Electrical installation

Work on installing the floor begins after the subfloor is completed.

To do this, the soil is cleaned to a depth of up to half a meter, a layer of sand and crushed stone is poured in and concrete is poured. Electric floor heating does not require a high screed, but its optimal height is 10 centimeters. Do-it-yourself work is performed in the following order:

- Laying waterproofing. Groundwater should not get onto the cable. To do this, use roofing felt or thick film.

- Creating a thermal insulation layer to prevent heat from escaping into the ground. It is not recommended to use foil as an insulator.

- Laying reinforced mesh and fixing it.

- Laying the cable and tying it to the sheathing. Calculate the required cable length in advance. Choose a solid wire, without solders. Heating mats can replace the wire.

- Installation of temperature sensors, especially in the area near the machine, where it is necessary to maintain a certain temperature.

- Connecting the cable to a separate panel and test switching on.

- If everything works properly, a layer of screed is poured over the grate, allowed to dry, and the finished floor is installed.

The system does not require special maintenance.

How to avoid problems

Although you can carry out the diagnosis yourself, you will spend a lot of time and effort. To repair your heating system, it is better to contact a specialized organization. Thanks to many years of experience and modern equipment, they quickly determine the cause of the malfunction and eliminate it.

You can avoid all these problems simply by following these recommendations:

- select the optimal and high-quality equipment, do not skimp and do not buy the cheapest - under high loads it will not be able to provide you with safety;

- carry out competent and high-quality installation of the heating system, in this case all components will operate within the operating load limits specified by the manufacturer;

- Carry out regular maintenance, at least once a year: before the heating season or immediately after it;

- Be sure to follow the manufacturer's requirements specified in the equipment instructions.

Only by observing all these points will you not only increase the service life of your equipment, but also be able to ensure its efficient and uninterrupted operation.

Standard pressure values in the heating system

Maintaining operating pressure in the heating circuit reduces the level of heat losses. This is possible due to the fact that the coolant passing through the pipeline at a properly selected pressure value practically does not have time to cool down. To properly configure the system, you need to know how many atmospheres there are in a particular type of heating.

Different types of heating systems have their own standard pressure indicators:

- Heating of a multi-storey building. Heating systems of apartment buildings are characterized by a high value of static pressure, and its value directly depends on the height of the building itself. In 9-story buildings, the pressure norm is about 5-7 atmospheres, and in houses with more than 12 floors - from 7 to 10 atmospheres. The pressure in the supply circuit is always about 12 atmospheres. In order for such a system to work, it must be equipped with a powerful pump with a dry rotor.

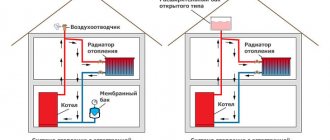

- Heating a private house. In an open heating system, the atmosphere and the system itself are combined through an expansion tank. Even if the system is equipped with a circulation pump, the pressure in the heating system of a private house will still coincide with the outside pressure, so the pressure gauge will constantly show 0 bar.

- Closed heating of a private house. The pressure in a closed heating system of a private house has slightly different characteristics. Firstly, in such a system the static pressure increases, which increases the efficiency of the structure, and secondly, the possibility of contact with air is completely eliminated. To calculate the static head in such a system, you need to multiply the distance between the highest and lowest points of the circuit by 0.1. 1.5 bar is added to the obtained value, and the calculation result will show the operating pressure in the heating system.

In the vast majority of cases, the normal pressure in a closed-circuit gas boiler is about 1.5-2 atmospheres. A significant excess of this indicator greatly increases the risk of system failure - for example, depressurization of a pipeline or damage to heating equipment may occur.

Of course, a higher pressure increases the efficiency of heating, but before calculating the pressure in the heating system, you need to take into account the technical features of specific heating equipment. Some boiler models are designed for a pressure of no more than 3 bar, but standard products can only operate effectively at a pressure of 2 bar. When setting up the heating, you need to do everything so that in the inactive system the pressure is 0.5 bar below the operating pressure - this reserve will ensure stable operation of the equipment after it starts (more details: “What should be the operating pressure in the heating system of a private house - norms, rules, restrictions").

For apartments, this information is irrelevant - it is simply impossible to measure or regulate heating pressure in such cases. All you can do is select the radiators and pipe diameters in your own pipeline. For example, it is undesirable to use cast iron radiators, since at a pressure above 6 bar they fail - and such low pressure is practically never found in the heating system of an apartment building. Pipes with excessively high throughput will, in turn, lead to a decrease in pressure throughout the entire circuit.

The pressure value also directly depends on the temperature of the coolant. A certain volume of coolant is poured into any heating system, at which the pressure is minimal. When the system reaches operating mode, the pressure rises - i.e. adjusting water heating also allows you to control the pressure in the pipeline.

For heating systems, it is always advisable to use expansion tanks (hydraulic accumulators). Such devices absorb excess coolant, thereby preventing the pressure from reaching a critical level. To make the system as reliable as possible, it is also worth supplementing it with a safety valve, which, if the tank overflows or the pressure in the circuit exceeds 3 atmospheres, will ensure automatic discharge of excess water.

Open

An open heating system must include an open expansion tank (tank). The highest part of the system is chosen as the location for its installation. This container functions as an expansion tank (compensating for excess expanding coolant when heated), an air vent and a safety valve. To ensure air removal through the expansion tank, the filling tank must be mounted at a stable slope.

The operating pressure in the heating system at each section of the circuit corresponds to the hydrostatic pressure of the water column. At the bottom, the column limits the measurement point, and at the top, the coolant level in the expansion tank. The excess pressure parameter of the 1st meter of water column is 0.1 kgf/cm2. In order for the water column to rise 10 m, the pressure drop must correspond to one atmosphere.

Limiting Factors

For all types of modern pipes and radiators, a working pressure of at least 6 atmospheres is declared.

Polypropylene pipes. PN—working pressure in megapascals. In atmospheres it is equal (from top to bottom) 20, 16 and 25.

Why not raise the autonomous heating parameters to, say, 5 bar?

There are several reasons.

First and foremost: increased blood pressure will not provide any benefits. The height of the water column is needed only when filling an empty contour. It is easy to calculate that 1.5 atmospheres of excess pressure will raise the water by 15 meters. Given the legal limit on the height of private buildings to three floors, this is quite enough.

Private sector in Omsk

Pay attention to the number of floors of the building

Next: do not forget about the likelihood of force majeure (the same water hammer or pressure increase due to a malfunction of the safety valve). The safety margin of batteries and pipes in this case will come in very handy.

Finally: do not overestimate the strength and service life of pipes, primarily plastic pipes, which are popular in private housing construction. As the temperature rises, both drop quickly.

Inexpensive polypropylene pipes are a typical solution for autonomous heating.

If at room temperature polypropylene pipes PN25 honestly withstand the declared 25 atmospheres and serve the promised 50 years, then at 90C increasing the water pressure to 7-9 atmospheres may well lead to the destruction of the liner or bottling. Even if disaster does not happen, the resource of the material will be reduced to several months, or even weeks.

Central heating

In the private sector, autonomous heating is not always used. For example, in areas with harsh climatic conditions, heat for houses is supplied through taps from the heating main. To regulate heat transfer, the entrance to the home is equipped with an autonomous water-jet elevator, the basis of which is the recirculation of part of the coolant.

The working pressure in such cases has similar parameters to apartment buildings:

- On the supply pipe: 5-7 kgf/cm2.

- On the return pipe: 3-4 kgf/cm2.

- After passing through the elevator: 0.1-0.2 kgf/cm2 more than in the return.

What tools and materials will be needed

The design of the heated floor resembles a layer cake. For its construction you will need:

- sand-cement mixture;

- reinforcing mesh 8-10 millimeters thick, with cells 15x15 centimeters;

- pipes and boiler or electrical cable and infrared film;

- a set of plastic clamps and supports for fixing the heating;

- hydro- and heat insulator (thick film, roofing felt, reinforced foil and other similar materials);

- finished floor covering: wood, tiles, painting.

The required tools are: a concrete mixer, a level, beacons, a rule and other available tools. It is advisable to make a drawing of pipes or wires before installation

It is important that the car does not drive through cable laying areas.

CALCULATION OF MEMBRANE EXPANSION TANK

In some cases, the pressure drop in the heating system is associated with the wrong choice of a double-circuit boiler. Thermal calculations take into account the area of the premises that need to be heated. Based on these conditions, the power of the heating device is selected. The calculation takes into account ordinary radiators, in which the volume of water is not very large. And if metal pipes are used instead of radiators, several times more liquid is required to fill them, and accordingly, the volume of expanded water will also be increased.

The expansion tank in double-circuit boilers is usually 6-8 liters. It is designed for approximately 120 liters of water in the heating system. This is quite enough for radiators. But what can happen if there is more water in the system than it should be according to calculations. Let's say that the liquid, heating up in the pipes, expands and fills the standard expansion tank. But the size of the tank is not enough to remove excess heated water, the pressure rises and an emergency release occurs through the safety valve. After the boiler turns off, water from the tank comes back into the system, but since the boiler had an emergency discharge, there is not enough liquid in the system, the pressure drops below a critical level. That’s it, without replenishing the system with water (that is, without human intervention), the boiler will not turn on. If the air temperature outside is low, defrosting of the system is ensured. Moreover, this can happen at the most inopportune moment.

Now automatic water rechargers have appeared on sale, which supply water to the system if the pressure in it drops below a certain level

Homeowners who leave their homes unattended for long periods of time should pay attention to them.

Typically, heating installations occur during the warm season in order to have time to prepare for winter. During startup, the boiler operates in medium mode, and it is still warm in the fall. Therefore, when the heating is not so intense, the liquid expands slightly, the pressure in the system is within normal limits. But when frost comes and the boiler starts working at maximum load, the volume of heated liquid increases, and then it turns out that the standard expansion tank is not enough. To prevent such a scenario from happening, you need to correctly calculate the heating system and install in time an additional membrane expansion tank, which is used in closed-type heating systems when the fluid moves under pressure created by a circulation pump.

It is difficult to determine the exact amount of water in heating pipes; this is usually done by power: it is multiplied by 15. For example, a 17 kW boiler has a heating system that holds 255 liters of water. There are methods to help calculate the volume of the expansion tank. The following calculation is suitable for heating systems installed in one-story houses.

Volume of the expansion tank = (V*E)/D, where V is the volume of water in the heating system, E is the expansion coefficient of the liquid, D is the efficiency of the expansion tank.

D = (Pmax—Ps)/(Pmax +1),

where Pmax is the maximum operating pressure of the heating system, equal to an average of 2.5 bar;

Ps – expansion tank charging pressure equal to 0.5 bar.

D = (2.5-0.5)/(2.5 +1)=0.57

So, for a 17 kW boiler, the volume of the expansion tank = (255*0.0359)/0.57=16.06 l.

The technical documentation says that the 17 kW device has a built-in expansion tank with a volume of 6.5 liters. For proper operation of a double-circuit boiler, it is necessary to install an additional expansion tank with a volume of 10 liters in the heating system.

How to determine whether an additional expansion tank is working in the system or not? To check it, pump up the air pressure with a pump, for example, up to 2 bar, and provide access to the nipple. Let's connect it to the heating system. Let's turn on the boiler. As the water heats up, the pressure will rise. If it increases to 1.8 bar, bleed the air from the expansion tank through the nipple, while looking at the boiler pressure gauge. As soon as the pressure in the tank drops below 1.8, water from the system will begin to enter the tank, and the pressure gauge needle on the boiler will show a decrease in pressure. This means that the additional expansion tank is installed correctly and is working correctly. Finally, you need to pump up the pressure to the desired level, for example, to 1 - 1.5 bar. That's all. If you liked the article, share it on social networks.

Leak testing

In order to maintain the quality of the heating system, it is necessary to test the heating equipment for leaks.

When testing, you can detect leaks and avoid equipment breakdowns during the heating season.

Testing must be carried out in 2 passes:

- Hot check. The heating circuit must be checked before the start of the heating season. The coolant is under compression, and its indicators are at critical levels for the device. With the help of such testing, you can ensure that your home is functionally ready for heating. And also check for leaks. It is advisable to carry out such testing before the heating season. Since in case of problems the entire house may be left without heating.

- Cold test. To do this, you need to fill the radiators and pipes with cold water. After this, you can measure the pressure. After 30 minutes, you need to check the pressure and if it is not lower than 0.06 MPa, then the system is working normally. And after 2 hours the indicator should be more than 0.02 MPa. As a result of the inspection, you should ensure that there are no leaks.

If you want to conduct accurate testing, it is better to contact qualified specialists. Such testing will be more accurate than self-testing.

Pressure in a closed heating system of a private house

- The maximum length of the circuit is practically unlimited (for a circuit with natural circulation - no more than 30 m). The most important thing here is to purchase a pump with high power ratings and durable devices (in the area where the pressure reaches its maximum).

- Pipes can be used with small diameters.

- Radiators can be connected gradually (single-pipe scheme).

- If the heating radiators were connected according to a two-pipe scheme, then by installing a circulation pump, the heat in the circuit will be distributed more evenly.

- Due to the fact that the coolant moves at a higher speed, it does not have time to cool down much and the boiler operates in a gentle mode.

- You can use a system that is equipped with a circulation pump in low-temperature mode, which is important in the off-season.

Circulation pump

It is important that it meets several rules:

- It should not exceed the figure stated in the instructions for the boiler equipment.

- The power must be sufficient to overcome the hydraulic resistance of the heating circuit, which directly depends on its length, configuration (single-pipe with series connection of radiators or two-pipe with parallel), also on the diameters of the pipes and the speed at which the coolant circulates.

You can calculate the hydraulic resistance of the pipeline here

Increase in pressure

The reasons for a spontaneous increase in pressure in the heating circuit, leading to the activation of the safety valve, may be as follows:

- Damage to the valve on the jumper with the cold water supply system. Screw valves and plug valves have one common problem - they are not able to provide absolute tightness when closed tightly. Gaps usually occur due to wear of the screw valve gaskets or scale trapped between it and the seat. This can also cause scratches on the faucet body and plug. When the pressure in a closed heating system exceeds a cold one (this happens very often), water gradually leaks into the circuit. It is subsequently discharged into the drainage through a safety valve.

- There is not enough expansion tank volume. The heating of the coolant and the subsequent increase in its volume cannot be fully compensated due to lack of space in the tank. Signs of this problem are an increase in pressure immediately when lighting or turning on the boiler.

To eliminate the first malfunction, it is better to replace the valve with a modern ball valve. This type of shut-off valve is characterized by stable tightness in the closed position and a huge service life. Frequent maintenance is also not required here. This usually comes down to tightening the gland nut under the handle after several hundred closing cycles.

To solve the second problem, you will have to replace the expansion tank by choosing a more capacious tank. There is also an option to equip the circuit with an additional expansion tank. In order for the system to operate without failures, the volume of the expansion tank should be approximately 1/10 of the total amount of coolant.

Sometimes it happens that an increase in pressure provokes the circulation pump. This is typical for the filling section after the impeller if the pipeline has high hydraulic resistance. The usual reason is undersized diameter. There is no need to panic in such a situation: this problem can be solved by simply installing a safety group (at a sufficient distance from the pump). Replacing the filling with a pipe of larger diameter is justified only if there is a large temperature difference between the first radiators from the boiler and the last ones in the direction of coolant circulation.

Control mechanisms

To prevent emergency situations in closed systems, relief and bypass valves are used.

Reset. It is installed with an outlet into the sewer for emergency drainage of excess energy from the system, protecting it from destruction.

Photo 4. Relief valve for the heating system. Used to drain excess coolant.

Bypass. Installed with access to an alternative circuit. Regulates the pressure drop by sending excess water into it to prevent an increase in the following sections of the main circuit.

Modern manufacturers of heating fittings produce “smart” fuses equipped with temperature sensors that respond not to an increase in pressure, but to the temperature indicators of the coolant.

Reference. It is not uncommon for pressure reduction valves to stick. Make sure that their design includes a rod for manually retracting the spring.

Don't forget that any problem in your home's heating system is fraught not only with loss of comfort and costs. Emergency situations in the heating network threaten the safety of residents and the building. Therefore, heating control requires care and competence.

Reducing pressure in the heating system of a private house

A decrease in pressure in a cold heating system (in the intervals between turning on/on the boiler) is normal. Usually, after heating the coolant, all parameters return to normal. This happens in any closed system. The negative consequences of a decrease in pressure is the formation of air pockets in the circuit, which impedes the circulation of the coolant.

At a stable temperature, pressure may drop for the following reasons:

- Some threaded or fitting connection of the circuit is leaking (this usually happens on an American radiator). A leak is usually indicated by a puddle on the floor. To fix it, you need to rewind the thread, tighten or change the fitting and sealing gasket.

- A fistula appeared on the heat exchanger in the heating boiler. To detect it, a visual inspection of the firebox or the opened body of a previously stopped boiler is carried out. The nature of the damage may require welding or replacement of the heat exchanger.

- The membrane of the expansion tank has torn or cracks have appeared on it. If the membrane tank is installed correctly (the line should point upward), air will be displaced into the system, followed by bleeding through an automatic air vent. When filling a larger volume with coolant, the pressure will definitely drop. The membrane or container needs to be replaced.

- The spool on the tank passes through which the container is pumped with air. Usually it is necessary to change the nipple tube or the entire spool.

- The air vent is poisoning. The systems can use automatic devices or Mayevsky cranes. If there are air pockets, water may not flow out. Such a gap is often detected by ear: it is indicated by a quiet hiss of air. There is also an option with alternate replacement of air vents.

- The seal between the radiator sections is leaking. A leak is indicated by a rusty mark on the battery. To solve the problem yourself, you will need a radiator wrench and two new seals. The battery needs to be unscrewed in the problem area, new gaskets installed and tightened again.

To solve the problem of how to increase the pressure in the heating system after completing repairs, open the tap on the jumper with cold water and fill the circuit. A pressure gauge is used to control the process.

Closed

To regulate the pressure inside a closed heating system of a fixed volume, the following is used:

- Pumping water

. To achieve this, the heating circuit is connected to the cold water supply system using a jumper. Using a tap, you can solve the problem of how to create pressure in the heating system of a private house, as well as fill the circuit that was emptied before carrying out repairs. - Membrane expansion tank

. A membrane tank is a steel container consisting of two halves. An elastic rubber membrane is used for separation. The operating state is characterized by the presence of air with excess pressure in one of the halves (it is also called charging pressure). The other half of the tank contains coolant. The task of the tank is the same as in an open system: to compensate for the pressure of water in the heating boiler when it is heated. Air differs from liquid in that it is easy to compress, which is why the rate of pressure increase in the circuit is an order of magnitude lower.

Along with the main function, with the help of a container it is possible to smooth out pressure differences within a closed circuit. This refers to water hammer, which is caused by a sudden stop in circulation. As for the operating pressure indicators, when the boiler is turned off, it corresponds to the factory tank charging pressure specified in the instructions (1.5 kgf/cm2). The upper permissible point is 2.5 kgf/cm2. The safety valve is usually set to operate when 2.5 atm is reached.

Possible faults and corrective actions

Absolute pressure gauge diagram: 1 - vessels; 2 - metal plates; 3 - mercury; 4 — glass connecting tubes; 5 — reading microscope; 6 - scale.

Whether there is electric heating in a private home or gas heating is not so important. Problems associated with pressure loss can occur in any heating system. or otherwise, after a few years it begins to malfunction, the boiler refuses to function or does not work so correctly

There is also such a problem as a constant drop in pressure, but with preservation of functionality, that is, without serious failures

or otherwise, after a few years it begins to malfunction, the boiler refuses to function or does not work so correctly. There is also such a problem as a constant drop in pressure, but with preservation of performance, that is, without serious failures.

If you observe that such problems are occurring, you need to start taking appropriate measures, but first you should find out what kind of problem caused the system failures. Let's look at the main reasons found in heating systems:

The most common problem is a hidden leak during the installation of a piping system. Any type of heating system may be susceptible to this problem (except infrared).

A leak can be eliminated by several methods, usually by installing a new unit, tightening a too weak connection, or tightening a separate element of the system. It’s better to do it on time than to spend it later on global issues in the house.

Electric boiler heating circuit.

- It also happens that it is not the pipes that are to blame for the pressure drop, but other equipment in the system. The causes may be problems such as diaphragm ruptures in the expansion tank. In this case, it is necessary to inspect the compensation tank itself. Repair in this case only includes the installation of a new nipple. This breakdown can be fixed quite quickly. But the reason may be an incorrect calculation of the tank volume or a rupture of the membrane. In this case, it is necessary to install new equipment, that is, replace the expansion tank;

- The pressure drop can also be caused by a problem such as a crack in the heat exchanger. This happens during the operation of water heating, but there may also be a reason such as a factory defect of the boiler, or its complete physical wear and tear. In this case, it may be necessary to install new equipment. Particular care must be taken to monitor gas equipment for a two- or one-story house;

- It also happens that the pressure drops not due to a breakdown of the heating system. There may be an air pocket in the pipes, from which the air gradually leaves, the private house begins to heat worse, and the pressure gradually drops. You need to find such a pocket and remove all the air from the system. But if the heating system is done correctly, then such a problem simply will not arise. Therefore, when installation is carried out, it is necessary to carefully follow all the steps in order to assemble the units strictly according to the instructions and prevent malfunctions.

What to do if the pressure in the system increases? But the pressure in the heating system does not always drop; it also happens that the pressure in the heating system of a one-story house increases. The causes of such problems may be:

Gas heating scheme.

- problems with the regulator. When the temperature drops, it can send a signal to cut off the coolant supply from the boiler. The operating principle of the heating system allows for such a situation, but solving the problem is simple: no calculation is required here, it is necessary to adjust the regulator settings so that the valves do not completely close;

- if the automation malfunctions, that is, when the calculation and installation were carried out incorrectly, the system can be constantly recharged and the pressure rise. To eliminate the problem, you should shut off one line, and then adjust the automatic coolant supply;

- The human factor is also possible. For example, one of the taps is shut off; the valve simply was not opened after carrying out maintenance work. This often happens when heating is carried out with a fireplace or other stoves. Carefully inspect all coolant supply taps, open them if necessary;

- An air lock can also cause an increase in pressure (as well as a decrease). It must be detected and removed;

- pressure increases due to filter clogging. In this case, you need to clean it properly, and then test the heating. In rare cases, it is necessary to install a new filter for the heating system.

Results of instability in circuits

Insufficient or very high pressure in the heating circuit is equally bad. In the first option, some of the heating devices will not heat the rooms well, in the other, the integrity of the heating system will be compromised, and some of its parts will break.

An increase in dynamic pressure in the heating pipeline occurs if:

- the coolant is excessively overheated;

- the pipe cross-section is insufficient;

- the boiler and pipe wires are overgrown with scale;

- air pockets in the system;

- an overly powerful booster pump was installed;

- water replenishment occurs.

Also, high pressure in a closed circuit is caused by incorrect balancing of the taps (the system is over-regulated) or breakdown of some regulator valves.

To control operating parameters in closed heating circuits and for their automatic adjustment, a safety group is set:

The pressure in the heating pipeline drops for the following reasons:

- leakage of coolant;

- pump breakdown;

- breakthrough of the membrane tissue of the expansion tank, cracks in the walls of an ordinary expansion tank;

- breakdown of the security unit;

- water leakage from the heating system into the feed circuit.

The dynamic pressure will be very high if the voids of pipes and heating devices are clogged, if the catch filters are dirty. In such situations, the pump does not stop working at a very high load, and the efficiency of the heating circuit decreases. A typical result of increasing pressure values is leaks in connections and even pipe ruptures.

The pressure parameters will be less than required for normal functionality if a pump of insufficient power is inserted into the line. It will not be able to move the coolant at the required speed, which means that a somewhat cooled working medium will be supplied to the device.

The second obvious example of a drop in pressure is when the flow is blocked by a tap. A sign of such problems is the loss of pressure in an individual segment of the pipeline located after the obstacle to the coolant.

Since all thermal circuits have devices that protect against excessive pressure (at least a safety valve), the problem of low pressure occurs much more often. Let's consider the reasons for the drop and ways to increase the pressure, and this means improving the movement of water along a closed circuit, in closed and open heating systems.