Modern heating circuits are practically no different from those that were in our houses and apartments forty or fifty years ago, since the laws of physics are unchanged. However, something has changed and, first of all, these are the heating radiators themselves, or, as they are often called in the old fashioned way, batteries. If previously only cast iron was used for their manufacture, now black and stainless steel, copper and, of course, aluminum have been added.

Radiators come in different sizes and with different numbers of sections Source otoplenieblog.ru

What are heating radiators?

As we have already mentioned, different metals are now being used to make heaters. This is primarily due to their thermal conductivity, because the higher the heat transfer, the faster the room will heat up. The materials for the circuits (boiler piping) have also changed - today almost no one will use metal pipes for this - everyone is switching to polypropylene, which is not subject to corrosion and can withstand heavy loads of internal pressure and coolant temperature. In addition, polypropylene, having low thermal conductivity, allows hot water to most efficiently transfer its energy to the battery.

Note: the strength of its sections plays a very important role when choosing radiators. If the working or nominal pressure in multi-storey buildings is kept at 4-10 atmospheres, then the pressure test (test) when starting the system at the beginning of the heating season can reach 22-23 atmospheres (depending on the altitude and location of the house).

Advantages and disadvantages of heating devices

Let us highlight the main advantages of aluminum radiators.

Under operating conditions, aluminum radiators allow you to save up to 35 energy resources. Radiators have a smaller volume of coolant in sections, so rapid heating and cooling occurs.

The devices can be controlled by thermal valves, thermostats and temperature-sensitive heads. Temperature-controlled parts limit the flow of coolant into the system when the appropriate temperature is reached.

Aluminum radiators have low thermal inertia, which is why thermostats respond quickly to temperature changes, which saves heat.

All batteries are presented in a modern ergonomic design, compatible with any interior of administrative and residential buildings. Aluminum radiators have the following disadvantages:

— risk of gases; — risk of leakage between sections; - heat concentration on the ribs. The accumulation of gases can damage the system or cause the battery to explode. This problem is eliminated by installing air vents operating in automatic mode. Aluminum is highly reactive and susceptible to corrosion. Therefore, chemical film or anti-corrosion treatment must be applied.

Video description

How to choose a heating radiator.

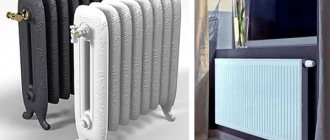

Cast iron

The 50+ generation remembers that when they heard the word “battery,” they usually associated it with a cast-iron radiator in an apartment, and occasionally in a private house—it’s just that there weren’t any others back then, except for homemade steel registers made from pipes. Cast iron, as a metal, has one interesting feature; The higher the temperature of the coolant, the lower its thermal conductivity. This is bad? Not really. If you live in a multi-storey building and are connected to centralized heating, you will notice that water is not constantly circulated through the system and this is due to the material of the heating circuit.

Cast iron batteries retain heat for a long time when the water circulation is turned off, that is, the hot water that fills the sections cools down for a very long time, since it does not give up its energy to the shell immediately, but in parts. It turns out that the more the coolant cools, the faster it gives up its heat to the radiator, but it does not have time to cool completely, since at this time the circulation pump motors start again. This system is very convenient for multi-storey buildings and somewhat expensive for the private sector with autonomous boiler houses. The maximum pressure that cast iron batteries can withstand ranges from 25-30 atmospheres - this is enough for short-term pressure testing. The thermal conductivity coefficient is 62.8 W/(m*deg).

Review of popular brands and their prices

The rating presents the best aluminum radiators produced both in Russia and abroad. Now there are many world-class companies that produce heating devices. Each produced model has its own characteristics, advantages and disadvantages.

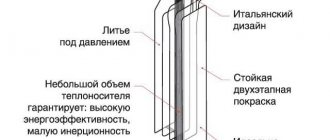

Global Di Fardelli Ottorino&C

This manufacturer is considered the most popular, as it produces reliable radiators with excellent technical characteristics.

For example, the Global ISEO 500 model is one of the popular small-sized radiators for an apartment or country house. Products from the VOX R line are designed to work in high pressure environments.

Features of Global batteries:

- Compactness. The dimensions of each section are as follows: 582 × 80 × 80 mm, this is the lowest figure in the segment. The heating elements are connected via threads.

- Withstands high pressure. The operating pressure for this equipment is 18 atm, tests are carried out at 24 atm. The devices are excellent for centralized heating systems, where they are not afraid of water hammer.

- Heat dissipation. The power indicator of one section varies from 160 to 195 W.

- Strength. Batteries are manufactured using the injection molding method.

- Oxidation protection. To do this, the inside of the radiators is coated with a double layer of polymers.

- Design. Thanks to the external paint coating, the products have an attractive appearance that lasts for many years.

- Life time. Global products can last about 30 years.

Aluminum heating radiators "Global" have a price of 350 rubles per section.

Sira Industry

It was this company that first began producing aluminum heating devices. We offer high quality products in various shapes and sizes. The equipment is manufactured both in Italy and in China. Based on this, the segment is divided into 2 classes: Alux - European, Nik - Chinese.

The technical characteristics, regardless of the place of production, are similar. The only difference between products manufactured in China is the lower thermal output parameter - 175 W; for Italian devices this value reaches 190 W.

Peculiarities:

- production method: injection molding;

- working pressure indicator - 16 atm;

- high level of heat transfer;

- the inner surface is protected by a polymer coating;

- painted using a special technology;

- warranty period - 15 years.

Such batteries can now be bought without problems in Moscow, and inexpensively - from 400 rubles.

Battery prices from Sira Industrie

batteries Sira Industry

Rommer

This is a Chinese manufacturer of aluminum batteries. As noted earlier, most companies from the Middle Kingdom produce low-quality, thin-walled products that do not last long. Rommer is one of the brands that deserves attention.

Peculiarities:

- produces wall and sectional products;

- maximum operating pressure - 16 atm;

- heat transfer level - 175 W;

- The coolant can be heated to a temperature of +110° C;

- compact dimensions - 572 × 80 × 80 mm;

- top and bottom connections;

- the presence of an external anti-corrosion coating;

- warranty period - 5 years;

- The internal surface of the batteries is protected by an oxide film and a fluorozirconium layer, which makes them neutral with respect to the quality of the coolant.

These Chinese radiators cost from 300 rubles per section.

Battery prices from Rommer

Rommer batteries

Royal

This is a Russian manufacturer of aluminum devices that adheres to European standards. The main feature of the batteries is their excellent compatibility with Russian heating systems.

During production, special technologies are used that make it possible to make wave-shaped sections. This improves the flow of air through the radiator, which improves thermal output.

Another advantage of this brand of batteries comes down to the quality of the intersection gaskets, made from natural cotton and graphite additives. This technology completely eliminates the possibility of leakage. Thanks to this, antifreeze can be used as a coolant, in addition to water.

The batteries themselves are made of a special alloy with titanium and silicon additives, which is necessary to increase strength and increase resistance to corrosion.

Peculiarities:

- number of sections - up to 20;

- working pressure - 20 atm;

- thermal output - 205 W;

- coolant temperature - up to +115 °C;

- specially designed fins that increase heat transfer;

- high-quality coating;

- The heating system can run on antifreeze.

The price of such equipment is from 400 rubles per section.

Battery prices from Royal

Royal batteries

Rifar

This is also a Russian brand that uses a license from the Italian company Global to produce batteries. A distinctive feature of the product is the special oval shape of the water channels, which allows the devices to withstand high pressure. Additionally, the movement of coolant throughout the device is facilitated, resulting in less deposits forming on the walls.

Thanks to special plugs, these batteries can be easily washed. During operation, you will not have to deal with water leaks, since the design is equipped with silicone sealing rings.

Each section, outside and inside, is treated with anodic electrodeposition and only after that is coated with powder enamel. This makes it possible to increase the resistance of devices to mechanical damage.

The only drawback of the product is its low resistance to the effects of coolant with high acidity, only 7 pH. For this reason, these radiators are not suitable for central heating.

Peculiarities:

- maximum pressure - 20 atm;

- power - 185 W;

- it is possible to heat the coolant to a temperature of +135 °C;

- the enamel is applied in a special way, which makes the batteries resistant to damage;

- there are technological holes that facilitate washing;

- made of lightweight aluminum alloy;

- sectional channels have a special cross-section.

The price of Russian heating equipment starts from 490 rubles.

How to choose a radiator based on system pressure

The choice of radiators depends on the pressure in the heating system Source teplowood.ru

Regardless of which radiator you like best, or what its cost is, such devices must still correspond to the pressure in the system, and not only the nominal operating pressure, but also the test pressure ). If you live in an apartment in a multi-storey building and use centralized heating, then you most likely know that a thermal power plant or boiler house releases water under high pressure into the system at the beginning of the heating season. This is a necessary measure that allows you to identify weak points in the circuit (pipes, batteries). However, residents, as a rule, complain about leaks, not understanding what is happening (after all, there was no leak last year), but it is better to fix the problem at the beginning of the season than to do it in winter, draining water from the entire riser, and in severe frosts this It’s noticeable, and it’s worth the money.

| Heater material | Average pressure, bar | |

| Crimping | Working | |

| Cast iron | 15-18 | 9-12 |

| Steel | 10-13 | 6-8 |

| Bimetal | 30-35 | 20-25 |

| Aluminum | 9-15 | 6-8 |

Note to the table: 1 Bar is equal to 0.986923 atmospheres, therefore, when installing pipelines, Bars are most often used.

The upper table shows the average operating and test pressure values, but it may be slightly higher, so when choosing radiators you will have to take these numbers into account. But you will also have to take into account what kind of house you live in (meaning buildings connected to central heating). According to SNiP 41-01-2003, the pressure during pressure testing of the system should be 1.5 times higher than the working pressure, but we can overestimate this level. Therefore, compare the capabilities of the desired radiators with the table below.

| Number of floors | Average pressure, bar | |

| Working | Crimping | |

| Up to 5 | 2-4 | 3-6 |

| 9-10 | 5-7 | 7,5-10,5 |

| 11 and above | 12-14 | 18-21 |

| Skyscrapers | Set by the building designer | |

Important! If you want to know the exact test and operating pressure of your heating system, you need to contact the utility company that services your home directly.

Classification of batteries by manufacturing technology

For the production of heating radiators, it is not aluminum in its pure form that is used, but its alloys with silicon. Separate sections and whole products are obtained from blanks. The main methods of metal processing are extrusion and casting.

Type #1 – extrusion

On production lines, the main tool for the manufacture of extrusion devices is a molding extruder, which literally extrudes the required profile onto metal blanks.

The disadvantage of the technology is the production of separate parts, which are subsequently connected by pressing. Of course, the seams on the structure make it vulnerable to pressure changes and unclean coolant.

Sections and manifolds are made using extrusion. After the parts undergo pressing processing, it is not possible to change their size, therefore, during installation, the length of the finished products cannot be changed

Extrusion models are the most inexpensive among aluminum ones. They are characterized by a smaller working surface area, which reduces the heat transfer of devices. The seams obtained as a result of pressing are gradually destroyed by contact with low-quality coolant.

The corrosion process is also more active because secondary aluminum is used as a raw material for extrusion, a characteristic feature of which is the presence of rapidly oxidizing impurities.

Type #2 – cast

Radiators produced by casting technology have higher performance indicators. They are safer, stronger and more resistant to aggressive environments than their extrusion counterparts, and therefore more expensive. For manufacturing, aluminum (from 88%) and alloys with the introduction of silicon (up to 12%) are used.

Production occurs as follows. The molten metal enters the casting molds, where it acquires a given profile. The parts that have received the design configuration are cooled, processed and checked for leaks. The walls of the workpieces are treated on all sides with an anti-corrosion compound.

After further cooling and drying, the almost finished sections are painted with protective polymer enamel with the addition of epoxy resins. Final stage – assembly and testing

Various manufacturers are experimenting with casting technology, resulting in new types of radiators. Let's say the Faral Trio company has released a line of two-channel radiators that have not lost strength and cope well with burst pressure of more than 55 atm.

And Italian Raden radiators have vertical fins of 6 rows, due to which there is an increase in heat transfer.

If you want your heating system to be equipped with truly reliable and protected devices, pay attention to anodized batteries. These are radiators made of aluminum coated with a durable oxide film, which has two purposes - protection and decoration.

The oxidation process several times increases the metal’s resistance to corrosion and other negative changes or reactions to the poor quality of the liquid circulating through the channels of the devices.

Coolant for aluminum radiators

Antifreeze has different properties depending on the content of various impurities in it Source probaltur.ru

Everyone knows that water is the cheapest coolant for heating systems of multi-storey and private houses, but aluminum radiators do not agree with this. Practice is the best teacher and it has shown that when using drinking or even process water, oxides, scale and some other strange sludge appear in the heating circuit (pipes, radiators). So such a system will have to be periodically flushed so that the deposits do not acquire the state of stone, when ordinary flushing will no longer help. This suggests that you need some kind of special coolant that is friendly with aluminum and can be bought in the store.

Important! When installing a heating system with aluminum radiators, under no circumstances should you use copper and brass taps and fittings. In this case, polypropylene pipes and fittings are best suited for the pipeline, all connections and shut-off valves.

For normal operation of the heating system, you need to choose the right antifreeze Source probaltur.ru

To stabilize the operation of autonomous heating systems, various antifreezes are used, but, as you understand, this is not always safe, so special attention should be paid to the reliability of the circuit (all soldered and threaded connections). Such liquids are usually not drained during the warm season - there is simply no need for this. Don’t forget that not all systems can be filled with such a coolant (we’ll talk about the limitations below).

Make your choice:

- Glycerin composition. As a substance, such a composition is completely harmless, which means it is not dangerous when cold. When working with glycerin coolant, there are practically no oxides or various sludge. The mixture is designed for long-term use.

- Ethylene glycol composition. This mixture is dangerous for humans, so when filling the system you must use a respirator, rubber gloves and safety glasses. The presence of such a substance in the coolant must be indicated by the manufacturer.

- Propylene glycol composition. Unlike ethylene, propylene is harmless to humans, but has a higher cost, which often stops buyers. For a heating circuit, such a coolant can be called one of the best.

SOLAOTERM-EKO is the most acceptable solution for preserving batteries for a long time Source elektroservis-rostov.ru