The search for high-quality material for insulating walls or ceilings increasingly leads us to products from well-known manufacturers. They have a range, quality, and reputation, which together provide some guarantee of a reliable purchase. One of such manufacturers is the URALITA concern, which is known for the production of thermal insulation materials. So the current topic of high-quality insulation continues with Ursa insulation - characteristics, composition, density of which we will consider in more detail.

Advantages of Ursa products

Most Ursa insulation is based on treated fiberglass. Therefore, such thermal insulation in terms of technical characteristics is close to glass wool . During the manufacturing process, sand grains, dolomite, soda, and various additives are used in certain proportions.

Under the influence of temperature, the composition is brought to melting and passed through the apparatus. The output is a fibrous mass with threads glued together.

Ursa mineral wool has the following advantages:

- reinforced structure thanks to durable fibers;

- increased elasticity, dimensional stability;

- guarantee for preservation of original qualities - 50 years;

- Water Guard water protection technology – liquid rolls off the coating, leaving the insulation dry ;

- safety and biostability.

Thanks to elastic, long fibers (15-30 cm), the material does not crumble during processing. The installation technology is not difficult. Slab insulation is compressed up to three times, roll insulation – up to seven. This saves space during transportation and storage of material.

Features of home insulation

*

When insulating different parts of the house, you should use a specific size and type of material. First of all, the façade will be insulated. To do this, it is better to use URSA GEO mineral wool, after which you can use external finishing with siding, natural and artificial stone, and brick.

Roof insulation

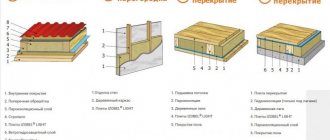

For the roof, you should select an insulation option based on the type of roof covering and the characteristics of the attic space. For pitched roofs, thermal insulation is laid under the rafters and between them, a super-diffusion membrane must be laid on the outside, and a waterproofing film on the room side.

To insulate a flat roof, materials with high strength should be used, so mineral wool is not used in this case. The optimal solution would be to use Ursa XPS, which is characterized by high strength and moisture resistance.

Installation of Ursa to a frame wall

For internal thermal insulation work, it is recommended to use various options of mineral wool. It not only protects from the cold, but also largely absorbs sound.

Installation of insulation

The use of high-quality insulation guarantees an optimal indoor microclimate and savings on heating. Installation of Ursa is quite simple, so even inexperienced builders can use it.

Price issue

The cost of insulation will vary depending on what type you prefer, what product you purchase, in what volume and from which distributor. Approximately the following prices can be mentioned:

- Ursa Geo mineral insulation will cost from 900 rubles per cubic meter (Ursa Geo light product) to 4,600 rubles per cubic meter. This is the cost of Ursa P-60 insulation. A cubic meter of Ursa light insulation contains about 20 square meters, and P-60 contains about 40 square meters.

- PureOne can be purchased at a price of 1500-1600 rubles per cubic meter of material, about the same price as TERRA insulation.

- As for URSA XPS slabs, their cost starts from 3,500 rubles per cubic meter of insulation and reaches 5,500 rubles per cubic meter. At the same time, depending on the thickness of the slab, a cube of this insulation contains from 10 to 30 square meters of material.

The cost of the material will be slightly lower if you make a wholesale purchase and pick up the purchase from the warehouse, pick-up.

Ursa insulation materials are attractive not only for their properties, but also for their high environmental friendliness of materials. Today this is an additional significant argument in favor of this product.

Varieties of fiberglass "Ursa"

Thermal insulators of this brand are divided according to density, degree of thermal conductivity and area of application into several main classes:

- URSA Geo. Used for thermal insulation of pipelines and sewer pipes. However, most often it is used in private and industrial housing construction to insulate walls, floors, ceilings and roofs from the cold. The most popular among owners of suburban areas is the Ursa M 11 insulation, which, among other things, can be used on the floor and in interfloor ceilings. These are mini-slabs for universal use. The “Light” type is intended mainly for covering unloaded structures - roofs and walls. The URSA Geo line also includes soundproofing varieties designed for rooms with high humidity, for pipes, raised floors, etc.

- PureOn. This variety consists of 95% natural ingredients. At the same time, in terms of softness and fineness of the fiber, it is not inferior to cotton wool.

- TERRA. These are high-density boards of small sizes, very convenient for use in private housing construction.

DIY installation of URSA mineral wool

Photo.

Application of URSA for thermal insulation of residential buildings Like any other inorganic thermal insulation made of fiberglass or basalt, URSA is afraid of contact with water. Therefore, when installing this material, you should use a vapor-waterproofing barrier to protect the mineral wool from getting wet. The air cells between the fibers of the material retain heat perfectly, but as soon as the fibers get wet, the thermal conductivity of URSA increases significantly.

Contact with water is not dangerous for extruded polystyrene foam URSA XPS, which is a clear plus when insulating the blind area and foundation of a house. The slabs can last over 50 years, while the slabs do not change in size, however, polystyrene foam emits harmful substances at high temperatures. Therefore, this thermal insulation is not recommended for use in residential premises.

On the roof

Thermal insulator from the “Pitched Roof” series of the “Ursa” product line is used. It is produced in the form of mats (slabs) with dimensions of 1200 mm x 4200 mm, which makes it possible to cut the material, eliminating a large amount of waste, and use it for roofing with absolutely any rafter pitch.

Stage one. Arrangement of waterproofing

The waterproofing film is applied directly to the upper plane of the rafters. It can be secured using staples from a construction stapler or galvanized nails with a flat head. Then it should be finally secured with a counter-lattice.

The film panels are applied exclusively across the slope, taking into account an overlap of no less than 100 mm. In this case, adjacent panels are secured using adhesive tape, and the resulting sag in the middle of the panel should not exceed 20 mm.

Waterproofing rafters

But in no case should the sheets be laid without mounting slack, that is, under tension. If this condition is not observed, then during the cold period, during the natural thermal shrinkage of the material, it may rupture.

Stage two. Installation of heat insulator

Professional builders recommend waiting ten to fifteen minutes after opening the original packaging. During this time, the insulation will restore its original dimensions.

The material should be placed between the rafters in a compressed-elastic state, that is, “by surprise”, and it will be securely fixed due to the friction that occurs between the side surfaces.

In any case, the width of the heat insulator must exceed the distance between the rafters by at least 3 cm; this is the only way to ensure its reliable installation and eliminate the presence of unwanted cracks and voids, which will significantly increase the efficiency of insulation.

Insulation is carried out with mandatory control of the size of the installation gap between the insulation itself and the waterproofing layer. Control markers can be bars of a given height.

Stage three. Vapor barrier

Produced indoors. The film is fixed with a stapler or galvanized nails on the lower plane of the rafter legs. The amount of overlap is also maintained (10 cm) in both longitudinal and transverse directions.

Vapor barrier of walls

Self-adhesive tape is used to tightly connect the canvases to each other. After this, the finishing covering of the ceiling surface is performed.

On the walls

It is more advisable to insulate walls from the outside, that is, from the facade. To do this, it is recommended to use the Ursa line, made from staple fiber, for example, P15 grade boards.

- Preparation. Removal of protruding segments (shimmers, lighting fixtures, trims, decorative elements, etc.). Next, a thorough cleaning of dust and dirt is carried out, as well as an inspection of the wall surface for possible defects. Cracks must be repaired and large irregularities removed.

- Waterproofing the wall with appropriate material.

- Marking. It is carried out on the wall surface to ensure parallelism and accuracy of further installation of the frame. Can be applied using a plumb line or laser level.

- Frame. It can be made of wooden blocks or metal profiles, the choice depends on the type of façade finishing. The components of the frame are fixed to the wall using dowels or self-tapping screws in increments of 58 cm. In this case, the frame must tightly fit around window and door openings, corners, top and the lower boundary of the insulated zone.

- The first layer of thermal insulation. The standard width of Ursa slabs is 600 mm, so they are easily placed in the space between the beams, ensuring a tight, airtight fit. For a tighter fit, the mats can be additionally fixed with construction dowels at the rate of five to eight pieces per insulation board.

The main thing is that the dowels do not compress the material at the place of fastening, otherwise this will lead to the appearance of “cold bridges”, consequently, to a deterioration in the level of thermal insulation efficiency. - Horizontal frame elements are installed on top of the first layer of insulation, similar to the technology for installing vertical posts. Just like in the previous paragraph, insulation is installed.

- Ventilated gap. Necessary for releasing steam and moisture from the material. As a rule, wooden blocks are used for its arrangement, attached to the frame in the vertical direction. As a result, a hollow space is formed; its width should be at least 50-60 mm.

- Finishing the walls.

On the floor

Experts recommend using Terra insulation from Ursa as a heat insulator for cold floors. An interesting fact is that the name of the heat-insulating material itself means “earth”, indirectly making it clear that it is preferable to choose it for insulating surfaces close to the soil.

Application area

Mineral wool insulation is produced on the basis of fiberglass using new and innovative technologies.

This made it possible to minimize the characteristic disadvantages of glass wool. The company also produces special membrane coatings to create effective thermal insulation systems. This insulation is widely used in the construction industry because it is universal. Most often it is used for the device:

- flat and pitched roofs;

- internal and external walls;

- interfloor ceilings;

- foundations;

- partitions;

- floor structures;

- highways;

- heating pipes;

- railway embankments;

- baths and saunas;:

- loggias and balconies;

- runways.

Installation of insulation can be performed not only by experienced builders. This can be done by people without experience in construction. During the work process, it is important to follow the basic rules and then the installation will be done efficiently and effectively.

Advantages of URSA mineral wool thermal insulation

URSA TERRA is an excellent thermal insulation material in a low price category. Despite its low cost, mineral wool is an environmentally friendly material, fireproof, has good noise insulation, minimal thermal conductivity (about 0.034 watts per meter per Kelvin) and is superior to its competitors in the same price category.

Do-it-yourself installation of URSA mineral wool

One of the most important characteristics of URSA GEO is that the material does not burn and prevents the spread of fire. Therefore, this glass wool is suitable for insulating residential premises. The material can be used to insulate floors, walls, interior partitions and floors. By insulating your home with a sufficient layer of mineral wool, you can be sure that the walls will not freeze.

The main advantage of URSA PureOne is that the fiberglass binder uses acrylic. New technology, used today all over the world, has become available in Russia. Thanks to the use of acrylic, URSA PureOne thermal insulation is safe for humans, it can be used in residential premises, and is recommended for thermal insulation of children's institutions and hospitals.

What are URSA insulation materials and their varieties?

This thermal insulator is based on treated staple fiberglass. So this material is the closest relative of glass wool. When making it, sand, soda, dolomite and other additives are taken in certain proportions. The mixture is heated to the melting point and passed through a special apparatus. The result is a fibrous substance, the thin threads of which are glued with a special composition.

There are several products manufactured by URSA. The most common are the URSA GEO series insulation, made of fiberglass. In addition, the company produces polystyrene foam heat insulator URSA XPS, made by extrusion. A new product from the manufacturer, manufactured using the latest technologies, is PureOne insulation. Let's take a closer look at all these materials.

1. URSA GEO fiberglass mineral insulation is distinguished by the fact that only environmentally friendly components are used in its production. This is strictly controlled at all stages of the production process. So you can be sure that neither the raw materials nor the finished material contain harmful additives.

Where are Ursa materials used?

"Ursa" is an insulation material used not only in the construction of buildings, but also in the assembly of water supply systems, heating systems, other communications, as well as in the construction of roads, bridges, airfield runways and in many other areas. In each specific case, varieties of this insulation are used, the technical characteristics of which most accurately correspond to this specific purpose. Next, we will consider what types of this material are currently produced by the company.