For most autonomous heating systems, no matter how the heating is carried out, through radiators or a heated floor is installed in the home, the main heat transmitter is the heated coolant. Most often, the coolant is ordinary water (up to 70% of heating systems used in households), but other liquid media can also be used for these purposes. Water is the most accessible and cheapest coolant. The only disadvantage of this option is that water reacts sensitively to changes in ambient temperature, significantly changing its physical properties.

Another, no less common option with a coolant, antifreeze is a liquid used for heated floors instead of water. Unlike boiler water, antifreeze is a liquid substance made from ethylene glycol and propylene glycol. Special additives (chemical additives) are added to the composition, which reduces the chemical and physical activity of the liquid.

Note: antifreeze, unlike ordinary water, has a low temperature threshold. Depending on the concentration and composition of additives, the freezing temperature can vary from 30 to 65 0C below zero.

Let's consider various options for choosing a coolant for a heated floor. Which is better, water or antifreeze, how much more practical is one or the other?

Heating with electricity

High price. If natural gas is the cheapest source of energy, then electricity is, if not the most expensive, then one of the most expensive. One kilowatt-hour of electricity will cost 4.01 rubles.

For comparison, a kilowatt-hour of natural gas costs 0.82 rubles, and propane-butane costs 2.57 rubles. Over the course of a year, this difference can result in tens and hundreds of thousands of rubles in additional expenses.

Insufficient selection. The general availability of electricity (unlike natural gas, it really is everywhere) does not mean that there will be enough energy to heat an entire country house. Not every suburban electrical network can handle the power consumed by the heating system. If the network fails, solving this problem is almost as difficult as installing a gas pipeline.

Disadvantages of electric heating

- High price.

- Voltage drop in the network in cold weather.

- Insufficient electricity output.

Criterias of choice

The selection of antifreeze for floor heating systems is carried out taking into account all the technical and structural features of the heating equipment. Since the main function of ready-made coolants is protection against freezing, when choosing a solution you should pay attention to the temperature limit for its use.

When using antifreeze for heated floors in residential premises, it is first necessary to consider such an indicator as complete safety of use and the absence of toxic substances in the composition.

To choose an effective coolant for a floor heating system, you should consider the following points:

- presence and composition of additives;

- the ability to combine with metals, plastic, zinc or rubber;

- temperature threshold;

- duration of use.

Additives that improve the properties of antifreeze must meet the design requirements of floor heating equipment. If a metal circuit is installed, it is recommended to pay attention to the quality of anti-corrosion additives. To protect rubber elements, special softening agents are required.

Heating with liquefied gas

Propane-butane is a liquefied gas that is used to fill cars with a gas engine and the well-known “dacha” red gas cylinders. It provides the best combination of price and comfort after natural gas.

For autonomous heating of a private house with gas, it is necessary to install an underground gas tank on the site. One gas tank holds several thousand liters of liquefied gas. This volume is enough to heat the house for many months. When the gas tank is empty (this happens once or twice a year), it will be replenished by special refueling vehicles.

Low price. Propane-butane is one and a half to two times cheaper than electricity or diesel fuel: 2.57 rubles per kWh versus 4.01 rubles for electricity and 4.75 rubles for diesel fuel.

In practice, this means the difference between 49 thousand rubles - the cost of heating 100 square meters with liquefied gas for a year - and 90 thousand rubles - a much more significant amount that would have to be paid when using diesel fuel.

Convenience. Like natural gas or electricity, propane-butane is supplied to the heating system without human intervention. This is not firewood or coal that needs to be thrown in several times a day. Liquefied gas does not require regular loading and constant supervision. The gas holder needs to be refilled once or twice a year, and this is done by a professional, not the homeowner. In winter, snow may need to be cleared so that the gas station can access the site. This is the worst thing that can happen.

Doesn't take up space. The gas tank is located underground. You can walk on it, herbaceous plants and even bushes can grow over it. During operation, the gas heating system does not emit a noticeable odor. There is no comparison with firewood, coal, pellets or diesel fuel, the storage of which will have to waste space on the site or in the house.

Disadvantages of heating with liquefied gas

- Sometimes you have to clear snow for winter delivery.

Specifics of special substances

In order to choose a liquid for a heated floor system according to the rules, you need to become familiar with all the properties of the composition. A similar substance can be used for other purposes and tasks. First of all, in areas with temporary power and gas supplies, and in fact where there are permanent or long-term shutdowns. In such a situation, antifreeze allows you to keep heat in the communication longer.

The product is also used in non-residential premises with a large area. This is specific:

- warehouse type premises;

- hangars;

- garages.

In such premises, constant temperature changes occur due to the continuous closing and opening of gates.

Antifreeze - quality and ease of use

However, the main feature that such a coolant has is the content of special substances that prevent the formation of corrosive processes. It is due to the additives in the composition that scale does not appear on the walls of pipes and other elements.

This liquid

under the influence of temperature, it does not have the ability to change its own characteristics and physical state. Actually, with the help of this composition, thermal energy is effectively transported throughout the communication. Even at negative temperatures, it does not harden or thicken, does not become wider, and, therefore, cannot lead to the destruction of system components. Such products can work without changing their own state down to –60 degrees C. If necessary, the concentration of the composition can be adjusted by diluting it in a 1:2 ratio with distilled water.

Heating with diesel fuel

For heating with diesel fuel, you will also need a tank, and the costs of its installation will be comparable to the costs of autonomous gasification at home. At the same time, unlike propane-butane, diesel fuel cannot be called cheap.

High price. Diesel fuel is the most expensive source of energy used for autonomous heating of a private home. A kilowatt-hour of diesel fuel costs 4.75 rubles. Even electricity is a little cheaper. It may not be easy to spend more on heating.

Unpleasant smell. This is an inevitable property of diesel fuel. A strong smell will follow the unfortunate owner of a diesel fuel tank everywhere. The house will smell like a garage, and the area will smell like a running tractor, and nothing can be done about it.

Problems when using low-quality fuel. The use of low-quality diesel fuel can lead to serious damage to heating equipment. Those who use liquefied gas and DESIGN PRESTIGE gas tanks do not have such a problem: the quality of propane-butane does not affect its consumer properties.

Disadvantages of heating with diesel fuel

- High price.

- Sometimes you have to clear snow for winter delivery.

- Strong odor in the house and area.

- Use of storage space.

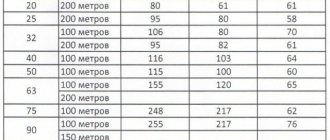

Crystallization temperature of ethylene glycol-based antifreeze

Ethylene glycol is not ideal as a coolant due to all its risks.

- Highly corrosive (much higher than water). Suitable inhibitors are used to reduce corrosiveness.

- It has the ability to foam, which is again compensated for by appropriate additives.

- More liquid than water causes leakage problems. Due to the toxicity of ethylene glycol, this can be a problem. It is necessary to work with liquids, paying attention to protective gloves and goggles. In addition, all objects and substances that absorbed the solution are toxic. They are subject to replacement and destruction.

- Ethylene glycol does not react well to overheating. When the temperature rises to 70°C, active precipitation occurs, which significantly reduces the heat transfer of the thermal device. And this again leads to overheating. After overheating, the properties of the liquid change dramatically, which makes the antifreeze impossible to continue working. According to this criterion, it should be noted that in systems with solid fuel boilers, ethylene glycol-based antifreeze cannot be used: without 95 ° C more regularly than without, and without automation to control the position of the heat exchanger, it inevitably overheats.

Heating with coal or wood

Wood and coal share the same disadvantages. They require very frequent loading (so often that a large house may need a stoker), require regular ash cleaning, and their storage takes up a fair amount of space on the property. In addition, they also emit a strong odor.

Frequent downloads. Firewood needs to be loaded into the heating system three to four times a day. Over the course of a season, this will take at least 147 hours. More than three working weeks of continuous physical labor, worked from bell to bell. It is not surprising that many people prefer to find a stoker. However, this in turn affects the price. Taking into account the payment for the stoker, heating a house with an area of 100 square meters using firewood for a year will cost 97 thousand rubles. This is more than the same amount for diesel fuel (90 thousand rubles) or electricity (76 thousand rubles).

Coal is not particularly better in this regard. It must be loaded into the heating system two to three times a day, that is, a little less often than firewood. As a result, the cost of time (and, accordingly, money if you have to pay a stoker) turns out to be slightly less than when using firewood, but the difference is insignificant: 101 thousand rubles for heating a house with an area of 100 square meters, taking into account the payment of the stoker.

In fairness, it should be noted that this problem has a partial solution. There are special boilers with a bunker into which coal is filled not several times a day, but only once every three to four days. This is a significant improvement over refueling every few hours, but compared to propane-butane or even diesel fuel it looks rather pale.

Warehouse space. The peculiarity of firewood is the need for a large room for storage and drying. To avoid wasting up to 40% of energy on moisture evaporation, they must be dried for three years. A large room will take up part of the site that could otherwise be put to more useful use. Coal storage also requires a significant area.

Danger of poisoning. An unpleasant odor is a constant companion of any type of solid fuel, but in this case we can talk about a threat not only to smell, but also to life. If the boiler room is located directly in the house, when using solid fuels, the danger of carbon monoxide poisoning cannot be completely eliminated.

Disadvantages of heating with wood or coal

- Very frequent downloads.

- The need to clean up the ash and pay for the stoker.

- Smell in the house and area.

- Part of the site is occupied by a warehouse.

Distilled water: the best option in a green card home

As you can see, it is better to use water as the coolant in your underfloor heating system, and it is a very inexpensive option. To make the system more attractive and almost completely safe, you can pre-treat the coolant. Soften the water The easiest way is to open the lid, put it in a metal pan and cook. In this case, part of the salt precipitates (unstable compounds of potassium and magnesium). But it is impossible to boil and remove stable compounds. It can be removed by adding a little lime, sodium orthophosphate or soda ash. But you can make it easier: use distilled water. If you use this liquid on warm soil, you will automatically eliminate the risk of salt deposits. This is a good choice because there is very little distilled water.

Heating with pellets

Fuel pellets made from peat and wood waste differ from firewood in their higher density and calorific value. This is the most profitable and comfortable solid fuel, but all its advantages outweigh the already familiar disadvantages: the need for frequent loading, a strong smell, a large storage room for bags of pellets.

Low price. Pellets are surprisingly cheap: only 2.32 rubles per kWh. If you didn't have to spend so much time loading, they would become the cheapest type of fuel. But you still have to spend time, albeit less than when using coal or firewood. Loading of pellets should be done at least once a week, and taking into account the work of the stoker, this type of fuel can be considered average in cost, but not the cheapest: 52 thousand rubles for heating one hundred square meters during the year.

Disadvantages of heating with pellets

- Very frequent downloads.

- The need to clean up the ash and pay for the stoker.

- Smell in the house and area.

- Part of the site is occupied by a warehouse.

- Electric heating

- Heating from cylinders and gas tank

- Diesel heating

- Wood heating

- Pellet heating

LLC DESIGN PRESTIGE

A reliable and high-quality partner for heating your home, cottage, or cottage.

We offer any types of autonomous heating for your choice:

Types of heating:

- gas;

- water;

- wood;

- solid fuel;

- electrical;

- diesel;

- atmospheric;

- gravitational;

- steam;

- air;

- individual;

- independent;

- private;

- autonomous.

Heating types:

- radiator;

- water heating

- heating with antifreeze

- heating with diesel fuel

- heating with diesel fuel

- heating with heated floors

- heating with warm walls

We work around the clock

Antifreeze

The heating system uses ethylene glycol and propylene glycol antifreeze. They are typically aqueous solutions of these polyhydric alcohols, and additives are added to improve their properties.

Heating system.

Only special compounds are used in the heating system. Universal antifreeze or a car should not be poured into a warm layer of water.

When choosing antifreeze, remember that ethylene glycol is a strong poison. In drug addiction, 60% of deaths occur, and in the remaining 40%, the kidneys are seriously damaged. The lethal dose for adults is 100-300 ml. Apart from ingestion, contact with skin or mucous membranes has serious consequences. Although toxic, vapor levels are low, but chronic inhalation has irreversible effects. However, antifreeze based on this ethylene glycol is used. They sell 5 times more than the safer and more expensive propylene glycol.

Installation of heated self-leveling floors

There are two types of heated self-leveling floors: electric and water. In our country, the first type is more common, largely due to the ease of its installation. At the same time, water self-leveling floors, popular in the West, are more economical, although they are difficult to install and operate: pipes for hot water are laid in the base (a rather labor-intensive and technically difficult task), then a standard screed is made, leveling is done, and the last step is pouring the self-leveling floor .

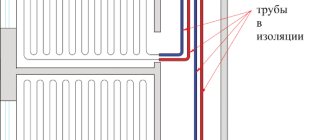

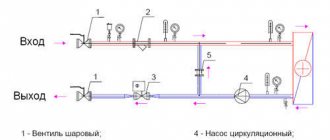

Both water and electric self-leveling heated floors are installed in the same sequence: first - the “warm floor” system, then - pouring the finishing coating. Let's look at this algorithm in more detail using the example of laying electric heated self-leveling floors. They are installed using a cable that carries heating elements under the coating. These elements are absolutely safe and easily heat floors to a comfortable temperature for humans. They are connected and conducted with special single-core and double-core cables.

The “warm floor” system is controlled through a thermostat connected to the mains. Heating up to 70 degrees is possible, and the floor is protected from fire by a reliable protective shell and insulation. Electric heated floors can be installed in different ways, but the principle by which they are installed is the same. The first step is to make a screed, lay insulation on it, then lay the cable, and install the heating elements. After the screed has completely dried, which usually takes a long time, up to a month, the finishing coating is poured - the self-leveling floor. This is done using standard technology: the finished mixture is poured out and immediately after that it is leveled using a needle roller (this way air bubbles are squeezed out of the coating and it is made homogeneous). Sometimes special chips are placed on the newly poured floor for decoration. The coating takes 12-20 hours to dry. The top of the self-leveling floors is coated with a protective transparent varnish.

Important nuances

In operation, a self-leveling heated floor made on the basis of an electrical system is not much different from conventional electrical appliances that receive power from wall wiring. Before laying the cable in the floor, it is necessary to plan the subsequent arrangement of the furniture (if the floor is installed in the bathroom, take into account the location of the plumbing and washing machine). The cable should be placed in places where it is guaranteed not to be at risk of overheating. Experts consider it advisable to draw and save a diagram of the cable layout in the floor, since in the future, if repairs are necessary, this can help in identifying the damaged area.

Types of heating elements

Various types of heating structures are used to heat floor coverings. Each of them has its own installation and subsequent operation features, which are worth learning about in advance.

- A water circuit within which a heated coolant circulates. The pipeline is laid in the form of a snake or spiral. When performing installation in an apartment in a multi-storey building, difficulties will arise with connecting to central heating. To regulate the degree of heating, a collector unit is installed. Despite the high cost of installation, such a floor has minimal operating costs. When installing it, it will require pouring a sufficiently thick layer of mortar to prevent the pipeline from moving during operation;

- Electric heated floor, formed by laying an electric cable. Installation is carried out according to a certain scheme. The cable can be single- or double-core of varying power. To simplify installation, special bases are often used. Manufacturers offer ready-made electrical mats, in which a cable of a certain power is initially laid with a predetermined pitch. In this case, installation consists of simply laying the finished product on a carefully prepared base. A thin layer of mortar is used to fix the mats. The thermostat included in the system allows you to control the degree of heating of the floor covering;

- Thermal film. Allows you to avoid using a thick screed. Scotch tape is used to secure the thermal film. Maintain the temperature at the specified level.

Installation of floors with ready-made mats