A heat pump is a device that heats water from heating and hot water supply systems by compressing freon, initially heated from a low-grade heat source, by a compressor to 28 bar. Under high pressure, a gaseous coolant with an initial temperature of 5-10 ° C; releases a large amount of heat. This allows you to warm up the coolant of the consumption system to 50-60 °C, without the use of traditional types of fuel. Therefore, it is believed that a heat pump provides the user with the cheapest heat.

For more information about the advantages and disadvantages, watch the video:

Such equipment has been in operation for more than 40 years in Sweden, Denmark, Finland and other countries that support the development of alternative energy at the state level. Not so actively, but more confidently every year, heat pumps are entering the Russian market.

Purpose of the article: to review popular models of heat pumps. The information will be useful to those who seek to save as much as possible on heating and hot water supply of their own home.

The heat pump heats the house with free energy from nature

In theory, heat can be extracted from the air, soil, groundwater, wastewater (including from a septic tank and water pumping station), and open reservoirs. In practice, for most cases, the feasibility of using equipment that takes thermal energy from the air and soil has been proven.

Options with heat extraction from a septic tank or sewage pumping station (SPS) are the most tempting. By passing the coolant through the HP at 15-20 °C, the output temperature can be at least 70 °C. But this option is acceptable only for a hot water supply system. The heating circuit reduces the temperature in the "tempting" source. Which leads to a number of unpleasant consequences. For example, freezing of drains; and if the heat exchange circuit of the heat pump is located on the walls of the sump, then the septic tank itself.

The most popular HPs for the needs of CO and DHW are geothermal (using the heat of the earth) devices. They are distinguished by their best performance in warm and cold climates, in sandy and clayey soils with different groundwater levels. Because the soil temperature below the freezing depth remains almost unchanged throughout the year.

Use of thermal installations in the world

The practice of using such thermal units in the world goes back more than 50 years. The main driving reasons for this phenomenon were the rise in price of traditional energy resources and the widespread support by the governments of many countries for the use of alternative energy sources.

Therefore, the number of heat pumps is constantly growing at a high rate - up to 10 - 30% per year, despite the high cost of installation. The number of such devices currently amounts to more than 270 pieces. Thermal systems are most actively used in the USA and Canada. They account for up to half of the installations used worldwide.

Russia, despite positive conditions for the use of heat pumps, lags behind global trends in their use. Our belief in a complete supply of natural resources seems to play a role here. At the same time, not all settlements in the country have gas pipelines. World experience in the use of heat pumps indicates positive trends in the development of their use.

Operating principle of a heat pump

The coolant is heated from a source of low-potential (5...10 °C) heat. The pump compresses the refrigerant, the temperature of which rises (50...60 °C) and heats the coolant of the heating system or hot water supply.

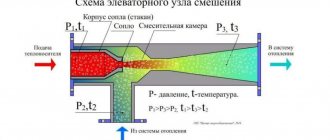

During the operation of the HP, three thermal circuits are involved:

- external (system with coolant and circulation pump);

- intermediate (heat exchanger, compressor, condenser, evaporator, throttle valve);

- consumer circuit (circulation pump, heated floor, radiators; for hot water supply - tank, water points).

The process itself looks like this:

Thermal energy removal circuit

- The soil heats the saline solution.

- The circulation pump lifts the brine into the heat exchanger.

- The solution is cooled by a refrigerant (freon) and returned to the ground.

Heat exchanger

- Liquid freon, evaporating, takes away thermal energy from the brine.

- The compressor compresses the refrigerant, causing its temperature to rise sharply.

- In the condenser, freon transfers energy through the evaporator to the coolant of the heating circuit and becomes liquid again.

- The cooled refrigerant goes through the throttle valve to the first heat exchanger.

Heating circuit

- The heated coolant of the heating system is drawn by the circulation pump to the dissipating elements.

- Transfers thermal energy to the air mass of the room.

- The cooled coolant returns through the return pipe to the intermediate heat exchanger.

Video with a detailed description of the process:

Conclusion

In the article I showed the types of heat pumps that can be used to heat a house. If you carefully read everything that was described above, you can come to the conclusion that a heat pump is an effective and cheap way to keep heating and water supply in the house. However, my opinion is that in Russia everyone should have affordable, cheap gas heating, without the “European eco-troubles” of extracting heat from shit.

©Obotoplenii.ru

More articles

- Stages of gasification at home

- Brick chimney for gas boiler

- Installation of a gas boiler in a house: stage of gasification of a private house

- Requirements for a room with a gas boiler

- Obtaining technical specifications for gasification of a house

- Construction and installation of internal gas supply at home

- Installation of a chimney for a gas boiler

What is cheaper for heating: electricity, gas or heat pump?

We present the costs of connecting each type of heating. To present the general picture, let’s take the Moscow region. Prices may differ in regions, but the price ratio will remain the same. In the calculations we assume that the site is “bare” - without gas or electricity.

Connection costs

Heat pump. Laying a horizontal contour at MO prices - 10,000 rubles per shift of an excavator with a bucket bucket (removes up to 1,000 m³ of soil in 8 hours). A system for a house of 100 m² will be buried in 2 days (true for loam, on which you can remove up to 30 W of thermal energy from 1 square meter of circuit). About 5,000 rubles will be required to prepare the circuit for operation. As a result, the horizontal option for placing the primary circuit will cost 25,000.

The well will be more expensive (1,000 rubles per linear meter, taking into account the installation of probes, piping them into one line, filling with coolant and pressure testing), but it will be much more profitable for future operation. With a smaller occupied area of the site, the output increases (for a 50 m well - at least 50 W per meter). The pump's needs are covered and additional potential appears. Therefore, the entire system will not work for wear, but with some reserve power. Place 350 meters of contour in vertical wells – 350,000 rubles.

A gas boiler. In the Moscow region, for connection to the gas network, work on the site and installation of the boiler, Mosoblgaz requests from 260,000 rubles.

Electric boiler. Connecting a three-phase network will cost 10,000 rubles: 550 for local electrical networks, the rest for the distribution board, meter and other contents.

Consumption

To operate a HP with a thermal power of 9 kW, 2.7 kW/h of electricity is required - 9 rubles. 53 kopecks at one o'clock,

The specific heat during combustion of 1 m³ of gas is the same 9 kW. Household gas for Moscow region is priced at 5 rubles. 14 kopecks per cubic meter

An electric boiler consumes 9 kW/h = 31 rubles. 77 kop. at one o'clock. The difference with TN is almost 3.5 times.

Exploitation

- If gas is supplied, then the most cost-effective option for heating is a gas boiler. The equipment (9 kW) costs at least 26,000 rubles, the monthly payment for gas (12 hours per day) will be 1,850 rubles.

- Powerful electrical equipment is more profitable from the point of view of organizing a three-phase network and purchasing the equipment itself (boilers - from 10,000 rubles). A warm house will cost 11,437 rubles per month.

- Taking into account the initial investment in alternative heating (equipment 275,000 and installation of a horizontal circuit 25,000), a heat pump that consumes electricity at 3,430 rubles/month will pay for itself no earlier than in 3 years.

Comparing all heating options, provided that the system is created from scratch, it becomes obvious: gas will not be much more profitable than a geothermal heat pump, and heating with electricity in the next 3 years is hopelessly inferior to both of these options.

Detailed calculations in favor of operating a heat pump can be found by watching a video from the manufacturer:

Some additions and experience of effective operation are highlighted in this video:

Vertical collector calculation

At a depth of over 15 m, the ground temperature remains stable at +10 degrees all year round. Therefore, the efficiency of a vertical collector is higher - on average, up to 50 W of heat can be removed from a meter-long area. To calculate the length of the heat exchanger, the type of medium must also be taken into account. So, from 1 meter of pipe it is possible to obtain the following thermal power:

- 20 W – when immersed in sedimentary soil (dry);

- 50 W – in rocky or wet sedimentary soil;

- 70 W – hard rocks (stone);

- 80 W – groundwater.

Application of vertical probe for heat pump

When constructing wells, the following condition must be observed: the distance between them must be at least 5 m.

To operate the heat pump from the above example, you will need a collector with a length of L = 5200 / 50 = 140 m.

Consequently, to equip the reservoir, it will be necessary to drill two wells with a depth of 70 m. In each of them, two U-shaped loops will need to be installed, for which it will be necessary to purchase 4x140 = 560 m of pipes.

Main characteristics

When choosing equipment from a wide variety of specifications, pay attention to the following characteristics.

Main characteristics of heat pumps

| Characteristics | Range of values | Peculiarities |

| Thermal power, kW | Up to 8 | Premises with an area of no more than 80 - 100 m², with a ceiling height of no more than 3 m. |

| 8-25 | For one-level country houses with a ceiling of 2.5 m, an area of 50 m²; cottages for permanent residence, up to 260 m². | |

| Over 25 | It is advisable to consider for 2-3 level residential buildings with ceilings of 2.7 m; industrial facilities - no more than 150 m², with a ceiling height of 3 or more. | |

| Power consumption of main equipment (maximum consumption of auxiliary elements) kW/h | From 2 (from 6) | Characterizes the energy consumption of the compressor and circulation pumps (heating elements). |

| Scheme of work | Air-to-air | The transformed thermal energy of the air is transferred into the room by a flow of heated air through a split system. |

| Air - water | The energy removed from the air passed through the device is transferred to the coolant of the liquid heating system. | |

| Brine-water | The transfer of thermal energy from a renewable source is carried out by a sodium or calcium solution. | |

| Water-water | Through the open primary circuit, groundwater carries thermal energy directly to the heat exchanger. | |

| Outlet coolant temperature, °C | 55-70 | The indicator is important for calculating losses on a long heating circuit and when organizing an additional hot heat supply system. |

| Mains voltage, V | 220, 380 | Single-phase - power consumption no more than 5.5 kW, only for a stable (lightly loaded) household network; the cheapest - only through a stabilizer. If there is a 380 V network, then three-phase devices are preferable - a larger power range, less likely to “sag” the network. |

Summarizing

Participants on our portal use a heat pump as a full-fledged heating system (not an auxiliary one). According to our observations, a heat pump is becoming an increasingly popular method of heating a country house. According to reviews from our users, a heat pump works best in houses with low heat loss, so ideally the house should be “tailored” for this device at the design stage. A good option would be a frame structure with all the necessary insulation, membranes and films, or a stone house. Second point: a heat pump is most effective in combination with low-temperature heating devices, so it’s better to immediately focus on heated floors.

On FORUMHOUSE you can find a huge amount of information for those who decide to make a heat pump with their own hands or someone else’s. There are recommendations for the correct design of a geothermal circuit of a heat pump, invaluable tips for making a heat pump yourself, find out how to make the most budget-friendly, “people’s” heating system based on a heat pump, watch our video about a house that is successfully heated with a heat pump.

Model summary table

In the article, we examined the most popular models and identified their strengths and weaknesses.

The list of models can be found in the following table: Summary table of models

| Model (country of origin) | Peculiarities | price, rub. |

| Heat pumps for heating small spaces or domestic hot water | ||

| 1. Huch EnTEC VARIO China S2-E (Germany) | Air-water system; works from a single-phase network; the protruding condensation line is inserted into the water tank. | 184 493 |

| 2. NIBE F1155-6 EXP (Sweden) | "Brine-water"; power supply from a three-phase network; variable power control; possibility of connecting additional equipment - recuperator, multi-temperature equipment. | 355 161 |

| 3. Fujitsu WSYA100DD6 (Japan) | Air-water heat pump powered by 220V mains and with frost protection function. | 524 640 |

| Equipment for heating systems of cottages for permanent residence | ||

| 4. Vaillant geoTHERM VWW 61/3 (Germany) | “Water - water” scheme. In order for the HP to produce a stable 62 °C coolant in the heating system, the capabilities of the set of compressor and pumps (1.5 kW) are complemented by an electric heater with a power of 6 kW. | 408 219 |

| 5. LG Therma V AH-W096A0 9 kW (Korea) | Based on the air-water circuit, the potentials of cooling and heating devices are realized in one device, consisting of two blocks. | 275 000 |

| 6. STIEBEL ELTRON WPF 10MS (Germany) | “brine-water”, the device heats the coolant for radiators up to 60 °C, can be used when organizing cascade heating systems. | 323 300 |

| 7. Daikin EGSQH (Japan) | In the same housing with the geothermal pump there is a storage tank for the hot water supply system, for 180 liters of coolant | 1 607 830 |

| Powerful heat pumps for heating and hot water supply needs | ||

| 8. WATERKOTTE EcoTouch DS 5027.5 Ai (Germany) | It is possible to extract heat from soil and groundwater; operation as part of cascade systems and remote control are possible; works from a three-phase network. | 708 521 |

| 9. DANFOSS DHP-R ECO 42 (Sweden) 9.6= 42 65 380 | "brine-water"; control of the compressor power and the rotation speed of the circulation pumps is carried out through frequency adjustment; additional heat exchanger; network – 380 V. | 1 180 453 |

| 10. Viessmann Vitocal 300-G WWC 110 (Germany) | “water-to-water” operating scheme; built-in primary and secondary circuit pumps; The possibility of connecting solar systems is provided. | 630 125 |

The time has come to substantively study foreign experience

Almost everyone now knows about heat pumps capable of extracting heat from the environment to heat buildings, and if until recently a potential customer, as a rule, asked the perplexed question “how is this possible?”, Now the question “how is this correct” is increasingly heard do?".

It is not easy to answer this question.

In search of an answer to the numerous questions that inevitably arise when trying to design heating systems with heat pumps, it is advisable to turn to the experience of specialists from those countries where heat pumps on ground heat exchangers have been used for a long time.

A visit* to the American exhibition AHR EXPO 2008, which was undertaken mainly to obtain information about methods of engineering calculations of ground heat exchangers, did not bring direct results in this direction, but a book was sold at the ASHRAE exhibition stand, some of the provisions of which served as the basis for this publications.

It should be said right away that transferring American methods to domestic soil is not an easy task. For Americans, everything is not the same as in Europe. Only they measure time in the same units as we do. All other units of measurement are purely American, or rather British. Americans are especially unlucky with heat flow, which can be measured both in British thermal units per unit of time and in tons of cooling, which were probably invented in America.

The main problem, however, was not the technical inconvenience of recalculating the units of measurement adopted in the United States, to which one can get used to over time, but the absence in the mentioned book of a clear methodological basis for constructing a calculation algorithm. Too much space is devoted to routine and well-known calculation methods, while some important provisions remain completely undisclosed.

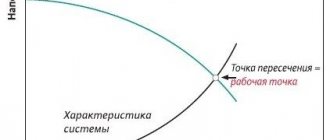

In particular, such physically related initial data for calculating vertical ground heat exchangers, such as the temperature of the liquid circulating in the heat exchanger and the conversion coefficient of the heat pump, cannot be set arbitrarily, and before proceeding with calculations related to unsteady heat exchange in the ground, it is necessary to determine the dependencies connecting these parameters.

The criterion for the efficiency of a heat pump is the conversion coefficient ?, the value of which is determined by the ratio of its thermal power to the power of the electric drive of the compressor. This value is a function of the boiling temperatures in the evaporator tu and the condensation temperatures tk, and in relation to water-to-water heat pumps, we can talk about the liquid temperatures at the outlet of the evaporator t2I and at the outlet of the condenser t2K:

? = ?(t2I,t2K). (1)

Analysis of the catalog characteristics of serial refrigeration machines and water-to-water heat pumps made it possible to display this function in the form of a diagram (Fig. 1).

Using the diagram, it is not difficult to determine the parameters of the heat pump at the very initial stages of design. It is obvious, for example, that if the heating system connected to the heat pump is designed to supply coolant with a supply temperature of 50°C, then the maximum possible conversion coefficient of the heat pump will be about 3.5. In this case, the glycol temperature at the outlet of the evaporator should not be lower than +3°C, which means that an expensive ground heat exchanger will be required.

At the same time, if the house is heated using underfloor heating, coolant with a temperature of 35°C will flow from the heat pump condenser into the heating system. In this case, the heat pump can operate more efficiently, for example with a conversion factor of 4.3, if the temperature of the glycol cooled in the evaporator is around -2°C.

Using Excel spreadsheets, you can express function (1) as an equation:

? = 0.1729 • (41.5 + t2I – 0.015t2I • t2K – 0.437 • t2K (2)

If, with the desired conversion coefficient and a given value of the coolant temperature in a heating system powered by a heat pump, it is necessary to determine the temperature of the liquid cooled in the evaporator, then equation (2) can be presented as:

(3)

You can select the coolant temperature in the heating system at given values of the heat pump conversion coefficient and the liquid temperature at the outlet of the evaporator using the formula:

(4)

In formulas (2)…(4) temperatures are expressed in degrees Celsius.

Having identified these dependencies, we can now move directly to the American experience.

Heat pumps for heating small spaces or domestic hot water

Purpose – economical heating of residential and auxiliary premises, maintenance of the hot water supply system. Single-phase models have the lowest consumption (up to 2 kW). To protect against power surges in the network, they need a stabilizer. The reliability of three-phase is explained by the characteristics of the network (the load is distributed evenly) and the presence of its own protective circuits that prevent damage to the device due to voltage surges. Equipment in this category does not always cope with simultaneous maintenance of the heating system and hot water supply circuit.

Huch EnTEC VARIO China S2-E (Germany) – from RUB 184,493.

The Huch EnTEC VARIO cannot be operated independently. Only in conjunction with the storage tank of the hot water supply system. The HP heats water for sanitary needs, cooling the air in the room.

Among the advantages are the low energy consumption of the device, an acceptable water temperature in the DHW circuit and the function of cleaning the system (by periodic short-term heating to 60 ° C) from pathogenic bacteria that develop in a humid environment.

The disadvantages are that gaskets, flanges and cuffs must be purchased separately. Be sure to be original, otherwise there will be drips.

When calculating, you must remember that the device pumps 500 m³ of air per hour, so the minimum area of the room in which the Huch EnTEC VARIO is installed must be at least 20 m², with a ceiling height of 3 meters or more.

Main characteristics of Huch EnTEC VARIO China S2-E

| Characteristics | Meaning |

| Scheme of work | Air - water |

| Thermal power, kW | 3.2 |

| Electricity consumption, kW/h (grid) | 1.9 (220) |

| Outlet coolant temperature, °C | 55 |

| Operating temperature range of the primary circuit, °C | +7…+35 |

| Refrigerant type | R134A |

| Weight, kg | 31 |

NIBE F1155-6 EXP (Sweden) – from RUB 355,161.

The model is declared as “intelligent” equipment, with automatic adjustment to the needs of the object. An inverter power supply circuit for the compressor has been introduced, making it possible to adjust the output power.

The presence of such a function with a small number of consumers (water points, heating radiators) makes heating a small house more profitable than in the case of a conventional, non-inverter HP (which does not have a soft start of the compressor and the output power is not regulated). Because at NIBE, at low power values, the heating elements are rarely turned on, and the heat pump’s own maximum consumption is no more than 2 kW.

In a small facility, the noise (47 dB) is not acceptable.

The optimal installation option is a separate room. Place the harness on walls not adjacent to the rest rooms. Main characteristics of NIBE F1155-6 EXP

| Characteristic | Meaning |

| Scheme of work | Brine - water |

| Thermal power, kW | 4-16 |

| Electricity consumption (network, V/pumps, compressor/heating elements), kW/h | 380 / 1.9 / 9 |

| Outlet coolant temperature, °C | 65 |

| Operating temperature range of the primary circuit, °C | 0… +35 |

| Refrigerant type | R 407C |

| Weight, kg | 185 |

Fujitsu WSYA100DD6 (Japan) – from RUB 524,640.

“Out of the box” only works for heating in one circuit. An optional kit for connecting a second circuit is available, with the possibility of independent configuration for each. But the heat pump itself is designed for heating a room up to 100 m², with a ceiling height of no more than 3 meters.

The list of advantages includes small dimensions, operation from a household power supply, adjustment of the output temperature from 8 to 55 °C, which, according to the manufacturer’s plan, should somehow affect the comfort and accuracy of control of connected systems.

But everything was canceled out by low power. In our climate, heating the declared 100 m², the device will work for wear. This is confirmed by the device’s frequent transitions to “emergency” mode, with the pump turning off and errors on the display. The case is not guaranteed. Fixed by restarting the equipment.

“Accidents” affect energy consumption.

Because when the compressor stops, the heating element comes into operation. Therefore, the joint connection of CO and underfloor heating (or DHW) circuits is permissible in a facility with an area of no more than 70 m². Main characteristics of Fujitsu WSYA100DD6

| Characteristic | Meaning |

| Scheme of work | Air - water |

| Thermal power, kW | 6 |

| Electricity consumption, kW/h (grid) | 2.04 (220) |

| Outlet coolant temperature, °C | 60 |

| Operating temperature range of the primary circuit, °C | -20… +35 |

| Refrigerant type | R410A |

| Weight, kg | 42 |

Making a geothermal installation

If the previous option allows you to achieve approximately double savings, then even a homemade earthen circuit will give a COP in the region of 3 (three kilowatts of heat per 1 kW of electricity consumed). True, financial and labor costs will also increase significantly.

Although a lot of examples of assembling such devices have been published on the Internet, there are no universal instructions with drawings. We will offer a working version, assembled and tested by a real home craftsman, although many things will have to be thought out and completed independently - it is difficult to put all the information about heat pumps in one publication.

Calculation of the soil circuit and pump heat exchangers

Following our own recommendations, we begin to calculate a geothermal pump with vertical U-shaped probes placed in wells. It is necessary to find out the total length of the external contour, and then the depth and number of vertical shafts.

Initial data for the example: you need to heat a private insulated house with an area of 80 m² and a ceiling height of 2.8 m, located in the middle zone. We will not calculate the heating load; we will determine the heat requirement by area, taking into account thermal insulation - 7 kW.

If desired, you can arrange a horizontal collector, but then you will have to allocate a large area for excavation work

Important clarification. Engineering calculations of heat pumps are quite complex and require highly qualified performers; entire books are devoted to this topic. The article provides simplified calculations taken from the practical experience of builders and craftsmen who love homemade products.

The intensity of heat exchange between the ground and the non-freezing liquid circulating along the circuit depends on the type of soil:

- 1 linear meter of a vertical probe immersed in underground water will receive about 80 W of heat;

- in rocky soils, the heat removal will be about 70 W/m;

- clayey soils saturated with moisture will deliver approximately 50 W per 1 m of collector;

- dry rocks – 20 W/m.

Reference. The vertical probe consists of 2 loops of pipes lowered to the bottom of the well and filled with concrete.

An example of calculating the length of a pipe. To extract the required 7 kW of thermal energy from raw clay rock, you will need 7000 W divided by 50 W/m, we get a total probe depth of 140 m. Now the pipeline is distributed into wells 20 m deep, which you can drill with your own hands. A total of 7 drillings for 2 heat exchange loops, the total length of the pipe is 7 x 20 x 4 = 560 m.

The next step is to calculate the heat exchange area of the evaporator and condenser. Various Internet resources and forums offer certain calculation formulas, which in most cases are incorrect. We will not take the liberty of recommending such methods and misleading you, but we will offer a cunning option:

- Contact any well-known manufacturer of plate heat exchangers, for example, Alfa Laval, Kaori, Anvitek and so on. You can go to the official website of the brand.

- Fill out the heat exchanger selection form or call the manager and order the selection of the unit, listing the parameters of the media (antifreeze, freon) - inlet and outlet temperatures, heat load.

- The company’s specialist will make the necessary calculations and offer a suitable heat exchanger model. Among its characteristics you will find the main one - the exchange surface area.

Plate units are very effective, but expensive (200-500 euros). It is cheaper to assemble a shell-and-tube heat exchanger from a copper tube with an outer diameter of 9.5 or 12.7 mm. Multiply the figure given by the manufacturer by a safety factor of 1.1 and divide by the circumference of the pipe to obtain the footage.

A stainless steel plate heat exchanger is an ideal evaporator option, it is efficient and takes up little space. The problem is the high price of the product

Example. The heat exchange area of the proposed unit was 0.9 m². Having selected a ½” copper tube with a diameter of 12.7 mm, we calculate the circumference in meters: 12.7 x 3.14 / 1000 ≈ 0.04 m. Determine the total footage: 0.9 x 1.1 / 0.04 ≈ 25 m.

Equipment and materials

It is proposed to build the future heat pump on the basis of an outdoor unit of a split system of suitable power (indicated on the plate). Why is it better to use a used air conditioner:

- the device is already equipped with all components - compressor, throttle, receiver and starting electrics;

- homemade heat exchangers can be placed in the body of the refrigeration machine;

- There are convenient service ports for refilling freon.

Note. Users who are knowledgeable about the topic select equipment separately - compressor, expansion valve, controller, and so on. If you have experience and knowledge, such an approach is only welcome.

It is impractical to assemble a HP on the basis of an old refrigerator - the power of the unit is too low. In the best case, it will be possible to “squeeze” up to 1 kW of heat, which is enough to heat one small room.

In addition to the external split unit, you will need the following materials:

- HDPE pipe Ø20 mm - to the earthen circuit;

- polyethylene fittings for assembling collectors and connecting to heat exchangers;

- circulation pumps – 2 pcs.;

- pressure gauges, thermometers;

- high-quality water hose or HDPE pipe with a diameter of 25-32 mm for the shell of the evaporator and condenser;

- copper tube Ø9.5–12.7 mm with a wall thickness of at least 1 mm;

- insulation for pipelines and freon lines;

- kit for sealing heating cables laid inside the water supply (needed to seal the ends of copper pipes).

A set of bushings for hermetically sealed insertion of a copper tube.

A saline solution of water or antifreeze for heating - ethylene glycol - is used as an external coolant. You will also need a supply of freon, the brand of which is indicated on the nameplate of the split system.

Assembling the heat exchange block

Before starting installation work, the outdoor module must be disassembled - remove all covers, remove the fan and the large standard radiator. Disconnect the solenoid that controls the reversing valve if you do not plan to use the pump as a coolant. Temperature and pressure sensors must be retained.

Assembly procedure for the main VT block:

- Make a condenser and evaporator by inserting a copper tube inside a hose of the estimated length. At the ends, install tees to connect the ground and heating circuits; seal the protruding copper tubes using a special kit for the heating cable.

- Using a piece of plastic pipe Ø150-250 mm as a core, wind homemade two-pipe circuits and bring the ends in the right directions, as is done below in the video.

- Place and secure both shell-and-tube heat exchangers in place of the standard radiator, solder the copper tubes to the corresponding terminals. It is better to connect a “hot” heat exchanger-condenser to the service ports.

- Install factory sensors that measure coolant temperature. Insulate the bare sections of the tubes and the heat exchange devices themselves.

- Place thermometers and pressure gauges on the water lines.

Advice. If you plan to install the main unit outdoors, you need to take measures to prevent the oil from solidifying in the compressor. Purchase and install a winter kit for electric oil sump heating.

On thematic forums there is another way to make an evaporator - a copper tube is wound in a spiral, then inserted inside a closed container (tank or barrel). The option is quite reasonable with a large number of turns, when the calculated heat exchanger simply does not fit in the air conditioner housing.

Construction of the soil contour

At this stage, simple but labor-intensive excavation work and placement of probes in wells are performed. The latter can be done manually or by inviting a drilling machine. The distance between adjacent wells is at least 5 m. Further work order:

- Dig a shallow trench between the drillings to lay the supply pipes.

- Place 2 loops of polyethylene pipes into each hole and fill the holes with concrete.

- Bring the lines to the connection point and mount a common manifold using HDPE fittings.

- Insulate pipelines laid in the ground and fill them with soil.

On the left in the photo is lowering the probe into a plastic casing pipe, on the right is laying connections in the trench

Important point. Before concreting and backfilling, be sure to check the tightness of the circuit. For example, connect an air compressor to the manifold, pump up a pressure of 3-4 bar and leave for several hours.

When connecting highways, follow the diagram presented below. Bends with taps will be needed when filling the system with brine or ethylene glycol. Lead the two main pipes from the collector to the heat pump and connect to the “cold” evaporator heat exchanger.

Air vents must be installed at the highest points of both water circuits; they are not shown in the diagram.

Do not forget to install a pump unit responsible for the circulation of the liquid, the direction of flow is towards the freon in the evaporator. The media passing through the condenser and evaporator must move towards each other. How to properly fill the cold side lines, watch the video:

In a similar way, the condenser is connected to the house floor heating system. A mixing unit with a three-way valve does not need to be installed due to the low supply temperature. If it is necessary to combine the transformer with other heat sources (solar collectors, boilers), use a buffer tank with several terminals.

Refueling and starting the system

After installing and connecting the unit to the electrical network, an important stage begins - filling the system with refrigerant. A pitfall awaits here: you don’t know how much freon you need to charge, because the volume of the main circuit has increased significantly due to the installation of a homemade condenser with an evaporator.

The issue is solved by the filling method based on the pressure and overheating temperature of the refrigerant, measured at the compressor inlet (freon is supplied there in a gaseous state). Detailed instructions for completing the temperature measurement method are provided in the following manual.

The second part of the video describes how to fill the system with R22 freon based on the pressure and superheat temperature of the refrigerant:

Upon completion of refueling, turn on both circulation pumps to first speed and start the compressor. Monitor the temperature of the brine and internal coolant using thermometers. During the warm-up stage, the lines with the refrigerant may freeze, and subsequently the frost should melt.

Equipment for heating systems of standard cottages for permanent residence

Geothermal, air and water (removing thermal energy from groundwater) devices are presented here. The declared output power (at least 8 kW) is enough to provide heat to all consumer systems of country (and permanent residence) houses. Many heat pumps in this category have a cooling mode. The implemented inverter power circuits are responsible for the smooth start of the compressor; due to its smooth operation, the delta (temperature difference) of the coolant is reduced. The optimal operating mode of the circuit is maintained (without unnecessary overheating and cooling). This allows you to reduce power consumption in all operating modes of the HP. The greatest economic effect is in air-to-air devices.

Vaillant geoTHERM VWW 61/3 (Germany) – from RUB 408,219.

The use of well water as the primary coolant (VWW only) made it possible to simplify the design and reduce the price of the HP without loss of performance.

The device is characterized by low power consumption in the main operating mode and low noise level.

The downside of Vaillant is its demands on water (there are known cases of damage to the supply line and heat exchanger by iron and manganese compounds); work with salt-containing waters should be avoided. The situation is not guaranteed, but if the installation was carried out by service center specialists, then there is someone to file a claim with.

A dry, frost-free room with a volume of at least 6.1 m³ (2.44 m² with a ceiling of 2.5 m) is required.

Dropping under the pump is not a defect (condensation is allowed to drain from the surfaces of insulated circuits). Main characteristics of Vaillant geoTHERM VWW 61/3

| Characteristic | Meaning |

| Scheme of work | Water - water |

| Thermal power, kW | 8.4 |

| Electricity consumption (network, V/pumps, compressor/heating elements), kW/h | 380 / 3.1 / 6 |

| Outlet coolant temperature, °C | 55 |

| Operating temperature range, °C | +7… +25 |

| Refrigerant type | R 407 C |

| Weight, kg | 145 |

LG Therma V AH-W096A0 (Korea) – from RUB 275,000.

Air-to-water heat pump. The device consists of 2 modules: the outer one takes thermal energy from the air masses, the inner one transforms and transfers it to the heating system.

The main advantage is versatility. Can be configured for both heating and cooling the object.

The disadvantage of this LG Therma series is that its (and the entire line’s) potential is not enough for the needs of a cottage with an area of more than 200 m².

An important point: the working units of a two-component system cannot be spaced more than 50 m horizontally and 30 m vertically.

Key Features of LG Therma V AH-W096A0

| Characteristic | Meaning |

| Scheme of work | Air - water |

| Thermal power (heating/cooling), kW | 9/8.6 |

| Electricity consumption (network, V/pumps, compressor/heating elements), kW/h | 220 / 2.7 / 3.5 |

| Outlet coolant temperature, °C | 60 |

| Operating temperature range (heating/cooling), °C | -20… +30 / +5… +48 |

| Refrigerant type | R410A |

| Weight (outdoor/indoor units), kg | 56/28 |

STIEBEL ELTRON WPF 10MS (Germany) – from RUB 323,300.

The WPF 10MS model is the most powerful of the STIEBEL ELTRON heat pumps.

Among the advantages are an automatically adjustable heating mode and the ability to connect 6 devices into a cascade (this is a parallel or serial connection of devices to increase flow, pressure or organize an emergency reserve) system with a power of up to 60 kW.

The downside is that organizing a powerful electrical network for simultaneous connection of 6 such devices is only possible with the permission of the local branch of Rostechnadzor.

There is a peculiarity in setting the modes: after making the necessary adjustments to the program, you should wait until the control lamp goes out.

Otherwise, after closing the lid, the system will return to the original settings. Main characteristics of STIEBEL ELTRON WPF 10MS

| Characteristic | Meaning |

| Scheme of work | Brine - water |

| Thermal power, kW | 9.9 |

| Electricity consumption (network, V/pumps, compressor/heating elements), kW/h | 380/3.1/8.8 |

| Outlet coolant temperature, °C | 60 |

| Operating temperature range, °C | 0… +35 |

| Refrigerant type | R410A |

| Weight, kg | 112 |

Daikin EGSQH10S18A9W (Japan) – from RUB 1,607,830.

A powerful device for simultaneous provision of heat from CO, DHW and heated floors of a residential building with an area of up to 130 m².

Programmable and user-controlled modes; All serviced circuits are controlled within the specified parameters; there is a built-in storage tank (for DHW needs) of 180 liters and auxiliary heaters.

Among the shortcomings is the impressive potential, which will not be fully utilized in a house of 130 m²;

a price due to which the payback period is extended indefinitely; automatic adaptation to external climatic conditions not implemented in the basic configuration. Environmental thermistors (thermal resistors) are optional. That is, when the external temperature changes, it is proposed to adjust the operating mode manually. Main characteristics of Daikin EGSQH10S18A9W

| Characteristic | Meaning |

| Scheme of work | Brine - water |

| Thermal power, kW | 13 |

| Electricity consumption (network, V/pumps, compressor/heating elements), kW/h | 380 / 2.3 / 2.8 |

| Outlet coolant temperature, °C | 60 |

| Operating temperature range, °C | -5… +20 |

| Refrigerant type | R410A |

| Weight, kg | 210 |

Which TN is better to collect

Let us formulate the problem: you need to build a homemade heat pump at the lowest cost. A number of logical conclusions follow from this:

- The installation will have to use a minimum of expensive parts, so it will not be possible to achieve a high COP value. In terms of performance coefficient, our device will lose to factory models.

- Accordingly, it makes no sense to make a purely air HP; it is easier to use an inverter air conditioner in heating mode.

- To get real benefits, you need to manufacture an air-to-water, water-to-water heat pump, or build a geothermal installation. In the first case, you can achieve a COP of about 2-2.2, in the rest you can achieve 3-3.5.

- It will not be possible to do without underfloor heating circuits. Coolant heated to 30-35 degrees is incompatible with the radiator network, except in the southern regions.

Laying the external circuit of the HP to the reservoir

Comment. Manufacturers claim: the inverter split system operates at street temperatures of minus 15-30 °C. In reality, heating efficiency is significantly reduced. According to homeowners' reviews, on frosty days the indoor unit supplies a barely warm air stream.

To implement the water version of the HP, certain conditions are required (optional):

- a pond 25-50 m from the home; at a greater distance, electricity consumption will increase significantly due to a powerful circulation pump;

- a well or well with a sufficient supply (debit) of water and a place for drainage (pit, second well, drainage ditch, sewer);

- prefabricated sewer (if they let you crash into it).

Groundwater flow is easy to calculate. In the process of heat extraction, a homemade heat pump will lower their temperature by 4-5 °C, from here the volume of the flow is determined through the heat capacity of the water. To obtain 1 kW of heat (we take the water temperature delta to be 5 degrees), you need to drive about 170 liters through the heat pump within an hour.

Heating a house with an area of 100 m² will require a power of 10 kW and a water consumption of 1.7 tons per hour - an impressive volume. A similar heat water pump is suitable for a small country house of 30-40 m², preferably insulated.

Methods for selecting heat from geothermal heat pumps

Assembling a geothermal system is more feasible, although the process is quite labor-intensive. We immediately reject the option of laying the pipe horizontally over an area at a depth of 1.5 m - you will have to shovel the entire area or pay money for the services of earth-moving equipment. The method of drilling wells is much simpler and cheaper to implement, with virtually no disturbance to the landscape.

Equipment for objects with high heat consumption

To fully meet the thermal energy needs of residential and commercial buildings with an area of more than 200 m². Remote control, cascade operation, interaction with recuperators and solar systems - expand the user’s capabilities in creating a comfortable temperature.

WATERKOTTE EcoTouch DS 5027.5 Ai (Germany) – from RUB 708,521.

The DS 5027.5 Ai modification is the most powerful in the EcoTouch line. Stably warms up the heating circuit coolant and provides thermal energy to the hot water supply system in rooms up to 280 m².

Scroll (the most productive existing) compressor; adjusting the coolant flow rate allows you to obtain stable output temperature readings; color display; Russified menu; neat appearance and low noise level. Every detail is for comfortable use.

When the water points are actively used, the heating elements are turned on, causing energy consumption to increase by 6 kW/h.

Main characteristics of WATERKOTTE EcoTouch DS 5027.5 Ai

| Characteristic | Meaning |

| Scheme of work | Brine-water |

| Thermal power, kW | 26 /19.6 |

| Electricity consumption (network, V/pumps, compressor/heating elements), kW/h | 380 / 4.3 / 6 |

| Outlet coolant temperature, °C | 65 |

| Operating temperature range of the primary circuit, °C | 0… +35 |

| Refrigerant type | R410A |

| Weight, kg | 183 |

DANFOSS DHP-R ECO 42 (Sweden) – from RUB 1,180,453.

Powerful enough equipment to provide thermal energy to the hot water supply system and heating circuits of a multi-level cottage with permanent residence.

Instead of an additional heater for DHW, the flow of hot water from the heating circuit supply is used here. By passing already hot water through the desuperheater, the heat pump heats the water in the additional DHW heat exchanger to 90 °C. A stable temperature in the CO and DHW tank is maintained by automatically adjusting the speed of the circulation pumps. Suitable for cascade connection (up to 8 TN).

There are no heating elements for the heating circuit. Additional resources are taken from any combined boiler - the control unit will take from it as much heat as is required in a particular case.

When calculating the space for installing a heat pump, it is necessary to leave a gap of 300 mm between the wall and the rear surface of the device (for ease of control and maintenance of communications).

Main characteristics of DANFOSS DHP-R ECO 42

| Characteristic | Meaning |

| Scheme of work | Brine - water |

| Thermal power, kW | 41.4 |

| Electricity consumption (network, V/pumps, compressor), kW/h | 380 / 9.6 |

| Outlet coolant temperature, °C | 65 |

| Operating temperature range of the primary circuit, °C | -10… +20 |

| Refrigerant type | R410A |

| Weight, kg | 290 |

Viessmann Vitocal 300-G WWC 110 (Germany) – from RUB 630,125.

Groundwater serves as the primary coolant. Hence the constant temperature on the first heat exchanger and the highest COP coefficient.

Among the advantages are a low-power auxiliary electric heater on the primary circuit and a proprietary controller (essentially a wireless remote control) for remote control.

Minus - the performance of the circulation pump, the condition of the main line and the primary circuit heat exchanger depend on the quality of the groundwater being distilled. Filtering is required.

Groundwater analysis will help eliminate the occurrence of difficult-to-solve problems with expensive equipment.

Which should be done before purchasing a water-to-water heat pump. Main characteristics of the Viessmann Vitocal 300-G WWC 110

| Characteristic | Meaning |

| Scheme of work | Water - water |

| Thermal power, kW | 13.6 |

| Electricity consumption (network, V/pumps, compressor/heating elements), kW/h | 400 / 2.3 / 9 |

| Outlet coolant temperature, °C | 60 |

| Operating temperature range of the primary circuit, °C | 0… +35 |

| Refrigerant type | R 407 C |

| Weight, kg | 152 |

Prices and manufacturers

The approximate average market cost of equipment and its installation is:

Horizontal collector:

- Pump – $4500;

- installation - $2500;

- operating cost is $350 per year.

Geothermal probe:

- Pump – $4500;

- installation - $4500;

- operating cost is $320 per year.

Air - for home:

- Pump – $6500;

- installation - $400;

- operating cost - $480 per year.

Water-to-water pump for home:

- Heat pump – $4500;

- installation - $3500;

- operating cost is $280 per year.

The prices shown are not final. The final cost will depend on the country and manufacturer of the device, type of terrain, climatic features, drilling costs, construction conditions, etc. For example, the price of an air pump from a Russian manufacturer will be about $7,000, and from a foreign one – $13,000.

Also, do not forget about the cost of electricity. Despite the fact that the equipment does not consume a lot of electricity, these costs should certainly be taken into account when drawing up an overall estimate and planning a budget.

Alternative fuel for pumps

There is no need to use carbon fuel in the form of firewood, coal, or gas to operate the HP. The source of energy is the heat of the planet scattered in the surrounding space, inside of which there is a constantly operating nuclear reactor.

The solid shell of continental plates floats on the surface of liquid hot magma. Sometimes it breaks out during volcanic eruptions. Near the volcanoes there are geothermal springs, where you can swim and sunbathe even in winter. A heat pump can collect energy almost anywhere.

To work with various sources of dissipated heat, there are several types of heat pumps:

- "Air-to-air." Extracts energy from the atmosphere and heats the air masses indoors.

- "Water-air". Heat is collected by an external circuit from the bottom of the reservoir for subsequent use in ventilation systems.

- "Ground-water" (geothermal). Heat collection pipes are located horizontally underground below the freezing level, so that even in the most severe frost they can receive energy to heat the coolant in the heating system of the building.

- "Water-water." The collector is laid out along the bottom of the reservoir at a depth of three meters, the collected heat heats the water circulating in the heated floors inside the house.

There is an option with an open external collector, when you can get by with two wells: one for collecting groundwater, and the second for draining back into the aquifer. This option is only possible if the quality of the liquid is good, because the filters quickly become clogged if the coolant contains too many hardness salts or suspended microparticles. Before installation, it is necessary to do a water analysis.

If a drilled well quickly silts up or the water contains a lot of hardness salts, then stable operation of the HP is ensured by drilling more holes in the ground. The loops of the sealed outer contour are lowered into them. Then the wells are plugged using plugging made from a mixture of clay and sand.

Water-to-water pumps

Almost anyone can place polyethylene collector pipes at the bottom of a nearby reservoir. This does not require much professional knowledge, skills, or tools. It is enough to evenly distribute the coils of the coil over the surface of the water. There must be a distance between the turns of at least 30 cm, and a flooding depth of at least 3 m. Then you need to tie the weights to the pipes so that they go to the bottom. Substandard brick or natural stone are quite suitable here.

Installing a water-to-water HP collector will require significantly less time and money than digging trenches or drilling wells. The cost of purchasing pipes will also be minimal, since heat removal during convective heat exchange in an aquatic environment reaches 80 W/m. The obvious benefit of using HP is that there is no need to burn carbon fuel to produce heat.

An alternative method of heating a home is becoming increasingly popular, as it has several more advantages:

- Environmentally friendly.

- Uses a renewable energy source.

- After commissioning is completed, there are no regular costs of consumables.

- Automatically adjusts the heating inside the house based on the outside temperature.

- The payback period for initial costs is 5–10 years.

- You can connect a boiler for hot water supply to the cottage.

- In summer it works like an air conditioner, cooling the supply air.

- The service life of the equipment is more than 30 years.

- Minimum energy consumption - generates up to 6 kW of heat using 1 kW of electricity.

- Complete independence of heating and air conditioning of the cottage in the presence of an electric generator of any type.

- Adaptation to the “smart home” system for remote control and additional energy savings is possible.

To operate a water-to-water HP, three independent systems are required: external, internal and compressor circuits. They are combined into one circuit by heat exchangers in which various coolants circulate.

When designing a power supply system, it should be taken into account that pumping coolant through the external circuit consumes electricity. The longer the length of the pipes, bends, and turns, the less profitable the VT. The optimal distance from the house to the shore is 100 m. It can be extended by 25% by increasing the diameter of the collector pipes from 32 to 40 mm.

Nuances of operation

To effectively use the operating principle of a VT, several conditions must be met.

Firstly, the heated room must be insulated. Heat losses should not be more than 100 W/m2.

It is advantageous to use a heat pump for heating low-temperature systems, for example, underfloor heating systems. The amount of heat conversion depends on the ratio of the temperature of the input and output circuits. In this case, each kilowatt of electricity spent will pump about five kilowatts of heat into the house.

Features of heating a house in winter

For stable heating using HP in winter, it is necessary to install systems where a reservoir with a sufficient supply of water or soil is used as a heat exchanger. The air-to-air system can be used in winter in areas with a mild climate, where the outside air temperature rarely drops below zero degrees.

In winter, it is also advisable to use additional heat sources - then if the outside temperature drops significantly, they can be used. In this case, there is no need to use a transformer with large excess power, which is almost never needed, but which significantly affects its price.

Air - split and mono

It is more profitable to use air HP in the southern regions, where the temperature rarely drops below 0 °C, but modern equipment can operate at -25 °C. Most often, split systems are installed, consisting of indoor and outdoor units. The external set consists of a fan blowing through the radiator grille, the internal set consists of a condenser heat exchanger and a compressor.

The design of split systems provides for reversible switching of operating modes using a valve. In winter, the external unit is a heat generator, and in summer, on the contrary, it releases it to the outside air, working like an air conditioner. Air heat pumps are characterized by extremely simple installation of the external unit.

Other benefits:

- The high efficiency of the outdoor unit is ensured by the large heat exchange area of the evaporator radiator grille.

- Uninterrupted operation is possible at outdoor temperatures down to -25 °C.

- The fan is located outside the room, so the noise level is within acceptable limits.

- In summer, the split system works like an air conditioner.

- The set temperature inside the room is automatically maintained.

When designing the heating of buildings located in regions with long and frosty winters, it is necessary to take into account the low efficiency of air heaters at subzero temperatures. For 1 kW of consumed electricity there is 1.5–2 kW of heat. Therefore, it is necessary to provide additional sources of heat supply.

The simplest installation of VT is possible when using monoblock systems. Only the coolant pipes go inside the room, and all other mechanisms are located outside in one housing. This design significantly increases the reliability of the equipment and also reduces noise to less than 35 dB - this is at the level of a normal conversation between two people.

Principle of operation

The thermodynamic principle of heat transfer, discovered at the beginning of the 19th century by the French scientist Carnot, was later detailed by Lord Kelvin. But the practical benefits of their works devoted to solving the problem of heating housing from alternative sources have appeared only in the last fifty years.

In the early seventies of the last century, the first global energy crisis occurred. The search for economical heating methods has led to the creation of devices capable of collecting energy from the environment, concentrating it and directing it to heat the house.

As a result, a HP design was developed with several thermodynamic processes interacting with each other:

- When the refrigerant from the compressor circuit enters the evaporator, the pressure and temperature of the freon drops almost instantly. The resulting temperature difference contributes to the extraction of thermal energy from the coolant of the external collector. This phase is called isothermal expansion.

- Then adiabatic compression occurs - the compressor increases the pressure of the refrigerant. At the same time, its temperature rises to +70 °C.

- Passing the condenser, freon becomes a liquid, since at increased pressure it gives off heat to the in-house heating circuit. This phase is called isothermal compression.

- When the freon passes through the choke, the pressure and temperature drop sharply. Adiabatic expansion occurs.

Heating the internal volume of a room according to the HP principle is possible only with the use of high-tech equipment equipped with automation to control all of the above processes. In addition, programmable controllers regulate the intensity of heat generation according to fluctuations in outside air temperature.

How to make a pump with your own hands

It is quite possible to make a HP with your own hands, but for this you need to find a good compressor. You can buy it at a parts store or use it from an old refrigerator or air conditioner.

A stainless steel tank of approximately 100 liters is used as a condenser. Thin copper plumbing pipes are perfect for the circuit.

Manufacturing stages:

- Using an angle, secure the compressor to the wall in the place where the HP will be placed.

- Next, make a coil of copper tubes: wrap them around a suitable cylinder. The winding pitch along the coil should be the same.

- The tank needs to be cut into two halves, the coil must be inserted inside and welded back. In this case, it is necessary to make several inlet holes through which to remove the coil tubes.

- You can use a plastic barrel as an evaporator - insert the internal circuit tubes into it.

- Next in the circuit you need to create excess pressure to check the tightness.

To transport heated water, you can use ordinary PVC pipes (made of polyvinyl chloride). It is advisable to charge the system with freon together with a specialist.

The video below is all about the HP of the water-water system: principle of operation, types, advantages and disadvantages, installation rules.