At the stage of installing a water supply or heating system using modern technologies, one cannot do without a distribution manifold. This device allows you to redirect fluid flows.

Thanks to the distribution manifold, you can easily turn off or limit the capacity of each heating or water supply circuit in a private house or apartment. This, in turn, allows you to significantly save money on heating those rooms in which maintaining a high temperature is not required.

This device also allows you to more evenly distribute the fluid pressure between consumers, which is almost impossible to do with a series connection.

Famous brands

Valtec is an Italian manufacturer of a line of products for constructing water supply systems.

A full range of products for metal-plastic, polypropylene water supply and stainless steel systems is always on sale. In Russia, representative offices are located in 6 cities, including Moscow, St. Petersburg, and Krasnodar. Rehau is a German manufacturer with a history dating back to 1948. Products undergo multi-stage quality control.

Far (FAR) is another Italian company. In addition to shut-off and distribution valves, the line includes metal-plastic, polypropylene, copper and steel pipes.

Complex design

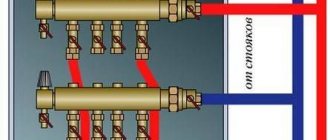

The most complex products also have a more complex design, some of which include:

- Ball Valves;

- Adjustment fittings;

- Mechanical or electronic sensors.

Why is this necessary?

Why and when do you need a water supply comb?

Collector water distribution is necessary in two cases:

- If you need to ensure the disconnection of several plumbing fixtures or their groups from one point (manifold cabinet). This feature is very useful in a mini-hotel or hostel;

All plumbing is disconnected from one manifold cabinet

- If you need to ensure constant water pressure on all devices at any ratio of water consumption between them.

The second point probably requires some clarification.

Remember the cute communal scene: one of your family members is taking a shower in the bathroom, the other is trying to wash up the dishes in the kitchen. As soon as he opens the cold water tap further, an angry roar from the scalded body can be heard from the bathroom.

Why is this happening?

Because an increase in cold water flow with a constant hydraulic resistance of the water supply leads to a drop in pressure at all water collection points.

Open the tap on one mixer and the pressure on another will drop sharply

This is a common problem with so-called tee (or series) connections.

Tee (sequential) water distribution

It is worth providing each plumbing fixture with its own supply connected to a common collector - and the problem of pressure drop will be solved: regardless of the water flow in the kitchen, the pressure in the bathroom will remain unchanged.

Scheme of collector wiring in a house with a boiler

Selection of pipes for the heating system

When creating a manifold wiring diagram for heating a low-rise residential building or other private building, it is necessary to take into account the method of laying pipes throughout the house. If the piping will run under the floor, in a concrete screed, then it is recommended to buy heating pipes in coils so as not to make connections in the floor, as mentioned above.

Plastic pipes must have sufficient flexibility, the pipe material must not be subject to corrosion and the influence of aggressive environments, must not be destroyed at low or too high temperatures, and the service life of the pipes must be extremely high.

The requirements for temperature resistance and tensile strength of pipes are determined by the performance characteristics of the installed heating system in a house or apartment. For individual development, the pressure in the pipes should not exceed 1.5 atm, and the maximum temperature regime should be in the range of 500C -750C. If the house has a “warm floor” system, then the temperature of the coolant in the pipes should not rise above 300C -400C.

Manifold for combined heating

When installing a manifold heating circuit in an apartment building, the pressure in the pipes will always be high, and the pipe material must withstand ≥ 10-15 atm. at a coolant temperature of up to 110-1200C. Therefore, when laying heating pipes in an apartment building, it is recommended to use corrugated pipes made of stainless steel, rather than metal-plastic or PVC products. As a working example, we can cite the Kofulso brand of pipes, which can withstand pressures of more than 15 atm. at coolant temperature ≥ 1100C. The pressure force that causes the destruction of this material is 215 kgf/cm², which is an excellent indicator.

Collector wiring in the apartment

The bending radius of such stainless pipes is equal to their diameter, which allows them to be laid in almost any place and with any bend, without fear that the pipe will leak at the bend. Connections in such piping are made using special fittings, and the twist points are fixed with a lock nut, which ensures the tightness of the connection of corrugated pipes with silicone seals.

But stainless steel is not the cheapest material, and when installing manifold pipes in a two- or three-story building, such a project will be quite expensive. Therefore, it makes sense to use pipes made of cross-linked polyethylene, for example, PE-X brand. These pipes, like other PVC products, are sold in coils, the length of one pipe is 200 meters, the material is able to withstand pressure up to 10 kgf/cm² at a coolant temperature in the system up to 950C. A short-term increase in temperature up to 1100C is allowed.

Corrugated stainless steel pipes

Water pipes made of cross-linked polyethylene are also connected to each other using special fittings in the form of plastic or metal (bronze, brass, copper) fittings with a locking ring, which fits tightly onto the pipe and seals it tightly. The advantage of such pipes is that cross-linked polyethylene has a mechanical memory, that is, assembly is carried out according to the following scheme: the pipe is stretched with a special extender so that a fitting can be inserted, and after some time (up to a minute) the pipe takes on the original diameter and tightly presses the fitting. Additionally, tightness is ensured by a locking ring.

DIY distribution comb for heating

Welding steel manifold

Considering the high cost of collectors, the pressing question remains - how to make a heating comb yourself. Knowing the principle of operation of the collector, it may seem that it will not be difficult to manufacture it; the main problem arises when selecting components. Square and round steel pipes are considered one of the best materials. However, it is not always possible to work with them at home - this will require a welding machine.

An alternative way is to make a comb for heating systems from polypropylene pipes. This will require tee connections and a welding tool to join them. It is recommended to choose the largest diameter of the inlet pipes, taking into account the principle of calculating the heating comb. Those. if the diameter of the pipes in the circuits is 20 mm, this parameter for the main body of the collector should be at least 3 times larger.

To make a heating comb with your own hands, you will need to perform the following steps:

- Measure the distance between the inlet and outlet pipes of the circuits.

- The size of the collector body should be 10-15 cm larger than the measured distance.

- Cut the pipe according to the dimensions obtained and install pipes on it to connect the circuits.

- Check the tightness of the resulting structure.

Polypropylene comb

It should be noted that before making a heating comb, you need to check the possibility of installing it for a specific system. The problem may lie in thermal conditions - polypropylene connecting fittings do not have reinforcement. Therefore, if the temperature is exceeded, their partial depressurization is possible.

It is important that the throughput of the structure is no less than that of the pipe leading from the boiler. An alternative to making the stroke yourself is to purchase a ready-made body

Its cost depends on the number of inlet pipes and can vary from 1400 to 1950 rubles

An alternative to making a paddle yourself is to purchase a ready-made casing. Its cost depends on the number of inlet pipes and can vary from 1400 to 1950 rubles.

Setting up a comb for heated floors

Factory products undergo bench testing, as evidenced by accompanying documents containing complete information about all hydrotests performed under special conditions. The use of such compact devices with a guarantee of tightness of welded and threaded connections is the best option in any in-house heating systems. Such units are characterized by an ergonomic arrangement of controls, and installation inside special mounting cabinets does not interfere with access to control valves.

The coolant from the supply pipe and the return pipe is mixed inside each outlet or directly in front of the collector, but it is advisable to entrust the calculation of the optimal circuit to specialists.

Regulating the temperature of the floor surface involves performing several sequential actions:

- Set the bypass valve to max, moving it to the 0.6 bar position. Triggering this node during the setup process causes an erroneous result.

- Calculate the balancing valve, using for this purpose the temperature indicators at the return, supply line and outlet of the heating device, under the conditions of a standard coefficient of 0.9 and according to the throughput formula: K = 0.9 × [(tk – to/tp – to) - 1]).

- Set up pumping equipment by calculating the boiling water flow rate and pressure loss on the circuits. It is allowed to set the minimum feed with a gradual addition of speed.

- Balance the branches by fully opening the control units and smoothly closing them to the required position.

At the final stage of setting up the comb for the “warm floor” system, the flow rate of the mixing unit is linked with other heating devices.

It should be noted that installing a flow meter will greatly facilitate obtaining accuracy when setting up all components. It is recommended to set the processing parameters of the bypass valve device approximately ten percent lower than the established maximum pressure values of the pumping equipment.

Reservoir classification

Switchgears differ in the material of the housing and parts and methods of fastening

This is important to consider when selecting, because... not all products are suitable for plastic pipes

The following types of collectors exist:

- Steel (made of stainless steel). Resistant to fire and high temperatures. The products are distinguished by their neat appearance and light weight; the collector is easily mounted on the wall.

- Brass (sometimes nickel-plated). They have a high cost, but are durable. Do not rust or deteriorate from high temperatures.

- Polypropylene. They are lightweight and resistant to corrosion.

According to the method of fixation, devices are classified as follows:

- with eurocone;

- threaded;

- with compression fittings that allow you to firmly connect plastic or metal-plastic pipes;

- with fittings for plastic pipes for soldering;

- combined.

The collectors are also available in 2 color options for installation on hot and cold water. Devices are divided by the number of outlets.

Material

Brass – characterized by increased strength and durability. The disadvantage is the high price.

Stainless steel is a good balance of reliability and price. The downside is that there are a large number of fakes on the market (authenticity is checked using a magnet). A steel manifold is inferior in strength to a solid brass manifold due to the presence of a weld.

Copper is a reliable material that can withstand significant temperatures and pressure. Disadvantages: high cost, incompatibility with aluminum radiators or pipes. Copper collectors are good in oil heating systems.

Polypropylene is the cheapest material. This collector is easy to install. Cons: insufficient strength, sensitivity to UV rays. It is advisable to use polypropylene collectors only in water heating systems.

Selecting a location

First of all, the water distributor must be installed in such a way as to maximize the length of each pipeline to the consumer. If this rule is neglected, then over longer sections the fluid pressure will differ significantly.

If the water supply is installed in a multi-storey building, then the collector is installed on each floor.

There are two ways to install a water comb:

- In the wall of the building.

- In the distribution cabinet.

The first installation option is used when the usable area of the room is limited, or the open installation of pipes and distribution boxes will significantly change the design of the room. In this case, a niche is built in the wall, which is closed with a valve, and if necessary, it will be possible to gain access to the control of the device.

If it is possible to install the distribution device in a utility room, then in this case a special box is installed, inside which the comb and all the pipes leading to this device are fixed.

If the water supply is installed in a multi-storey building, then the collector is installed on each floor

Advantages

Combs in water supply systems have their advantages, such as:

- Connection reliability;

- Well-functioning work;

- Pressure stabilization;

- Provides comfortable use of household appliances dependent on water supply;

- Makes it possible to install them on DHW;

- Prevents large changes in water temperature;

- Makes it possible to lay a water supply system using a hidden method;

- When repairing a separate area, it allows you not to completely shut down the system.

Installation of distribution comb

Installation of the comb does not bode well for easy work. As a rule, it takes a lot of time and requires the hands of a specialist who knows a lot about this matter. But, despite all the installation difficulties, they try to install this particular wiring in modern houses and apartments, since it is very effective and easy to use. New models of combs are produced taking into account the complexity of installation, this greatly facilitates the work of the master during installation. You can mount it not only in a mounting cabinet, but also to the wall; for this purpose, the kit includes mounting clamps for greater stability of the device, and its high resistance to corrosion allows the comb to serve for many years.

In order to clearly understand what a distribution comb is, you need to know about it all the information necessary for a person who does not understand anything about this matter. For a complete overview, it is worth presenting several types of different combs.

Manufacturing materials can be polymer, steel, brass or copper.

Configuration:

Simple ones lack an important quality - control of coolant flows. Such combs divide the total flow of water by the number of nodes present in the house; they supply a uniform flow to the bathroom, kitchen, toilet and other places where water flows

The design of the comb is the simplest - a coupler with special connections on both sides and branches in the amount of 2, 3 or 4 pieces.

Complex - have many useful additional elements: pipeline fittings; control and accounting sensor; automation. Temperature sensors, or as they are also called, thermal sensors, are installed in combs with an electronic or mechanical system. They completely control the flow and supply of water through the pipes, especially convenient when the coolant is connected.

Peculiarities

The manifold is also called the distribution comb. These concepts mean a pipe equipped with side outlets. They are located at the same distance from each other, perpendicular to the axis of the pipe itself.

The inlet hole on the collector has a larger diameter (20-40%) than the outlet. This feature makes it possible to provide stable water pressure for each consumer, even if the water is distributed to several people at the same time. The collector is responsible for distributing the main flow into several small ones.

A water collector is necessary to simultaneously connect several devices or create outlets for several groups of such devices. The last installation option allows you to equalize the water supply pressure along all lines. On each branch pipe there is a shut-off valve, with which you can disconnect a device or a group of consumers from the water supply at any time.

The collector is also good for a water supply system because it provides the user with control over the pressure. For example, when the washing machine switches to water supply mode, the water pressure in the shower will not change. In a system with a collector, there are no unnecessary connections, which always have a high risk of leakage.

When you already have an idea of the principle of operation of the collector, it is important to familiarize yourself with the secrets of its selection. After all, the collector market is diverse

There are models for heating systems, organizing heated floors, installing water supply and connecting additional elements. Recommendations for selection are necessary so that an inexperienced user does not get confused in the variety of products.

How to install?

Before installing a water distribution unit for cold and hot water supply, give an accurate answer to the following questions and consider the following points:

- How many water consumers are there on site? The number of collector outlets should be the same or slightly greater than the number of consumers. Excess branches are closed with plugs.

- What type of pipes will be used to install the water supply? It is necessary to purchase devices designed specifically for pipes made of the selected material.

- Estimate in advance the position of all engineering elements in the space of the plumbing cabinet (you can make markings on the wall). Please note that a water meter and a water filter are installed in front of the distribution comb. The convenient location of all devices facilitates maintenance and repair work.

- Get reliable fastening - a poorly secured distribution unit can lead to depressurization of connections and damage to the pipeline.

- Before installation, make sure that you have all the necessary consumables on hand: sealing material, gaskets, adapters.

Installation of the water distribution unit occurs in the following sequence:

- Install the inlet shut-off valves on the water supply riser.

- Install the meter, filter and check valve.

- Connect the manifold and securely fix it to the wall

- Install a water supply to each consumer. Secure the pipes with fasteners.

This operating algorithm will allow you to avoid errors. Regardless of whether the collector is needed for water supply or heating, its installation is the same. Such wiring requires more time, skill and money, but pays off quickly and provides comfort in further use. Collectors are appropriate not only in cottages and large houses, but also in apartments.

Flaws

The disadvantages of the devices are their cost and some properties of the components necessary for its installation (valves, risers, fittings, etc.).

In addition, some connection methods make the system bulkier. Despite all these disadvantages, the costs and inconveniences are fully worth it.

Project implementation

In order not to become a victim of the situation described earlier, you need to connect a manifold with the correctly selected pipe diameter. You can make a pipe from a half-inch product for the shower and tank. At the same time, the entrance to the collector should be several times larger.

But you shouldn’t be overzealous either. There is no need to install a doubled entrance. A slight increase in the input channel compared to smaller outputs will already give a positive result.

These materials are easy to work with. There is no point in repeating the benefits of using plastic.

It turns out that the work may be difficult, but the result is worth it. Manifold wiring allows you to save money on the purchase of tees. And if metal-plastic pipes are installed, then the tees for them are very expensive. But still, there are no special restrictions here. The owner himself makes the decision.

It should be noted that every owner can independently perform collector wiring. But before starting work, you need to draw up a diagram on paper, which can then be implemented in practice. The collector system for distributing water pipes requires careful operation.

As you might guess, the system will have many connections of pipes, adapters, shut-off valves and other elements

Therefore, it is very important to pay special attention to every detail, so that later you don’t have to redo all the work, which will add even more hassle.

Today you can buy metal-plastic pipes, copper pipes, stainless steel pipes and polypropylene pipes in any construction or specialized store. There are also all kinds of connections, adapters, taps.

That is why it is necessary to have a work plan in advance. It will allow you to purchase the required amount of building materials for the system.

Products on the market

The catalogs of accessories for collector water supply systems provide a wide variety of not only combs, but also their components.

- Dividers without taps are much cheaper. They allow you to assemble a device that will best suit the object. This option is preferable, as it allows you to easily replace only the failed faucet. While the one-piece design will require complete replacement.

- Devices with shut-off valves greatly simplify the installation of a water supply collector. They simplify the assembly of the unit - there is no need to install taps.

- Accessories allow you to adapt the system according to your wishes: valves, pump groups, plugs, valves, brackets, couplings, ends, servos, fittings.

- Manifold cabinets are sold separately, which are mounted into the wall and provide an aesthetic appearance, as well as access to the engineering unit.

What are air vents and what are they for?

Many owners of radiator systems have encountered a situation where, with hot pipes, some parts of the radiator do not heat well or are generally cold; similar problems arise with insulation with water floors. The main reason for this phenomenon is the presence of air in the pipes, which rises and impedes the movement of the coolant.

If in an open circuit air bubbles are sent to an unclosed expansion tank located on high floors of a building or attic, and bleeding is not so important, then in a closed system an air bleeder for the heating system is vital on all circuits and individual heat exchange devices.

When plugs interfere with the operation of the system, manual or automatic heating drain valves are used to remove accumulated air. One of the simplest devices is a regular valve installed at the top point of heating radiators. To bleed air from the batteries, open the valve and wait for the moment when the stream stops flowing jerkily along with the air - in radiators without air, the water flow will be uniform.

In individual heating lines of private houses, instead of ordinary valves, special locks are installed on the radiators, which function automatically or are manually adjusted. With their help, they remove not only air from devices in which gas formation occurs, but also, when necessary, oxygen from water, which causes accelerated corrosion of metal fittings.

Rice. 2 Air vent for venting air from the heating system - design

Heating the pool water

This system has its own heat exchanger, and the distribution function is assigned to the collector. The operation of the pump is controlled by an automation unit. First, the water is heated, and then it is switched on periodically in order to maintain the temperature of the water in the pool at a certain level. The main thing for the performance of such a system is the correct selection of the heat exchanger.

When installing a heating comb with your own hands or having this work done by specialists, it is necessary to install adjustment levers - balancing valves - on the distribution manifold for heating, and thermal valves on each radiator.

Leaders of sells

For an even clearer understanding of what a distribution comb is and how to choose the best device for yourself, you need to look at the recent sales leaders. From this information, you can find out what requirements must be met and what new functions have been added by manufacturers.

You will be presented with 2 types of distribution comb and distribution manifold, common throughout the world, which have the most modern functions:

- Rehau Rautitan distribution comb for 2 pipes. Combines low price and excellent quality. The manufacturer is the famous company Rehau. The average price in Russia is 700 rubles. Serves to regulate the coolant on several circuits. You can connect to the device both ordinary cold water passing through pipes and a heated floor system, as well as other heating devices. Installation of the comb is facilitated thanks to the sliding sleeves with which it is attached to the pipes. Made of brass, this material is characterized by long service life and high strength.

- Rehau Rautitan HLV distribution manifold for 11 groups. The manifolds have the same functions as the combs, the only difference is in the number of connections - the manifold has many more, connections are made in groups, for cold and hot water separately. Rehau has proven the high quality of its devices. This is evidenced by the numerous purchases by Russians of collectors and combs from their company. The Rehau Rautitan HLV distribution manifold branches out the circuits of radiator distribution systems. All devices have passed mandatory quality checks and necessary tests, including pressure testing in emergency situations. Just like the comb, the manifold of this company is made of brass, which indicates high quality and durability. The average price in Russia for the Rehau Rautitan HLV distribution manifold is 11,000 rubles. The kit includes: eurocone, ball valves, connecting nipples and built-in air valve.

The market of modern technologies is filled with new products every day; distribution combs and manifolds are supplemented with convenient functions for ease of use. They all have their positive, and in rare cases, negative qualities. To choose the right distribution comb or manifold for your home or apartment, you should learn as much as possible about these devices, then it will be difficult to make a mistake in your choice.

Best manufacturers, price

Oventrop water combs

The Oventrop brand is very well known both in the domestic and world markets, its products are sold out well.

- The maximum operating pressure is 6 bar at a temperature of 70 degrees. The price of this model, like any other, depends on the number of circuits. Thus, the cost of a distributor designed for 2 circuits is approximately 3,500 rubles, for 12 circuits, respectively, 11,500 rubles.

- The maximum operating pressure and temperature are the same as the previous model. The price of a collector for 2 circuits is 4,000 rubles, for 12 circuits - 16,000 rubles.

- Can withstand a maximum internal pressure of 10 bar and operating boiling water temperature. The cost of a dual-circuit distributor is 2000 rubles, for 12 - 7000 rubles.

The most popular models of distribution manifolds from the Rehau brand are:

Rehau HKV

Made from brass, grade Ms 63. It allows you to heat water by no more than 80 degrees and can withstand pressure up to 6 bar. Such a dual-circuit manifold will cost you about 7,000 rubles; for 12 circuits it will cost 19,000 rubles.

Rehau HKV-D

Made of brass, grade Ms 63. Performance characteristics are the same as the above model. The cost of a two-circuit device is 8,000 rubles, for a twelve-circuit device - 21,000 rubles.

Rehau HLV

Made from brass Ms 63. Technical characteristics are the same as those of the above models. The price of a double-circuit manifold is 5,000 rubles, and a twelve-circuit manifold is 10,500 rubles.

Self-production and installation

In order for a self-made device to do its job well, it must not only be manufactured correctly, but also installed

In this case, it is important to take into account the advice of professionals and take into account the recommendations of manufacturers of individual parts. Only in this case can you achieve the desired result and complete the work in the shortest possible period of time

Recommendations from experts

Before you start making a comb, you should read the advice of people who have already done similar work. This will help beginners avoid most mistakes and make a truly high-quality product. Professionals recommend:

- It is advisable to make the distribution comb with a round or square cross-section.

- To avoid problems with coolant movement, it is necessary to install separate circulation pumps for each circuit. In this case, the comb should not synchronize their work.

- If the unit will be located in a separate room, then a protective box may not be installed for it.

- In order to be able to change the volume of coolant, it is necessary to install control valves, balancing flow meters and inlet valves at each inlet and outlet pipe.

- During planning work, a place should be provided for installing a security group.

Distribution and calculation of contours

Before starting the manufacture of the device, it is necessary to calculate the number of required circuits and draw up drawings for their connection

In this case, it is important to provide separate units for some heating structures:

- water-based underfloor heating;

- heating devices for each floor of the house;

- radiators in rooms where the temperature is higher or lower than other rooms.

In addition, it is important to perform all calculations efficiently and provide various geometric parameters. If everything is done correctly, then you can ensure easy access to all components of the structure

This will help simplify repair or maintenance work. Nuances to consider when making calculations:

- intervals between layering should be from 10 to 15 cm;

- the distance between the supply and return manifolds should be set from 20 to 30 cm;

- diameter of pipes for connecting radiators - 0.5 inches;

- collector cross-section is from 1 to 1.5 inches.

- intervals between layering should be from 10 to 15 cm;

- the distance between the supply and return manifolds should be set from 20 to 30 cm;

- diameter of pipes for connecting radiators - 0.5 inches;

- collector cross-section is from 1 to 1.5 inches.

Creating a comb from a profile pipe

To make a comb yourself, you need to purchase a profile pipe and round-section products, the length and size of which must be pre-calculated and repeatedly checked. Procedure:

- According to a pre-prepared diagram, the profile pipe is marked.

- Holes of the required diameter are made in the right places. This work is best done with a gas cutter.

- After this, the pre-threaded pipes are welded.

- Mounting brackets are attached to the resulting structure by welding.

- The surface of the product is cleaned and coated with heat-resistant paint.

- The finished comb is mounted in the selected location of the system.

A heating comb is an important device that helps to simultaneously connect all existing radiators to the heating system. With the right approach to business and following all the recommendations of professionals, you can significantly simplify the work and complete it in a short period of time

One of the methods of connecting heating devices - today it is considered the most modern - involves the presence of an element called a comb.

Below in the article we will talk about how a distribution comb for heating functions and how you can make it yourself.

Device Description

Manifold for water heated floor

The design of a water distribution manifold is generally a piece of pipe with an inlet for connecting the main line and several outlets for flow points

When choosing a device, pay attention to the design and technical characteristics

Types of combs

Manufacturers produce a range of products in question, which is sufficient to organize the most complex water supply or heating system.

Combs are usually divided into several types depending on:

- body material;

- number of exits;

- center distance of fittings or bends;

- availability of additional options.

Construction material

The development of technology in industry makes it possible to produce combs for water supply from different materials. Manufacturing companies and marketers skillfully take advantage of this, offering products of any choice:

- bronze - an alloy of copper with tin and the addition of other elements to give the required properties;

- brass - an alloy of copper, zinc and additives;

- steel;

- polypropylene;

- silumin.

When comparing bronze and brass, preference should be given to the first material - it is much stronger, and accordingly, there is less likelihood of accidents and breakdowns

This is very important in apartment buildings, when a leak floods apartments located below the floor

Models can be distinguished by touch and weight. Bronze has a coarse grain structure, while brass products are smooth to the touch. The weight of similar structures made of bronze is much higher than that of brass.

Steel elements are susceptible to corrosion, so they last less than devices made of non-ferrous metals. Steel combs should be cheaper, but manufacturers use a trick by covering the body with nickel plating. This gives the product a presentable appearance, allowing sellers to inflate the price. Steel appliances are used in dry rooms where the risk of rust is low.

Water supply collectors made of polypropylene gained popularity with the beginning of the mass use of plastic pipes in construction. The comb body is thicker and can withstand a greater load than the connected pipes, so you should not be afraid of a breakthrough in this place - the supply pipes will be the first to collapse from water hammer.

An important advantage is that the polypropylene manifold is connected to the entire system using high-temperature welding, like other components of the water supply system. In this case, threaded products are not used, which simplifies installation, reduces the likelihood of leaks, and reduces cost

Silumin collectors are the cheapest of the products under consideration. They are produced mainly by companies from China. The equipment has one advantage - low price. Disadvantages include poor oxidation resistance

The material is fragile, be careful when installing - do not use excessive force

Types of collectors

Comb with two outlets

For small apartments or separate rooms, purchase a water collector with two outlets. Options with three or four exits are designed for two-story houses.

All metal combs have two threaded holes for connection to the main line, which allow you to connect several collectors in series. For example, by connecting 2 and 3 output collectors in series, a comb with 5 outputs is assembled. You can increase the number of leads by soldering polypropylene products.

The center distances of the bends have little effect on the technical characteristics. Most manufacturers produce products with such distances in the range from 36 to 110 mm.

The closer the fittings are located, the more difficult the installation and the more inconvenient it is to manipulate the taps. On the other hand, such switching equipment takes up less space during installation.

Products with large gaps are more expensive; it is used in cases where the equipment is installed in a separate room.

Collectors are distinguished by the ability to regulate the flow of water:

- without regulators - the outlet looks like a thread or fitting for connecting a metal-plastic pipe;

- with ball valves;

- with adjustable taps;

- with automatic shut-off equipment that regulates the flow;

- the choice depends on the complexity and tasks assigned to the plumbing.

The nuances of homemade work

The main condition for correct heating operation is the creation of hydraulic balance in the system. The ring collector for heating must have the same throughput capacity of the incoming pipe (the cross-section of the main pipe connected to the supply line) as the sum of the same indicators in all circuits. For example, for a system with 4 circuits, it looks like this:

D = D1 + D2 +D3 +D4

When making a heating manifold with your own hands, remember that the distance between the supply and return sections of the pipe should be a value equal to at least six comb diameters.

When installing the device, take into account the following nuances:

- an electric boiler or gas boiler is connected to the upper or lower pipes

- the circulation pump only fits into the end side of the comb

- heating circuits are connected to the top or bottom of the collector.

To heat a house with a large area, circulation pumps are installed on each circuit. In addition, to select the optimal volume of coolant, additional equipment is installed on each inlet and outlet pipe - balancing flow meters and adjustment valves. These devices limit the flow of hot liquid to a single pipe.

In order for the boiler distribution manifold to perform its functions in full, it is necessary that the length of all circuits connected to it be approximately the same length.

It is possible (but not necessary) to additionally equip a mixing unit when manufacturing heating collectors. It consists of pipes that connect the inlet and return combs. In this case, to regulate the amount of cold and hot water as a percentage, install a two or three-way valve. It is controlled by a closed-type servo drive, which receives a signal from a temperature sensor installed in the heating circuit.

This entire design allows you to regulate the heating temperature of a particular room or a separate circuit. If too hot water enters the collector in the boiler room, the flow of cold liquid into the system increases.

For a complex heating system in which several collectors are installed, a hydraulic arrow is installed. It improves the performance of distribution combs.

A manifold for a boiler room, which you make yourself, will ensure normal heating operation only if you accurately select the parameters of the system piping. Therefore, you first need to entrust the calculations to a professional, and then get to work.

Remember that a comfortable temperature in your home depends on many factors. Only a fully balanced system will ensure correct heating operation.

Do you need a hydraulic gun?

A hydraulic separator (hydraulic arrow) is a device that is usually placed between the boiler and the collector; it provides zero resistance in this area. Visually, the element is a hollow pipe with 4 pipes: on one side, two are intended for the boiler, on the other, for the collector. The question of installing a hydraulic separator arises when there is a need to install more than 4 pumps and more than 1 boiler.

The hydraulic arrow can be fixed vertically or horizontally, it does not matter. The first option is often chosen, as it simplifies the installation of the air vent in the upper part. A tap can be attached to the bottom to remove sludge.

Often in articles this device is attributed properties that it does not possess. We list the tasks for which you should not buy a hydraulic gun.

- Does not increase boiler efficiency

- Does not reduce fuel costs

- Does not protect against heat stroke

- You still need to select pumps for each circuit separately.

- Not intended for air bleeding or sludge protection.

The hydraulic arrow can worsen the operation of the system if the pumps are incorrectly selected. For example, a boiler unit is much inferior to the total power of devices on other circuits. As a result, the coolant reaches the comb already cold due to mixing with the reverse flow.

Are a manifold and mixing unit required?

In a small house, a heated floor may not take up so much, in which case the costs of a collector and mixer will not be worth it. The simplest solution would be to install a heated floor with one or two circuits, controlled by a TSG thermal head or an RTL tap. Regulation in this circuit occurs by limiting the temperature on the return flow.

The RTL valve is not intended for installation on a manifold; it has high hydraulic resistance. Due to the large size of the head, it is inconvenient to screw the element onto a distribution unit with a large number of adjacent circuits. This also makes it impossible to use built-in plumbing cabinets. It is not recommended to install RTL cranes on a circuit longer than 70 meters. The thermal head is usually placed in a plastic box that is hung on the wall.

The TSG head also limits the return flow, but has a Eurocone, so it can be installed on the return of the manifold. The actuator acts on the stem, and not on the valve itself. In this case, the head is occupied by the working valve of the manifold, because of this, installation of the servo drive becomes impossible. The absence of resistance makes it possible to install a longer circuit.

manifold mounting

I looked through the entire section and I can’t find how to secure the collector so as not to accidentally collapse

Look at photos of examples of completed work, manufacturers' catalogs. Either specialized fasteners for “steep manifolds” or ordinary plumbing clamps on plumbing studs are used.

If the collector is in a metal collector cabinet, then special fasteners, otherwise - plumbing clamps on plumbing studs.

Please give me some advice: are the collectors attached correctly and can the play of the fasteners in the brick wall affect the operation of the system? (Behind the brick there is one row of emptiness). Thank you.

Right. But everything else is not. Use polypropylene for manifold wiring. bue.

Exclusively metal-plastic? This is polypropylene with fiberglass.

As far as I understand, the choice of material is related to the number of hidden connections from the collector to the consumers? Or something else?

Dmitry - yes. Number of connections and ease of installation.

Here's what's about it

AlexMax wrote: Number of connections and ease of installation.

Well, the installation is almost complete. I hope that the connections are soldered securely, especially in places that will be hidden by tiles.

Interpreter, respected Technician-san, in his review, missed the flexible copper KME Q-tec and flexible corrugated steel. They, too, seem to already exist and are walled up. I don’t mention any joint ventures at all. The statements of Technician-san for MP are true for them.

By the way, information on composite pipes (glass fiber reinforced polypropylene)

Dmitry, that's all bullshit. Press - yes, it gives a gain, but all these PP pipes. When using drill stripping, virtually no time is lost; much more time is gained by proper labor planning and clear phasing in carrying out the planned work. But you can't teach this.

What can you say about the reliability of the system “in general” in this design? Is it worth (and how) to additionally mount the collector where there is a gap from the wall?

Here's the big picture: [

Yes, it's worth it. The collectors, judging by the appearance, are Grandini? If possible, attach it to the console, at least from Hilti. To prevent it from dangling, take a smaller clamp. a half-inch will do. Collectors for 34?

Tiemme manifolds 3/4 (3*16 + 4*16) x 2 pcs. (art. 1866N160404, 1866N160404):

The console also needs to be attached to the brick - and it’s not entirely solid. There are gaps behind the brick where the dowels with spacers fit.

It's worth attaching anyway. Everything has to be tough. and I’m bothered by the pipe coming from the meter from the MP under the press, where does it go?

If you are talking about the white pipe that runs along the wall to the left (from the lower HB meter), this is a temporary “snot” for collecting water and flushing the “repair” toilet.

Greetings! I wanted to create a topic, but here is just a similar one. The question arose: I wanted to attach FAR 3/4 collectors (two in series with 3 and 4 pins, almost like in the photo of the vehicle) to the plumbing wall with 3/4 clamps. However, when I secured the clamps between the outlets, this completely blocked the possibility of connecting pipes to the outlets, since the nut there no longer rotated, and if I attached the clamp at the end, it did not stay there - it fell off. Bends are planned with kofulso pipes, while temporary flexible hoses. So the question is, how to secure them to these clamps so that this does not interfere with the connection of consumers?

Other tips

The living room with the kitchen can be combined and decorated with various shortcomings

It is important to calculate and anticipate everything in advance. Decorators and craftsmen share tips that will help avoid problems during repairs and furnishings:

The result depends on how detailed the project is drawn up. Oddly enough, it is worth taking into account the growth of loved ones and relatives. It is also recommended to calculate the approximate number of possible guests. You can get rid of food smells by installing a strong hood or ventilation system.

Small models are more suitable for housewives who do little cooking. If you plan to have a sleeping place in the living room, then it is important that the ringing of appliances and other kitchen utensils is not heard. Silent dishwashers and other appliances will come in handy.

In addition, you can install a sliding door and install a soundproof partition. If there is sensitivity to ultraviolet radiation, the owners hang thick curtains made of light-proof fabric. If household appliances do not match the direction of the interior, they are hidden behind furniture or put away in kitchen cabinets. When installing luminaires and lamps, they are guided by several criteria

It is important that the light falls evenly throughout the entire space. Especially bright lighting is preferable in the kitchen area and where the dining table is installed

In the living room, designers create a subdued atmosphere using wall sconces and table lamps. Multi-level stretch ceilings with LED strip also look good in this room. Moisture-resistant finishing materials are more durable and easy to clean. Thus, they retain their appearance for a long time. The kitchen combined with the living room combines:

- personal tastes of the owners;

- reliable finishing materials;

- current design ideas;

- convenience;

- trends. The best photos of kitchen living room design

Types of distribution combs

Collectors are mounted on hot and cold water supply. For convenience and to prevent confusion, manufacturers produce models in different colors (red and blue).

By type, combs differ in the number of taps, which varies from 2 to 4. For a larger number of connections, it is recommended to use combinations of several distribution devices. For example, the existing 6 points can be equipped with two combs for 3 outputs.

Equipping the heating system with a manifold will be no less useful. Heating will be carried out evenly, which will eliminate differences in the temperature of individual rooms.

The operation of any type of switchgear is safe. The absence of pressure drop will eliminate emergency situations with breakthroughs and flooding.