Every housewife is familiar with the problem of reducing pressure in the water supply when several points are turned on simultaneously. Equipping the system with a distribution manifold will help solve the issue. In common parlance, the knot is called a water comb.

This wiring scheme is currently considered the most effective and in demand. The engineering design has a complex structure, but has advantageous qualities.

Advantages of a collector distribution system

— strong connection in the system;

— ensures convenient operation of household equipment connected to the water supply;

— installation on a pipe with hot water is allowed;

— eliminates temperature changes;

— makes it possible to install plumbing in a hidden way;

— nodal connections facilitate repairs in individual areas and do not require a complete shutdown.

The only disadvantages include the cost of the manifold and the individual parts required for its installation (fittings, risers, valves, etc.). In addition, a large number of connections makes the system cumbersome. But if you take into account the benefits and reliability of the device, then the costs are fully justified by the benefits received.

Types of distribution combs

Collectors are mounted on hot and cold water supply. For convenience and to prevent confusion, manufacturers produce models in different colors (red and blue).

By type, combs differ in the number of taps, which varies from 2 to 4. For a larger number of connections, it is recommended to use combinations of several distribution devices. For example, the existing 6 points can be equipped with two combs for 3 outputs.

Equipping the heating system with a manifold will be no less useful. Heating will be carried out evenly, which will eliminate differences in the temperature of individual rooms.

The operation of any type of switchgear is safe. The absence of pressure drop will eliminate emergency situations with breakthroughs and flooding.

How to choose a water distribution manifold?

Before purchasing a comb, you should familiarize yourself with the technical characteristics of different types in order to choose the optimal model for your water supply.

Factors to consider when choosing:

• pressure in the water supply system;

• collector throughput;

• number of water intake points;

• installation on hot or cold water supply;

• possibility of connecting an additional point.

The material from which the switchgear is made deserves no less attention:

The distribution comb plays an important role in the water supply and heating system. This is a separate part that is designed to distribute water evenly throughout all parts of the water supply in the house. The comb can also be used for underfloor heating systems; thanks to its properties, thermal energy will be distributed evenly, which means that the warm air in the room will flow evenly. Let's take a closer look at the device and installation features of the distribution comb.

Tooth shape

The purpose of the spatula-comb and the efficiency of its operation depend on the shape, size and arrangement of the teeth. First, choose a tile—we described the process in detail in the article “How to Decide on a Tile Format”—and only then study the types of tools.

Triangular-shaped teeth carefully spread the adhesive mixture, so they are used when working with lighter, smaller tiles: they are suitable for mosaics or panels made of plastic and other lightweight materials. The type and size of the teeth are indicated by letters on the label of the spatula-comb:

- A - standard;

- B - wide;

- S - close, like a saw.

For large formats or working with uneven bases, choose combs with rectangular teeth or irregularly shaped gaps: these are described in the text of the spatula label.

Square Prongs o: These fit standard size tiles. In most cases, they will solve any repair problem.

Semicircular o. Suitable if you need a layer more than 13-15 mm thick. This form of spatula-comb works well for applying thick adhesive mixtures, synthetic or concrete, to the tiles.

Why do you need a distribution comb?

During the construction of old-type houses and apartments, main pipe routing (sequential laying) was used, which is inconvenient for modern times. Many people faced the problem of uneven heating of apartments, and, unfortunately, no one could cope with the different pressures in the pipes. But today the problem has been solved; a solution called a distribution comb has arrived on the modern market. Unfortunately, in order to correct the situation in houses and apartments with a ready-made heating system, you will have to change the pipe layout to a collector system. If you are just planning to heat the room, this article will be useful for you.

What will change after installing the distribution comb:

- The pressure in the pipes will be equalized throughout the room.

- The problem of sudden cooling of water in the bathroom when you turn on the tap in another place will disappear

- The house will be heated evenly

This is only part of all the advantages of manifold pipe routing after installing the comb. To minimize uneven water supply, the comb should be installed for both cold and hot water. Special taps are installed on it; they allow you to shut off the flow of water in a separate unit ; this is convenient in the event of a leak in the toilet or a broken tap in the bathroom.

Scope of application

Distribution manifolds are used as part of the following types of utility networks:

- water supply;

- water heated floors;

- heating systems with radiant wiring.

Installing a comb allows you to create an independent feed into each line. This helps to equalize pressure, ensure accurate distribution and regulation of supply to each device, and prevent a decrease in water temperature when opening the tap at other water intake points. A water distribution manifold simplifies repairs by allowing you to shut off the desired line without shutting down the entire network.

Installation of distribution comb

Installation of the comb does not bode well for easy work. As a rule, it takes a lot of time and requires the hands of a specialist who knows a lot about this matter. But, despite all the installation difficulties, they try to install this particular wiring in modern houses and apartments, since it is very effective and easy to use . New models of combs are produced taking into account the complexity of installation, this greatly facilitates the work of the master during installation. You can mount it not only in a mounting cabinet, but also to the wall; for this purpose, the kit includes mounting clamps for greater stability of the device, and its high resistance to corrosion allows the comb to serve for many years.

In order to clearly understand what a distribution comb is, you need to know about it all the information necessary for a person who does not understand anything about this matter. For a complete overview, it is worth presenting several types of different combs.

Manufacturing materials can be polymer, steel, brass or copper.

Configuration:

- Simple ones lack an important quality - control of coolant flows. Such combs divide the total flow of water by the number of nodes present in the house; they supply a uniform flow to the bathroom, kitchen, toilet and other places where water flows. The design of the comb is the simplest - a coupler with special connections on both sides and branches in the amount of 2, 3 or 4 pieces.

- Complex - have many useful additional elements: pipeline fittings; control and accounting sensor; automation _ Temperature sensors, or as they are also called, thermal sensors, are installed in combs with an electronic or mechanical system. They completely control the flow and supply of water through the pipes, especially convenient when the coolant is connected.

A selection of tile comb manufacturers

Below are the most popular manufacturers of notched spatulas.

Russia

- Polytech. Russian company - manufacturer. Among other things, also hand tools.

- Sibrtech . Siberian Technologies presents more than 5,000 types of hand-finishing tools.

- Bison Probably one of the most popular manufacturers on the Russian market.

Europe

- Forbo. Association of companies from Germany, Sweden and Switzerland. They work on flooring, as well as hand tools.

- COLOR EXPERT. The homeland of the brand is Germany. They produce professional hand tools. The company is confident that there is a professional in everyone, the main thing is to work with a quality tool!

- Hardy. The country of origin is Poland. They produce professional hand and painting tools at affordable prices.

- STANLEY. Not exactly a European manufacturer, but it was impossible not to mention! American company producing professional hand tools.

How not to make a mistake when choosing a distribution comb

Before purchasing a device, it is important to consider every little detail. Correlate all the functions that will need to be performed in the future comb. In this case, special attention should be paid not to the material, unfortunately many people look only at it, but also to other important factors.

What to pay attention to first:

- The throughput capacity of the purchased device - it is important that it copes with the flow of water to all nodes.

- What pressure in the system is the comb designed for?

- Energy consumption based on each connection point.

- Possibility of expansion when new water supply units appear in the house.

Choosing the right distribution comb is an important job that is difficult to do on your own, especially if a person understands nothing at all about this difficult matter.

Comb for laying tiles

Operating principle of a notched trowel.

After a layer of glue is applied to the surface with a flat spatula (the layer should correspond to the height of the tooth on the comb with a small margin), excess glue is removed at an angle of 45 - 75° with a notched spatula . This allows you to maintain the same layer over the entire area. After going through the comb, apply and press the tile, with good force, but without excessive pressure, lightly tap with a rubber mallet. After pressing the tile, the glue between the tile and the surface spreads, and a suction cup effect due to the air displaced by the glue. This is another advantage of the tile comb.

Leaders of sells

For an even clearer understanding of what a distribution comb is and how to choose the best device for yourself, you need to look at the recent sales leaders. From this information, you can find out what requirements must be met and what new functions have been added by manufacturers.

You will be presented with 2 types of distribution comb and distribution manifold, common throughout the world, which have the most modern functions:

- distribution comb for 2 pipes. Combines low price and excellent quality. The manufacturer is the famous company Rehau. The average price in Russia is 700 rubles. Serves to regulate the coolant on several circuits. You can connect to the device both ordinary cold water passing through pipes and a heated floor system, as well as other heating devices. Installation of the comb is facilitated thanks to the sliding sleeves with which it is attached to the pipes. Made of brass, this material is characterized by long service life and high strength.

- distribution manifold for 11 groups. Collectors have the same functions as combs, the only difference is in the number of connections - the collector has many more of them, connections are made in groups, for cold and hot water separately. Rehau has proven the high quality of its devices. This is evidenced by the numerous purchases by Russians of collectors and combs from their company. The Rehau Rautitan HLV distribution manifold branches out the circuits of radiator distribution systems. All devices have passed mandatory quality checks and necessary tests, including pressure testing in emergency situations. Just like the comb, the manifold of this company is made of brass, which indicates high quality and durability. The average price in Russia for the Rehau Rautitan HLV distribution manifold is 11,000 rubles. The kit includes: eurocone, ball valves, connecting nipples and built-in air valve.

What is it needed for

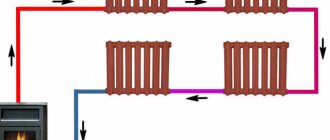

When installing water pressure systems, there is a rule: the total diameter of all branches should not exceed the diameter of the supply pipe. In relation to heating equipment, this rule looks like this: if the diameter of the boiler outlet fitting is 1 inch, then the system allows two circuits with a pipe diameter of ½ inch. For a small house heated only with radiators, such a system will work effectively.

In fact, there are more heating circuits in a private house or cottage: heated floors. heating of several floors, utility rooms, garage. When they are connected through a tapping system, the pressure in each circuit will be insufficient to effectively heat the radiators, and the temperature in the house will not be comfortable.

Therefore, branched heating systems are made using collector systems; this technique allows you to adjust each circuit separately and set the desired temperature in each room. So, for a garage, plus 10-15ºС is enough, and for a nursery, a temperature of about plus 23-25ºС is required. In addition, heated floors should not heat up more than 35-37 degrees, otherwise it will be unpleasant to walk on them, and the floor covering may become deformed. With the help of a manifold and shut-off temperature, this problem can also be solved.

Manifold groups for heating systems are sold ready-made, and they can have different configurations and the number of outlets. You can select a suitable collector assembly and install it yourself or with the help of specialists.

However, most industrial models are universal and do not always fit the needs of a particular home. Redesigning or modifying them can significantly increase costs. Therefore, in most cases it is easier to assemble it from separate blocks with your own hands, taking into account the characteristics of a particular heating system.

Manifold group for heating system assembly

The design of the universal collector group is shown in the figure. It consists of two blocks for forward and reverse coolant flow, equipped with the required number of outlets. Flow meters are installed on the supply (direct) manifold, and thermal heads are located on the return manifold to regulate the return water temperature in each circuit. With their help, you can set the required coolant flow rate, which will determine the temperature in the heating radiators.

The manifold distribution unit is equipped with a pressure gauge, circulation pump and air valves. The supply and return manifolds are combined into one unit with brackets, which also serve to attach the unit to a wall or cabinet. The price of such a block is from 15 to 20 thousand rubles. and if some of the taps are not used, its installation will be clearly impractical.

What is a collector?

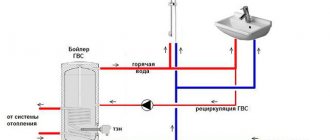

When installing a water supply system from scratch or replacing an old one, you need to think about the location of all consumers: toilet, washbasin, washing machine.

In a typical apartment, the number of plumbing fixtures varies from four to ten. Experienced plumbers recommend their customers to install a water collector.

A water collector is a kind of distributor, which is an important plumbing element of a cold and hot water supply and heating system. It is installed on the central riser and hidden in the plumbing closet. Access to the distribution comb should not be blocked by furniture or sewn tightly into the wall. However, professional repairmen will give the engineering unit an aesthetic appearance.

Collector design and principle of operation

The direct function of a collector in a water supply system is to distribute one water flow into several flows of equal pressure.

Combs with two, three and four outlets are available. If more branches are needed, the distributors are connected to each other. In this way, a water supply collector is assembled for the required number of outlets.

The collector is connected directly to the riser. On two opposite sides of the device there is a threaded connection (internal thread on one side, external thread on the other) for connecting to the main line and connecting the combs to each other.

A plug or an additional plumbing device, for example, a membrane water hammer absorber, is installed at the free end of the collector.

The diameter of the inlet hole is 20-40% larger than the outlet hole. For example, on a standard manifold for installing water supply in an apartment, the diameter of the inlet hole is 3/4 inch, the outlet hole is 1/2 inch.

1. Manifold with valves. 2. Manifold with ball valves.

Both ball valves and valves can be installed at the outlet openings, allowing not only to open and close the water flow, but also to regulate the power of the flow in this area.

Making a comb with your own hands

elements for the comb

Although this is not very economically justified, with the necessary tools and a lot of patience, you can make a polypropylene comb yourself. To do this you will need the following materials:

- hacksaw and soldering iron for polypropylene;

- pieces of polypropylene pipe with a diameter of 25 and 32 mm;

- tees 32x25x32;

- plugs for 32nd diameter;

- couplings with internal threads 32:1 inch and 25:3\4;

- couplings with external thread 25:3\4;

- sealant;

- Ball Valves;

- air extractor.

You can do without an air extractor. But be sure to leave space at both ends to connect additional devices to the water supply comb in the future. During welding, it is important to “by eye” check the quality of the seams to prevent completely welded elements.

Video on how to make and install a cold water distribution comb yourself:

Why do you need a collector?

A water supply system with a separator and a separate pipe supply to each consumer will cost more than a classic wiring. Is it worth overpaying for a collector for water and heating?

- The device is used to regulate water pressure in the apartment. In standard wiring, the pressure in an open tap often decreases if someone opens another tap or flushes the toilet. This threatens not only discomfort, but also burns due to too hot water, which suddenly begins to flow. The well-thought-out diameter of the manifold eliminates pressure problems. No matter how many taps are open in the apartment, the water pressure remains the same.

- There are taps at each outlet that allow you to regulate the flow of water along the branch. If the mixer is being repaired, it is not necessary to completely turn off the supply of cold and hot water from the risers. It is enough to switch only a certain branch.

- The absence of joints and tees built into the wall minimizes the risk of leaks. If a faucet or fitting fails, it can be easily replaced by disassembling the manifold system in the cabinet. The lining in the bathroom will not be damaged.

- If you need to add another consumer to the water supply system, you will not have to redo the entire wiring. Connection will be inexpensive and will not require much time.

Reservoir classification

Separating combs for water supply differ in both their design and materials. Before choosing a collector, study the entire range on the market.

Separators are made from different materials:

- Stainless steel is resistant to corrosion, fire and high temperature. The weight of the stainless steel collector is light, which makes it easy to attach it to the wall. This is an absolutely harmless material that gives the product an attractive appearance.

- Brass is an incredibly durable metal that is not afraid of corrosion and high temperatures. Brass combs are expensive, but they guarantee maximum strength.

- Dividers made of polypropylene are not afraid of rust and are lightweight.

Manifold made of polypropylene.

Some craftsmen can make a collector with their own hands from polypropylene pipes, which is in no way inferior in quality to factory products.

Collectors differ in the way the pipes are attached. Depending on the material of the pipes used, the comb model is selected.

1. A comb for installing taps and any plumbing fixtures at your discretion. 2. With compression fittings - designed for installation of pipes made of metal-plastic or cross-linked polyethylene. 3. For installation of polypropylene pipes. 4. Under the Eurocone. Suitable for installing pipes from almost any material through an adapter (Eurocone).

Separating combs differ in the number of bends. Minimum – 2 outputs, maximum – 6. Bends that are not currently in use can be closed with plugs. If it is necessary to make more than 6 outputs, several collectors are connected to each other.

Products on the market

The catalogs of accessories for collector water supply systems provide a wide variety of not only combs, but also their components.

- Dividers without taps are much cheaper. They allow you to assemble a device that will best suit the object. This option is preferable, as it allows you to easily replace only the failed faucet. While the one-piece design will require complete replacement.

- Devices with shut-off valves greatly simplify the installation of a water supply collector. They simplify the assembly of the unit - there is no need to install taps.

- Accessories allow you to adapt the system according to your wishes: valves, pump groups, plugs, valves, brackets, couplings, ends, servos, fittings.

- Manifold cabinets are sold separately, which are mounted into the wall and provide an aesthetic appearance, as well as access to the engineering unit.

How to install?

Before installing a water distribution unit for cold and hot water supply, give an accurate answer to the following questions and consider the following points:

- How many water consumers are there on site? The number of collector outlets should be the same or slightly greater than the number of consumers. Excess branches are closed with plugs.

- What type of pipes will be used to install the water supply? It is necessary to purchase devices designed specifically for pipes made of the selected material.

- Estimate in advance the position of all engineering elements in the space of the plumbing cabinet (you can make markings on the wall). Please note that a water meter and a water filter are installed in front of the distribution comb. The convenient location of all devices facilitates maintenance and repair work.

- Get reliable fastening - a poorly secured distribution unit can lead to depressurization of connections and damage to the pipeline.

- Before installation, make sure that you have all the necessary consumables on hand: sealing material, gaskets, adapters.

Installation of the water distribution unit occurs in the following sequence:

- Install the inlet shut-off valves on the water supply riser.

- Install the meter, filter and check valve.

- Connect the manifold and securely fix it to the wall

- Install a water supply to each consumer. Secure the pipes with fasteners.

This operating algorithm will allow you to avoid errors. Regardless of whether the collector is needed for water supply or heating, its installation is the same. Such wiring requires more time, skill and money, but pays off quickly and provides comfort in further use. Collectors are appropriate not only in cottages and large houses, but also in apartments.

What is a notched trowel used for?

The process of laying tiles begins with applying adhesive to the facing surface. These manipulations are carried out with a regular construction spatula, but to remove the excess amount of adhesive solution, you need a special comb with teeth. This tool allows you to distribute the required volume of joining solution over the surface. After pressing the decorating plates to the place of installation, the glue evenly fills the required space.

Thanks to these actions, the material is securely fixed to the surface.

If the installation is carried out on the wall, you can be sure that the tiles will not fall off. If the installation is done on the floor, then if heavy objects fall, holes will not appear on it, although cracks may form on the top layer of tiles.

Using a tile comb has many advantages:

- The installation is reliable and of high quality, since the adhesive mixture is distributed in an equal layer over the entire surface. The main condition is that the base should not have defects.

- The pace of work is significantly accelerated, since additional time is not wasted on displacing the glue and removing its excess.

- The adhesive solution is consumed in the optimal amount. A notched trowel helps to use exactly as much glue as the instructions indicate. Therefore, you don’t have to worry about over-consumption of the mixture and, accordingly, about unnecessary material costs.