Installing a classic fireplace will not allow you to heat the entire house at once. Today it’s just more of a decorative item that decorates the interior. However, the use of modern technologies makes it possible to use a solid fuel fireplace to organize a heating system. This refers to a fireplace stove equipped with a water circuit, which, in turn, is connected to radiators. The possible heating area depends on the thermal output and the installed number of radiators. Let's look at the main pros and cons of installing fireplaces with a water circuit and the basic nuances of organizing such a system.

Design Features

Let's consider the main nuances of the design of fireplaces with a water circuit:

- In a classic fireplace, the firebox can be open or closed. Open structures have low heat transfer rates. In this regard, it is irrational to use them as a heat source for the heating system of the entire building. The power of such equipment is only sufficient to heat one room, that is, the one where the fireplace is installed. A fireplace with a closed firebox is more efficient. The efficiency of the system in this case will be significantly higher.

- Unlike a classic fireplace with a water circuit, it has double walls. Inside them there is a coil heat exchanger system.

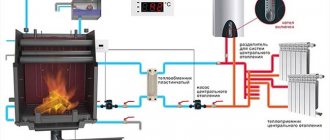

- The heat exchanger, heated by the combustion of solid fuel, is connected to the heating system: a pipeline and a connected radiator.

- Additionally, the fireplace can be used to organize hot water supply.

- Wood is traditionally used as fuel. However, to increase heat transfer and efficiency in general, it is recommended to use special briquettes. They are made from sawdust. This fuel produces more heat while leaving very little ash behind.

Thus, a fireplace with a water circuit performs two functions at once. On the one hand, it decorates the interior and is its significant element. On the other hand, this design allows you to heat the house. The basis of such a system can be a brick fireplace assembled independently or to order, or a ready-made fireplace stove. There are many models of various configurations and power available on the market.

Advantages

We can summarize all the advantages of using such heating equipment in homes:

- creates a unique cozy atmosphere in the house;

- work autonomy is guaranteed;

- the house can warm up very quickly;

- the device runs on economical fuel - firewood;

- the possibility of combination with any type of heating systems is provided;

- relative accessibility.

As already mentioned, the design diagram may contain an addition that allows the device to perform heating and cooking functions. Dishes prepared in this format are characterized by a special taste, which clearly surpasses the taste of food created on classic, as we understand it now, electric or gas surfaces. Therefore, the heating and cooking function is a very advantageous advantage of fireplace stoves.

Heating and cooking stove

Fireplace design

The fireplace to which the water circuit is connected has a number of features in its design. Since it must heat water, a metal heat exchanger is placed inside. Water circulates inside it, its temperature rises under the influence of fuel combustion. The heat exchanger is made in the form of a coil or labyrinth.

Installation with an accumulator makes it possible to select coolant as needed. In addition, this allows you to connect the system to the water supply for organizing hot water supply.

Installing a tank inside a fireplace will cause an unjustified increase in the dimensions of the fireplace. Typically, the battery is installed directly at the outlet of the pipelines from the heat exchanger. The tank itself is located next to the fireplace. To prevent the metal of the heat exchanger from being destroyed by an open flame, it is placed between two walls of the fireplace. Another option is to immerse the coil in the fireplace cavity, which is filled with water. This design is called a water jacket. It is suitable for installing a heating system for small cottages.

How to calculate the power of the unit?

It is logical that the larger the area of the house, the greater the number of radiators that need to be installed and filled to heat it. On the market for fireplace stoves of this type, you can choose fireboxes with a power of up to 20 kW. Such a unit allocates power up to 10 kW for heating the coolant. It is generally accepted that the unit requires 1 kW to heat 1 standard radiator of 7 sections. It follows that a fireplace stove capable of delivering 10 kW of power to heat the coolant will provide hot water to 10 radiators.

For a standard 3-room apartment with an area of 80 m2, it is enough to install a 6 kW unit. The second option for calculating the rated power: a room with an area of 10 m2 with a ceiling height of no more than 2.6 m requires 1 kW/h for heating. You can also calculate average fuel consumption. To do this, they are based on the following data: 1 kg of hardwood wood emits an amount of heat equal to 3.5 kW (provided that the moisture content of the wood does not exceed 20%).

Pros and cons of fireplaces with a water circuit

Among the advantages of fireplaces with a water circuit it is worth noting:

- System price. A ready-made stove model or custom-assembled brick fireplace will not cost that much.

- Cost of operation. The system is completely energy independent, the price of solid fuel is low, which means its use will not ruin the family budget.

- Multitasking. Such a system will decorate the interior; a separate boiler room is not required.

- A fireplace with a water circuit can be a replacement for a traditional heating system.

The disadvantages of such systems include:

- Not very high efficiency, especially when it comes to fireplaces with an open firebox. The power of such equipment may not be enough to heat the house in frosty winters.

- Lack of automation systems. It is impossible to quickly adjust the coolant temperature. You will have to add firewood or briquettes and clean the firebox manually.

Results

Note: If you want to not only heat a private house or cottage, but also get some pleasure, then a fireplace stove can be a good choice. It will allow you to combine the efficiency of water heating and the aesthetics of a fireplace.

And if the device is equipped with a hob, then it can also help in cooking. As a result, you can get a universal solution that will create warmth, comfort, and even save money by ensuring reduced fuel consumption.

Ignition and use of the branded stove-fireplace

What else to read:

Construction of fireplaces with a water circuit

All work can be divided into two stages:

- Construction of the body of the heat source, that is, the fireplace itself;

- Installation of heat exchanger.

Construction of the fireplace body

The construction of the fireplace body should begin with the search for a formal masonry scheme. When choosing materials, give preference to those that allow you to build a fireplace with a water jacket. To ensure tightness, steel sheets are usually used.

The construction of a fireplace begins with the installation of the foundation. To fill it you will need:

- Boards for installation of formwork;

- Ruberoid;

- Crushed stone;

- Sand;

- Cement.

The size of the base should be slightly larger than the dimensions of the future fireplace. To ensure waterproofing of the finished foundation, roofing material is laid on it. After this you can start laying. Fire-resistant bricks are used for the construction of the building; the firebox is assembled from a heat-resistant fireclay grade. A special clay mixture is used as a solution. It is not recommended to make it yourself. Experts use ready-made dosage formulations.

The masonry should be assembled from horizontal main rows. At this stage, it is important to ensure accurate positioning in the horizontal plane. After this, the ash pan is assembled, then the craftsmen lay out the fireplace firebox. The final part of the installation differs significantly from the construction of a classic fireplace. At this stage, installation of the heat exchanger is required.

Heat exchanger organization

The simplest type of heat exchanger is a small tank with two flanges for connecting pipes. Cold water enters through the first pipe, heated water is discharged through the second. Due to the harmful effects of open flames, temperature changes, and the negative effects of combustion products, it will not last long. The material for the heat exchanger must be sheet steel with a thickness of at least 4 mm.

The exact dimensions of the tank are determined by the design of the fireplace. To increase efficiency, it is recommended to use coil-type heat exchangers. Such designs consist of sections and registers, assembled in the form of a labyrinth.

After the heat exchanger is manufactured, it is built into the body of the fireplace. After this, special stands are formed on which the tank will rest. Installation is carried out in such a way that the heat exchanger flows are outside the fireplace. This allows for repairs in the event of a breakdown.

After installing the heat exchanger, the assembly of the fireplace fuel chamber is completed. It is covered with masonry with the obligatory organization of a smoke hole. Finally, a chimney is erected.

After the masonry has completely dried, which will take at least 10 days, the system can be filled with water for the first time. During initial start-up, it is necessary to check for leaks. In an open system, leaks lead to a decrease in the volume of water, but in a closed system they will cause a lack of circulation.

If the fireplace will be used as a backup heat source, a system must be provided for turning on and off the circuits from it. Using a bypass valve allows you to stop the water supply.

Review of popular models

The easiest to install and connect are considered to be free-standing devices made of steel and cast iron with a built-in heat exchanger. They can be located in a double housing, creating a water jacket around the camera, or located in the upper part of it. The pipes brought outside are simply connected to the heating circuit. For the heating device itself, it is enough to find a convenient place in any area of the room where the chimney can be removed. The main thing is not to forget to cover the floor with a metal screen over a non-flammable coating (minerite sheet, for example).

Stove-fireplace AQUA

They are made of steel in the form of 5 mm plates. The transverse edge and chambers are covered with heat-resistant tiles, which can be replaced if damaged.

The product includes a tempered glass door for viewing. There is a niche for firewood at the bottom.

Specifications:

- energy supply ranges from 13 to 16 kW;

- the circuit gives a power indicator of 5-7 kilowatts;

- steel heat exchanger;

- designed for wall installation;

- the lining of the side walls is made of ceramics;

- the front panel has panoramic heat-resistant glass;

- chimney diameter – 150 mm.

Even if there is no connection to the heating system, the ability to warm up the space is not lost. Only this method increases wear. It is imperative to fill the circuit with water when turning it on, otherwise the elements will be damaged and they will fail.

Bavaria fireplace stove

Manufactured from steel sheets, complemented by a cast iron grate to separate the firebox and ash pan. Experts note good technical characteristics:

- compact size - the device is suitable even for small spaces:

- mobility – the fireplace stove can be moved from one place to another at the owner’s discretion;

- the units are easy to install and use;

- strong heat-resistant glass ensures safety by reducing the risk of flame entering the room;

- warm-up speed is very high;

- fairly high productivity (efficiency - 80%);

- environmental friendliness - carbon dioxide emissions are reduced and barely reach 0.20%;

- if you purchase a model that has a built-in hob and oven, you can cook food over an open fire by first removing the cast iron rings from the burners;

- Externally the devices are very attractive.

Devices with a water circuit are connected to pipes in all rooms of the house. On top of the chamber or in the partitions of the stove there is a heat exchanger with a coil through which the liquid coming from the distribution tank moves. On both sides, pipes diverge along the edges to supply cold and hot water, which have the property of removing boiling water that gets into the heating system. To determine whether the stove will perform its functions fully, you need to evaluate the power factor.

Heating distribution systems

When organizing a heating distribution system, it is worth considering that they come in two varieties: open and closed.

In the first case, water circulation occurs due to the inclination of the pipeline. Heated water is supplied to the highest point. After this, it passes through the entire pipeline by gravity. The level gradually decreases. Water returns to the boiler through a pipe called return. An expansion tank is installed in the attic to allow for expansion as temperatures increase. The heated water is forced into the expansion tank; with gradual cooling, the reverse process is observed.

The main advantage of an open system is its simplicity. Installation can be done independently. However, it is not suitable for heating a large area.

The closed type circulation system is forced using a special pump. In this case, the pipeline is most often installed from plastic pipes. Since their design includes several layers, they have increased thermal insulation compared to metal pipes. This allows you to reduce heat loss during water transportation.

Water in a closed system heats up to 90 degrees or even lower. It enters the storage boiler, after which it enters the pipeline system. Its movement is carried out due to the functioning of the circulation pump. The cessation or disruption of heat transfer may cause water to boil. This will lead to a shutdown of the pumping equipment and an increase in pressure inside. This, in turn, will cause the system to fail.

To prevent this, an additional coil is installed in the fireplace. If necessary, cold water is supplied through it, lowering the temperature of the system. Another protection option is to install a temperature sensor. As soon as the water temperature reaches critical values, the automatic system discharges it into the sewer system.

A fireplace with a water circuit is an economical option for organizing additional heat supply or heating a small cottage or country house.