Requirements for heating a house in winter is a must for a comfortable stay. To provide heating, a whole system of pipes and equipment is required to maintain constant pressure. One of these is a fluid supply pump.

Its function is to ensure constant pressure in the circulation system without changing the pressure in it. In fact, it provides efficient heating of rooms. Power is supplied from the network. At the same time, the pump allows you to use all the main parts of the heating system in private homes, and also significantly reduces the noise level.

Pump installation

Features of circulation pumps

In systems with a forced circulation system, a pump is installed to increase heat capacity. Correct installation of the circulation pump in the heating system allows you to change the heat that is transferred depending on the outside temperature while maintaining stability of the heating in the room.

There are two types of such equipment : with a dry and wet rotor. Devices with a dry rotor have increased efficiency (about 80%), do not create much noise and require constant maintenance. The operation of a device with a wet rotor is different; it has a low efficiency (about 50%), is noisier, and its performance is sufficient to heat any private home.

30 years ago, homes used so-called vertical central heating, which was powered by liquid circulating through pipes, and the heat source was a gas boiler or wood-burning stove. Now there has been a transition to the construction of private housing using heaters with a pump, which has the following advantages:

- The coolant speed increases.

- The heat produced by the boiler is quickly delivered to the radiators and returned to its place.

- The heating process is significantly accelerated.

- The speed is higher, so the same amount of heat can be supplied to pipes with a smaller diameter. In other words, a pipe with forced circulation of water in a pump is cheaper. The barrel can now be wrapped with minimal deflection and added complexity. The main thing is to make the correct selection of the pump unit and set the pressure.

- An internal pump for circulating water in the heating system made it possible to have heated floors and efficient closed systems operating under high pressure.

- We managed to remove the pipes that run along the walls and do not always harmonize with the kitchen interior. Nowadays, heating lines are built into the walls, under the floor and behind the suspended ceiling.

As the main disadvantage of the pumps, it can be noted that if there is a need to frequently turn off the circulation pump, a generator must be installed or connected.

Installation instructions

So, we will describe the installation stages when circulation pumps are installed on the bypass. This scheme is used most often and is recommended by experts due to the following advantages:

- quick, convenient dismantling;

- convenient temporary shutdown.

For wet options, a horizontal, level position is critical:

There are various modifications of already assembled bypass loops on the market: for welding, for flanges, with segments for shut-off elements.

If it is not advisable to buy a ready-made assembly, for example, when all the parts are in stock or if there are specific features of the location, then the bypass piping is made from scratch. But you will need skills in working with pipes (welding, thread cutting).

A good, recommended location is between the membrane tank and the boiler. Below is a universal option: for open/closed circuits, for connecting using the collector method (several pumps).

Assembly order

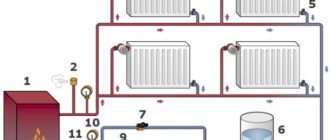

Diagram showing the movement of water, please note: shut-off valves are mandatory - when removing the device for repair or maintenance, they are turned off:

They start by assembling a unit (module) with taps: one per inlet/outlet. pump, the third is part of the lower straight pipe. It is necessary to carefully measure the return segment in order to accurately weld the segment with the shut-off fittings.

The bypass section from the central station is assembled. The nuts are only screwed on, tightening is postponed until the final stage. The top is the pump part (in the photo below the GRUNDFOS UPS pump) with two already screwed in taps, a filter, at the ends of the module there are small sections of pipe with threads like squeegees, they serve as material for welding. Below is a shut-off valve for the supply pipe (main).

They try on a bypass loop, mark the welding points on the pipe, use a drill with special drills to make a hole for the diameter of the section being mounted, and weld the joint.

They cut in the entire assembly with the lower shut-off valve on the main pipe, in our case, on the supply from the gas boiler:

The last step is to connect the pump to power.

Connecting the pump to power

So, the system is completely assembled, the pump is selected, installed, and then the device is connected to the power supply. Before the procedure, the entire line is completely de-energized—the machine is turned off on the panel. The device may have a plug for a socket or without it - just wires of a certain length for connecting directly to the home network on the panel.

Procedure: The pump wires are connected, taking into account the polarity, to the line. The terminals are labeled and have standard colors. If the device does not have a cable with a plug for a socket and you decide to use just such a connection, then you can buy it in any store, you will need a three-core cable, usually a cross-section of 2.5 mm² is more than enough.

It is highly desirable to have grounding (three-wire wiring), since proximity to water creates a significant risk of current entering the equipment elements. It is recommended to connect the device via an uninterruptible power supply (UPS); you can also connect a boiler to it.

An excellent solution is to insert a thermostat into the system (see diagram below), it can also be immediately included in the unit, which will automatically switch off when the coolant temperature drops below the set limits.

It is also highly advisable to install the device with a connection to the network through a difavtomat (its analogue of an RCD + AB) or through the boiler automation system, on which all these measures should be taken by default. And also, if there is an automatic protective device on any line with an outlet and the pump is not too powerful, for example, 90 W, that is, it will withstand all the consumers hung on it, then separate individual wiring with RCBOs and RCDs under the pump may not be installed. The device can be connected to such an outlet and not bother.

Connections without grounding are allowed, for example, when the house is old with two-wire wiring, but then the presence of a difavtomat or RCD+AV in the diagram is vital.

Device operation

Despite the large amount of information, many find it difficult to understand where and how to properly install a circulation pump to ensure forced circulation of water in the home heating system. You need to follow the instructions. Often this block is located on the return pipeline , which leads to the following situations:

- The temperature of the liquid in the supply is much higher, so the pump does not work.

- Hot water is less dense.

- The static pressure in the pipeline is higher, which facilitates the operation of the device.

Sometimes, when you get into a room where a boiler is installed that provides heating in the apartment, you can see that the system is based on return. We can say that this is the only correct solution, even if you don’t know about the centrifugal device that can be installed in the outlet pipe.

In an emergency and as a result of an increase in pressure, a safety valve is activated, which releases steam from the boiler. If the action is not completed, the valve allows pressure to be released, resulting in an explosion of the boiler shell.

Experience shows that no more than 5 minutes after the start of the heating process, the safety valve is activated. If you install the device on the return pipeline, steam will not appear in it, and the time before an accident will increase to 20 minutes. That is, if you install a check valve, you cannot prevent an explosion, but you can delay it in order to gain time to make a decision.

Installation diagrams in various types of systems

To begin with, let’s clarify the place where to install the flow pump, which circulates water through the boiler and forcibly directs it to the radiators of the heating system. According to our expert Vladimir Sukhorukov, whose experience is trustworthy, the installation location must be chosen in such a way that the unit is convenient to maintain. On the supply side it should be located after the safety group and shut-off valves, as shown in the installation diagram:

In order for the unit to be removed and serviced, shut-off valves must be installed on the sides

On the return line, the pump must be placed directly in front of the heat generator, and in tandem with a filter - a mud trap, so that you do not have to buy and install extra taps. The wiring diagram for the pumping unit looks like this:

When installing on the return line, it is better to place the mud collector in front of the pump unit

Recommendation. A circulation pump can be installed in this way in both a closed and an open heating system, there is not much difference. The statement also applies to the collector system, where the coolant moves to the radiators through separate connections connected to the distribution comb.

A separate issue is an open heating system with a circulation pump, capable of operating in 2 modes - forced and gravity. The latter is useful for homes where power outages often occur, and the owners’ income does not allow them to buy an uninterruptible power supply unit or a generator. Then the device with shut-off valves must be installed on the bypass, and a tap must be inserted into a straight line, as shown in the diagram:

This scheme can operate in forced and gravity mode

Important point. On sale there are ready-made bypass units with a pump, where instead of a tap on the flow there is a check valve. Such a solution cannot be called correct, since a spring-type check valve creates a resistance of the order of 0.08-0.1 Bar, which is too much for a gravity heating system. Instead, you can use a petal valve, but it must be installed only in a horizontal position.

Finally, we will explain how to install and connect a circulation pump to a boiler that burns solid fuel. As mentioned above, it is better to place the unit on the line coming from the heating system to the heat generator, as shown in the diagram:

As you can see, the piping uses a pump connection to the boiler circulation circuit with a bypass and a three-way mixing valve. The important role of these piping elements is described in detail in the manual on connecting solid fuel boilers.

Pump operating principle

Circulators operate on electricity. There are two approaches to the system, which leads to their division into “dry” and “wet” type devices. The principle of operation of a dry chain is that the drive is completely isolated from each pump and turbine, and rotation is transmitted through the shaft. As a rule, such devices are quite massive.

Dry pumps for circulating water in a heating system are powerful and efficient devices that provide very high flow rates and high pressure in the system. Without them it is difficult to control the heating. They must be installed in an apartment or private house. However, there are some disadvantages:

- The shaft that transmits rotation is a complex sealing system that prevents leakage of liquid under pressure. These seals gradually wear out, requiring regular preventive maintenance, including replacement with new ones.

- The operation of the pump is always accompanied by an air-cooled sound effect.

Finally, the system is a very expensive choice; the best option would be to purchase a wet rotor pump. The vertical wet rotor pump also comes in different types.

Description and advantages of the technology

In the offer of the Italian company Baxi you can find various gas, electric and solid fuel heating boilers, which are intended for both small country houses and full-size country buildings. Such equipment is technologically advanced. It is efficient and economical, characterized by reliability and complete safety in operation.

The range of Baksi gas boilers has different capacities

The advantages of this brand’s equipment include:

- ease of maintenance of Baksi boilers;

- high degree of automation;

- affordable price;

- Possibility of choosing units of different power.

The Italian manufacturer produces equipment that can operate on various types of fuel, including pellets, wood, coal, electricity or natural gas.

You can choose both installations with a capacity of several kilowatts, which will be an excellent choice for a summer residence, and equipment that can quickly heat a house with an area of 200-300 square meters.

This video will help you get acquainted with the Baxi brand:

One-pipe and two-pipe systems

Experts distinguish between two heating schemes with forced circulation of the thermal agent - one-pipe and two-pipe. The choice of one or another option determines not only the location of the circuits, but also the length of the pipelines, as well as the type and quantity of equipment for shutdown, regulation and control.

A single-pipe heating system is characterized by the sequential inclusion of heating radiators in the circuit. The coolant returns through a separate pipeline to the boiler only after it turns one by one through all the devices of the system. The disadvantage of this method is that radiators that are closer to the thermal block become warmer than those further away, and this reduces thermal efficiency and equipment life. Introducing a circulation pump into the circuit and equalizing the temperature is achieved at all points of the system.

A two-pipe arrangement has advantages over a single-pipe arrangement, since all heating devices are connected in parallel to the supply and return lines, which promotes uniform temperature distribution throughout all rooms. Forced circulation of the refrigerant leads to increased efficiency of the system and the ability to regulate its thermal power.

At what speed should the pump in the heating system operate?

The purpose of forced circulation is to effectively heat the house through the reliable delivery of heat to all consumers of the system, right up to the furthest radiator. To do this, the pumping unit must develop the required pressure (otherwise known as pressure), which is ideally calculated by design engineers based on the hydraulic resistance of the pipeline network.

Most household pumps have from 3 to 7 rotor speeds, due to which the performance and pressure generated can be increased or decreased. In order not to torment you with hydraulic calculations, we offer the following method for selecting the optimal speed:

- Find a laser surface thermometer (pyrometer). Put the heating system into operating mode.

- Measure the surface temperature of the pipe at the inlet and outlet of the boiler.

- If the temperature difference is more than 20 °C, increase the rotor speed. After 30 minutes, repeat the measurement.

- When the temperature difference is less than 10 °C, the water flow rate must be reduced. The goal is to achieve a delta between supply and return of about 15 °C.

The minimum number of rotor speeds is 3, but sometimes 7 or more

Advice. Do not switch the pump to a different circulation speed “on the fly”. Disconnect it from the network, move the regulator to a different position, and then put it back into operation.

You can do without a pyrometer when thermometers are installed on the supply and return lines. If the adjustment limits do not allow you to enter the range of 10-20 °C temperature difference, your system is not working efficiently due to an incorrectly selected circulation pump. Too cold return water increases the load on the boiler and increases fuel consumption. Water that is too hot means that it flows too quickly and does not have time to transfer heat to the heating devices.

The leading European brand Grundfos offers the latest generation Alpfa3 circulation pumps, which can independently select performance depending on the load and thus adapt the work to changing conditions. With their help, you can even balance the heating system, which our expert will tell you about in the next video:

DIY installation

It is important to know how to properly install a heating pump. You also need to know which pump to install in the heating system. Each unit comes with instructions that you will study carefully to ensure you can complete the installation yourself correctly. All liquid is drained from the system, part of the pipe is cut off in the place where the pump is to be installed.

In many cases, an old system that has accumulated dirt and rust will need to be cleaned. It is inconvenient to do this through the drain valve due to the small cross-section of the hole, so use the cut point. A hose is connected to one side through which water is fed under pressure, and on the other side the water flows out.

Filter installation

In order for the pump to work more reliably and longer, the coolant passing through it must be absolutely clean. Otherwise, the bearings and impeller may simply be destroyed by foreign objects entering them. The dirt filter, which is installed in front of it during the cooling process, captures all contaminants, sand and other small abrasive particles that appear in the system. Filters can always be changed .

As a dirt filter, you can use a regular coarse filter used in a water supply system. This is a small piece of pipe with an external dirt trap.

The straight cut has a metal structure that cuts out debris that could damage equipment. All debris should settle in the pipe, which can be periodically cleaned by unscrewing the plug at its end. Clogging must not be allowed.

The efficient functioning of the heating system in a cottage or country house is impossible without a circulation pump. Its uninterrupted operation guarantees that residents will be comfortable indoors during the cold season.

Circulation pump in the heating system

A heating circulation pump is considered reliable equipment that is easy to maintain. By following operating rules and performing timely preventive maintenance, you can minimize the likelihood of malfunctions. If malfunctions do occur, most of them do not pose a problem even for a technician with little experience. Repairing a heating circulation pump with your own hands is not difficult; it is enough to have general knowledge about the design of such equipment.

Diagnostics

Units of this type are conventionally divided into two groups: “wet” and “dry”. The latter are equipped with a fan, which is noisy even in normal mode, as manufacturers and sellers warn about. If backlashes appear during operation, the noise increases. Such a device must be installed in a separate room with good sound insulation. But sometimes experts install it in the living room or kitchen, arguing that it is highly efficient.

If the “wet” unit is noisy, you will need to diagnose the entire heating system. During this work, it may turn out that the water device is not to blame - the creaking is heard for another reason. It will need to be eliminated. If you follow the rules for installing, starting and operating the heating system, there will be fewer problems.

Dry and wet rotors

Units in which the rotor does not come into contact with the liquid during operation are usually called “dry”. They are able to withstand high loads. The main problem with models with this design is that their O-rings quickly become unusable. Although these parts are designed to operate for 3 years, they quite often fail long before the specified time.

The reason for rapid destruction is usually impurities, which are always present in one quantity or another in the coolant. Particles contained in the air around the boiler can also have a negative impact.

If the tightness of the device is broken, this will inevitably lead to a short circuit. Electrical elements fail, and repairing the circulation pump with your own hands in the event of such breakdowns is already extremely difficult, if not impossible.

Units with a “wet” type of rotor, for example, such as pumps from the German brand Vilo, are much more often used for domestic purposes. They are designed using a modular principle, and therefore are more reliable, easier to maintain and more repairable.

Important! If you carefully ensure that a working device does not operate “dry,” then the equipment will not fail for a long time.

Models of pumps with a “wet” rotor

Note! When purchasing a circulation pump, you need to check whether it can be repaired and whether the manufacturer supplies spare parts for this brand of equipment.

Bottom line

As you can see, the main difficulty of installation for a circulation pump is the need for welding, cutting pipes, and threading. The assembly itself is elementary: you need to carefully measure all the distances and screw in the elements. The connections are sealed with tow and sealant.

What to pay attention to during operation:

- it is necessary to periodically clean the filter and check the pressure gauge readings;

- The noise emitted by the device does not always indicate a breakdown; often the cause is air accumulating in the circuit. The problem can be solved simply - by bleeding with special valves;

- Dry pumps may require periodic lubrication.

Heating circulation pump: device

Owners of private houses usually give preference to economical, low-power pumps with a “wet” type rotor.

The operating principle of this unit is simple: the impeller, rigidly fixed to the electric motor shaft, rotates and draws in the coolant coming from the inlet pipe. Then, under pressure, it pushes it into the discharge pipe, thus ensuring circulation.

If we disassemble the pump with our own hands, we must have a good understanding of its structure.

Diagram of a circulation pump with a “wet” rotor

Important! It must be taken into account that in “dry” type models, the rotor and drive motor are separated into a separate unit, and the rotation is transmitted to the impeller using a clutch.

How to disassemble a circulation pump

Disassembling the circulation pump is carried out only after the device is disconnected from the network. The taps mounted at the inlet and outlet are closed to prevent water from entering the device. In some cases, it is removed from the pipeline by shutting off the bypass and connecting a backup pump. The heating system continues to function normally, and the technician can deal with the breakdown without haste.

Let's look at how to disassemble a water pump using the example of repairing a Wilo circulation pump.

First, remove the terminal box cover. To do this, unscrew the screw on which it is attached.

Inspect the contents of the box. How to check if the starting capacitors are working? They are called using a tester.

The performance of starting capacitors is checked using a tester

At the next stage, the “snail” is removed. Unscrew two screws located diagonally and separate the element from the electrical part of the pump (rotor and stator).

The internal surface of the dismantled device is inspected for the presence of deposits that form due to poor water quality. The rotor cartridge is picked up with a screwdriver and pulled out of the housing.

Disassembly of the pump is completed, access to all parts located inside the pump is provided. Now the parts of the device can be carefully inspected and cleaned. The modular design allows you to reduce repairs to replacing a failed unit.

Preparing the pump for the heating season

To ensure that your heating system does not fail during the winter, it is necessary to check the operation of the entire system, and in particular the circulation pump, before the start of the heating season.

It is necessary to check the serviceability of the device:

- There should always be lubricant on the gasket and pipes. If it has dried out, then it is necessary to lubricate the elements again; It is necessary to check the mesh filter. It often becomes dirty and interferes with the normal operation of the pump. If you notice blockages, you need to clear them;

- The circulation pump must be connected to the pipelines correctly. The best installation option would be in front of the heating boiler. With this arrangement, the formation of air pockets is minimized;

- The correct connection of heating equipment to the network can be checked with a special tester;

- Before the start of the heating season, it is necessary to check the operation of the pump. You can perform a test run.

Causes of circulation pump malfunctions

There are many reasons why the circulation pump may not work. For example, the presence of a large amount of suspended matter in the coolant can lead to malfunctions of circulation pumps. Small particles are deposited on the surface of the rotor, reducing the distance between it and the glass. Because of this, jamming occurs, leading to overheating and short circuit of the windings.

Wear and tear of the unit, operation in an unacceptable mode and a number of other factors lead to the need to replace some piece of equipment.

In cases of typical breakdowns, it is not difficult to repair the heating pump yourself. You can identify such problems by knowing their characteristic signs. This does not even always require disassembling the pump.

Moving a gas boiler in a private house: is it possible to move it and how best to do it

We can make as many repairs as we want in our home, rearranging furniture and household appliances. However, such a conversion as moving a gas boiler in a private house can cause certain problems with the gas service. In addition, disagreements will certainly arise with the local authorities of the city/town/district, which will be resolved in court.

Agree, it’s better to foresee everything and make it official than to then wander around the courts, pay fines and change everything back. But how to carry out the transfer correctly - with minimal loss of time and damage to nerves?

We will tell you everything about this difficult procedure. Let's look at whether it is even possible to move gas equipment in suburban private property and in a city apartment. We will tell you where and with whom to coordinate the reconstruction, as well as what documents need to be collected.

Relocation of the boiler from a regulatory point of view

Internal gasification project is a document containing detailed schematic information on the floor plan of a residential building with identification of technical points for the location of gas-using equipment on a scale of 1:100.

That is, moving a gas-fired heat generator to another location is a violation of the design documentation and requires changes to it.

The gas supply project is drawn up taking into account design and technical features. The adjustments made to it require careful calculations from specialists of the relevant profile

Let's figure out whether it is possible to move a gas boiler to another place? And if it is possible, then by what regulatory documents is this approved and where is it recorded?

The “housing issue” regarding the transfer of a gas boiler and other equipment in an apartment is determined by a number of articles of the Housing Code (Housing Code) numbered 25-29. And this process is called reorganization. The regulatory collection contains detailed information on the approval of the procedure, possible refusal and its protest, the consequences of unauthorized transfer, and so on.

The specified articles of the code of housing standards apply specifically to the premises of multi-apartment buildings, i.e. regulate measures and standards for the transfer of gas pipes, meters, boilers within apartments. However, this does not mean that no rules apply to private houses.

According to the resolution of the State Construction Committee of the Russian Federation dated September 27, 2003, clause 1.7., only after obtaining permission is it possible to carry out the refurbishment of premises for any purpose. In this case, the transfer of gas appliances falls under this definition.

Moreover, independent installation and replacement of a gas heat generator is not prohibited, but its admission into operation and connection must be carried out by employees of a gas supply company with the appropriate license.

In addition, you will have to coordinate the transfer of gas distribution, metering devices and other gas equipment at home. For uncoordinated actions, you may be required to return all gas equipment to its original location. In this case, you will have to pay considerable fines for each of the moved devices, even after reinstallation.

Administrative liability for unauthorized transfer of a boiler is determined according to the type and severity of the violation. There are penalties, obligations to return devices to their original location, and even shutdown of gas supply. It is almost impossible to challenge the sanctions in court, because you will in fact violate the requirements of the housing code.

Relocating the boiler also involves altering the gas wiring. When working independently, such actions are equated to unauthorized connection and threaten with fines, as well as termination of the gas supply contract

The punishment is justified, because unprofessional installation of equipment, as well as changes in the design, are a gross disregard of fire safety requirements, a threat to the life and health of people living in the building, and a violation of the gas supply engineering scheme.

How to arrange the transfer of a boiler in a private house?

Coordination on the movement of gas-using equipment and gas distribution is carried out with representatives of the resource supply organization. The application is filled out according to the form approved by Decree of the Government of the Russian Federation No. 266.

When visiting the gas service, you should have a package of the following documents with you:

- Passport of the applicant (owner of the residential premises).

- Home gas supply project.

- Technical passport for residential premises.

- Passport for a gas-using device.

- Consent of all other homeowners, if the house is in shared ownership (representative of the interests of minor owners).

The exact list of documents should be clarified in advance during a call or visit.

In the middle of the content

If you need to order high-quality installation of engineering systems (heating, water supply), please contact DESIGN PRESTIGE by phone +7 , and we will install the system at a professional level in accordance with high quality standards.

You will receive the commission's decision on a separate form by mail or in person.

A sample application for refurbishment and reconstruction must contain information about the applicant, the facility, a list of attached documents and information about the planned work. If you receive a refusal to restructure, it must be justified by the relevant paragraphs on the reasons for such a decision

In practice, failures practically never happen. They can only be associated with the non-compliance of the new boiler room with established standards and the lack of documents for the facility confirming the rights of the owner. Gas workers don’t care how many times and where you move the boiler.

If you want to speed up and simplify the procedure, try using the services of a gas service that offers to perform all types of work on a turnkey basis. Some organizations provide a similar service and all you need to do is write an application and conclude an agreement.

Representatives of the company will come to the site, draw up protocols for the replacement and transfer of all required equipment, carry out coordination and installation work from installation and grounding of the gas boiler to its start-up and configuration.

Important points for moving the boiler

First of all, please note that transfer is only possible to an officially registered premises. That is, you will not be allowed to use recently constructed extensions that are not technically present in the house as a boiler room.

If you are moving a boiler with a design change, be prepared that you will have to do so under the new SP that came into force in July 2019. Regulatory acts of 1989, 2003, 2011 are invalid.

The joint venture specifies all the basic requirements for boiler rooms, chimneys, ventilation systems, as well as references to other current norms and rules for gas supply for both apartment buildings and private houses

SP 402.1325800.2018 “Residential buildings. Rules for the design of gas consumption systems" differs slightly from the old standards and at the same time is mandatory for use according to the order of the Ministry of Construction.

Let's consider the main nuances of gas design, taking into account old and new rules:

- The room into which you are moving the boiler must be non-residential and included in the house plan.

- The ceiling height in a room with a boiler with an open combustion chamber must be at least 2.2 m.

- The volume of the room (kitchen, kitchen-dining room, corridor) with a gas stove must be at least 8 cubic meters for an appliance with 2 burners, each subsequent burner increases the volume by 3 cubic meters. meters.

- The room with a gas stove and a heat generator with an open combustion chamber must be at least 6 cubic meters. meters more than in point No. 3, but not less than 15 cubic meters. meters.

- The heat generator can be installed in the basement or basement, but it is prohibited to place it in the bathroom and sanitary facilities.

- It is necessary to equip a natural exhaust with three air changes per hour, and the influx should be in the volume of the exhaust + combustion air. For accurate calculations, technical calculations are carried out.

- In kitchen-dining rooms, exhaust ducts are provided with one air exchange per hour + 100 cubic meters. meters.

- The door to the room opens outwards

- The socket for volatile boilers should be located no further than 0.5 m from the device

You will also find other important nuances that may be useful to you when moving the boiler in SP 62.13330.2011 and SP 402.1325800.2018.

The boiler room into which gas equipment is transferred must comply with the requirements specified in the joint venture. Otherwise, the owners will be denied reconstruction at the stage of making a decision

Complying with the rules is quite difficult in terms of constructive arrangement. If you are just building a new boiler room, take into account the entire list of requirements while designing the room.

How much does it cost to move a gas boiler?

It is difficult to answer how much it will cost you to move a gas boiler to another location.

This depends on many factors:

- Transit distance.

- Replacement of shut-off and control valves, supply hoses.

- Possibility and necessity of transferring other equipment.

- Replacing or making changes to the project.

- Difficulty completing the task.

- Local price list for similar types of services.

Before implementing your plans, it is best to calculate everything and make sure of your financial capabilities. It is also worth rounding the resulting figure, since unexpected expenses may arise in the process. On average, the final estimate starts at least 8 thousand rubles, but the figure can be many times higher.

How is equipment transferred?

The procedure for changing the installation location is not as complicated as it might seem. You take the package of documents to the local branch of the GorGaz company and write an application. In this case, it is important to indicate the new installation location, specifying the dimensions and other features. The easiest way is to use the registration certificate at home.

Gas workers come to you and draw up project documentation for the transfer, one copy of which is given to the owner of the house for review.

Be prepared for the fact that in addition to moving the gas boiler, you will also have to change the gas wiring, move the meter, and so on. All these nuances (cost and need for work) should be carefully clarified with gas specialists

Next comes the transfer of the heating system complex and gas distribution, and then the starting start of the heat generator. If everything goes well, the contractors draw up an act according to which the owner of the house goes to the gas organization to register the installation activities carried out.

To ensure that all work is completed faster, first prepare the place for installing the boiler if you are sure that it meets all the standards.

You will need:

- Remove flammable items from the room.

- Rehang the door if it previously opened inward.

- Install the outlet in accordance with regulations.

- Place gas and water pipes, as well as electrical wires, to the places required by regulations.

- Hang a shield made of non-combustible material at the installation site of the wall-mounted boiler and attach brackets to form a flat base for the floor-standing unit that meets fire safety standards.

- Make a hole for the chimney.

Finally, you will need to check the exhaust openings and make sure that the passage to the unit installed in the new location is clear.

Free space around the gas boiler is necessary for monitoring the equipment by you personally, as well as for technical inspections and maintenance by employees of the company with which you have an agreement to monitor the condition of the device and supply blue fuel.

Conclusions and useful video on the topic

Video: What are the dangers of installing gas equipment:

Moving gas equipment to a more convenient location in a private home is a complex procedure, but quite feasible. However, it is strictly not recommended to carry it out without the approval and services of the gas company. If you complete everything correctly and save the received work certificates, you will not have any problems with supervisory structures.

Would you like to talk about how you received permission to move a gas unit into your house/apartment? Do you have useful information on the topic of the article? Please write comments in the block below, share valuable information, ask questions.

Common problems

For what reason might the circulation pump not work? Owners of electric heating pumps most often encounter the following problems:

- the shaft does not rotate;

- the device vibrates too much;

- pump operation is accompanied by uncharacteristic sounds or excessive noise;

- the equipment heats up;

- coolant pressure is below the standard value;

- The unit suddenly switches off.

Let's look at each of these situations in more detail.

Shaft blocking is determined by the following signs: after switching on, the pump hums, but the impeller remains motionless. This usually happens after a long period of equipment downtime due to oxidation of the shaft surface.

Inner surface of the circulation pump housing

Vibration of the device in most cases is caused by the fact that the bearing that ensures the rotation of the impeller blades has worn out. The noise may be caused by a clogged filter. Sounds uncharacteristic of pump operation are also a sign that there is air in the system.

A discrepancy between the coolant pressure and the standard value can be caused by a number of factors: violation of instructions when connecting a three-phase device; clogged filter on the suction line; increased viscosity of the coolant.

Heating occurs in cases where the pump operates in an unusual mode with a significant excess of the permissible load.

The pump in the heating system turns off some time after it starts working due to scale and deposits that accumulate on the inner surface of the stator. Incorrectly connected wires and oxidized fuse contacts can also cause malfunctions.

Common pump malfunctions - how to fix them yourself?

Pumps from different manufacturers, as stated, have the same design. Therefore, their faults are usually the same. Many users are faced with the fact that the circulation device begins to hum upon startup, but the rotor does not rotate. This problem occurs due to:

- Incorrect electrical wiring connection or lack of power at the pump terminals. The problem is solved by checking the presence of power with a tester and reconnecting (correctly!) cables.

- Oxidation of the engine shaft. This phenomenon is most often observed in cases where the pump has not been used for a long time (several years). Do-it-yourself repair in such a situation will be as follows - turn off the power, drain the water from the pipeline and the pump itself, disassemble the electric motor (remove the cover and rotor). Now the main thing. You need to take a screwdriver and turn the rotor until it stops against the working notch. The operation can also be performed by hand if the mechanism rotates without difficulty.

- Foreign objects entering the mechanism. You need to disassemble the cover and rotor. Remove the foreign body. After this, be sure to replace the mesh filter. As a rule, a foreign object disables it.

If the pump starts normally and then stops, it is most likely not connected to the terminals correctly. Check it out. If necessary, make a proper connection. Another reason for the described breakdown is the appearance of scale between the rotating components of the mechanism. You should disassemble the unit, remove any existing lime deposits, and lubricate the joints of all parts with oil. Sometimes the pump stops due to a loose fuse. It is necessary to dismantle this element and clean the clamps securing it.

A faulty fuse is often the reason why pumping equipment does not turn on.

Check the clamps, measure the voltage at the terminals with a multimeter. If the fuse is broken, replace it. Such situations often occur due to power surges. If you do not want to constantly install a new fuse, connect a stabilizer to the equipment. It will reliably protect the system from voltage surges.

The pump may make a loud noise when starting up. This signals that air has entered the closed circuit of the circulation system. This phenomenon is prevented by installing special node in the pipeline. Such a small element eliminates the possibility of air locks forming in the system. If a special unit has not been installed, you will have to purge the pipeline. Strong noise, as well as noticeable vibration, sometimes occur due to wear of the bearing, which is placed on the wheel with the impeller. You disassemble the unit housing, analyze the condition of the bearing, and replace it with a new one if necessary.

When the pump does not provide the required coolant pressure, the reason lies in the incorrect (in the opposite direction) rotation of the impeller. This problem only occurs when pumping equipment is connected to a 380-volt power supply. The solution is to connect the wire to the desired phase. Also, the pressure decreases with increasing viscosity of the coolant. In such situations, the wheel encounters high resistance and cannot perform its functions. You will need to remove the strainer from the pump, clean it or replace it.

As you can see, it is quite possible to repair the circulation pump with your own hands. Of course, if we are talking about common breakdowns. In other cases, it is better to entrust the restoration of the pump to service center specialists.

Troubleshooting Methods

The ability to avoid going to a workshop to repair the circulation pump will save money and time. But only if the owner of the device is able to determine the cause of the breakdown himself and knows how to disassemble the pump and replace the faulty part.

Our recommendations are designed to resolve simple problems. Attempts to repair the pump with your own hands in the event of a serious breakdown that requires qualified intervention can permanently damage the equipment.

Attention! The engine can only be dismantled after turning off the power supply and draining the water from the unit.

Shaft blocked

Dismantle the engine and inspect the shaft surface. If it has oxidized, then the shaft should be turned by pressing the screwdriver against the special notch of the rotor.

The body vibrates

To stop strong vibration, replace the bearings. The worn part is removed, and a new bearing is carefully driven into the seat using a wooden hammer. The size of the spare part can be clarified in the technical documentation supplied with the device.

The pump is noisy

The metal mesh mounted at the inlet of the pump is pulled out and thoroughly washed under running water. Then, without turning on the device, open the taps. Find a nut on the body designed to bleed air and unscrew it. After the excess air has been bled off and water has flowed out, the nut is tightened.

Attention! For uninterrupted operation of the system, it is necessary that air is removed in a timely manner in each area. It is recommended to install air vents that will perform this task automatically.

Removing air from the circulation pump

Weak pressure

In a three-phase pump, the first thing to check is whether the phases are connected correctly. If the rotation of the blades is performed in the desired direction, then pay attention to the cleanliness of the filter. The clogged filter is pulled out and washed.

Pump casing heating

The problem can be eliminated if you follow the operating rules of the device and do not exceed the maximum load specified in the documentation.

Switching off the unit after starting

Lime deposits that impede the movement of the shaft are removed. If the surface is clean, then check whether the phase wires are connected correctly. Oxidized contacts are cleaned.

Prevention of circulation pump breakdowns

The equipment must be prepared in advance for intensive use during the cold season. Emergency repair of a heating circulation pump can cause a lot of inconvenience and lead to unplanned expenses. Prevention, to some extent, is a guarantee that the system will not fail at the most inopportune moment.

The pump in the heating system circulates the coolant

Careful owners perform the following activities before the onset of cold weather:

- check whether the device is installed correctly;

- renew the lubricant on the pipes and gaskets of the pump;

- clean the filter of the suction pipe;

- check how tight the connecting nodes are;

- Using a tester, they evaluate whether the device is correctly connected to the electrical network.

It is also necessary to conduct a test run to ensure that the equipment is working properly.

Owners of a house with autonomous heating need basic knowledge about the design and operating principle of circulation pumps. Any signs that the device is operating abnormally should not be ignored. After all, breakdowns in most cases are caused by improper operation. In order for the pump to function without failures, it is enough to regularly monitor the system throughout the heating season and carry out the necessary preventive maintenance.

Proper operation of the pump - so that emergency repairs are not needed

Proper handling of pumping equipment and regular maintenance eliminates the need for repair work for many years. When operating the pump, consider the following:

- Do not start the pump if the pipeline is not filled with coolant.

- Turn on the circulation equipment at least once a month for 15–20 minutes. Prolonged downtime of the pump is guaranteed to lead to malfunctions of its individual components and mechanisms.

- Follow the manufacturer's recommended volume of pumped liquid. If the device is designed for 100 liters of coolant per hour, it is prohibited to pump more water through it.

- Before the start of the heating season, check the system for leaks and the correct connection of the circulation unit to the electrical network. Carry out test runs of the pump to make sure there is no vibration or extraneous noise.

Regular maintenance is also important for the stable operation of the circulation pump. You can perform this procedure yourself. You need to make sure that the wires leading to the terminals are securely fixed, that there are no leaks in the unit, and that there is grounding between the terminal and the pump body. You also need to lubricate the threaded flanges and tighten all pump bolts every 1–3 months. Do not forget about the described preventive measures, and then the circulation unit will serve you without accidents for decades.

They very rarely break. But if there are any malfunctions, you should seek help from a specialist. But in order to prevent equipment malfunctions, it is necessary to periodically check its operation and monitor the serviceability of all pump elements.