Warm floors are an affordable alternative to traditional home heating that are easy to assemble without outside help. Any equipment can warm up the floor covering and room, but not all are suitable for use with water models. In this review, we will analyze the most successful boilers for working with such a heating system.

Equipment for heated floors Source valles.ru

How to choose a boiler?

Owners usually select a heating unit for a private home based on the benefits of using any of the available energy carriers. This approach is correct, and it should be followed when choosing a boiler for underfloor heating (HF). That is, when choosing a suitable heater, you need to consider the following factors:

- which energy carrier is most profitable;

- what thermal power is needed;

- How is electricity supplied in your region of residence, are there frequent outages;

- comfort during operation, including ease of maintenance;

- how easily the future heat source interfaces with the underfloor heating circuits.

In the context of this article, the last point is of particular interest. The fact is that not a single manufacturer produces special boilers for heated floors. In some models of gas heat generators you can only find the function of working with water heated floors and nothing more.

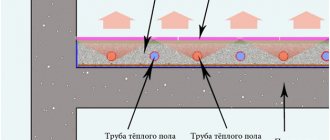

The main difference between a radiator heating system and floor heating circuits is the temperature of the coolant. For supply to radiators, water is heated to a maximum of 85 °C, while in water floor pipes it should not exceed 55 °C.

The optimal temperature schedule in a floor heating system is 35–45 °C in the supply and 25–35 °C in the return pipeline. If the heating of the house involves underfloor heating and radiators supplied with heated water from one boiler, then this does not affect the choice of heat generator. Another question is when batteries are not provided, and the boiler installation must serve only a low-temperature floor heating system.

Not every heat source is capable of maintaining a coolant temperature of 30-40 °C. The issue is resolved using various methods of piping the heating unit. The complexity of the connection depends on the type of boiler used for a warm water floor:

- gas wall or floor;

- electric;

- solid fuel;

- automatic pellet or coal.

How compatible these boilers are with heated floors and how to connect them correctly, we will consider separately for each of the varieties.

Electricity

The most expensive to operate are electric boilers: electricity is expensive in any region. This is partly compensated by the affordable prices of the boilers themselves and other advantages: absolute environmental friendliness, maximum possibilities for automating the process.

The downside is dependence on the power grid: power outages in suburban conditions are not uncommon. True, in this case the pump also turns off, and without it the warm floor will not work.

Therefore, when installing a system, it is advisable to have a backup/autonomous power source on the household - a generator, solar panels, etc. (what is an autonomous power supply at home)

Warm floor from gas boiler

If your home is gasified, then it would be logical to choose a heat source that runs on natural gas. You just need to choose the right power and compare the selected model with the operating conditions. If there are frequent power outages, it is easier to install a non-volatile floor heater with an open combustion chamber than to buy and operate gasoline or diesel electric generators.

In the Russian Federation and Belarus, the use of natural gas for heating a home is one of the most profitable options in terms of paying for energy. In Ukraine the situation is different, where the price of gas is so high that the first place in terms of profit is occupied by solid fuels - firewood, coal and pellets.

When everything is in order with the electricity supply, the easiest way is to install and connect a wall-mounted gas boiler for heated floors. It is good because it has its own circulation pump, expansion tank, safety valve and strainer. In this case, the connection diagram for a heated floor is very simple: the heater is connected to the distribution comb via pipes directly, but taking into account the following nuances:

- There should be shut-off ball valves at the inlet and outlet of the heat generator.

- The capacity of the built-in expansion tank (usually no more than 10 liters) should be enough to service the heating system. Calculate the volume of water in the pipes and compare it with the capacity of the tank. If the latter is less than 1/10 of the total amount of coolant, then place an additional expansion tank on the return pipeline before entering the boiler.

- If the design of the wall-mounted heating unit does not provide for a built-in expansion tank, place it separately on the return pipeline, as stated above.

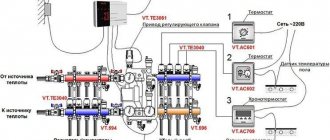

The diagram below shows how to connect a heated floor to a wall-mounted gas boiler. As you can see, there is no circulation pump in the system, since the boiler unit is involved. The distribution manifold without a mixing unit is equipped with RTL-type thermal heads; more details about this type of connection of water circuits are described in this article.

Since the expansion tank is built into the wall heater, an additional tank can be installed if necessary. For example, a large amount of water in the heating system

Floor-standing gas heat generators, with rare exceptions, are not equipped with pumps and expansion tanks. Therefore, its connection is carried out according to a similar scheme, but with missing elements in the harness:

In closed systems, which include heated floors, a safety group and a pump must be installed. Floor-mounted boilers do not have these elements.

When it is necessary to install a traditional circuit, where heated floors and radiators receive heat from one boiler, the connection is made as follows:

Note. The diagram shows a piping method using servos operating in conjunction with room thermostats. The heater can be connected without automation using the same scheme.

Types by fuel type

Heating boilers are a fairly large group of devices that have different principles of operation. According to the type of fuel (energy source), boilers are

:

- Gas

. The most efficient and economical boilers. The cost of 1 kW of energy is the lowest, and the efficiency is the highest. - . Water is heated using heating elements, electrodes or induction. The easiest to maintain and most expensive source of heating fluid.

- Solid fuel

. Boilers that use almost everything that burns as fuel - wood, coal, briquettes, pallets, etc. The availability of fuel makes such a boiler most suitable for autonomous heating of a house, but the combustion chamber has to be constantly filled. Modern models, however, are capable of long-term combustion without human intervention. - Diesel

. The source of thermal energy is burning diesel fuel. A diesel fuel boiler can operate independently for a long time - up to several months. This type of boiler may turn out to be more profitable than even a gas one, if it is not connected to the mains, but uses imported gas. - Combined

. Boilers that have the ability to switch to another type of fuel if necessary. The design of such a boiler can have two fireboxes, or one universal for different types of fuel; you just need to replace the burner. At the same time, there are universal boilers with the option of converting wood to electricity when a second firebox is not needed. The ability to have an alternative heating option is a valuable quality for a country house when fuel shortages are possible.

Features of underfloor heating without radiators

Let's start with the fact that expert practitioners do not recommend using underfloor heating without the support of a radiator system, and here's why:

- To impart a sufficient amount of heat to the room, you will have to raise the temperature of the floor surface to 30 ° C and higher, which is no longer comfortable for those living in the house.

- Radiators equipped with thermostatic valves respond faster to changes in room temperature than heated floors. The latter are more inert due to the massiveness and heat capacity of the screed.

- Any water boilers, except electric ones, cannot operate efficiently in the minimum combustion mode, when it is necessary to maintain a low coolant temperature. Imagine that the efficiency of gas and solid fuel units drops by 5-20%, and think how much fuel you will burn in vain.

If the gas heat generator is switched to normal operation by setting the water heating temperature to at least 60 °C, the burner will often ignite and turn off (the so-called clocking will appear), since the underfloor heating system does not require a large amount of heat. This mode is unsuitable for the heater; it can quickly fail.

For normal joint operation of gas and other boilers with underfloor heating, but without radiators, there is an optimal solution - installing a buffer tank. Even a small tank will allow you to avoid “clocking” the unit burning natural gas.

We will consider an example of installing a buffer tank together with a solid fuel boiler, which cannot do without it when supplying floor heating.

Safety requirements

Safety requirements for operating gas equipment are almost the same for all types of boilers.

Basic provisions

:

- a separate room is required to accommodate the gas boiler;

- The boiler room must be equipped with a gas analyzer so that in case of gas accumulation (for example, spontaneous extinguishing of the burner) it can be notified in time;

- there should be no foreign objects in the boiler room, especially flammable ones - paint, solvent, chemicals, etc.;

- the boiler must be free for air flow, it is prohibited to lean or lean anything against it;

- If you detect a smell of gas, immediately turn off the supply, notify the gas service and ventilate the room. When using propane-butane, ventilation may be useless, since it is heavier than air and accumulates at the bottom;

- Do-it-yourself repair of boiler safety sensors is prohibited.

The requirements are simple, but they must be strictly observed to avoid dangerous consequences.

Connecting a solid fuel unit

Have you chosen to heat your home with wood using underfloor heating without connecting radiators? Get ready for significant investments in the piping of a solid fuel boiler, since in this situation you cannot do without a buffer tank. The reason is that wood heaters need to dump heat somewhere, otherwise the water jacket of the unit may boil.

Moreover, a solid fuel heat generator is not able to heat the coolant to just 40 °C; its minimum operating temperature is 55 °C. If it is lower, condensation will form in the combustion chamber, which will have a detrimental effect on the metal walls. Even in a cast-iron boiler that is not subject to corrosion, condensation forms a layer of plaque that prevents efficient combustion of fuel.

In order for a solid fuel boiler to function with maximum efficiency, and for you to burn wood with the greatest benefit, you need to maintain the coolant temperature at 80-90 ° C, which is absolutely incompatible with heated floors. This means that a buffer capacity is needed - a heat accumulator.

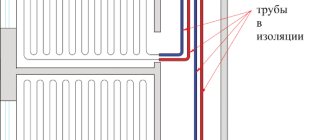

During maximum burning of firewood, excess heat will accumulate in the heat accumulator, and the underfloor heating system will gradually select the required amount using a mixing unit, as shown in the diagram:

The diagram does not conventionally show shut-off valves for the heat accumulator

According to the proposed scheme, you can connect any solid fuel or gas boiler; this is the best existing option, although not the cheapest. It is recommended to connect pellet and coal automated heat generators in the same way. Calculation and selection of the volume of the heat accumulator used is a separate topic discussed here.

Underfloor heating with electric boiler

Any type of electric heat generators is perfect for working with underfloor heating water circuits:

- heating elements;

- electrode;

- induction

A household electric boiler for heated floors is the simplest and most convenient option. Regardless of the type and design, these heaters are capable of maintaining any temperature in the heating network without loss of efficiency. Therefore, they do not need buffer tanks and complex connection diagrams. To connect an electric heating unit to a comb of heating circuits, you can use the diagrams given above for gas boilers.

As a rule, heating element electric boilers are manufactured in a wall-mounted version and are equipped with their own pumps and expansion tanks. Simpler models, as well as induction and electrode heat generators, are connected in a similar way to floor-standing gas boilers. The missing working elements are added to the circuit, only in addition an electrical control cabinet is installed.

Step-by-step instructions for installing and connecting an electric boiler to water heating are presented in a separate publication.

Gas valve (automatic) EUROSIT 630 (boiler). Mariupol

Gas valve (automatic) EUROSIT 630 (boiler)

Multifunctional gas supply regulator with modulating thermostat and function of complete modulating shutdown of the main burner

Multifunctional gas supply regulator with a modulating thermostat and the function of complete modulating shutdown of the main burner - 630 EUROSIT is a non-volatile device and is available in various designs and is intended for use in boilers and other gas-consuming equipment that requires precise temperature control, with a power of up to 24 kW.

Control knob with positions for off, ignition and temperature selection (MS).

Thermoelectric flame protection system with blocking of gas supply to the main burner after switching off (GM).

Device for setting maximum gas flow (RQ), pressure regulator (PR).

Minimum gas flow adjustment screw (by pass).

Modulating thermostat with the function of completely switching off the main burner (TH).

Gas outlet to the pilot burner with gas flow adjustment screw (RQ).

Inlet filter and pilot burner filter (FL).

Connections for measuring gas flow.

Conclusions and recommendations

For successful and long-term operation of the underfloor heating system, it is allowed to use any currently existing boiler. It is not the type of heating unit that plays a role, but its correct connection to the underfloor heating distribution manifold. Other selection criteria, such as power, functionality and type of energy carrier, are selected using a standard algorithm.

By choosing a heat source and knowing the risks of combining it with heated floors, you can select equipment and piping elements in advance. This will give you a future picture of the financial costs of installation, from which the payback of a specific heating system is calculated.

Think twice before introducing underfloor heating without a radiator. If you have high requirements for the interior design of rooms and you do not want to see heating devices under the windows, use a more modern solution - baseboard convectors or air heaters built into the floor.

Choice

First of all, you should choose a water heater for underfloor heating of suitable power.

Calculating the power of a boiler is a difficult task; the easiest way is to proceed from the average value - 1 kW of power per 10 sq. m. area. It is necessary to pay attention to the possibility of adjusting the boiler operating mode. It is best if there is the possibility of smooth adjustment. It is also necessary to decide on the required number of circuits, type of installation and other characteristics of the boiler that will best meet the requirements of the existing room

It is also necessary to decide on the required number of circuits, type of installation and other characteristics of the boiler, which will best meet the requirements of the existing premises.