Differences between Navien Ace and Navien Delux

Navien Delux is a modified model that replaced Navien Ace. Navien Delux Coaxial is a series of boilers with two heat exchangers with a power from 10 to 30 kW with a closed combustion chamber and forced smoke removal using a turbine. The manufacturer notes the following features of Navien Delux:

- Frost protection system. Unlike boilers from other manufacturers, in addition to automatically turning on the burner when the temperature drops below 6 degrees, at temperatures below 10 degrees the boiler ensures continuous movement of the coolant by activating the circulation pump.

- Fan with variable speed. Navien Delux boilers are equipped with a turbine with adjustable blade rotation speed depending on the readings of a special air pressure sensor. This ensures an optimal gas-air mixture ratio and increases boiler performance.

- The heat exchanger is made of stainless steel. By using a fan with variable rotation speed and increasing combustion efficiency, it became possible to replace the copper heat exchanger with a stainless steel heat exchanger, which certainly has a significantly longer service life.

- It is also noted that the boilers are protected from the influence of mains voltage surges by a special protective chip and the ability to operate at low (up to 4 mBar) pressure of main gas and water. In other words, the manufacturer tried to make a product that is maximally adapted to the worst operating conditions.

Technical characteristics of Navien gas boilers

Navien is one of the leading manufacturers of boiler equipment from South Korea; its products are in demand in many countries around the world and are of guaranteed high quality. The model range is widely represented by both single and double-circuit units, including:

- turbocharged;

- atmospheric;

- condensation

Recently, electric boilers of this brand have also appeared. The manufacturer places special emphasis on the fact that Navien gas boilers are in no way inferior to competitors in terms of technical characteristics, and most importantly, they are maximally adapted to domestic conditions with their unstable pressure, differences in the gas main and electrical network.

Unfortunately, in practice, a situation occurs when an error code is displayed on the information display of the unit and you need to decide what to do next.

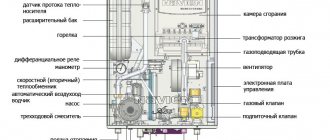

Navien Delux Coaxial device

The word Coaxial in the name of the boiler means the use of coaxial chimneys (pipe in pipe). This system is convenient in that only one pipe is used to supply air to the combustion chamber and remove exhaust gases, which can be led from the room to the street by the shortest route. In general, the boiler is not fundamentally different from products from other brands. You can note the convenient location of the expansion tank and the non-standard location of the fan - it is located below the burner.

It is noteworthy that Navien boilers do not have a built-in control panel. All adjustments are made using a separate control panel. The remote control is also equipped with a temperature sensor and displays various information about the operating status of the equipment and will report a malfunction with an error code. A special feature of Navien is also the presence of an air pressure sensor, which not only performs a draft check function, but also sends data to the control unit for portion control and determines the presence of reverse draft. If there is excess pressure in the chimney, for example due to wind blowing, the gas supply to the burner will be stopped and the boiler will stop.

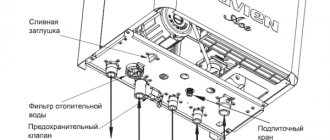

At the bottom of the boiler there are inlets and outlets of the heating and hot water circuits, a make-up tap, a drain plug, a cleaning filter and a safety valve for relieving excess pressure.

Air in the heating system

Error 16 appears if there is air in the heating system. In this case, we do not mean the presence of one large air plug, but the movement of bubbles along the circuit along with the coolant. As a result, the flow rate decreases and this affects the functioning of the device’s pump.

How to fix

The only way out is to bleed the air. But this must be done not in one specific place in the circuit, but wherever the corresponding fittings are installed. There is no need to rely on the valves to respond automatically, as they often become clogged or the springs weaken. You can effectively bleed air only manually by checking the heating of the radiators in each room.

They remove air not only from the system, but also from the pump. Here the principle is slightly different:

- Find a small washer on the end of the pump.

- Place a deep container under it.

- Unscrew the washer a maximum of 1.5 turns.

- A thin stream of water will appear.

- Drain until only liquid flows, no bubbles.

Operating principle of the Navien boiler

The operating principles of modern gas boilers are almost the same for all manufacturers, the only differences are in the configuration of the equipment and the internal arrangement of the actuators. The flow diagram of water in the boiler is shown in the figures. The Navien boiler works either to maintain the required temperature in the CO, when heated water from the first heat exchanger is pumped by a circulation pump in a large circle, or in the DHW preparation mode. The DHW mode is a priority, which means that if it is necessary to heat the water, a special three-way valve switches the circulation to the DHW plate heat exchanger, and the coolant flow through the heating circuit is blocked. The signal to switch the boiler to the DHW preparation mode comes from the flow sensor located on the hydraulic unit with the make-up tap.

Navien malfunctions

A gas boiler is a structurally simple device, but to ensure safe operation, any such units are equipped with automatic safety equipment, which serves to prevent serious accidents when operating errors occur. Almost all physical processes occurring during the operation of the unit are controlled by various sensors, information from which is sent to the control unit and continuously processed.

For the convenience of diagnosing and troubleshooting, information is provided to the user on the control panel display in the form of codes, which can be used to determine which specific system the malfunction has occurred and what checks can be carried out to eliminate it. Next we will look at the most common errors of Navien boilers in more detail.

Navien boiler error 02

Error 02 is caused by the heating circuit flow sensor located at the outlet of the main heat exchanger. If nothing prevents the movement of water in the CO circuit, after turning on the pump, the sensor contacts close and the signal is registered by the control unit, otherwise error 02

.

The following main reasons can be identified:

- low pressure in the heating system (to control the pressure, Navien boilers are equipped with a dial pressure gauge located on the front cover - you need to check and, if necessary, feed the system to 1.2-1.5 bar)

- failure of the flow sensor (to check, measure the resistance of the sensor before and after turning on the pump)

- no circulation in the heating circuit

- control board is faulty

Lack of circulation means that for some reason the coolant cannot move normally through the heating pipes. Obstacles can be: clogged cleaning filters, freezing of a section of the pipeline, closed taps around the perimeter of the heating system, the presence of an air lock or a malfunction of the pump.

To remove air, you can try to start the boiler in a special test mode, after first opening the air vent valve on the pump. To activate the test mode, you need to turn off the boiler and move switch No. 1 on the DIP-Switch block of the board to the ON position. We will discuss the testing of actuators in more detail in a separate article.

We recommend watching a video in which one of the users simulates error 02 on a Navien boiler:

Boiler pump malfunction

Error 16 sometimes occurs when there are problems with the pump. The pump may not be damaged and work properly, but its operation does not correspond to the user-specified mode. In this case, you need to check:

- Pressure in the heating circuit. If there are frequent and sharp surges, these are the first signs of problems with the pump.

- Nutrition. It may be supplied from the board, but not reach the motor due to defective connections. Fixing such a breakdown takes 10-15 minutes.

- Impeller activity. To check it, the boiler is first turned off. Then remove the washer that covers the hole to remove air from the pump. In the center you can see the top of the motor shaft. A horizontal slit is visible on it. The functioning of the pump is checked using a simple screwdriver. They insert it into a horizontal slot and try to turn it. If this is easy to do, everything is fine with the pump, but if it is difficult, it does not work correctly. Reasons: deposits on the blades, bearing destruction, lack of lubrication (heat-resistant composition).

In some cases, the situation can be corrected by installing a new shaft, cleaning the system, or removing air from the circuit. If all this does not help, it is better to contact a specialist.

Navien boiler circulation pump

Navien boiler error 03

In gas boilers, the presence of a flame on the burner is checked by a special sensor - an ionization electrode. The operating logic of the unit is to continuously check for the presence of a flame after opening the gas valve. Symptoms of error 03 on Navien boilers can be divided into two groups:

- unsuccessful attempts to ignite (no flame appears)

- ignition occurs, but the flame goes out

If ignition does not occur, you need to check:

- gas pressure at the inlet and outlet of the gas valve (can only be carried out by a qualified specialist using special equipment - a differential pressure gauge)

- condition of the ignition electrodes (compliance of the gap with the manufacturer’s standard, contamination of the electrodes). The normal distance between the electrodes is 3.5-4.5 mm.

- integrity of the insulation of the electrode power wire (you can visually verify that the spark breakdown occurs specifically on the body of the gas burner, and not somewhere else)

- correct setting of the boiler power on the DIP switch (valid if there is a problem during the first start of the boiler or after replacing the electronic board)

- presence of voltage on the ignition transformer

Error 03

on a Navien boiler will also appear if combustion is unstable (intermittent flame) or if the control unit is unable to detect the presence of a flame. In this case, you need to make sure that the connection between the ionization electrode and the control board is reliable, check that the boiler is grounded and that there is no contamination on the electrode. Unstability of combustion can be caused by an increase in fan speed, so you need to make sure that the yellow hose going from the turbine to the APS sensor is securely connected and not damaged.

If during the checks it was not possible to normalize the operation of the boiler, diagnostics of the boiler board, repair or replacement will most likely be required. We recommend watching a video in which one of the users simulates error 03 on a Navien boiler:

Causes of malfunctions

For a Navien gas boiler, faults are concentrated in several probable areas:

- problems with the coolant;

- ignition does not work;

- there is no fuel (gas) supply.

First, before planning a visit to the service center or estimating the cost of repairs, you should try to analyze the possible causes of the indicated error. This is, first of all, a failure in the automatic system receiving a signal about the normal flame level in the igniter. Further search for the probable source of the malfunction will lead to the ionization sensor (failure), gas pressure in the system (valve closed by mistake, no supply), problems with the grounding loop.

You can start by inspecting the flame sensor: it should be clean, free of deposits and dirt. If this is not the case, the sensor is cleaned and then they try to turn on the boiler. At the same time, check the position of the valve at the gas inlet to the unit and the grounding connection.

Practice shows that in most cases these simple manipulations will allow you to do without calling specialists and the cost of diagnostics.

Important. Before you begin troubleshooting any problems yourself, you should carefully study the error code, check its compliance with the manufacturer’s classification, and only then try to solve the problem.

Navien boiler error 10

This error is related to the smoke removal system of the gas boiler. Combustion products must be removed; for this purpose, the boilers are equipped with a fan. To control the operation of the fan and determine the presence of permissible draft for boiler operation, a differential relay is used, which is connected to the turbine by two plastic tubes. When the fan is running, a vacuum is created, the relay closes, and the boiler functions normally.

Reasons for error 10

may be a clogged chimney, the presence of reverse draft, or incorrect connection of the air pressure control sensor to the fan. For the latter case, you need to check that the yellow tube is connected to the bottom of the fan, and the transparent one is connected to the top, and the tubes themselves are not damaged, deformed or condensation inside.

Increased resistance in the chimney can occur due to direct gusts of wind or blockage of the chimney (bird nest or cobwebs, freezing in winter). That's right, the location of the chimney should be taken into account the direction of the winds of a particular region at the design stage and the chimney should not be installed on the leeward side of the house.

We focused on the most common malfunctions of Navien boilers, but in fact there are significantly more error codes. Methods for checking and troubleshooting are the topic of a separate article. For convenience, here is a summary table of codes with a brief description:

| Fault number | Brief description of the problem |

| 02 | Low water pressure in the heating system or breakdown of the flow sensor |

| 03 | No signal from the ionization electrode |

| 04 | Incorrect signal from flame sensor or short circuit. Make sure there is no contact of the ionization electrode with the boiler or burner body, and diagnose the control board. |

| 05 | Damage to the heating temperature sensor. Measure the electrical resistance of the sensor and its compliance with the temperature table, and make sure that the connection between the sensor and the control board is secure. |

| 06 | Short circuit of the heating water temperature sensor circuit. Ring or replace the sensor. |

| 07 | Damage to the DHW temperature sensor. Check the dependence of the resistance on the temperature on the sensor, make sure that the connection of the sensor to the control unit is secure. |

| 08 | Short circuit of the DHW temperature sensor. Ring or replace the sensor. |

| 09 | Fan failure. Measure the resistance of the fan winding (test value is approximately 23 Ohms). Make sure that there is a voltage of 220 V at the fan terminals. There may be a problem with the control board circuit (diagnostics of the Navien board is required) |

| 10 | Malfunction of the combustion products removal system |

| 13 | Short circuit of the CO flow sensor. The sensor is stuck or the control unit is faulty. |

| 15 | Internal control board error (requires diagnosis and repair) |

| 16 | Boiler overheating. Signal from the emergency thermostat. The causes of overheating may be insufficient coolant circulation (see error 02), a clogged heat exchanger, or a malfunction of the thermostat itself. Operation occurs at 98 degrees, the alarm turns off when it cools down to 83 degrees. |

| 27 | Open or short circuit of the air pressure sensor circuit |

Malfunctions of Navien gas boilers and their elimination

As you know, nothing is absolutely reliable or eternal; any equipment has a tendency to fail. When learning how to eliminate error 03 issued by the Navien boiler, you should not forget about other possible failures and failures.

Sometimes these are minor faults that the owner himself can easily diagnose (and even fix). Code “01” accumulates several probable reasons for a malfunction in normal operation, such as a clogged heating circuit, a failure of the circulation pump, or a deterioration in the normal flow in the pipes. You can try to eliminate this problem by squeezing out excess air from the heating line filter. After this, you should check the pump (impeller and motor) by visual inspection and measuring the resistance of the motor winding.

With code “02”, outwardly everything seems to be working: the hot water circuit is functioning, which runs regularly from the tap, but then suddenly suddenly becomes cold. The reasons should be sought in a low water level, sensor failure, or a simply closed distribution tap. The circulation pump may also be malfunctioning.

To eliminate the error, bleed the air, check the circulation system (engine), and the position of the shut-off valves. It doesn’t hurt to inspect the sensor, but most often the reason for the malfunction of the Navien double-circuit wall-mounted gas boiler is that the system is airy.

Code “10” is characterized by problems with the fan air supply tubes: incorrect connection or damage. The same error can be caused by a clogged chimney (sharp gusts of wind); in any case, you need to start by inspecting the exhaust line for combustion products.

Coding “05” corresponds to a failure in the automatic temperature measurement. At the same time, the condition of the conductors connecting the sensor to the controller board is checked. Sometimes it is enough, without replacing the sensor, to clean the contacts or first disconnect and then connect it again.

In addition to the above malfunctions, sometimes the boiler starts to hum when the hot water tap is opened. Experts consider this problem to be typical and widespread, and attribute it to a clogged heat exchanger. The radical solution is to replace the unit, but first you can try to clean it.

A failed three-way valve, the service life of which rarely exceeds 4 years, leads to the fact that the Navien boiler does not heat hot water well (with normal operation of other systems, including the heating circuit). Solved by installing a new one.