Due to this malfunction, the temperature of the measuring device increases. The bimetallic plate opens the contacts and the gas supply to the burner stops, that is, the boiler control unit performs an emergency shutdown.

Work will resume when the sensor cools down and its temperature drops within the appropriate range. This means that it also acts as a thermostat.

With forced draft and closed combustion chamber

In this case, the draft sensor has a pneumatic relay design with a very sensitive membrane. The blowing device creates strong draft and movement of burnt gases. Under their influence, the membrane is deformed and closes the sensor contacts. At this time, the control unit detects normal operation of the boiler with sufficient draft.

But, with insufficient traction, there is not enough force to displace the membrane and it returns to its original position. The contacts open and the heating device stops operating.

With condensing heating type

The sensors, as on boilers with natural draft, operate on the principle of deforming a bimetallic plate, but are set by the manufacturer to a lower temperature regime.

When and why it works

There are a number of reasons why the draft in a gas boiler is disrupted and the sensor is triggered:

- improper design of heating equipment;

The reason that you first need to pay attention to. It implies an incorrect design of the chimney, the presence of bends, or poor-quality installation.

Gas boilers leave much less soot, unlike solid fuel boilers. Despite this, over a longer period of time, soot tends to accumulate in gas boilers, which is the reason for poor chimney permeability.

The next reason for a clogged chimney can be foreign objects, such as leaves, tree branches, and flying debris.

It is extremely rare for animals to get into the chimney. Often these are birds that make nests on the chimney during the non-heating period or during the absence of people and the boiler has not been working for a long time.

The chimney requires periodic inspection and, depending on the degree of contamination, mechanical cleaning.

Moscow is a city of frequent changes in weather conditions.

The cause of shutdowns may be dense fog, heavy precipitation, or simply high humidity. This creates high atmospheric pressure, which is an obstacle to air exchange.

Strong winds also create high pressure in the atmosphere. It can harm natural draft and contribute to the reverse movement of combustion products (backdraft).

Bad weather conditions can only harm the operation of boilers with natural draft and an open combustion chamber.

It is advisable to install a protective cap on the chimney. Its name is traction stabilizer.

It prevents wind from blowing into the air duct and prevents the burner from extinguishing.

Smoke removal requires continuous movement of air masses. An air lock in the chimney can interfere with air exchange and cause combustion products to flow back.

An air lock occurs due to poor-quality thermal insulation of the chimney and a large temperature difference in its lower and upper parts. At the top it is usually cold, heavier and thicker.

- insufficient height and incorrect installation location of the chimney;

It depends on the distance of installation of the pipe from the highest point of the roof - the ridge of the roof. The ideal location is the middle of the roof side and the height above the ridge is about 50 cm.

- Unstable voltage level in the electrical circuit.

Power surges can negatively affect the operation of all electronic components of heating equipment.

If the sensor is triggered and the boiler is turned off, it is not recommended to force it to start again. This will damage the heating equipment and increase the danger to human health and life. In such cases, diagnostics, identification and elimination of the causes of the malfunction are necessary.

Ignition operating principle

Electric ignitions, which are equipped with most modern models of gas boilers, include the following elements: diode, resistor, capacitor, transformer, spark plug, switch.

This convenient and practical invention facilitates the operation of the unit, speeding up its activation and configuration. With the help of a compact device, you can ignite a flame in a burner not only quickly, but also safely, without the use of matches and lighters, which tend to run out and deteriorate. The flame appears immediately after pressing a button or turning a lever.

It is customary to distinguish between several types of electric ignitions for gas boilers - mechanical, automatic and semi-automatic. If the unit is equipped with mechanical ignition, to turn it on you need not only to activate the burner by turning the switch, but also to press a special button. The device will generate a spark and ignite the flame.

If the electric ignition is automatic, then the equipment turns on when you turn the handle - there is no need to use additional devices.

To be able to use automatic ignition, the heat-generating device must be connected to the network (a grounded socket must be nearby). If the electric ignition of a gas boiler fails, you should call a heating equipment repairman to your home.

Types of temperature sensors for gas

Thermocouples of gas stoves differ in the alloy of conductors and the type of connection to the valve. And the main thing here is that each manufacturer of gas-powered equipment uses its own versions of electromagnets with different connection connectors.

We recommend: Open type heating system: open heating system with circulation pump and expansion tank, diagram

In most cases, it is impossible to move the thermocouple gas control sensor from one tile to another.

The thermocouple must correspond to the model of the gas stove; installing a “left” control device is prohibited for safety reasons

The following alloys and metals are used to create thermocouples:

- constantan + chromel;

- copper + constantan;

- copper+copel;

- nisil + nichrosil;

- alumel+chromel;

- constantan+iron;

- chromel+copel;

- platinum+platinum;

- tungsten+rhenium.

The accuracy of the device and its operating temperature range depend on the alloys used. For example, a chromel-alumel thermocouple is designed to operate at 0–1100 0C, an iron-constant thermocouple at 0–700 0C, and a platinum-platinum-rhodium thermocouple can withstand heating up to +1700 0C.

Household gas stoves usually use thermocouple sensors made of alumel and chromel or constantan and iron. They are inexpensive and quite suitable for the temperature conditions of a gas cooktop.

Why the ignition may not work

Electric ignition is considered one of the most vulnerable elements of a gas boiler, since it is the one that most often fails than other components. The causes of failure may be errors made during operation of the device, wear of parts or mechanical damage.

Having discovered that the ignition is not working, first of all you need to make sure that it is connected to the electrical network and that there is voltage in it.

If everything is fine with the power supply, but the device still does not function, the reason may be a faulty power supply or button, or a damaged wire. To diagnose a breakdown, you will need a tester; it allows you to check for conductivity.

Electric ignition of a gas boiler

Unlike piezo ignition, electric ignition is part of an automatic control system for gas equipment. The user does not need to press any button. The boiler starts up automatically. Agree, it’s very convenient. Another advantage of this type of ignition is real energy savings.

Gas boiler CELTIC (Korea) with a smooth electric ignition system and a flame presence control function.

In other systems, the igniter must continuously maintain the flame. In automatic systems with electric ignition there is no such need. But there are also disadvantages. If piezo ignition is completely autonomous, then electric ignition, in accordance with its name, requires a connection to electricity. And if there are problems with electricity at the place where the gas boiler is installed and there is no uninterruptible power supply system, it will not be possible to start the boiler equipment in any other way. We'll have to wait until the light comes on. However, there is no need to worry about safety. If you turn off the electricity, protection is triggered, blocking access to energy. When electricity appears, the electric ignition is activated automatically, restarting the heating system.

How to fix the ignition yourself

Self-repair of household appliances or their components is a rather risky undertaking, since the likelihood of aggravating the problem is quite high. It is very difficult to repair the electric ignition of a gas boiler without special knowledge and skills. The device may fail due to contact with water or grease, power surges, or neglect.

The main sign of a device malfunction is the absence of a spark. If there is a spark, but the flame cannot be ignited, it is necessary to clean the contact areas of the burner and candle. If the electric ignition unit is broken, you should check the current-carrying paths and winding resistance. When repairing the ignition, new components may be needed.

Applicable igniters

Used igniters for a gas boiler:

- Manual ignition devices, without fire adjustment. They look like tubes with holes along the axis (also called “running fire” tubes).

- Electric ignition devices, without fire adjustment. Here, almost the entire mass of the mixture of gas and air moves from the mixer to the mouth of the igniter. The remaining part of the mixture moves from the mixer to the ignition chamber, in which it begins to burn from a spark plug with a voltage of 10 kV.

- Devices with electric ignition and fire control. These are ignition-protective devices that are needed for automated ignition or remote ignition of gas or oil burners. Equipped with a control element with a sensor that monitors the presence of a torch in the furnace.

An electric igniter or pilot control burner is also used.

Diagnostics at the service center

Repair of electric ignition of a gas boiler is included in the list of services of many service centers specializing in the maintenance of household appliances and heating equipment. By contacting qualified specialists, you can count on the fact that device malfunctions will be eliminated as quickly as possible. Reliable service centers that value their own reputation provide customers with a long-term guarantee for equipment repairs.

To determine the cause of a malfunction in the electric ignition of a gas boiler, technicians use modern diagnostic devices. During repairs, specialists use only high-quality original components. In addition, the service center offers to call a technician to your home. This service eliminates the need to deliver a large unit to the workshop yourself.

Repairing a gas boiler may involve replacing the ignition unit, restoring the control unit, eliminating leaks, or installing a new tap. An experienced specialist will be happy to answer all the client’s questions regarding the rules for operating the equipment, and will also tell you how to avoid breakdowns in the future. Service centers offer advice or order a particular service at any time of the day. This can be done by phone or through the website.

Hello, dear readers. What to do if the piezoelectric element in the gas water heater does not work? In what situations can you solve a dilemma with your own efforts? When is it necessary to contact specialists? And how to fix the problem in Amina, Zanussi cash advance businesses and other brands?

This material examines the reasons for the failure of a piezoelectric element in a gas apparatus. Cases with models of different brands are reflected. Methods for solving this problem are provided.

Types of gas burners

For a long time, only simple, non-automated boilers without complex electronics were presented on the heating equipment market in the country. They required the installation of full-fledged chimneys, and placed them in well-ventilated rooms. Today there are devices on sale that operate in almost any conditions. Traditional models are being implemented alongside them.

There are the following types of burners:

- atmospheric;

- closed type;

- with a burning igniter;

- with electronic ignition.

Methods for troubleshooting geysers

Geyser "Vector" is one of the most popular in Russia. This is evidenced by sales statistics.

When the piezoelectric element does not work in the Vector gas water heater, a spark does not appear and the burner does not ignite. The reasons for the problems are:

- Lack of draft in the chimney. It could simply be clogged and need to be cleaned. There is a special sensor in the column that monitors the presence of traction. If it is not there, it will not start working. If you cannot do this yourself, it is better to call a special service.

- No water pressure. If the water pressure is very good, then it affects the membrane, which presses on the valve. Very low pressure may indicate problems with the membrane or that the filter is clogged.

Solution: You need to disassemble the filter and wash it under water, and it is best to replace the membrane as it becomes damaged over time. You can do this yourself.

- The nutrient element is not working. Ignition is done using batteries, without which there will be no current to create a spark. You need to remove the panel, then take out the battery pack, pull them out and insert new ones.

Elements of safety and comfortable operation

The group of automatic devices for boilers includes many elements that can be divided into two large groups: mechanisms that ensure safe operation, and devices that facilitate comfortable operation of the boiler.

The following parts are responsible for safe operation:

- thermostat;

- draft and flame control sensors;

- safety valve.

The flame control sensor consists of a thermocouple and an electromagnetic gas valve that shuts off or turns on the gas supply.

The flame temperature regulator ( thermostat ) maintains the required temperature of the coolant and also provides protection against overheating. This module turns the boiler on or off as soon as the coolant reaches a critical point (maximum or minimum).

The draft control module stops gas supply to the burner as soon as the location of the bimetallic plate changes due to increased temperature (it bends when heated, blocking the pipe through which the fuel is supplied).

We examined temperature, draft, pressure and flame sensors in more detail in this article.

The safety valve is used to regulate, distribute and shut off the gas flow

In a heating system, a safety valve is an integral component of pipeline fittings, which is important in controlling the volume of coolant involved in the circuit.

The hole in the valve through which gaseous fuel moves is called the seat. To turn off the device, you need to close it with a disk or piston.

Depending on the number of operating positions, gas valves can be one-, two- and three-stage, as well as modeling:

- Single-stage devices have only two operating positions: on/off.

- The two-stage device is equipped with one input and two outputs, and the valve opens when it is turned to an intermediate position, due to which the switching occurs more smoothly.

- A three-stage device is equipped with boilers that have two power levels.

- Modulating valves are used to smoothly change the power rating of devices.

Automation, used for convenience, includes options that are usually performed by users of heating systems. These include auto-ignition of the burner, self-diagnosis, selection of the optimal operating mode, and others.

There is a spark, but no ignition

When this dilemma arises, the following factors appear:

- The valve responsible for the gas supply is closed. Measure - twist it all the way.

- Low water pressure. It may be not only in the main line, but also at the inlet section of the boiler, where the filter may become clogged.

- The water is slightly fixed annuity interest rate heated. Solution: cleaning the heat exchanger (HE). Fastenings on which plaque has accumulated can be cleaned using VD-40, and the radiator can be placed in a basin with a composition based on citric acid. Then heat on the stove for half an hour until the scale disappears completely.

- The burner is clogged. Sometimes a lot of soot and soot appear in the jets. You can get rid of it using a thin copper wire.

If the piezo did not work in the Electrolux geyser or other similar equipment, then you should periodically check it for gas leaks using a soap emulsion. If there are no bubbles, then everything is fine.

How does a "hot" alloy temperature sensor work in a flame?

The operating principle of a thermocouple is based on the physical phenomenon of thermoEMF. If you weld two conductors from different metals at one point and heat one of them and cool the other, a potential difference will appear at the ends.

In a thermocouple for a gas boiler, the outer surface of the junction head acts as a hot conductor, and the inner surface acts as a cold conductor. Heat is removed from it through a copper conductor. The temperature difference between outside and inside can reach several hundred degrees.

The voltage across the thermocouple when the gas burner is burning depends on the alloys and metals used in the junction. The most sensitive ones based on platinum group metals produce up to 50 mV for a long time. Sensors based on non-ferrous metals give 17-25 mV.

The temperature sensor is not immersed directly into the flame front. This cannot be done, since when the temperature sensor comes into contact with a hot gas flame, all parts will heat up to a high temperature, and the thermoEMF effect will disappear.

Therefore, they place the thermocouple at a distance of 3-4 cm from the igniter. This will ensure heating of the hot junction and normal cooling of the copper tube. Thermocouples are also installed in solid fuel heating boilers. For example, in the Lemax model the temperature sensor is installed above the grate.

Lights up and goes out immediately

The reasons for this problem are:

- Weak traction. The chimney needs cleaning. If there is poor ventilation in the kitchen, then you need to open the windows or install a ventilation valve on the window frame.

- The ignition button is pressed poorly. It needs to be held for 20 to 30 seconds.

- The sensor that removes combustion products does not work. This can be found out using a multimeter. If the sensor is working, there will be a sign on the screen indicating infinity.

- Mixing streams. You need to set the regulator to a constant normal temperature.

- High pressure in models with low power. Set water parameters as indicated in the instructions.

- Systematic switching off of the overheating sensor. Solution: replacing it.

- Adjust the igniter. Disconnect the electrode from the igniter so that the spark is in the central part of the burner. Inspect and test the tube connections for leaks.

If ignition is delayed, clean the burner. There is a high probability that soot and soot have accumulated in it. The problem may also lie in the microswitch.

How and in what cases can it be restored?

The thermocouple is designed in such a way that any damage or contamination can reduce the voltage it produces below a critical level. A very common cause of malfunction is carbon deposits or a layer of soot on its working (heated) part. To restore the thermocouple, just clean it with a soft brush or cotton wool and alcohol, while avoiding scratches and other damage. After cleaning, it is worth checking the voltage again following the instructions above.

We recommend: Which boiler is more profitable - gas or electric?

Oxidized contacts are also a common cause; they can be carefully treated with sandpaper. If the thermocouple has a deep black dent or hole due to burning, it is guaranteed to need to be replaced.

The advantage of domestic speakers

There are many types of faults, so it is easier to find domestically produced parts. Therefore, speakers made in Russia, such as Neva, are in great demand.

And the newer model “Neva 4511” consumes even less gas and is completely silent.

A gas water heater called “Oasis” is in demand, which can operate at low pressure and is protected from scale.

It is also equipped with a safety system that blocks operation if the column overheats.

Features of the autoblock device

As a rule, manufacturers use special control units, which include the devices listed above. Despite their external differences, they all act on the basis of the same principles. To get acquainted with the best models and manufacturers of automation, follow this link.

The most widely used products are the Italian brand EuroSIT. The most popular model is Eurosit 630, which is characterized by easy functionality, compatibility with designs from various manufacturers, reliability and durability.

Using Eurosit 630 as an example, we will consider in detail the design of the automatic block.

Detailed design of the automatic control unit Eurosit 630, which is equipped with a significant part of modern gas boilers produced by different manufacturers

The device is a casing containing all structural components (spring valve, pressure regulator module, shut-off valve), which makes its installation much easier.

A pipe is connected to the body through which gas is supplied, as well as cables from sensors and other devices.

In addition to the Eurosit 630 block, there are also other models on the market: SABC, “Vakula” SIT, Dungs, Honneywell, which include sets of valves, pressure stabilizers, filters, temperature regulators

There are some difficulties when installing and setting up this device, but once you get used to it, you can practically not worry about the operation of the gas boiler.

How to set up the automatic heating device?

The adjustment involves setting up the EUROSIT 630 controller, which maintains the temperature regime of the liquid in the circuit, and in a critical situation blocks the gas supply.

Before setting up the automation of various models of gas boilers, you should install the equipment, strictly following the drawing. In this case, it is important to check the complete set of device parts, which must match those stated in the instructions.

The adjustment is carried out using a knob that allows you to control the transfer of the boiler to three positions:

- shutdown;

- ignition;

- setting the temperature mode (from 1 to 7).

To turn on the ignition device, the lever must be moved to the second position, placing it opposite the icon with the image of a spark.

When pressed, the piezo ignition button will be activated, causing the pilot burner to light. In this case, the lever must be held in this position for 10-30 seconds. After releasing the button, the igniter should stop working.

When the flame is ignited, the thermocouple heats up, due to which an EMF (25 mV) begins to be generated in it. This leads to the formation of a chain, the links of which are the sensor and the solenoid valve

When the lever is pressed, the solenoid valve opens and gas is supplied to the igniter (it should be left open even after the handle is released).

In this case, the thermocouple must provide protection against the return of fire. The sensors, which are elements of the circuit, are closed in the working position. After receiving the signal, they open, which causes the unit to shut down.

Problems when turning on the ignition device

If you have difficulty turning on the device, you can use the following instructions. First of all, you need to stock up on the necessary equipment, namely open-end wrenches, a screwdriver, a multimeter, pliers, and alcohol for cleaning parts.

Carefully remove the terminals of the device: they are shorted together, then tightened with pliers. To determine the cause of the malfunction, you need to turn on the igniter.

If ignition occurs normally, most likely there is a breakdown in the draft sensor. In this case, it is necessary to unscrew this element (to prevent overheating, it is surrounded by paronite gaskets).

When externally examining the device, you should pay attention to its contacts, which must be securely fixed to the body and not have any traces of oxidation on the surface. The temperature in the open state should be 75 °C

After this, using a tester you need to measure the resistance, the value of which should be 1-2 ohms. If a malfunction is detected, this part must be replaced. If the element functions normally, it is enough to wipe it with alcohol, after which the device is reinstalled.

To identify problems in the thermocouple traction breaker, the terminals are removed, after which the resistance is checked, the value of which should be equal to 3.

If the obtained value does not correspond to the optimal value, you need to use wrench No. 9 to unscrew the nut that secures the thermocouple to the traction breaker, after which use wrench No. 12 to unscrew the latter half a turn.

After this, you need to remove the plastic insert with contacts, then the part is completely unscrewed. The thermocouple is checked: it should be connected to the solenoid valve and secured with key No. 9. If after this ignition is still not possible, the problem lies in this part.

To resolve the issue, the nut securing the thermocouple to the igniter is unscrewed with a No. 10 wrench, after which the element is installed in the desired position.

To evaluate the result of the work, you need to measure the EMF (it should be equal to 18 mV), then clean the thermocouple contact and the elements of the traction breaker with alcohol. The final stage is assembling the device.

Troubleshooting other problems with automation

A common reason for lack of ignition is contamination of the insulator along which the wire leading into the combustion chamber is laid. Such a malfunction can be easily eliminated by wiping this part with a soft cloth. If it is heavily soiled, it can be moistened with solvent and then wiped dry.

Soot deposits that form inside the combustion chamber can also prevent the pilot from turning on. This defect can be easily eliminated by tapping the tube supplying gas to the burner.

After a break in operation, it is recommended to check the condition of the pipes. If not used, spiders may build nests in them or other insects may get in, which may impede gas flow.

High-tech models of gas boilers are equipped with sophisticated electronics. As a rule, information about problems is displayed on the display in the form of a code with a specific error

Poor water heating may indicate too large deposits on the walls of the heat exchanger. To solve the problem, it is advisable to rinse the circuit with hot water with the addition of a mineral solvent.

If this does not help, it is better to contact a specialist, as the cause may be damage to the electronics or the flow sensor.

In boilers that are too powerful, a “clocking” effect may occur, which manifests itself in too frequent switching on caused by intense heating of the gas. To correct the situation, it is recommended to reduce the fuel consumption supplied to the burners.

In mechanical devices, this can be achieved by rotating the adjustment lever on the gas valve, and in electronic models it is enough to use the control panel, where the corresponding operating parameter is set.

To extend the life of the equipment and gas boiler, it is recommended to carry out regular inspection and maintenance. We discussed how to perform maintenance correctly in the next article.