Principle of operation

Heating furnaces with a water circuit are made of steel or cast iron.

They require operation under steam pressure. The boiler is installed in a stove firebox and water heating is connected to it. The radiator is made of metal pipes or sheet steel 0.3-0.5 cm thick. A steel heat exchanger is more popular, since its maintenance is not particularly difficult (steel sheets are easy to clean from combustion products) and the water circulation is uniform. The advantage of boilers made from pipes is a larger heating area, as well as the ability to install a stove above the pipes for cooking. The operation of such a heating system is that heated gases pass through the channels of the heating tank and give off heat to the liquid. There are ovens with multiple heating tanks. In the first container, the water is heated, and in the second, the heating intensifies and steam is formed. There are several types of heating stoves with a water circuit, operating on peat, wood and other solid fuels:

- cast iron – provides a high level of heat transfer;

- wood-burning - has a lower level of heat transfer, but is equipped with a steel firebox, which is more durable and wear-resistant;

- brick - a reliable heating system, the main disadvantage of which is that installing a stove takes a lot of time and effort;

- Buleryan is a cylindrical stove that works on the principle of smoldering.

Cast iron stove

This model can withstand sudden temperature changes and also has a longer service life than its steel counterparts. Thus, heat accumulation is 8% more. A “water jacket” made of steel profiles is built into the cast-iron stove. Each of the 4 legs of such a stove has a screw that allows you to adjust the device, i.e. align it when installing the stove. Thanks to the individual fit to the door, the oven is sealed. A cast iron stove is a godsend for those who want to heat just one room. In this case, radiators will not be needed, because the heat emitted by the firebox is evenly distributed throughout the room.

Cast iron stoves for summer cottages

We advise you to look at our detailed review of models of cast iron stoves for the garden and home,

Wood burning stove

This is a steel structure with boiler tubes running between its walls. About 40 liters of coolant circulate through them. Heating occurs as a result of the combustion of solid fuel and the release of energy

When choosing a heating system for your home, it is important to consider the power of the furnace. This indicator depends on the dimensions of the combustion chamber

The power of the firebox is higher if more fuel is placed in the chamber. Power calculations are carried out according to the following formula: 1 kW of power is spent on heating 10 sq. m. premises.

Wood heating stoves

Design, review of models and technical characteristics of wood-burning heating stoves. You can find out more here

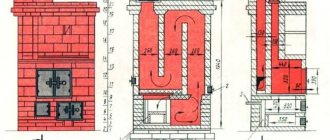

Brick oven

Brick stoves can heat up to 100 square meters at minimal cost. m. area. This achieves the optimal temperature level in the room. A brick stove with a water circuit works on the same principle as a solid fuel boiler. The difference is that in a brick oven all the “participants” in heating the room are heated: liquid, walls and smoke ducts. During the combustion process, heat is transferred to the radiators, while the stove itself exudes heat literally until it cools down.

How to make a brick oven for your home

In this article we analyze in detail the structure, masonry scheme and order of the heating brick oven. You can find it here

Buleryan

Such a stove is a round body, the internal space of which is divided into two parts. The lower level is the firebox, where wood is placed and lit. The second level is filled with hot gases - products of combustion and smoldering of firewood. Curved pipes surround the furnace cylinder itself. Cold air enters the device through these pipes. In the firebox, it collides with the hot circuit, resulting in a rapidly moving air stream. It breaks out into the outer space at high speed and takes the heat of the firebox with it.

Buleryan stove

Previously, we told you how to make a buleryan oven yourself. We advise you to read this manual.

Choosing the best option

It will be difficult to install a massive brick stove in an already built house. In this case, water heating is best organized on the basis of a metal potbelly stove, which can be placed on a reinforced wooden floor without pouring the foundation.

However, if it is possible to make the foundation as it should be, then preference should be given to a more reliable brick stove structure.

The water circuit around the house for a wood-burning stove is best made from thick steel pipes and with natural circulation of coolant

Installing a circulation pump and/or accumulator in the heating circuit in question is a waste of money and zero additional benefit. They will only complicate the installation of the system. And if the lights go out, these devices will create problems. Whereas the heating option without them will continue to calmly heat the house if there are problems in the electrical network.

Classic solid fuel boilers

This is the most common type of heating installations that burn solid fuel; they are also called direct combustion boilers. Due to their simplicity of design, these units are the cheapest of all and therefore are most often purchased by homeowners.

They are also popular among do-it-yourselfers, which is why it is not difficult to find drawings for the manufacture of traditional heat generators. The units can be divided into 2 types:

- non-volatile, operating on natural chimney draft;

- supercharged, with forced air injection.

The first operate on the principle of a conventional stove, only “clad” in a water jacket. The volumetric fuel chamber is located above the ash pan, separated from it by grates. Air from the room enters the firebox through the damper in the ash pan door and the grate. Its quantity is regulated by a chain-driven thermostat, which is guided by the temperature of the water in the boiler jacket and controls the air damper mechanically. For a better understanding of the process, a diagram of a solid fuel boiler is shown below:

Flue gases released in the firebox pass through the flame tubes of the heat exchanger, washed externally with water. Depending on the design of the heater, combustion products can make 2 or 3 passes through the gas ducts, intensively exchanging heat with the water jacket. Having given up their heat, the gases leave the unit through the chimney.

Non-volatile solid fuel units cannot boast of high efficiency, a maximum of 70%. The duration of combustion depends on the volume of the firebox and the operating mode, although it is strongly recommended to use them in conjunction with a heat accumulator. The second type of boilers is more productive; their efficiency reaches 75% due to forced air supply by a fan. The design of such an installation is well reflected in the operation diagram of a solid fuel boiler presented below:

Related restrictions

Let us remember the saying of the “shaggy” years: free cheese can only be found in a mousetrap. A heating furnace with a water circuit is built and operated with serious restrictions compared to a simple one:

- The heat exchanger cannot be walled up in the body (structure) of a brick kiln: the difference between the TCR (thermal expansion coefficients) of it and the structure of the kiln will very soon disable both;

- If the firebox has a water jacket, then it is impossible to achieve optimal fuel consumption for the stove/fireplace. Therefore, devices of this type can only serve as additional ones in the existing local system;

- The heat exchanger of a furnace with a water circuit must be completely surrounded by flue or flue gases;

- It is unacceptable to start a stove/fireplace with a water circuit when the CO is empty. If this is a heating and cooking stove used year-round, it should have a winter-summer switch, and the heat exchanger should be installed only in the winter part of the stove structure;

- Let water into the CO from below, i.e. directly into the oven, this is possible only if it (the oven) is made of steel and the feed from below is indicated as standard in the manufacturer’s specifications. CO with a brick stove is fed with cold water only and only from above, from the expansion tank;

- Since in a CO with a periodically fired furnace, the heat exchanger experiences regular alternating thermal loads, it is unacceptable to build a closed-type CO furnace with excess pressure;

- For the reason in the previous At this point, building a heating system with a furnace constantly filled with antifreeze is pointless: the expensive coolant will age, degrade and disappear even before the end of the current heating season;

- At the end of the heating season, the coolant (water) from the CO must be drained. This is necessary to form a dense film of iron hydroxide in the pipes, preventing further corrosion;

- Before starting next. season, the system is filled with water, sealed and pressurized by pumping air from the expansion tank to 2.2 ati;

- Filling the system must be done at an outside temperature of at least 15 degrees;

- The heating device is started no earlier than one day after pressure testing the system, but not earlier than the coolant temperature is equal to room temperature;

- A wood-burning stove with a water circuit must be heated with intervals between fireboxes of no more than 12 hours, regardless of the heat capacity of the stove structure and external conditions, i.e. The oven should not be allowed to cool completely. This is explained by the low calorific value of firewood and the high probability of acid precipitation from wood flue gases.

Note: it is impossible to build with a Leningradka-type CO stove - the Leningradka requires excess pressure and forced circulation.

Advantages

- Economical. The services of a stove maker will cost much less than the purchase of modern devices, their maintenance and installation. The stove can be made from mortar and bricks that were left over after building the house. Repair and operation of such devices does not require large investments.

- Design variability. A modern master can build a stove of any shape and size. It can be decorated with exquisite designer decor and painted in various colors. There are designs that combine a fireplace and stove.

- High degree of maintainability. Over many years of operation, this equipment requires only minor cosmetic repairs. This is much faster, cheaper and easier than taking an expensive unit for service.

- Possibility of regulation of combustion intensity in the firebox.

- An atmosphere of comfort, which is characteristic only of Russian ancient huts with stoves.

- The intensity and speed of air heating is determined by the position of the dampers.

Advantages and disadvantages of heating with wood

The high popularity of wood heating is due to the presence of a number of advantages of this fuel. Let's look at their advantages:

The most important and significant advantage of firewood is its availability. If you look at our country from space, you can see that its territory is completely covered with dense forests

Almost all areas of dense human settlement are located in places with an abundance of wood, while electricity networks and gas mains do not reach all populated areas. Their second undoubted advantage is their low price. When choosing a boiler to heat your home, for many of us, its cost is decisive. Therefore, even if electricity and gas are available, many people prefer to buy an inexpensive wood-burning boiler instead of a more expensive electric or gas one. The next advantage is ease of installation. A wood-burning boiler does not require expensive approvals and installation permits. Just buy, connect and use. Simplicity of design. As can be seen from the previous section, the boiler design is very simple. That is why many craftsmen independently make homemade solid fuel boilers with their own hands.

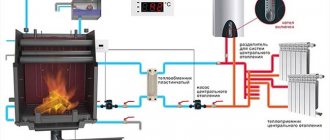

Photo 5: Installation and piping of a wood-burning water heating boiler at the dacha

We talked about the benefits of heating with wood. Now about the disadvantages. And they are very significant:

- The first thing I want to say is the high consumption of firewood. Since this fuel has a low calorie content, even to heat a small wooden house, you will need an impressive woodpile. What can we say about modern private houses and cottages with an area of several hundred square meters.

- The second is low efficiency. The design of such a device does not allow extracting maximum energy from the fuel, so part of it flies into the pipe. The efficiency of a wood-burning boiler with a water circuit is in the range of 70-80%.

- The wood in the boiler burns out quickly. To maintain a comfortable temperature in the premises, it is necessary to stand near the boiler day and night, constantly adding new portions of fuel to the firebox. Agree, this is not a very pleasant prospect, and you are unlikely to be able to automate the supply of firewood.

- The need for a room to install both the heating boiler itself and to store a huge supply of firewood. For safety reasons, the heating device must be placed in a boiler room built for it. The woodpile should also be installed nearby so that fuel is always within walking distance.

Here is a brief summary of the features of these devices. For more information about the operation of wood heating boilers, see the following video:

Types of systems

There are two options for heating a house using a stove. In the first case, it will be a system with a natural type of coolant circulation, and in the second - forced circulation.

Steam heating from a natural circulation stove does not require an electrical connection, since water circulates through the heating circuit due to the laws of physics. However, in this case, the heating pipeline must be of a large diameter, which leads to an increase in the volume and inertia of the system. Such a stove will take quite a long time to heat up when lit. At the same time, when the wood burns out completely, the coolant in the circuit will remain warm longer.

Among the disadvantages of natural circulation in steam heating from a stove in a private house, it is also worth mentioning the fact that the supply pipes must be placed either under the ceiling or at the level of the radiators. If the house is two-story, a pipe comes out from the top of the stove, through which the coolant disperses through the radiators of the second floor, and only then falls to the first floor and heats the rooms on it.

Do-it-yourself stove heating with a natural circulation type is not highly efficient, since the water in the circuit moves slowly and does not supply enough heat to the premises.

In the second case, a water-heated brick oven is equipped with a circulation pump, which ensures constant movement of the coolant inside the circuit at a certain speed. By changing the speed parameters, you can regulate the degree of heating of the rooms. Thus, this type of system is more efficient. However, it requires electricity to operate. If there is a power failure, the pump will turn off and the coolant inside the operating furnace will boil. To avoid such troubles, in case of sudden power outages, the circulation pump should be connected to an uninterruptible power supply with a battery. If there are regular power outages, you will also need a power generator, and this is quite expensive.

Construction of an option for heating a greenhouse

To increase yield in the cold season, supplementary heating must be provided for the greenhouse. Unlike heating with electricity, using homemade heating boilers will be more financially profitable.

Rice. 3 Boiler for greenhouse

The best option would be to build a stove in the greenhouse with an exhaust chimney, which can be done with your own hands. Drawings for this can also be easily found on the World Wide Web.

The process of constructing equipment in a greenhouse consists of the following stages:

- It is necessary to lay a brick oven in the vestibule of the greenhouse.

- A chimney is installed along the entire length of the greenhouse at the top of the structure or under the beds.

- The exit for the pipe must be made on the other side of the greenhouse. Thus, carbon dioxide will escape, but the heat will remain inside the greenhouse.

Another option for a homemade boiler for a greenhouse is also possible:

- Selecting a large-volume barrel and painting it from the inside to avoid corrosion.

- Making holes in the barrel for the chimney, stove, additional barrel and cream tap.

- Installation of the firebox inside the barrel.

- Exhaust from the chimney barrel.

- Installing an additional expansion tank on the barrel.

- Welding heating for a greenhouse from a profile pipe.

- Layout of pipes inside the greenhouse structure.

- Purchasing a pump to circulate water in the greenhouse system.

A similar option for a greenhouse can operate both on wood and on other types of fuel. To control the temperature inside the greenhouse, homemade heating boilers can be equipped with an electronic temperature sensor, and the digital display itself can be placed directly in the house.

Autonomous heating in the form of homemade heating boilers is in demand both among owners of private houses and among residents of multi-storey buildings. This allows you to significantly save on the purchase of expensive equipment, as well as control the heating process itself. Homemade heating boilers can operate on wood, coal or other types of fuel, which allows the use of such units in various fields.

Russian-made pellet boilers

Fire tube boiler

Tips for choosing a stove

Recommendation number one: to heat the coolant in the water heating network, use a solid fuel boiler. If necessary, buy a long-burning model with a loading chamber volume of more than 100 liters. Modern TT boilers direct 75-80% of combustion energy to heat water and hardly raise the ambient temperature.

If, for various reasons, you want to install a stove with a heat exchanger, listen to the following tips:

- A cast iron or steel potbelly stove is well suited for a small cottage with an area of 40-80 m². The heater is enough for convection heating of the central room; place radiators in adjacent rooms.

- A fireplace insert or iron stove, equipped with panoramic glass, will be a successful decoration in the living room. One condition: use the product as an additional heat source, and place the main load on a gas or wood heat generator. Then you will be able to maintain cleanliness and order around the potbelly stove.

An example of a diagram for connecting a fireplace, a gas double-circuit boiler and radiator heating - When building a house, definitely install a brick stove. This is the best option compared to iron heaters.

- Theoretically, the power of the fireplace insert is enough to heat an area of 100-120 m². Practice shows: without the help of a second heat generator, it will have to be loaded with firewood at intervals of 3-4 hours. Therefore, expect a smaller heating area.

Important point. All wood-burning heaters equipped with a water circuit have one feature in common: due to intensive heat extraction, the surfaces of the register and the walls of the chimney are abundantly covered with soot. The only way out is to heat the stove at maximum so that the soot deposits burn out from the high temperature. Maintaining this mode is not always convenient.

How to select a design and calculate the heat exchanger area in a brick version of the furnace:

- If the register is located inside the firebox, 1 m² of its area can transfer up to 10 kW of heat to water. Example: you need to heat 80 square meters of space - you will need about 8 kW of energy and a heat exchange surface of 0.8 m².

- The coil in the chimney duct is not as effective. Expect a heat output of 400-500 W per 1 m² of register.

- For ease of cleaning, it is better to make the boiler flat - in the form of a tank with inlet pipes. Ribbed structures made from round pipelines are more difficult to clean. For installation inside the flue, weld the register from profile pipes.

- The heat exchanger material is low-carbon steel St10...St20 with a thickness of 4-5 mm. It is allowed to use heat-resistant and stainless steel 2-4 mm, but it must be cooked in an inert gas environment - argon.

- It is strictly not recommended to use ready-made cast iron batteries. Reasons: the metal cracks from temperature shock, and the seal between the sections will burn out over time and leak.

Advice. Do not overestimate the heat exchange area of the circuit “in reserve”. The furnace body will receive much less heat, and the water in the register may overheat and boil. Do not place corrugated stainless steel pipes in the chimney - its actual area and workmanship are difficult to determine.

Home craftsmen are constantly putting forward various ideas for improving heaters. The option with steel flat batteries used as furnace water heaters is worthy of attention. Watch the video for an overview of the wizard:

Combined operation of an electric and solid fuel boiler

If you already have an electric heater in the furnace room of your house, but there is a desire to switch to solid fuel, then the problem of cooling the coolant has already been solved from the beginning

It is important here that the piping of the solid fuel boiler and electric boiler is done correctly. The first should function as the main source of heat, operating constantly

The second unit will serve as a safety net in case the firebox goes out or is turned off in order to clean the chamber and smoke pipes.

Most modern electric heating systems are equipped with built-in circulation pumps. If there is none, you will have to buy it and install it in the return water pipeline at the entrance to the electrical apparatus. The simplest connection of an electric boiler to a solid fuel boiler can be seen below.

Combination boiler diagram

Both boilers are connected to the heating system in parallel, each with its own circulation pump. For a solid fuel installation, a small circle of coolant movement with a thermostatic three-way valve is provided. It is recommended to install a check valve at the inlet of the return water pipelines to each boiler immediately after the pump. This is necessary to prevent the circulation of water between the units, and in the event of a pipeline failure, it will not allow the water jacket to empty. For horizontal sections of pipes, a valve of a petal design is adopted, and for vertical sections, a spring design is used.

If the thermostat of a solid fuel installation is set to an operating temperature of 60 or 70 ⁰C, and an electric one - to 40 ⁰C, then you can save electricity, since the auxiliary device will not start working immediately, but after the temperature in the system drops, which it will maintain. Below is a more complex scheme for connecting a solid fuel boiler with an electric boiler and using a heat accumulator as a buffer tank.

Connecting an electric boiler to a solid fuel boiler

In this case, the operation of the entire furnace will be more economical, since the temperature in the heating system after the wood has burned will be maintained by a heat accumulator for some time. And only after this time the electric heat source will turn on. To optimize the operation of the system, it is recommended to use a remote controller with a set of sensors. It will control the circulation pumps based on signals from temperature sensors installed on the supply and return coolant pipelines. This will allow you to constantly use one pump for circulation, rather than two.

How the system works

The simplest water circuit is with natural circulation of water flow. Its basis is a simple physical phenomenon: the expansion of liquids when they are heated. The unit that creates pressure is an expansion tank (a container for collecting water), installed in the attic or attic.

The water circuit is a closed system. The boiler heats the water in it and, expanding, it is directed through a pipe into a storage tank. The movement is carried out under pressure created by the cooled water constantly entering the boiler and passing through the entire system. Boiling water from the expansion tank is directed by gravity down through the pipes leading to the batteries. Having given off the heat, it returns to the tank and heats up again.

Installing a pump will help to significantly increase the pressure in the system and speed up the circulation of the coolant. At average outdoor temperatures, it can be turned off and the circuit will function on the natural movement of water. This will save you on your energy bills. Water enters the pump with the check valve closed. By turning it off (leaving it open), the entire volume of coolant is directed to bypass the pump.

Such a stove can be loaded not only with wood or coal. When using alternative fuels, it is possible to complicate the structure of the system by adding:

- granule storage tank;

- a mechanism that feeds pallets into the firebox (pneumatic or auger).

You can make the operation of the furnace easier by installing an automatic system for regulating its operation and forced ventilation.

How to build a water stove at home

- There are three ways to do stove heating with a water circuit with your own hands:

- buy a steel stove from a manufacturer whose services include system installation;

- hire a craftsman - a specialist will select the material, make the device, lay out the stove and install the boiler;

- do it yourself.

How to make such a stove yourself

The principle of a boiler for water heating

Can you make such a system yourself? Quite, just experience in welding and bricklaying when building a furnace is enough. First you need to prepare the boiler (register, coil, heat exchanger).

You can buy such a device or make it yourself using sheet iron and pipes. Since the full process of manufacturing and installing a water circuit cannot be summarized in a short review, the main recommendations are presented below.

Manufacturing options and recommendations

Water heating from a wood-burning stove - diagram

For the boiler, a sheet of metal with a thickness of at least 5 mm is used, and its design is made in such a way that there is maximum heating of the water for further circulation. The boiler, welded from sheet steel, is easy to manufacture and operate – it is easy to clean.

But such a heat exchanger has a smaller heating area, unlike a pipe register. It is difficult to make a pipe register at home yourself - you need an accurate calculation and suitable working conditions; usually such boilers are made to order by specialists who themselves install the system on site.

The simplest method of a solid fuel heat exchanger is a regular potbelly stove with a built-in water system. Here you can take a thick pipe as a basis, then there will be much less welding work.

Attention! All welding seams must be made double, since the temperature in the firebox is not lower than 1000 degrees. If you weld ordinary seams, then there is a chance that this place will quickly burn out.. Complete the register drawings in accordance with the dimensions of the stove at home

The layout of the rooms of the house and the arrangement of furniture also need to be taken into account. Here you need to pay attention that it is better to choose a scheme with sheet-metal boilers - they do not have pipe bends connected into one continuous circuit. It is not so troublesome to build such a structure. It is also convenient because after installation you can use the hob without any problems, which cannot be said about some tube boilers

Complete the register drawings in accordance with the dimensions of the stove at home. The layout of the rooms of the house and the arrangement of furniture also need to be taken into account.

Here you need to pay attention that it is better to choose a scheme with sheet-metal boilers - they do not have pipe bends connected into one continuous circuit. It is not so troublesome to build such a structure

It is also convenient because after installation you can use the hob without any problems, which is not the case with some tube boilers.

Registry made of smooth pipes - drawing

When the coolant moves by gravity, you need to raise the expansion tank higher and use larger diameter pipes. If the pipes are of insufficient size, then you cannot do without a pump, since there will not be good circulation.

Boilers equipped with pumps have their pros and cons: you can save money by installing pipes of a smaller diameter and not raising the system so high, but there is one significant disadvantage - when the electricity is turned off or the circulation pump burns out, the heated boiler may simply explode.

It is better to assemble the structure at home, on site, since the device, like individual parts, has a very large weight and dimensions.

System installation

Heat exchanger made of cast iron battery

- Before installation, a solid foundation is poured, on top of which it is better to lay a layer of brick.

- The grate can be laid at different stages: before the boiler, if there is a double structure, the lower part of which can be equal to or higher than the upper part of the grate, when the stove is low and the system is placed a little higher, then the grate, doors, corner on the stove are usually installed after installing the boiler .

- The housing is installed - usually it consists of two containers connected to each other by pipes.

- The entire heat exchange system is welded to the boiler: the exhaust pipe goes to the expander, goes in a circle, through the radiators, and on the other side the return pipe is welded to the boiler from below.

Stove heating with a water circuit allows, firstly, to use firewood much more rationally, and secondly, to evenly distribute warm air throughout the heated room.

If you decide to make your own heating system at home with a water circuit using wood, think through all the stages of the work, and if you have doubts about the successful outcome, it is better to contact specialists.

About the features of furnaces with a water circuit (PVC)

Wood-burning stoves for water heating at home can have different appearance, power characteristics and additional functionality. If they are installed not in a technical room (basement, boiler room), but in a residential area (kitchen, living room), its appearance also becomes important. A modern wood-burning stove can fit into any interior and become a decoration of the living room. Based on the material used, stoves are divided into three types:

- Brick.

- Metal (steel or cast iron is used).

- Combined (as a rule, a metal combustion chamber is framed by a brick body).

Rules for installing solid fuel boilers

Before connecting a solid fuel boiler, you should know that the following requirements apply to the installation of units of this type:

- Professional installation of pipes and radiators. Only in this case can you count on the correct operation of the heating system and the correct connection of a solid fuel boiler that has an input and output for connecting the rest of the circuit.

- Presence of a certain temperature. The greatest efficiency of a solid fuel boiler is possible only at an outlet temperature of 55 degrees and an inlet temperature of 45 degrees. With these same indicators, you can count on the longest possible period of flawless operation. A different temperature in the system can cause condensation to form, which has a destructive effect on metal parts.

Correct installation of the boiler

It is very important to understand the rule of how to connect a solid fuel heating boiler. The unit should be placed on a rigid base in a strictly vertical position

As a platform, you can use a cement screed with a thickness of at least 5 cm with bedding of the same height. For solid fuel boilers, it is recommended to use an open expansion tank, which should be located at a higher level than the entire heating system. The best option for this part of the system is the attic.

A properly equipped chimney. Mandatory conditions for a chimney include the following: the presence of a stainless steel valve and a condensate collector at the bottom of the chimney. In addition, it is necessary to have special hatches that provide access to clean the channel from soot. That part of the pipe that will pass through an unheated room requires careful insulation. This will help increase the service life of the chimney pipe.

The piping diagram of a solid fuel boiler must necessarily contain a safety valve. It is recommended to connect a water circuit in which the pressure does not exceed 0.2 MPa, and the temperature of the working environment cannot be higher than 90 degrees.

Buy or build?

Only metal stoves with a water circuit are available for sale. A foundation and destruction of the house are not needed to install a metal stove, but it does not have the useful qualities of a brick stove. In an energy-efficient house (see below), only a metal stove can be installed. These are produced by many stove companies, incl. foreign ABX (Czech Republic), MBS (Serbia), EdilKamin (Italy). Here, firstly, there is a nuance: do not confuse it with a sauna stove equipped with a hot water heater; Sauna stoves are not suitable for heating. Differences, if the specification does not indicate that the stove is heating - a sauna stove always has a heater. Secondly, the same stove, but with a water circuit, is often sold as a boiler. How to distinguish it from a real boiler? By the presence of a cooking surface and a combustion door with a viewing glass. The boiler is not intended for gatherings by the fire. Third, EdilKamin are built using a water jacket and are not intended for use as main heating devices; this is actually a fireplace stove with a water circuit, see below. And finally, Russian stoves with a Breneran water jacket (the sign is “Aqua” in the name) should be installed in a non-residential building or in a separate boiler room, but for Breneran’s dacha it’s the best: it’s Breneran Aquaten that costs up to 20,000 rubles. (without delivery). For other domestic furnaces with a water circuit, see video reviews:

Video: reviews of furnaces with a water circuit

In addition, if you intend to buy a furnace for water heating, consider:

- For factory furnaces with a water circuit, all of the following operating limitations apply;

- If a heating boiler is often sold with a full set of standard piping, then a stove is always sold without it. Selection and installation of piping is a particularly difficult topic, and its cost can cover the difference in the price of a stove or boiler;

- Fireplace inserts with a water circuit are also available for sale. These are by no means the main heating devices, no matter what they promise in advertising! A fireplace insert with a water jacket (like the EdilKamin stove) is included in the existing local (house) heating system with a boiler to save standard fuel or in the heating system of an energy-efficient house, see below.

Note: it is necessary to include additional heat-generating devices in the existing CO with several degrees of protection from their unwanted influence on each other, see for example. video below:

Video: about the dangers of a fireplace with a water circuit

Basement as a decision criterion

In general, if your house has a basement, the first thing you need to consider is purchasing and installing a boiler. The basement will always provide an elevation of the registers above the heating device, necessary for the construction of a simple, inexpensive and non-volatile gravitational CO (see below). The heat from a stove (fireplace) without a water circuit for cooking and/or admiring the fire with cognac and caviar will not be wasted: the boiler automation “senses” it and saves standard fuel.

Choosing the type of solid fuel boiler

How to understand which boiler will be optimal for servicing a particular heating system? Obviously, you need to decide on the type of fuel, the required power of the unit and the features of its design, installation process and subsequent operation, as well as the features of the connected heating system.

Homemade solid fuel boiler

Among the materials that can be used as solid fuel, the most widely used are:

- coal;

- peat briquettes;

- pellets;

- firewood;

- sawdust and other combustible production waste.