A convector is a device used to heat residential premises. The design involves the use of its own heating element to heat the room.

This allows you to bypass the mediation of any coolant, making the heating element for the convector the central part of the unit.

That is why systems without the use of water or oil as an intermediary are placed in a separate class.

The modern convector assembly scheme allows for efficient operation at a fairly low heater temperature.

Types of heating elements

An electric convector (there are also gas and water) is the most popular heating device on the market today. It has earned its reputation not only for its ease of use, but also for its reliability. This equipment can provide comfortable conditions both in the living room and in public areas. Experts consider the main feature of the design to be the absence of intermediaries for heat transfer.

A modern convector uses one of three types of heating elements.

He can be:

- needle-shaped, ribbon-shaped, stick-type heater;

- a tubular-type electric heater with aluminum fins, abbreviated as heating elements;

- monolithic type.

Each type has its own characteristics and disadvantages. The decision about which one to choose must be made based on the characteristics of the heated room.

Diagnostics of heating elements for electric convectors

In general, a convection heater is a fairly simple device with a small number of components built inside. The basis of the device is one or more heating elements capable of generating heat. If they malfunction, the convector stops heating the room. You can make sure that it is the heater that has failed only by testing it.

As a rule, modern convectors are equipped with closed-type heaters. Their open structures are extremely rare. In the event of a breakdown, a closed heating element is replaced - it cannot be repaired. It is best to check its performance using the simplest multimeter (tester) turned on in resistance measurement mode.

The resistance of the heating element is measured as follows:

The heating element is operational if the measured resistance value does not exceed several tens of Ohms . In cases where the display shows “0” (short circuit) or the “infinity” icon (break), we can conclude that the heating element is faulty and must be replaced.

Important! Heating elements for convectors belong to the category of non-repairable units. They can be replaced by anyone who knows how to hold the simplest tools in their hands. The main thing is to find and select a heater model that is similar or suitable in terms of technical parameters, overall and connection dimensions.

So, when choosing a convector, you should first of all find out the type of heating element used. This determines in which room it can be used for its intended purpose. And during operation, you must follow the rules and recommendations indicated by the manufacturer of the equipment in the user manual. This is necessary so that the electric heater lasts as long as possible, since it cannot be repaired.

Needle type heating elements

The design of such a heater consists of a dielectric plate densely stitched with nichrome wire. Due to the manufacturing features, a needle-shaped heating element for a convector is also called a stitch or stitch. The metal thread forms numerous loops on both sides of the base. It is coated with a special heat-resistant varnish to insulate it from oxygen, so it lasts quite a long time.

The total heating surface of the stitch element is large enough to heat the mass of air passing through it. Most often, manufacturers install 2 needle elements.

Among the advantages of a needle heater are:

- almost instantaneous achievement of a working state: thin threads heat up to a high temperature (more than +250°C) in a few seconds and immediately begin to heat the air passing through them;

- Stitch elements are considered the most economical and inexpensive;

- The heating device operates silently.

The main disadvantage of an element of this design is its vulnerability to moisture. Convectors with stick heaters are not recommended to be installed in a room with high humidity (bathroom, toilet, etc.).

Recommendations for selection

Regardless of the type of heating element, the convector must be installed where air can circulate freely. If you force the radiator with furniture and curtains, the efficiency will noticeably decrease. It is enough to maintain a distance of 0.5 m.

If the choice is made on an inexpensive needle heating element, then it is important to exclude the accumulation of dust. It is also necessary to monitor the relative humidity, since an open filament helps dry out the air. The tubular element is not always sufficiently protected from moisture to heat the kitchen or plumbing room.

Source

Tubular type heating elements

Tubular heating elements for convectors (heating elements) are more protected from external influences than the previous type. Their nichrome thread is enclosed in a metal tube filled with loose dielectric. Quartz sand is most often used as backfill. When an electric current passes through a nickel-chromium alloy, the wire or spiral heats up to + 200°C or slightly higher, gradually heating the filler. The process of heating the heating element to operating temperature takes longer than that of a needle heater.

To increase the heat transfer surface of a tubular heater, manufacturers fin the heating element: they attach spiral or flat metal ribs to a tube with a heating coil, which also become very hot during operation. Each manufacturer develops its own heat-exchange fin design, but the air heating efficiency is approximately the same for all similar designs.

The advantage of a convection heater with heating elements is its complete safety and reliability. The tube with the heating filament inside is closed at both ends with dielectric plugs, and the spiral inside the tube is reliably protected from moisture and water droplets. The relatively low heating temperature of the nichrome thread allows tubular heaters to last 1.5-2 times longer than the previous ones.

You can install a convector with tubular finned heat exchangers in any room. Heating elements for convectors are most often made in a splash-proof version. This is evidenced by the IP24 marking in the technical documentation for the product. But even a splash-proof device is not recommended to be placed closer than 60-100 cm to water sources (shower, tap or edge of the bathtub). Atlantic or Thermor convectors are most often made using heating elements.

Among the disadvantages, the high energy consumption of devices equipped with heating elements is noted. Such convectors also have a slightly higher price than the previous type. Powerful convectors tend to crack during operation or cooling due to uneven expansion of the metal.

The design and principle of operation of such a heater

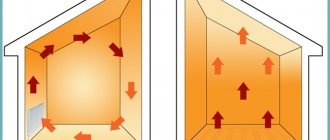

A simple device is the main feature of convector equipment. In fact, the design of these devices consists of two parts - the body and the heating element. At the bottom of the electric convector structure there are holes for drawing in cold air. In the upper part there are holes for releasing cold air.

One of the design elements of this device is the heating element, which is located at the bottom of the device. It processes the cold air entering the convector housing. After it heats up, it rushes upward. The outlet openings are located at a slight angle relative to the vertical in the electric convector. The heated air mass moves along a parabolic trajectory. As it cools, it sinks to the floor. Then the cycle repeats again.

The main advantage of an electric convector is that it distributes heated air evenly throughout the entire volume of the room. During operation, it does not make any noise , which is possible with

Monolithic heating elements

Monolithic heating elements are used for convectors with a degree of protection IP 24. They contain a nichrome filament filled with dielectric material. All the “filling” is packaged in a cast aluminum case with metal ribs.

During heating and cooling, each part of the monoblock increases and contracts in volume. This feature allows you to avoid friction and the development of microcracks. A good monolithic convector is silent, very reliable and durable. The monolithic body minimizes intermediate heat loss and also reduces heating of the fin structure.

Types and features of thermostats

The design of the electric convector includes a thermostat. In modern models it can be mechanically or electronically controlled. Devices with a mechanical thermostat are more affordable. However, its presence in the convector also brings certain inconveniences.

Among the most serious, we highlight the following:

- does not hold temperature well;

- during operation consumes large quantities of electricity;

- When the device operates, characteristic clicks occur - not only when turned on, but also when turned off. This can be annoying for the owner.

Compared to a mechanical thermostat, an electronic thermostat has many advantages:

- does not make noise during operation;

- the set temperature with minimal deviation - it does not exceed one tenth of a degree;

- reduces the energy consumption of the installation within its capabilities;

- “climate control” can be carried out remotely;

- has support for several operating modes.

Although heating devices equipped with an electronic thermostat are more expensive, their price tag is quite justified.

Which convector to choose

If we talk about which heater is better to choose, the answer will be ambiguous. With all the obvious advantages, each type has its own disadvantages. For example, the tubular element has the longest glow time. During active operation, it can make clicking sounds and squeaks caused by the expansion of the structure.

In turn, the monolithic element scares off most buyers due to its high cost. Not everyone is willing to overpay for a significant degree of protection and minimal heat loss.

The decision about which convector is more efficient should be made based on the characteristics of the heated room:

- If the room is not humid and the speed of air heating does not play a key role, a conventional heating element is best suited.

- However, if it is necessary to constantly maintain comfortable conditions in the room, it would be more correct to give preference to a monolithic element. An efficient convection system will allow you to save a little on electricity.

- You can also turn your attention to combined type models, such as an infrared heater with a convection function. This device combines heating through a heating element and an infrared element, which allows you to quickly warm up the room with little electrical energy consumption.

Experts advise paying attention not only to the heating element. Maximum operating power, spatial arrangement, mobility and ergonomics of the housing also make a significant contribution to efficiency. Carefully study the technical characteristics of the device, and you can easily choose the convector that suits you.

What is the convection process?

From a school physics course, everyone knows that when air is heated, its density decreases and it rushes upward. Cold layers of air, due to their gravity, easily displace it. This is how cyclones form in the atmosphere of our planet. Over individual areas of the surface, heated masses of air rush upward, and the vacated space is occupied by flows from cold areas.

This process also occurs in confined spaces, but on a much smaller scale. It's called convection. Convectors are designed to effectively manage it.