Gas boilers are used quite often nowadays. Unfortunately, problems with the operation of this equipment are also not uncommon. In this case, the design features of the boiler or the company that manufactured it do not matter. Sooner or later, any device begins to work worse or fails. People often ask why the water in their taps is not hot enough, or why the boiler does not heat the water to the temperature set on the control panel. Similar questions are usually asked by those who purchased boilers without boilers - they have a slightly different device, and there are fewer problems with them.

Operating principle of the boiler

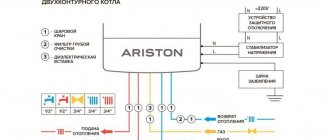

To understand the causes of the breakdown, you need to understand how the boiler works. Double-circuit devices “Ariston”, “Baksi” and other models have several blocks. In the gas unit, ignition and combustion take place, the water unit is responsible for the water supply and pressure in the line. The smoke exhaust unit removes combustion products to the street.

As soon as you start the boiler, the pump is activated, which pumps water into the system. The gas valve opens. The liquid circulates through the tubes of the heat exchanger, and the burner evenly heats its body. Sensors control the heating process. As soon as the temperature reaches the set temperature, the gas supply is turned off and heating stops.

When the temperature begins to decrease, the sensors will send a signal to the control module - the heating cycle will start again.

When the mixer is opened, the flow sensor is activated. It signals the board to switch the three-way valve to DHW heating. When the mixer closes, the valve switches to the heating system. Some models are equipped with a “quick start” mode. Then the valve periodically switches, heating both the first and second heat exchangers.

Possible nuances

Today there are many gas wall-mounted boilers from various manufacturers on the market. The principle of operation of the units for all models is essentially the same, but each brand has its own nuances that may be related to the causes of malfunctions and, as a result, poor water heating.

- "Ariston" is an Italian brand that is distinguished by its reliability. The brand’s boilers are adapted to domestic utilities and operating conditions. The most common cause of malfunctions is hard water, which contributes to the formation of blockages in the heat exchanger and circulation pump.

- "Navien" - Korean autonomous gas boilers. They are easy to use and effective. A special feature of the modification is the presence of two heat exchangers and the absence of a control panel on the body. The reason why the Navien boiler does not heat hot water well may be a stop in the operation of the equipment. This is due to the air pressure sensor, which, in the presence of reverse draft in the smoke exhaust unit, sends a signal to the control board, which causes the gas supply valve to the burner to close.

- "Vailant." German quality is fully reflected in the units under this brand. Since the device is of European origin, its heat exchangers most often suffer, becoming clogged due to the poor quality of the conductive heat fluid.

- “Baksi” is another representative of Italian manufacturers of autonomous heating equipment. He has simple and reliable boilers. The main reason why the Baksi does not heat the water, as noted by specialists servicing such units, is a manufacturing defect, which is sometimes found in this model line - a South Korean manufacturer. He provided a certain algorithm for controlling heating equipment. Incorrect settings may be the answer to the question of why the boiler stopped heating water.

- Proterm is a subsidiary of the German company. When operating these boilers, you need to monitor the quality of the heat-conducting fluid and use cleaning filters to prevent clogging of the heat exchanger.

- “Buderus” is another “German” in the domestic market of autonomous heating equipment, which has proven itself on the positive side. Like all Europeans, malfunctions can be caused by the formation of limescale inside the heat exchange system, as well as clogging of the working fluid flow sensor.

The principle of operation of a double-circuit heating boiler

Using a gas unit as an example, let’s look at the operating principle of a double-circuit boiler. The design of the unit is a system of blocks, the operation of which is interconnected and controlled by a security system, which includes various sensors. The main blocks are a gas block, where ignition and combustion occurs, a hydraulic block, which regulates the flow and pressure of liquid, and a smoke removal block, which removes gas combustion products.

When the boiler is turned on, the circulation pump is initially started, then gas is supplied using the gas valve. Automatic ignition ignites the gas, and as the gas burns, the heat exchanger heats up, heating the coolant passing through it. In this mode, the unit will work for some time until the parameters that are regulated by sensors change.

Sensors monitor the temperature in the room, in the return flow, gas pressure, system pressure, draft flow, and the presence of flame. Temperature sensors can regulate the temperature at the inlet or outlet of the heating circuit. If there is a sensor on the return, when the set temperature is reached, the thermostat sends a signal to the electronic board, which, after processing it, turns off the gas supply.

In this case, the circulation pump will run for some time to cool the heat exchanger. This is done so that the remaining heat in the heat exchanger does not bring the coolant to a boil. After the water in the system has cooled to the set temperature, the electronic board will start the pump, the gas valve will open the gas and the entire cycle of operation of the double-circuit boiler will be repeated.

When a hot water tap is opened, the flow sensor is activated and the control board switches the three-way valve to heat the secondary heat exchanger. Heating hot water in the system is a priority, i.e. immediately after you open the hot water tap, the entire system will only work to heat this water.

When the tap closes, the reverse process occurs - the board transmits a signal to the three-way valve, it closes the DHW system and the unit again starts working on the heating circuit. Please remember that it will take some time for the unit to produce hot water from your tap.

Some devices are equipped with a “quick start” or “comfort” function. This function allows the boiler to periodically switch the three-way valve and heat the water in the secondary coolant.

The insertion was carried out poorly: the diameter does not match or there are narrowings in the gas pipeline

A common reason for a complaint that a gas boiler in a house does not heat well is poor-quality connection of heating equipment to the general gas supply system (gas pipeline).

Often, gas service workers weld an additional thread, screw a tap onto it and drill a small hole where the thread joins the gas pipe. The diameter of such a hole is much smaller than the diameter of the pipe, which leads to a drop in pressure. As a result, the gas boiler does not heat hot water well.

You can determine this reason in the following way:

- there is a sharp decrease in the flame after ignition of the boiler;

- stops gaining temperature, or the flame goes out on its own.

Special calculators are used to calculate the required diameter of pipes in a particular room. The power of the boiler requires a larger volume of gas supply, therefore it is necessary to use pipes with a larger diameter. Before connecting the boiler to the gas pipeline, you must call a qualified specialist who will calculate the required diameter for the pipes, taking into account the characteristics of the room and the power of the boiler.

The following factors influence the choice of a larger cross-section in the connected pipes:

- low pressure requires connection to pipes with a large diameter;

- boiler power and room area affect the diameter;

- the longer the system, the larger the cross-section must be used;

- a reserve in diameter is necessary when there are many turns in the system (gas flow slows down at turns);

- number of consumed points;

- the required room heating temperature with the water heating temperature for domestic use;

- what pump is installed in the boiler.

Malfunctions of heating boilers

A dirty heat exchanger is a common reason for the lack of hot water in the DHW circuit.

Common boiler breakdowns include:

- coolant leak;

- water hammer;

- after turning on the burner, the lock is activated;

- the burner does not turn on;

- fuel burns unevenly, in waves;

- soot is formed;

- decreased productivity;

- During operation of the burner, the ignition is switched on;

- soot forms on the walls of the chimney and combustion chamber.

To resolve a problem, you must first determine the cause of the problem.

Built-in pump malfunction

The reason for the lack of hot water may be a clogged built-in pump.

An important part in the heating system is the circulation pump. The quality of heating and the functioning of hot water supply depend on its uninterrupted operation. There are several signs and causes of breakdowns:

- The unit makes uncharacteristic sounds. This occurs due to oxidation of the shaft, the entry of a foreign object into the structure, problems with the power supply, air in the pipes, dry running of the mechanism, and the appearance of cavitation.

- After turning on the boiler, the pump does not start. Perhaps there is no power supply, the fuse has tripped.

- After a short period of time after switching on, the structure switches off: limescale deposits in the stator shell.

- Hot water does not turn on in a double-circuit boiler.

Also, the reasons for poor operation of the circulation pump are poor pressure in the system, wear of the bearing, which causes additional vibrations in the line, and low pressure.

To troubleshoot problems, you need to check the presence of electricity, clean the pipes and other elements, replace failed parts, and remove foreign objects from the system.

The heat exchanger is clogged

You can clean the heat exchanger from scale using a solution of citric acid and an electric charge.

Heated gases are transported through channels, which are collectively called a heat exchanger. The design features are that the walls of the artery simultaneously serve as partitions of the water circuit, along which the coolant constantly moves, heating the metal surface. The combustion process is associated with the intense release of flue gases, partly consisting of soot and tar, which create a deposit inside the boiler, on the chimney. Therefore, the manufacturer recommends regularly cleaning the equipment at least once every 30 days and during the preparation of the device for the heating season.

We recommend: How to clean chimneys in a stove using folk remedies: how to clean a chimney

When soot settles on surfaces, the performance of the mechanism decreases, fuel consumption increases, and the risk of costly breakdowns and internal fire in the contaminated area increases.

Chemical cleaning of bithermal heat exchanger

Washing is carried out without dismantling the heat exchanger; to perform the procedure, you will need a booster with a volume of 20-30 liters. Before starting work, it is necessary to drain the coolant from the heating system using a Mayevsky tap.

Fill the booster reservoir with the flushing solution, and lower the hoses into the container, the free ends of which are connected to the heat exchanger pipes. Liquid movement is possible only under the action of a circulation pump; it must be connected to one of the hoses.

The ends of the hoses must be put on the heat exchanger pipes, and the free ends must be placed in a booster with flushing liquid, connecting the circulation pump. Work can be performed without removing the heat exchanger

It would be ideal to connect a reversible pump with the ability to change the direction of fluid flow. All that remains is to start the boiler for heating at a set temperature of 50-60 degrees and leave for 15 minutes, periodically changing the direction of circulation.

Chemical cleaning of the secondary heat exchanger

Flushing the secondary heat exchanger of a double-circuit gas boiler can be performed in a similar way to flushing a bithermic heat exchanger. However, you need to take into account that the secondary heat exchanger is easily removed, so you can improve the quality of cleaning by dismantling it.

To gain access to the heat exchanger, it is necessary to dismantle the front panel of the unit and move the control unit to the side. The heat exchanger is secured with two bolts at the bottom, which can be easily removed by unscrewing them.

It is most effective to place the heat exchanger removed from its original location for washing in a container with a salt-dissolving solution and boil it. Instead of a suitable household product, you can use a 20% citric acid solution.

Good results can be achieved by boiling the secondary heat exchanger in a washing solution

When cleaning any heat exchanger, the final stage is rinsing with clean water. This measure is necessary to remove traces of a chemically aggressive substance and stop its effect on the walls of the heat exchanger.

There is another way to clean the heat exchanger - hydrodynamic. Its implementation requires special equipment and pressure control at each stage of cleaning. Therefore, without special knowledge and skills, doing it yourself can be dangerous.

Regular cleaning of the heat exchanger will avoid the need to use very aggressive compounds and will make it possible to extend its service life. It is recommended to clean the heat exchanger annually at the end of the heating season.

Problems with the heating circuit

The pump must be selected according to the requirements of the heating circuit.

Malfunctions in the operating mode of the heating circuit are not always associated with a malfunction of the main heating element. If the boiler works, but does not heat the batteries, the reason must be sought in the wiring itself.

List of main heating circuit malfunctions:

- the filter on the return line or the needle tap (Maevsky tap) is clogged;

- insufficient power of the circulation pump;

- the rules for installing a heating circuit with natural circulation have not been followed.

Any of the above problems must be resolved before the start of the heating season. Otherwise, the room may be left without heat for several days, since the repair involves completely draining the coolant.

So, why doesn’t the boiler heat the batteries if everything worked fine over the previous years? The reason is a dirt plug that has formed on the heating circuit filter and completely blocks the coolant flow. It can be solved simply - the water is drained from the pipes or its circulation is blocked using bypasses, and the filter is cleaned. To prevent a recurrence of such a situation, it is necessary to completely replace the coolant with parallel flushing of the entire circuit.

In a gravity system, the slope of the pipes is key.

The second reason why the boiler works but the radiators are cold is the insufficient power of the circulation pump. The performance of the device is not enough to pump the entire volume of coolant in a timely and efficient manner. Or the heating system in the house has branches that are located at a significant distance from the pump. As a result, the circulation pump overheats, the heating equipment operates with excessive energy consumption, and the radiators remain cold. The solution is to change the coolant pumping device to a more powerful one.

If the house has a two-pipe heating circuit with natural circulation of water, and during the heating season it is often noticed that the boiler is on and the radiators are cold, then the reason lies in non-compliance with the slope of the main line. According to regulatory documentation, only a pipe slope of 10 mm per linear meter in a heating system with natural circulation will ensure normal coolant movement. The result is uniform heating of the batteries throughout the house. If there is no slope, the coolant stagnates, which negatively affects the temperature of the radiators. The problem can be solved by completely redoing the wiring.

Modulation errors on the burner

To heat running water, in most cases a boiler power close to maximum is required. In modern boilers, the burner power is regulated over a wide range. The adjustment occurs by changing the amount of gas supplied by the gas valve. The amount of adjustment is determined by the control board depending on the operating logic and settings. The process can be observed visually by the height of the flames on the burner.

If the boiler settings are set to 100% boiler power in DHW mode, but visually the flames on the burner are weak, or obvious interruptions are visible, then you should check:

- setting the gas valve (static and dynamic gas pressure)

- control board

Such checks should only be performed by a qualified person.

Three-way valve

A three-way valve is installed in boilers with two heat exchangers. When a signal is received from the flow sensor, the electronics gives a signal to the valve and the heated water from the first heat exchanger is sent to the second heat exchanger, where the heat is transferred to the passing tap water. If, for example, no actual switching occurs (the valve is faulty), then the coolant will continue to circulate in the heating circuit and no heat transfer to the hot water circuit will occur.

If, for example, a valve only partially closes the heating circuit due to a malfunction, then there will be problems with insufficient heating of hot water, since part of the heat will go to the heating system.

We recommend: Korean gas boilers: detailed review and recommendations for choosing wall-mounted and floor-mounted, single-circuit and double-circuit models, reviews from owners, comparison of their characteristics and costs

Problems with the flow sensor

A possible reason why a gas boiler may stop heating water is a problem with the flow sensor. The device is a small fan that rotates under the influence of water flow. As a result of rotation, a signal is sent to the control board to heat the water. Due to clogging, the fan may stop rotating.

You can clear the blockage without dismantling the device. To clean it, just open and close the water supply tap several times. If such actions do not give the desired result, you will have to remove the sensor and clean it.

To do this you need:

- Disconnect the gas boiler from the electrical network;

- Turn off the water supply tap;

- Drain the water from the unit.

Typically, the flow sensor is secured with a bracket, by removing which you can easily remove the device. The assembly is removed completely; to remove the inner part, you need to turn the parts in the groove. During disassembly, you should clean the filter mesh and remove the turbine.

Often, turbine blades are covered with a layer of rust that needs to be thoroughly cleaned. If you remove the three clamps, you can remove the turbine itself to clean the internal plane of its landing. Now all that remains is to reassemble in reverse order.

When disassembling the flow sensor, you need to clean the filter and turbine blades

If cleaning the flow sensor does not bring the desired result and there is no hot water, you will have to replace the entire assembly.

Control board errors

The control board should be considered as the cause of hot water problems when all other checks have failed.

The cause may be a malfunction in the flame modulation circuit. The boiler control unit constantly adjusts the burner power depending on the conditions, and if there is a fault on the board, the boiler can spontaneously reboot or turn off when it reaches maximum power, which in most cases is required precisely in the hot water preparation mode. It is also possible that boards may be configured incorrectly as errors. But this only applies to those cases where problems appeared after its replacement. BAXI boards are universal and require customization for a specific boiler.

Good evening everyone! After 4 months of operating the Baxi double-circuit gas boiler, it stopped heating hot water. Why? What is the reason? I assume that the boiler runs on untreated water and is possibly “overgrown” with scale or rust. What do you advise Lord?

NURLAN_DRAGON 2015.06.21 06:21

User Answers:

None. I don’t communicate closely with them))))) Oh, I remembered - when Dolph Lungren, Van Damme, ... If other problems in connection with the move do not bother you, go calmly! ... Happy holiday, Irina! Beautiful photo. How I love mimosas! I didn’t have to choose, my hand reached out to

The most common cause of boiler breakdowns is scale. Most likely, your boiler heat exchanger is clogged with scale and that’s why it’s not heating. Solution - install special. filters. For example, magnetic or electromagnetic. They are placed in front of boilers and work for many years without requiring maintenance. See manufacturers Kema (Moscow) or Aquashield (Ufa). Good luck!

Yes, most likely your double-circuit boiler is covered with scale. That's why it stopped heating hot water! Why? Hard water! What to do? Install a filter. For example, ion exchange or electromagnetic.

OBAPATEH 2015.06.21 12:26

User Answers:

Chakapuli, chashushuli…. and many more dishes of Georgian cuisine... also fried potatoes with wild mushrooms.... I’m listening to biology now... I can’t even imagine this. It would be boring for me alone, to get involved with all sorts of dubious companies

Vaillant and Baxi boilers are particularly reliable and safe. Breakdowns of such complex equipment must be repaired by a specialist. But, minor faults can be removed yourself if you have a basic level of knowledge about the design of heating and heating gas double-circuit boilers Baxi, Aristan or Naien. Most faults are indicated on the display of the Baxi double-circuit gas boiler. Having deciphered the errors, you can figure out the reason for the boiler’s failure to heat water. Where to start the search if the heating of water in a double-circuit gas boiler Baksi or Vaillant does not work, and the indicator does not show an error or it can be interpreted differently? The gas boiler does not heat hot water. Why? Cause? Double-circuit boiler Baxi (baxi). If the Vailant, Baksi, Aristan or Navien double-circuit gas boiler does not heat hot water, you should check the secondary heat exchanger. It also tends to get clogged quickly. But, fortunately, it can be easily removed, cleaned and reinstalled. What is the reason? Why is this happening?

Water heaters are used as the main or additional source of hot water supply in apartments and country houses. A complex device can fail for various reasons; breakdowns cause a lot of everyday inconvenience and require urgent repair. Let's take a closer look at why cold water does not flow into the water heater, why the pressure may decrease, and why difficulties arise with heating.

Water heater

Why does the boiler not heat water for the heating system?

There can be many reasons why a gas boiler does not heat water for heating. We will consider the main ones and ways to eliminate these reasons below.

The boiler turns on, but the heating does not heat.

Possible causes and their elimination:

- First of all, you should check whether air has accumulated in the batteries; using taps, you need to remove air from the system. To avoid air venting, install an air vent.

Battery bleed valve

It operates on the principle of an expansion tank, without reducing the pressure in the system. After the unit has been idle for a long time, check the valve; it may become clogged with scale;

- Batteries are clogged, what should I do in this case? It is necessary to drain the water from the cooled batteries. If you see that water flows out with debris, and sometimes black slurry may flow out, you need to flush the system to clean water;

- incorrectly made connection and piping. The diameter of the pipes may be incorrectly selected, shut-off valves may not be installed correctly, or the heat exchanger may be incorrectly connected. Check the manufacturer's recommendations in the instructions and correct any errors;

- at reduced pressure the unit also does not heat well, add water to the system;

- the appearance of scale in the heat exchanger. It is necessary to flush the heat exchanger from deposits. Not all models make it easy to remove the heat exchanger from the device. Where this is difficult to do, you can clean it without removing it. To do this, the boiler must be turned off and cooled.

Connect pump hoses with a filtration system to the inlet and outlet and rinse the heat exchanger with a special cleaning liquid. Afterwards, be sure to rinse the boiler with clean water to remove chemical residues, otherwise the remaining particles of the product can lead to corrosion of the heat exchanger, pipes and heating batteries.

Flushing the heat exchangerThe use of reagents as coolant additives significantly reduces scale formation. But not all models allow the use of antifreeze. Manufacturers Ariston (Ariston), Arderia (Arderia), Navien (Navien), Buderus, Viessmann (Wismann), Electrolux (Electrolux) prohibit the use of antifreeze, recommending the use of distilled water.

In the instructions for the models Rinnai, Baxi, Vaillant, Celtic, Ferroli, AOGV 11 6, Beretta, Bosch, Neva Lux, Protherm, Junkers, Koreastar (Koreastar), Daewoo allows the use of antifreeze. Please note that not all antifreeze is suitable for these boilers.

- contamination of the heating water filter also becomes the reason why the boiler does not heat the batteries well - clean the filter under a strong stream of water, after turning off and cooling the boiler. If the contamination is severe and cannot be cleaned, replace the filter;

- The coolant heating temperature is set too low, increase the temperature;

- incorrect operation of the circulation pump or its overheating also becomes the reason why your unit began to heat the batteries poorly, adjust its power;

- incorrectly selected battery design. The batteries must correspond to a specific heating mode, since each type of radiator has an individual heat transfer value depending on this mode.

General recommendations

There are many ways to fix a radiator leak available to the owner, and he can choose the most suitable option based on the equipment available. However, the above recommendations make it possible to urgently solve problems in the winter season, when it is not possible to turn off the heating system for a long time and carry out major repairs of heating devices.

It is quite natural that homeowners have a question: the heating battery is leaking, what to do in the summer? Having survived the winter with a hastily patched radiator, in the summer you should remove the battery from its mounts, inspect for damage and carry out a number of measures:

- remove old patches;

- clean leaks with a wire brush;

- treat cracks and holes with a grinder and a cleaning wheel;

- eliminate the defect by soldering or welding.

Next, you should paint the battery (you can read about paint for radiators here) and install it in place

In this case, it is important to follow the installation rules - use tow, FUM tape, high-quality shut-off valves and pay special attention to the joints

Having installed the battery in the circuit, it is worth filling the system with water and checking the tightness of the heating device

It is important to carry out this step while the boiler is running, since the circulation of coolant under pressure can reveal leaks and weak points in connections. If no leak is detected during intensive use of the heating system during the day, then the problem can be considered solved

Gas boiler Navien, main faults and their elimination

Do-it-yourself repairs require certain knowledge and skills in working with gas equipment. There is a special manual that describes the main fault codes. There are no repair instructions provided for users. The manufacturer assumes that troubleshooting will be carried out exclusively by service centers.

But many breakdowns can be fixed on your own without wasting time and money on a professional technician. To do this, it is enough to familiarize yourself with the main malfunctions and their elimination.

Navien gas boiler does not start

If the system does not turn on the control panel, then the problem is usually a lack of power from the electrical network. If the power supply is turned off by utilities, you should wait until the supply is restored. To understand how to turn on the equipment, just plug the cord into an outlet.

A common problem is the gas boiler turning on and off frequently. The source of the malfunction is an incorrectly installed circulation pump. The heating often turns off when the temperature range is incorrect. Also, the equipment turns on and off every 5-7 minutes in the absence of a thermostat.

The Navien boiler does not reach the set temperature

The most common malfunction of a Navien gas boiler is that the system does not heat up to the specified parameters. To fix the problem, you need to clean the heat exchanger using household plumbing chemicals or specialized compounds. To do this, the device is dismantled, the selected solution is poured into it, after which the part is thoroughly washed with a large amount of water. If the boiler does not heat hot water, then you can clean the heat exchanger of the DHW circuit in the same way.

The Navien boiler quickly gains and drops temperature

If the Navien gas boiler quickly heats up and cools down, then the fault should be sought in the heating system. You can adjust the pump speed to force fluid movement or remove air pockets.

We recommend: Infrared heated floor under linoleum: installation, instructions, video reviews

During diagnostics, it is necessary to inspect the filtration system and the lumen of the heat exchanger. You may also need to replace the antifreeze. Spare parts for Navien gas boilers are freely available - they can be ordered online or purchased in a specialized store.

Malfunction of the boiler ventilation system

If you do not use Navien Deluxe floor or wall heating equipment for a long time, a lot of dust accumulates inside, which negatively affects the operation of the fan. To fix the problem, you will need to clean and lubricate the system.

Water oversaturated with oxygen

During natural circulation, water bubbles form, which burst and cause noisy operation of Navien Ice 24 and other models. If you add membranes to the system, the problem will disappear.

Pressure failures

Failures in water pressure of Navien heating devices are usually associated with leaks. The coolant penetrates into all small cracks, which affects the operation of the equipment. Also, the reasons include a malfunction of the three-way valve or secondary heat exchanger.

Three-way valve does not work

It may be necessary to replace the three-way valve responsible for flow distribution.

Depending on the model, the part plays the role of a flow separator, switch, or mixer. Loss of device performance often leads to overheating and incorrect coolant temperature.

Causes:

- violation of the integrity of the electric drive;

- wear of the flow distribution mechanism;

- malfunction of the electromagnetic coil;

- presence of condensation;

- power surge;

- stray currents;

- entry of a foreign body.

To diagnose and fix the problem, it is recommended to call gas specialists with appropriate qualifications. You can blow it yourself and release the resulting air plug. During the repair process, worn out seals, non-working elements or the entire valve are replaced.

Ways to solve the problem

The problem can be solved in ways that require significant investment, for example:

- using an indirect heating boiler together with a boiler,

- purchasing a new boiler with a built-in boiler.

However, there is a less expensive, but very productive method - inserting an electric storage heater into the hot water supply circuit. Moreover, for this purpose, any standard heater with a volume of 30 liters is quite suitable, regardless of the manufacturer.

Use a water heater

A water heater embedded in the hot water supply circuit acts as a buffer tank. Its purpose is to equalize the temperature of hot water and smooth out possible temperature surges. The storage water heater and the gas boiler heater are set to the same operating temperature.

Even if the hot water taps are turned on simultaneously at different points of its intake, all users will initially receive water from the storage tank. The time spent waiting for a comfortable water temperature is reduced. Unproductive water consumption is reduced.

Turning the hot water supply on and off at any point of intake causes a temperature difference in the water leaving the gas boiler. However, this water enters the lower part of the water heater, and when it leaves the upper part, the temperature jump is completely smoothed out.

Connecting the water heater through a ball valve allows you to switch to a conventional gas boiler operating system at any time, which can ensure uninterrupted hot water supply in the event of a water heater failure.

Using a bypass jumper with a tap in close proximity to the boiler allows you to exclude the boiler from the hot water supply system. If the boiler is under maintenance, using the existing water heater will ensure uninterrupted operation of the hot water supply system.

Use an expansion tank

In winter, when the boiler's heating circuit is activated, any activation of hot water results in the heating circuit being turned off so that the hot water supply circuit can turn on. In the summer, when the boiler's heating circuit is not activated, each turn on of the hot water leads to the gas boiler turning on.

Often the user opens the hot water tap to simply rinse his hands. The boiler turns on or switches, hot water flows through the pipes. But the user may simply not wait for it, washing his hands with cold water.

Meanwhile, frequent and useless turning on and switching of the boiler “eats up” its operating life. A possible solution is to install a small expansion tank. It is installed in front of the water heater. If there is such a tank, for the first time after turning on the tap, hot water enters the pipe exclusively from the water heater due to the increase in pressure in the tank. Thus, in case of short-term use of hot water, there is no need to turn on and switch the boiler.

It is recommended to use a tank designed for hot water supply. Using a tank intended for heating will cause an odor because its membrane is made of rubber.

Use a recirculation pump

The best option is that the water heater is located in close proximity to the hot water intake points. The closer it is, the faster the hot water enters the tap, the more efficiently it is used. If this option for installing a water heater is not possible, then it is recommended to install a recirculation pump.

The pump is installed in the section between the water heater and the hot water intake points, ensuring the slow movement of hot water through the pipes. In addition, if you install a heated towel rail in this section, it will perform its direct function at any time of the year, regardless of the operation of the heating circuit of the boiler.

Heat exchanger clogged (reduced throughput)

Often the fouling of the internal walls of the heat exchanger with scale or mud deposits is the cause of problems with hot water. If tap water does not undergo pre-filtration (rough cleaning) and the temperature of the hot water is too high, the walls of the heat exchanger become overgrown with scale and dirt over time, reducing their thermal conductivity and flow area. Each time the user increases the DHW temperature on the boiler more and more in order to obtain the desired result on the mixer. As the temperature rises, scale forms even faster and, as a result, the temperature of the boiler's hot water supply is at its maximum, and the water does not heat up enough. This process has a particularly negative effect on a boiler with a bithermic heat exchanger. Plate heat exchangers are easy to clean.

Prevention and cleaning methods

The heating circuit in the boiler is clogged with scale and needs to be cleaned

. Many gas boilers do not heat water because preventive measures have not been taken beforehand. Heating equipment requires timely maintenance:

- cleaning;

- replacement of components and worn parts, gaskets, seals;

- gas adjustment;

- pressure control.

It is also important to ensure that the coolant level in the expansion tank is correct.

If the Baxi boiler does not heat water due to contamination of the OS elements, it is necessary to clean it. There are several ways:

- Mechanical. It is produced with scale thickness from 1 mm to 3 mm using equipment made of a flexible shaft, with a drive and cutters.

- Hydrodynamic. Occurs by flushing pipes with high pressure water.

- Chemical. For the event, specialized equipment and a composition of aggressive effects on the surface are used.

- Electric discharge. The method allows you to remove high-strength contaminants. A working cable with a certain power/frequency of electric discharge is transported along a water-filled line.

The cleaning method is selected taking into account the type of boiler, the nature of the contamination and the thickness of the scale.

Gas pressure at the entrance to the house has decreased

A gas boiler may not reach temperature due to low gas pressure. Typically, a sensor is installed at the entrance to the boiler to measure pressure. First of all, its indicators are checked to make sure of this malfunction.

Also read with this article: What to do if the pressure in the gas boiler increases

Modern heating equipment is often equipped with a pressure reducer. Adjusting the values on it helps solve the problem described. For private houses with one or two floors, the optimal value is from 1.5 to 2 atmospheres. In houses with more than two floors, the gas pressure should be in the range from 2 to 4 atmospheres.

ATTENTION. Any boiler adjustment requires a careful approach with preliminary study of the instructions. Gas is a dangerous flammable component that can lead to explosions and fires if consumed incorrectly. If you doubt your own abilities, contact a company that services gas installations.