Domestic double-circuit gas boilers are one of the most popular types of heating equipment on the market. Their main advantages include ease of installation and operation, reliability, high efficiency, practicality, durability and, most importantly, the ability to simultaneously organize heating and water supply. As is known, gas is one of the most economical and environmentally friendly types of fuel, providing ample opportunities for operating thermal gas equipment in various conditions.

Why is a floor-standing gas boiler better than a wall-mounted one?

Although the choice should be entirely individual, a universal assessment shows that a floor-mounted unit will be better. Such designs can often be found in private country houses or cottages.

And wall-mounted versions are installed in apartments, this is due to the lack of free space and visual appeal, but not due to characteristics. The advantages of a floor-standing boiler include:

- Good performance.

- Long service life.

- High-quality, thick-walled parts.

- Energy independence.

Wall-mounted units are quite often subject to breakdowns associated with voltage surges; the manufacturer takes care to reduce the weight of the product as much as possible.

This affects the quality of the components; they cannot boast of a long service life, and setting up this type of double-circuit boiler will take much longer; the process can rightfully be called lengthy.

Difficulties in connecting a double-circuit boiler to an indirect heating boiler

The implementation of such a work scheme is quite possible, but its practical implementation is not advisable. After all, to get hot water inside a boiler at a temperature of 50 degrees, you will need to spend a considerable amount of time, which is due to the following reasons:

- the water temperature at the outlet of the water heating circuit cannot exceed 60 degrees;

- reducing the intensity of heat transfer and increasing the heating time of the boiler when it reaches 40 degrees;

- The boiler electronics are designed that the input will be cold water from the water supply, and the output will be 50-60 degrees. However, at the inlet, due to the circulation of the boiler-boiler, the water temperature rises to 50 degrees, so the boiler modulates the flame or completely turns off the burner;

- It is not possible to prevent the development of Legeonella in sanitary boiler water.

As you can see, it makes no sense to buy a double-circuit gas boiler in Moscow to heat a boiler in a private house through a hot sanitary water preparation circuit. In addition, the final price of the boiler increases significantly.

To implement a similar scheme for connecting a boiler with an indirect heating boiler, a single-circuit gas boiler, where the temperature of the heating circuit reaches 80 degrees, is best suited.

Design and principle of operation

Apart from the increased strength of important parts and assemblies, there are no fundamental differences between the types; the main elements look like this:

- First heat exchanger.

- Burner.

- Second heat exchanger.

- Circulation pump.

- Turbocharging

- Control Panel.

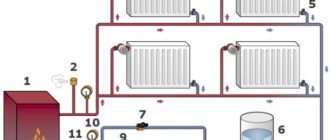

Taking into account the specified parameters, the coolant is heated and enters the heating system; it returns through the return line for the next cycle. When water leaves the first heat exchanger, it gives up some of the heat in the secondary unit to heat the liquid there to operating temperature.

Thanks to the three-way valve, the coolant is mixed with cooled water and reaches the required temperatures, after which it is sent into the main line. Gas combustion products are discharged through a chimney; there are models with natural draft and a turbocharger fan.

Rules for choosing a gas double-circuit floor-standing boiler

The power of the unit is an important indicator when purchasing, but there are many more characteristics that should not be forgotten, these include:

- How much gas is consumed?

- Efficiency

- The performance of the circuit responsible for hot water.

- If the equipment is volatile, then you need to find out the power consumption.

- Indicators of maximum temperatures.

- System pressure.

Thanks to a thorough study of the technology, you can determine a suitable copy from the many brands presented. By comparing the characteristics, it will be possible to identify significant shortcomings and positive aspects; it is equally important to take into account the opinion of the repair and service departments and the possibility of quick service.

Convection or condensation

Convection types of equipment cannot be called the most productive, because part of the heat released to heat the coolant simply goes into the atmosphere. Such units often have an efficiency rate of 85%; actual productivity rarely exceeds these figures.

The positive aspects are obvious: simplicity of design, low cost, compactness and ease of installation. Condensing types of gas double-circuit floor-standing units are much better, they are at least 20% more efficient, thanks to the installed additional heat exchanger, steam energy is used to heat the liquid. They will cost more, but these expenses will quickly pay for themselves, gas is consumed economically, and efficiency is at a high level.

Volatile or non-volatile

A device that operates from the network is not the most profitable option for installation, because the cost of electricity consumption will additionally fall on the owner of the building. Therefore, most consumers choose units of this type with class A++.

One cannot help but notice the high cost of spare parts, repairs and automation, because breakdowns can happen at the most inopportune moment. Failure of the board can rightfully be called a frequent occurrence; replacement will cost half the cost of the equipment; repairs are also expensive.

Non-volatile models operate on the principle of a gas stove, heating a tank of liquid; voltage drops and power outages are not a problem, since the double-circuit gas boiler operates autonomously.

It is necessary to foresee the location of heating devices in advance, since it is specific and the coolant circulates naturally.

Open combustion chamber or closed

Equipment with an open combustion chamber is considered the most economical, the efficiency indicator reaches 109%, air intake occurs due to gas combustion. The package includes two burners, one of them is the main burner, and the second is a pilot, the intensity of the main component can be adjusted with the burner, the pilot element operates in constant mode.

Devices with a closed combustion chamber cannot operate without forced draft, which makes them less practical. The intake of fresh air occurs thanks to this component; equipment of this type is often used in apartments to be built into a single furniture ensemble or installed using a special box.

Optimal gas consumption

You can calculate the minimum indicator by comparing several models with the same power. To calculate the amount of gas per 1 kW, you need to know the efficiency of the device and the calorific value of the fuel. Taking into account standard standards, in a regular main line the mixture has data that is 9.3 kW/cu. m. If the unit coefficient is 90%, then the generation of 1 kW will require 0.12 cubic meters. m. this is determined in this way: 9.3x90%, then 1/8.37.

Required power for floor-standing double-circuit gas boilers

This indicator is one of the important ones; when purchasing a device in a store, all visitors pay attention to the device’s passport data. There is no need to purchase equipment that is too powerful; this will entail high fuel consumption, which will affect the family budget.

If it is not enough, then there can be no talk of a comfortable temperature regime, or the equipment will constantly work on the verge of its limit and will soon fail.

There is a universal formula for calculation; it involves multiplying the specific power, which is calculated for each region of the country, by the square footage of the building, and the resulting result is divided by 10. Example: 200 sq. m. x 1.1 kW/10 = 22 kW. I take the middle band into account.

Data on climate zones looks like this:

- Southern: 0.7-0.9 kW.

- Middle band: 1.0-1.2 kW.

- Moscow region: 1.2-1.5 kW.

- Northern: 1.5-20 kW.

For the most accurate calculation, it is necessary to make adjustments taking into account the characteristics of the premises.

Heat exchanger

If a private building is located outside the city or is a cottage in which you do not plan to live permanently, then it would not be superfluous to provide protection against freezing of the system.

The most common liquid is antifreeze; it should be added to the line after calculating the number of liters. When temperatures drop, these substances prevent water from hardening, it goes into a gel-like state, and all connections and pipes remain intact.

Storage tank

Floor-standing double-circuit boilers with a built-in tank can ensure continuous operation of heating and hot water supply, especially if the liquid is planned to be used in large quantities. Flow-through types of equipment cannot boast of such technical characteristics.

The capacity of the container ranges from 25 to 60 liters, the power is selected taking into account operational needs. The built-in element serves to minimize temperature differences in the heating line, because part of the heat will be spent on heating the water.

Smoke removal process

If the building has an existing chimney, you can connect to it to reduce waste. There are several options; to implement the plan, a hole is made in the ceiling or wall; it is important to ensure the correct assembly of the components, this will protect against the occurrence of various excesses.

The mechanism of action will require a separate room for installation, the boiler room should be equipped according to all the rules, and to enhance the effect, most owners install forced fans.

Efficiency

This data can be found in the passport for the device; the efficiency of blue fuel and the comfort of the premises depend on it. The higher the indicator, the more efficiently the device will work; according to many people, in reality the situation is different, but I advise you to pay attention to these characteristics. Condensing types of boilers for heating a private home will be the best in this indicator, their data is often 98% or higher.

Advantages and disadvantages

Advantages:

- ease of installation;

- aesthetic appearance;

- ease of use;

- silent operation;

- the ability to set the required temperature;

- fire safety;

- no exhaust gases emitted.

Flaws:

- inappropriate use for large rooms due to high energy consumption;

- reduction in the efficiency of the device due to constant power outages or power outages;

- the need to change the wiring, because old wires may not withstand heavy loads.

Rating of the 7 best models of double-circuit gas floor-standing boilers

Thanks to the detailed description of the devices, which I compiled taking into account the opinions of experts and consumer reviews, every owner will be able to make the right choice and avoid fatal mistakes when coming to a specialized store.

Protherm Bear

The first place goes to a brand popular in most countries, which produces units that best match the price and quality.

The compact installation is designed for 30 kW; the pump is capable of maintaining a given pressure when raising the liquid to the 3rd floor. Fuel is consumed economically; the protherm gas boiler burns 3 cubic meters per hour. built-in boiler for 90 liters.

Siberia 17K

Second place goes to the model with a steel heat exchanger, the equipment is non-volatile, the coolant circulates naturally.

The power of 17.4 kW is complemented by a minimum consumption per hour of 1.76 cubic meters. The dimensions are quite compact, their data looks like this: 28 by 85 by 56 cm.

Lemax Premium-12.5NB

The third line of the rating is rightfully occupied by the Lemax gas boiler, which is resistant to changes in gas pressure and does not require power supply for operation. Consumption is 0.75 cubic/hour. complemented by an Italian safety system, it modulates the flame.

Lemax Premium-12.5NB

Lemax Premium-25B

The fourth position was taken by a unit with moderate characteristics, gas consumption is 3 cubic meters per hour. This model has mechanical controls, an open combustion chamber, and weighs 88 kg. An important advantage is independence from electricity, thermal protection of the heat exchanger and anti-corrosion coating of components.

Lemax Premium-30B

Lemax Premium-30B

Fifth place. Ideal for installation in houses with an area of 200 to 300 square meters. m. The steel heat exchanger has walls of 2 mm, which affects the service life of the device. Gas consumption is 3.5 cubic meters/hour.

Lemax Premium-20B

The sixth position is assigned to a gas boiler with an open combustion chamber, the maximum consumption of blue fuel is 2.4 cubic / h. The unit is compact in size, reliable in operational terms, easy to install and adjust.