Thin and flat heating radiators are not only a space saver. Single-panel devices that are not equipped with convection fins emit heat to a greater extent by radiation rather than by convection, and therefore dry out the air to a much lesser extent and transfer dust masses. Such panels are great for children's rooms, kindergartens, schools, and for owners with an allergic reaction to dust.

The thickness of radiators classified as flat is from 46 to 80 mm; they can be used in conjunction with a narrow window sill, do not require the installation of screens and look harmonious in almost any interior. In addition, they collect less dust and are less traumatic. However, the price to pay for comfort is much lower heat transfer and efficiency, susceptibility to corrosion and vulnerability to water hammer.

Manufacturers of flat panel heating batteries

The domestic market mainly presents foreign products - products from Kermi, Zehnder and Buderus.

Kermi

Flat models are offered here in two variations - with a smooth (Plan series) or grooved (Profil series) front surface, painted in two layers using a cataphoretic method. The side and top grilles can be removed to clean the products from dust. German models are available in the following varieties:

- valve modifications ThermX2. Depending on the power, different types of control valves are introduced;

- ThermX2 Kompakt small flat batteries are universal, they are mainly used in low temperature conditions;

- The Kompakt Hygiene hygiene line has a double varnish coating; it is common in hospitals, as its protective layer and simple design allow the use of disinfectant solutions.

The products are sold in the high price segment and exhibit effective heat transfer.

Zehnder

The manufacturer from Germany, in addition to classic variations, offers lines with non-standard sizes, shapes, and raw materials. Models with printed mirrors, wood and stone front panels, and paintings are common. Vertical and horizontal devices with angular and radius designs are offered.

The Plano series has a discreet design; convective lamellas are built into the batteries. Nova Mirror - ultra-fashionable flat products with shallow depth and a built-in mirror, optimal for narrow spaces.

Buderus

One of the concern's specializations is the production of flat steel radiators with bottom (Logatrend VK-Profil series) and side connections (Logatrend K-Profil). The models attract with high efficiency and unsurpassed quality of welds. The package includes valves designed for 1- and 2-pipe systems. Manufacturer's warranty – from 5 years.

If we compare the price ranges of the products of the three companies, Buderus flat radiators are the most affordable, while the upper limit is observed in the Plano series of the Zehnder brand.

The huge variety of heating devices that are present on the modern heating equipment market often confuses consumers. After all, the question of which is better is tormented precisely when the eyes run wide. This article will discuss heating radiators - “flat”. Why is this topic so interesting nowadays? Judge for yourself.

- Firstly, the flat design of the heating device increases the free space in the room. Accordingly, it becomes possible to install a window sill of smaller width.

- Secondly, it reduces the dust collection plane.

- Thirdly, it is an unusual and attractive appearance.

But here the question arises: what about heat transfer? It is no secret that this indicator largely depends on the size of the heating battery. That’s right, the heat transfer rate decreases, but it’s not for nothing that manufacturers produce these devices, which means there is some kind of trick that maintains the radiator power at the required size. We will deal with all these questions here.

Parameters for choosing the right radiator for an apartment

All heating devices, depending on the material of manufacture and design features, are classified into several groups. Batteries are made from:

- cast iron;

- become;

- aluminum;

- bimetal.

Structurally, radiators are:

- panel;

- sectional;

- tubular;

- lamellar.

Threats of central heating in apartment buildings

When choosing a heating device, think about what factors speak in favor of one or another type of battery. The difference between an apartment and a private house is that the heating of the latter is autonomous. But central heating, which has a number of undeniable advantages, also poses threats, so when choosing a heater you should consider that:

- Water that travels through pipes for a long time contains impurities that cause corrosion of heating system elements (CO).

- Solid particles invariably get into liquids, which scratch pipes and batteries from the inside, and after a few years they wipe them to holes.

- Central heating often suffers from temperature changes, depending on weather conditions.

- And the biggest danger is pressure drops or water hammer. The reasons for this trouble are the sudden closing of the valve of the pumping station or the entry of air into the CO. Water hammer can cause a huge number of troubles, a small of which will be battery failure, but hot and far from clean water can ruin furnishings, flood the neighbors below, and even cause harm to people nearby.

Attention! According to the risks hidden in the heating system of apartment buildings, it is necessary to choose heating radiators that can withstand these threats

Atmosphere pressure

The battery pressure declared by the manufacturers must exceed the operating and test pressure in CO. Information about how many atmospheres the pressure is in your home is available from the management company.

The test pressure is one and a half times higher than the working pressure, so it is better to focus on it.

Reference. Five-story houses built in the 70s and 80s, Khrushchev buildings, have a test pressure of no more than 8 atmospheres, while in modern houses this figure is no less than 15.

Water hammer

The older the house and, accordingly, the CO pipes, the higher the likelihood of water hammer occurring.

Clicking, buzzing and other extraneous sounds indicate that the pressure in the pipes is “mischievous”. If they occur, contact your utility service.

But it is not always possible to protect yourself from such trouble. Therefore, if you notice extraneous noise in the pipes when replacing a heating radiator, choose one that can withstand sudden pressure surges in the system.

Coolant quality

The quality of water in CO is far from ideal, so radiators need to be able to withstand both chemical and physical attacks. Heaters must be made of neutral material or have a special coating inside.

The thickness of the battery walls is also important. Slag particles flowing through the pipes act like sandpaper and rub down each metal over time. The thicker the wall of the heating device, the longer it will last.

Heat dissipation

The main function of radiators is to heat the room. When choosing a battery for an apartment, take into account its heat transfer, which depends on the thickness of the walls, material of manufacture and design features. The higher the heat transfer, the warmer the house will be.

Appearance

In Soviet times, apartments had ugly cast-iron sectional radiators.

The owners went to great lengths to give them a pleasant appearance: they painted them, installed screens and covered them with curtains.

Now there is no need for this, since modern heating radiators can harmoniously complement the interior, the main thing is to choose them correctly.

Life time

Not the last parameter when choosing a heating radiator is the service life. It is clear that this depends not only on the quality of the battery, but also on the properties of CO. And yet, the longer the service life of a particular heater declared by the manufacturers, the longer it will last. This means that you don’t have to tinker with bulky devices every few years, invite specialists and pay for the purchase and installation of new heating devices.

Criterias of choice

Flat steel heating radiators are not installed in systems with natural coolant circulation, since a large amount of working fluid is needed here. Such batteries perform well in forced circulation circuits, but here it is necessary to correctly calculate the volume of the expansion tank and the performance of the circulation pump.

When choosing a model, it is necessary to take into account the height and thermal power. Low radiators are relevant for the characteristic height of the window sill (when it is not possible to install higher equipment). The lower the heating device, the more evenly the heat is distributed, creating a dense curtain.

Single-pipe wiring allows you to reduce installation costs, but here it is necessary to equip a bypass line. The shut-off valve will become a barrier to the coolant; it is necessary to ensure rational output of the device. With a single-pipe scheme, the most advantageous is a diagonal connection, when the coolant is supplied from the top left, and the outlet is organized from the bottom right.

The width of the radiator is selected so that it covers 50-75% of the same parameter of the window opening. Narrow models are not able to create a dense thermal curtain.

Technical specifications

Paying attention primarily to the appearance and cost of the radiator, however, do not forget that the technical and operational characteristics of the device should be in the foreground. Not every heating battery, both imported and domestic, will withstand operating conditions in existing domestic heating networks

The centralized heating system, which we inherited from the Soviet Union, is characterized by fluctuations in pressure and temperature, as well as poor quality of the coolant (water). The design temperature for a single-pipe open domestic system in high-rise buildings is 105 degrees Celsius, pressure is 10 atmospheres. However, these parameters sometimes go off scale when starting the heating system after the summer period, which leads to water hammer, which some heating devices from foreign manufacturers are not designed for.

Not every heating battery, both imported and domestically produced, will withstand operating conditions in existing domestic heating networks. The centralized heating system, which we inherited from the Soviet Union, is characterized by fluctuations in pressure and temperature, as well as poor quality of the coolant (water). The design temperature for a single-pipe open domestic system in high-rise buildings is 105 degrees Celsius, pressure is 10 atmospheres. However, these parameters sometimes go off scale when starting the heating system after the summer period, which leads to water hammer, which some heating devices from foreign manufacturers are not designed for.

It is necessary to pay attention to the permissible temperature and pressure of the coolant in the heating system, which are indicated in the passport of the heating device. Aluminum panel radiators with anodized coating allow operation in systems with high pressure and do not require paint coating

Aluminum panel radiators with anodized coating allow operation in systems with high pressure and do not require paint coating

Another fundamental parameter for a heating battery is its heat transfer. This characteristic affects the efficiency of heating the air in the room and depends on the material included in the design. It is well known that the heat transfer of steel is lower than that of aluminum, and copper is better than cast iron in this indicator. But relying on any one technical parameter will not be entirely correct. It is necessary to comprehensively evaluate all the pros and cons of each type of heating device in order to choose the best option.

Installation

A flat radiator is used for heating systems that have forced circulation of a coolant, that is, where circulation pumps are used.

The heating system using a flat battery is a closed structure and includes a membrane expansion tank. It looks something like this: the coolant, under the influence of the pump, flows through a direct pipeline, passes through the valve and then reaches the heat consumer, then passing through the air vent, it goes through the return pipeline to the membrane expansion tank. And from there the process repeats again.

Scheme of a closed heating system with flat radiators

If the coin cell battery installation uses an open system, the battery life will be significantly shorter. There is often no need to drain the water. Newly poured liquid always contains a high oxygen content, which will lead to corrosion on the radiator. It is not recommended to install thin devices in rooms with high air humidity, for example, in the bathroom. If all requirements and recommendations are followed, the risk of corrosion is minimal.

It is possible to install flat radiators with your own hands one after another, in this case the heat output will decrease by forty percent per meter, since the heat transfer through radiation after the second row will decrease. If they are installed in rows and equipped with plates on top, the result is a structure that looks like one device.

A flat battery is a closed, flat-type device through which a coolant moves.

When the battery device is used for a water heating system with plastic or metal pipes, an anti-diffusion barrier must be installed. It will protect against exposure to oxygen masses.

Before purchasing flat batteries, check the specifications of the flat battery device to see if they are suitable for your building. For example, when a building uses a gas boiler with a safety valve, the liquid pressure should be a maximum of 3.0 bar.

Pay attention to the temperature of the water in the pipes. The one who decides to change the radiators, throw out the outdated ones and install new ones argues incorrectly.

Before purchasing new radiators for heating, you need to make accurate calculations, take into account the characteristics of the building, the design of the installed or existing system, the technical characteristics of the device, and entrust the installation work to specialists

The one who decides to change the radiators, throw out the outdated ones and install new ones argues incorrectly. Before purchasing new radiators for heating, you need to make accurate calculations, take into account the characteristics of the building, the design of the installed or existing system, the technical characteristics of the device, and entrust the installation work to specialists.

Installation process

Options for connecting radiators - side, bottom.

Flat modifications are installed only in closed heating systems, where the movement of the coolant is regulated by special pumps, and the system itself contains an expansion tank.

Coolant movement technology:

- By means of a pump, thermal energy moves along the pipeline.

- It goes through the valve.

- Reaches to the end consumer.

- Moves along the air vent.

- Then towards the return pipeline until it reaches the expansion tank with a membrane.

- Then the movement process is repeated.

When such samples are connected to an open heating system, their service life is significantly reduced. This is explained by corrosive processes affecting radiators when oxygen enters the battery, which is formed due to frequent drainage of liquid in the system.

In rooms with high humidity levels, the installation of flat radiators is not recommended.

Advantages and disadvantages

Flat radiators have the following advantages:

- modern design, attractive performance. The equipment can complement most interior designs; if you want to disguise the device, you can use a special decorative screen;

- the devices do not require specific care; it is enough to wipe them with a damp cloth from time to time;

- radiators are supplied in such a configuration that there is no need for additional expenses;

- technical characteristics help save coolant;

- the compact device can be hidden in a niche or opening;

- possibility of DIY installation;

- The batteries heat the room efficiently.

Flaws:

- the need for strict compliance with the operating conditions recommended by the manufacturer, the vulnerability of steel models to corrosion;

- instability to water hammer. To ensure safe use, you need to install a pressure reducer or its equivalent into the system.

Another significant disadvantage is the relative fragility of the equipment, so it is important to organize careful transportation of products

Advantages and disadvantages

Corrosion on radiators is formed in the central heating system due to the high level of oxygen in the water.

Thin radiators for heating owe their popularity and demand to the following characteristics:

- aesthetic appearance;

- compactness;

- ease of care and maintenance;

- low dust accumulation ability;

- easy installation;

- light weight;

- no additional purchase of parts is required, the original package is complete;

- high heat transfer;

- energy saving.

Such products are not without their disadvantages:

- susceptibility to corrosion;

- vulnerability to water hammer;

- fragility and vulnerability to damage during transportation.

The resistance of batteries to water hammer can be increased by installing a pressure reducer.

How to make a flat screen for a battery out of wood, work sequence

So, in order to make a battery screen with your own hands from wood, you will need to purchase:

- Bar with a cross section of 20x20mm. Its quantity should correspond to the perimeter of the niche.

- Rail. You can choose its sizes at your discretion. From experience I will say that the best option would be a thin strip 20mm wide.

- 50mm wide rail for screen cashing.

- Self-tapping screws for connecting bars.

- Small nails for fastening the slats.

The tools you will need are a hacksaw, hammer, screwdriver, tape measure, drill or screwdriver.

How to make a screen for a battery with your own hands photo

Let's start manufacturing. We measure the length of the niche and cut off two bars accordingly. We do the same with the height of the niche, only we additionally reduce the length of the cut bars by two of its thickness. In principle, it is better to reduce both the length and height of the finished frame by at least 5mm. This is necessary so that small deviations in the geometry of the niche do not cause problems during installation. We connect the resulting four bars together into a rectangular frame using self-tapping screws. To prevent the beam from cracking when screwing in the screws, you need to drill a hole for them in advance - the diameter of the drill should be one third or half less than the diameter of the self-tapping screws used.

At the next stage, we cover the resulting frame with slats. Here you need to check one point - the diagonal of the future screen. If it turns out skewed, then inserting it into a niche will be problematic, and its appearance will be, to put it mildly, useless. Once the frame is trimmed and painted or varnished, you can begin installing the screen.

Screen for battery photo

Installing such a screen on a battery is very simple. On the side slopes of the niche, from its outer corner, a size equal to the thickness of the screen is deposited. You need two marks at the top and bottom of the slope. In these places, a wooden block is installed using a hammer drill and dowels, to which the screen is screwed with self-tapping screws. If the need arises to get to the battery, it will be enough to unscrew four screws.

This is how flat screens for radiators are made. All that remains is to install the decorative trim and hide the places where the screen is attached and its contact with the slopes. Before installation, the trim will need to be trimmed and painted. They are fastened with nails, the head of which is first removed.

Author of the article Alexander Kulikov

Features of choosing a device for heating a home

If you need to save space, choose baseboard radiators. When purchasing a heating device, you need to consider several factors:

- Material of manufacture. Aluminum ones are lightweight and compatible with any coolant. Bimetallic ones are less susceptible to corrosion, and cast iron ones have the highest heat capacity.

- Construction. Sectional options are easy to match to the window parameters due to the ability to remove or add elements. Panel heats up quickly and is easy to install. Tubular ones are resistant to pressure fluctuations and can withstand loads of up to 20 atm.

- Dimensions and characteristics. The height of floor-standing devices is from 14 to 50 cm, and the length is up to 2 m. They are designed for pressure up to 15 atm. and water temperature up to 110 degrees.

- Heating method and shape. Water batteries are heated by coolant and are equipped with temperature regulators. Electric ones can work together with the “warm floor” system, and combined ones operate from the heating line and the electrical network.

Classification

When classifying heating batteries, numbers are used, the first of which indicates the number of lamellar sheets, the second - the number of ribs:

- The figure shows that there is only one plate and a complete absence of ribs.

- One lamellar sheet complemented by a rib design.

- Two lamellar sheets, one equipped with convection fins.

- Three lamellar leaves, all connected to ribs.

Classification of flat radiators

An additional part of flat batteries is the upper grille, which has side housings on both sides. As a rule, it is snow-white. The battery packaging kit is supplemented with fastening parts. Wall partitions made from different materials require different means of fastening. If the packaging kit is not supplemented with the fastening elements that are needed in a particular case, you will have to purchase others yourself.

Flat radiators are equipped with four connection pipes. This makes it possible to connect the device to the entire heating system from any side. As a rule, they are connected directly to the heating riser or specially designed fittings are used.

There are flat steel radiators equipped with a thermostatic valve. It regulates the fluid inside the product. It is connected on the right side; to connect on the left, you need to make a special order.

Some factories that manufacture flat batteries and heating radiators create horizontal models that connect to the wall surface in the middle. The presence of a valve insert is not necessary. To make a connection from below, hiding the heating pipes in the floor, the packaging set must be integrated. There are connecting parts that are hidden in the walls.

When choosing a method for connecting radiators, take into account the price cost of the product, the design of the room, building, type or type of heating in general. Standard heating systems require side connections; if pipes run under the floor, use bottom connections.

Overview of flat products

Production Features

If we talk about flat models, then most often we mean not the surface topography, but the depth of the radiator. At the same time, the term “flat” can be interpreted in different ways, because this category very often includes all batteries whose depth is less than that of a standard cast iron product.

Aluminum products with shallow depth

Almost all devices that belong to this type are steel panel heaters. No, in principle, you can find a flat oil cooler and an aluminum structure, but the main niche in this market segment is occupied by steel.

The following radiators are produced using mixed technology:

- The basis of the product is a stamped steel sheet, which is machined and forms the internal contour of the heating device.

- Due to stamping, a profile is formed that provides an increase in the heat transfer area.

- To improve operating efficiency, trapezoidal convection fins are sometimes welded to the main sheet. When passing through the fins, the air is heated and then distributed throughout the room. (See also the article Repair of heating pipes: features.)

Appearance of a flat panel model

As a result of all these operations, a flat steel radiator is obtained, which combines compact dimensions with fairly good heat dissipation. Of course, in this parameter it will be inferior to full-size models, but if the shape is important to us, then we will have to put up with some heat losses.

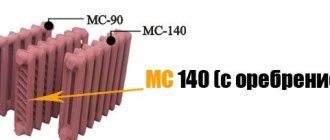

Types of panel radiators

Most manufacturers of panel radiators use the same product classification. Having understood it, you will be able to determine at first glance the depth of the model and its design - even if in front of you is not the battery itself, but only instructions with markings.

Note! As a rule, the first number indicates the number of panels, the second – the number of rows of convection fins

Design features of different types

We will describe how the symbols are deciphered in the table below:

Features of operation

When using technology, you must adhere to the following restrictions:

- the coolant temperature should not exceed 110-120°C;

- the recommended operating pressure, depending on the model, varies between 4.5-10 MPa;

- the small volume of working fluid used implies forced circulation;

- the maximum permissible acidity of water is 8.5 pH;

- It is not recommended to install steel products in damp areas.

Flat batteries are not intended for installation in apartments connected to central heating. Experts do not advise frequently replacing the coolant to prevent oxygen from entering the radiator cavities. The optimal conditions for using the product are a closed system with a circulation pump and a membrane-type expansion tank (the latter protects the equipment from water hammer).

Technical and operational characteristics

An example of using a thin flat radiator against a wall; its compact dimensions do not take up as much space as standard models with a depth of 100 mm.

| Radiator characteristics | Range of values of existing models |

| Height, mm | 300-900 |

| Length, mm | 400-3000 |

| Thermal power (heat transfer), W | 69 — 4942 |

| Heated area, m2 | 2-26,4 |

| Limit operating temperature, °C | 110-120 |

| Required coolant volume, l | 0,85 – 9,09 |

| Maximum operating pressure, bar | 8-10 |

| Water acidity, pH | 7-10 |

| Connection type | side, bottom |

| Connection hole thread, inch | ½ (rarely found ¾) |

| Weight, kg | 3,4-28 |

| Warranty period, years | 5-10 |

| Service life, years | 15-20 |

The table below shows in more detail the average power of radiators of various lengths with a height from 300 mm to 900 mm in a certain range of temperature parameters:

I range – 90/70/20°C (water temperature supplied to the water heater/water temperature returning from the water heater/indoor temperature),

II – 70/55/20°C,

III– 55/45/20°C.

| Length, mm | Type 10 Radiator power (W) in the temperature range | Type 11 Radiator power (W) in the temperature range | ||||

| I | II | III | I | II | III | |

| 400 | 172 — 448 | 109 — 290 | 69 — 187 | 271 – 659 | 174 — 420 | 111 — 267 |

| 500 | 214 — 560 | 136 — 362 | 87 — 234 | 338 — 823 | 217 — 525 | 139 — 334 |

| 600 | 258 — 671 | 164 — 434 | 104 — 280 | 405 — 988 | 260 — 630 | 167 — 401 |

| 700 | 301 — 784 | 191 — 507 | 121 — 327 | 473 — 1154 | 304 — 736 | 195 — 468 |

| 800 | 343 — 895 | 218 — 579 | 138 — 374 | 540 — 1319 | 347 – 841 | 223 — 535 |

| 900 | 387 — 1008 | 246 — 652 | 156 — 420 | 607 — 1483 | 390 – 946 | 250 — 601 |

| 1000 | 430 — 1120 | 273 — 724 | 173 — 467 | 676 — 1648 | 434 — 1051 | 278 — 668 |

| 1200 | 515 — 1344 | 327 — 869 | 208 — 561 | 811 — 1977 | 521 — 1261 | 334 — 802 |

| 1400 | 601 — 1568 | 382 — 1014 | 242 — 654 | 945 — 2306 | 607 — 1471 | 390 — 935 |

| 1600 | 688 — 1791 | 437 — 1158 | 277 — 747 | 1081 – 2636 | 694 — 1681 | 445 — 1069 |

| 1800 | 773 — 2015 | 491 — 1303 | 311 -841 | 1216 — 2965 | 781 – 1891 | 501 — 1203 |

| 2000 | 859 — 2239 | 546 — 1448 | 346 — 934 | 1352 — 3294 | 868 — 2101 | 557 — 1336 |

| 2300 | 988 — 2575 | 628 — 1665 | 398 — 1074 | 1554 — 3790 | 998 — 2417 | 640 — 1537 |

| 2600 | 1117 — 2912 | 710 — 1883 | 450 — 1215 | 1756 — 4284 | 1128 — 2732 | 724 — 1737 |

| 3000 | 1289 — 3359 | 819 — 2172 | 519 — 1402 | 2027 — 4942 | 1302 — 3152 | 835 — 2004 |

Type classification

The main criterion for dividing into types is the standard size, it is indicated on the product labeling:

- type 10. Standard panel models that do not have additional options, they are simple, have a minimum depth of 46 mm;

- type 11. Slightly thicker than the previous version due to the fact that convection ribs were added to one side. Here the depth is 59 mm;

- type 12. A complex product formed by two panels and fins between them, the thickness of the device is 64 mm;

- type 22. Two panels equipped with two fin systems, depth 102 mm;

- type 33. The thickest panels are 157 mm, these are three panels with three parts of fins.

Sectional and panel oil heaters can be floor-mounted or wall-mounted; here mineral oil is used as a coolant. The liquid cools down longer than water, which enhances the operational advantages of the model. Flat oil-type radiators have the following advantages:

- simple installation that you can do yourself;

- low dead weight, expanding the possibilities of application on any walls;

- loyal prices and a wide range of technical solutions and dimensions;

- low-temperature mode of use, eliminating burns;

- the device does not dry out the air and ensures a healthy microclimate;

- moderate energy consumption.

Wall-mounted flat convectors have a heating element inside; it directs thermal energy to metal plates. Heated air enters the room through the slots provided in the upper segment of the casing. The principle of convection of air flows ensures rapid and uniform heating of the room. Such universal devices are often used in country cottages with year-round use.

The battery connection can be side or bottom: the letter “K” on the marking is for the first option, “Kv” for the second.

Radiators and convectors

The types of heating devices used in a water heating system are distinguished not only by the material from which they are made, but also by their operating principle. Since the times of the Soviet Union, radiators and convectors have been used in heating systems. Radiators have higher heat transfer rates than convectors. They radiate heat from their surface and provide constant heating of the room, and convectors move air flows from bottom to top, thereby forming a draft.

Externally, convectors are also very different from radiators; just look at the photos of these devices, and you can accurately determine which device is a convector and which is a radiator.

The basis of the convector design is the pipe through which the coolant passes. The pipe has thin, sharp steel plates.

The advantages of convectors include small size, reliability, and low cost. These devices can be built into the floor, into the wall and placed where there is simply not enough space to install a radiator.

The disadvantages of convectors include a low heat transfer coefficient. Therefore, it is unlikely that it will be possible to warm up a large room using these devices; they can only be used as additional heat sources.

The convection method of heating a room can hardly be called an advantage. Since air convection, or more simply air movement, is nothing more than a draft, and you are unlikely to be happy with such a phenomenon in your home. Convectors are often used in office buildings, where a large glass area does not make it possible to install conventional radiators.

What types of radiator connections are possible?

The efficiency of heating devices is influenced by the chosen installation scheme.

There are different types of connecting heating radiators:

- Diagonal connection. This method of installing heating devices is suitable for long batteries that can heat up evenly. The pipe supplying the coolant is connected on one side to the nozzle at the top, and the outlet pipe is connected to the nozzle at the bottom. If hot water is supplied from below, the battery efficiency will decrease by 10%.

- One way side connection. This is the most common way to install radiators. This connection method, in which the inlet pipe is connected to the upper pipe, and the outlet pipe to the bottom, provides the greatest heat transfer.

- Bottom connection. This method of wiring batteries is used only if the heating system is located in the floor.

The service life of the heating system, as well as its functionality, efficiency and reliability, depend on how correctly the type of connection is chosen and how well the radiators are installed in the heating system.

What are flat heating radiators

We need to start talking about flat radiators with their depth size. There is no exact indicator that would indicate the thinness of the device. This is mainly determined by eye. For example, you can take a cast iron radiator as a standard - this is a common design. Anything less than half its depth can be classified as flat heating radiators.

If we review all existing models, then only steel panel batteries are suitable for this standard. We will consider them. Why is it that panel structures have a small thickness? It's all about the technology of their manufacture.

These are devices made from stamped steel sheets. The form is based on a single sheet with a fairly large recessed area. That is, it is not a sectional design, but a flat one covering the entire area of the heating device itself. This is precisely what increases thermal output. But at the same time, the depth of each panel is not very large, and accordingly the volume of coolant used in the heating system in the flattest radiator will be small. This ratio has an undoubted advantage - low fuel consumption for heating the coolant. That is, these two quantities are in direct proportion to each other.

Flat battery

The producers went further. They did not focus on devices with a purely panel form, because, as mentioned above, this form has reduced power. To increase this indicator, additions were made to the structure itself in the form of a fin system, the so-called convection fins. They are welded over the entire area of the battery using spot welding. The basic shape of the ribs is trapezoidal.

Radiator compatibility with heating system

The modern range of batteries is diverse - cast iron, aluminum, steel, copper, bimetallic devices - it is only important to understand which heating radiators will best “fit” into the specific heating system of your home. What does this mean? This means how much the technical parameters of the heating device - the permissible temperature of the coolant, its pressure and composition, as well as heat transfer and inertia - correspond to the performance of your heating system

A heating radiator not only heats the room, but also has an aesthetic effect in interior design

When purchasing a radiator, its appearance, durability, and, of course, price are also important. It should be taken into account that there are nuances in the selection of heating batteries for open systems (apartment buildings) and closed systems (individual houses). If the indicators declared by the manufacturer do not correspond to the characteristics of your heating system, then rapid wear and even failure is possible.

Differences between floor batteries

Radiators located on the floor are not a new product, but have been used for a long time, but are not widely used on the market for such products. After all, they are used in certain cases - in buildings with large windows.

Conventional radiators are installed under window sills, providing protection against icy air flow from windows and providing effective heating in rooms.

- Radiators installed on the floor are used where installing conventional radiators is not possible.

- The facades of various buildings, nowadays, are finished with glass, this is done in shops, cinemas, buildings for exhibition centers and other buildings.

- Heating in them is done using thermal curtains, as well as floor radiators.

The floor-standing type of radiators is minimalist; their height reaches above 15-20 cm, even with legs. The type of connection used is: from below or from the sides, depending on which model is taken.

Heating in baseboards

Relatively recently, a new and lowest method of creating heating has appeared. In this case, the heat supply structure consists of copper tubes finned with plates, due to which heat transfer increases. Water circulates through them.

The tubes are laid around the perimeter of the room and covered with special metal baseboards. This heating design has the smallest dimensions. It is 30 millimeters wide and has a height of 100–200 millimeters (depending on the power of the system).

Heating in baseboards has the following advantages:

- Great opportunities for implementing design solutions in the interior.

- Uniform distribution of warm flows along the walls.

When a unique design is created in a room, it is low radiators for stained glass windows that allow the heating system to be correctly and beautifully integrated into the interior.

Cons of floor radiators

- They may not always fit well into the interior of the room;

- It cannot be hidden by furniture or walls placed in front of them;

They do not heat the room equally: the space above quickly warms up, but the air near the floor is not heated.

Is it worth buying plate heating devices?

Old style plate radiator.

Any buyer asks a similar question when he is asked to pay attention to a heating device that is so unpopular in our time - a plate radiator. The following number of advantages speaks in its favor:

The following number of advantages speaks in its favor:

- simplicity of design;

- low purchase cost and inexpensive service;

- durability when used correctly;

- high speed of heating the room.

As practice shows, if the structural material is steel, then the equipment is able to withstand pressure up to 20 atm, which has a positive effect on its performance and durability. In addition, the plate radiator will not be harmed by high coolant temperatures (120°C and above).

If old-style plate heating radiators had an unsightly appearance, modern equipment models have an interesting design. This will help when creating the interior of the room. Such radiators no longer have to be hidden behind panels, which, by the way, reduces their performance. They act as a kind of decoration for the room.

Disadvantages of the device:

- heating the room only due to convection. However, the efficiency of the device can be increased by equipping it with a fan;

- as the coolant temperature decreases, the efficiency of the equipment decreases. The air temperature in the room also drops sharply;

- Dust accumulates between the plates.

Installation of a forced convection heating duct in the floor for water heating

If you install a heating boiler with forced convection in the floor, in addition to the steps listed above, you need to connect a ventilation system.

Fans should be located closer to the window or on both sides of the heat exchanger.

Depending on the length of the heating duct, there may be several fans. All of them are combined into a common scheme. The fans are powered from alternating current 220 volts or through a step-down transformer, which is included in the radiator kit.

There are no difficulties in connecting, you just need to supply power to the fans in advance.

Obotoplenii.ru

Structure, types and features

The design of built-in convectors is simple: it is a metal box housing in which the heating element is located. To increase heat transfer, a large number of convective fins are attached to the heater. The structure is closed from above with a grille, which is flush with the floor.

In some models, fans are installed to increase thermal power. Thus, the air heating rate (with the same dimensions and power) increases by 70-90%. But with the installation of fans, one problem arises: they make noise. Therefore, in order to reduce noise, the design must include inserts of porous rubber that will dampen vibrations. The units can also operate with the fan turned off: then the processes occur due to natural convection. This function is needed if there is no need for high power.

To regulate the temperature, electronic or electromechanical regulators are used. They are located inside the case, as well as temperature sensors. The same unit also controls the rotation speed of the fans. It is useful if there is a function for switching to “manual” control: suddenly you need to set other parameters, or the control panel is out of order.

Each part performs its own functions and is made of different materials. Moreover, the quality of the device must be assessed in its entirety.

To increase efficiency, a fan is built in, and to control the temperature, a thermostat

Frame

Its appearance is not so important - it is in the floor. But the quality of workmanship must be at its best: the class of the device is determined by the case and one can judge its overall reliability. The metal from which it is made is also important.

For wet rooms, you need a material with increased resistance to moisture - stainless steel. For dry ones, black or galvanized steel is quite suitable. It is still covered with paint that is resistant to external influences and protects against corrosion. Most often these are powder formulations. They protect metal well. Moreover, it is desirable that the inner walls and the parts themselves be painted in a dark color - this way they are not visible during installation.

Lattices

It’s worth paying close attention to what the grille looks like. This is the only part that remains visible

She will be responsible for the overall impression. They are made from different materials:

- aluminum;

- ordinary steel, galvanized and stainless steel;

- tree;

- marble.

There are two types of gratings: linear and roll. Rolled ones are much more expensive, but more convenient to use. They are simply rolled up. Linear ones are cheaper, but they have to be raised completely. With a roll version, the slats are positioned only across, with a linear version they can be positioned both lengthwise and crosswise.

The design of the grating is important if it will be walked on

Then you need to pay attention not only to the appearance, but also to the design. In this case, it should not contain any plastic parts (sometimes placed at the junction of the slats and the frame)

To smoothly distribute the load and make the structure low-noise, some manufacturers install springs at the junction of the lamella and the frame (German company VARMANN). This reduces the noise level and increases comfort.

Trench convector design

With increased load, it would be good if the grille itself was the same on both sides. Then, after it is erased on one side, it can be turned over to the other and used further.

Heating elements

Built-in convectors have two types of heating elements:

- water in-floor convectors;

- built-in electric heaters.

Our most popular models are those connected to water heating. This is understandable, almost everyone has such heating. But electric in-floor convectors can also become the main and additional source of heat in places where water heating is not possible.

Panel type steel radiators

The peculiarity of such devices as steel panel heating radiators is that they combine the properties of a convector and a battery. They are usually produced in the form of rectangular panels of different thicknesses and dimensions. In the photo you can see what they look like.

The design of steel heating panel radiators is simple:

- the base of the device is a panel consisting of two profiled steel plates, which are connected along the perimeter with a weld. Inside, vertically located oblong channels are formed from steel using the stamping method. Hot coolant circulates through them during the heating process;

- U-shaped ribs are welded to the panels on the back side, resulting in more efficient heat transfer. This element for convective heating of a room is made from cold-rolled steel, only thinner;

- the design of one device can consist of the three panels described above. In the case of connecting several panels into a single system, manufacturers cover them using side covers;

- A steel panel heating radiator can have a variety of dimensions. Most models presented on the domestic market have heights from 300 to 900 millimeters and widths from 400 to 3000 millimeters. The depth of the panel device depends on the number of steel panels and can reach 170 millimeters.

According to connection options, panel radiators are:

- with side connection;

- with bottom connection;

- with universal connection.

In terms of cost, the most expensive models are those with a lower connection option, since they often have a thermostat built into them. If the device does not have a built-in thermostat, it is connected using a special thermostatic valve.

Panel steel radiators have technical characteristics depending on the model:

- operating pressure in the range of 6 – 8.5 atmospheres;

- crimping pressure does not exceed 13 atmospheres;

- The maximum temperature of the coolant is no more than 110 – 120 °C.

The fact that the testing pressure is low is the reason why experts in the field of heating engineering do not recommend installing steel panel radiators in multi-storey buildings.

Design

Flat heating radiators consist of two plates, made by stamping and welded together. Between such plates there is a space (channel) - this is where the coolant will circulate. To connect the batteries to the heating system, there are special pipes. Using certain types of connections, you can form flat, thin heating radiators from two or three plates.

That is why the power of a device that has fins will be almost 60% greater. But there will also be more dust on such products, so they are placed in rooms that have high sanitary requirements.

Sectional view of a panel heating radiator

In order to correctly classify plate heating radiators, special designations with numbers are used, which are the same for most manufacturers of such products. The first number is the number of plates, the second is the number of plates that have convection fins:

- 10 – one plate without convection fins.

- 11 – one plate with convection ribs.

- 21 – two plates, one of them has convection ribs.

- 33 – three plates and each has convection ribs.

The thin heating radiators, which are presented above, are also additionally equipped with side casings with grilles on top. They are usually white in color.

White flat radiator

If we talk about the standard delivery set, it includes a set of fastening elements for brick walls. If your walls are different, you will have to buy separately all the fasteners that are required to install narrow radiators.

Typically, narrow heating radiators are connected either directly to the heating system riser, or using special fittings.

In addition, there are also batteries that immediately have a kit for connecting to a thermostatic valve. With the help of such an insert with a thermostatic head, the speed of water in the product is controlled. Such a kit is usually connected on the right side, however, upon special order, the manufacturer can create a battery with a kit for installation on the left side.

Flat vertical radiator with connection in the middle

Some manufacturers have in their assortment such narrow horizontal heating radiators that can be connected to the heating system in the middle - with or without a valve insert. If the heating radiators have an integrated kit, then they will be ready to be connected to the heating system from below, when the pipes are hidden under the floor. Special connecting elements with pipes that are hidden in the wall are also used. Such pipelines will not spoil the appearance of the room that is heated.

For a standard type heating system, when the pipes go on or in the wall, plate heating radiators with a side connection are used. For a system with a pipeline in the floor - connection from below.