Maintaining a positive temperature in the garage is necessary not only for the comfort of its owner, but also to ensure the safety of the car. Therefore, the question of how to heat a garage: with electricity, gas or wood always remains relevant. A network connection is almost always available in a given room, but using this resource is not a very economical method of heating. Equipment operating on solid fuel requires the constant presence of the user to ensure timely loading. As a result, gas heating remains, which is worth considering in more detail.

Advantages and disadvantages

If the garage is located on the territory of a private house, it can be quickly and easily connected to a water system powered by a boiler. This is the best option. However, if the building is autonomous, heating the garage with gas still has many advantages

- Low fuel cost. Especially compared to electricity.

- Economical consumption. Maintaining the required temperature in a small room does not require much energy.

- Possibility of organizing an autonomous system. The equipment used in this case does not depend on the voltage supply; there is also no need to pull the line, since fuel can be purchased in a cylinder.

This heating method also has a number of disadvantages.

- strict adherence to safety precautions during installation and operation, since gas heating of the garage is associated with a fire hazard

- the need to organize supply and exhaust ventilation, arrangement of a chimney to remove combustion products

- higher cost of units compared to electric, solid fuel analogues

Radiator preparation: inspection, adjustment

To make a radiator, you will need two sections of a cast iron battery assembled together. One side of them should be muffled. The lower plug with the fitting must be unscrewed in order to inspect and improve the tightness of the connection.

PHOTO: YouTube.com The cast iron plug with fitting must be unscrewed from the radiator

The long thread on the plug fitting is not needed, so it can be trimmed a little and then carefully chamfered. Otherwise, screwing the nut onto the thread will be problematic.

PHOTO: YouTube.comThe thread is shortened and carefully processed

Next, a sealant (FUM tape) is wound onto the threads of the plug, and the element is screwed into place. The plug is pulled out using a gas wrench. This requires a lot of force - everything must be extremely tight.

PHOTO: YouTube.com For tightness, FUM tape is wound onto the threads

The principle of operation of gas equipment for heating a garage

The operation of any device is based on the technology of converting the energy of burned fuel into heat, which is transferred directly to air or water, which carries it to radiators through a pipeline network. This process takes place in a special insulated chamber equipped with a burner. It can be open, when oxygen is taken from the room to maintain the flame, or closed, when the intake is from the street.

It is necessary to ensure a constant supply of fuel to the equipment. In this case, two options are possible: heating the garage with gas from propane cylinders or from a centralized main. The second method is less applicable, although the natural resource supplied through communications is cheaper. Its unpopularity is explained by the difficulty of connecting and obtaining the appropriate permits. As a result, the hassle is not worth the scale of the problem.

Propane gas boiler for garage

This unit is equipped with a coil heat exchanger, in the pipes of which water circulates, then enters the heating devices through the piping. Its use for heating is associated with increased costs for the purchase of equipment, fittings and its installation. The car owner will have to equip the whole system, which is not always rational in a small space. In addition, a gas boiler using bottled propane for heating a garage with piping and communications takes up quite a lot of space. The best option here is to choose a wall-mounted model.

If, nevertheless, a decision has been made to install a water heating complex, it is important to remember that in winter, when the unit is turned off, the coolant can freeze and rupture the pipes. Therefore, the system must function continuously.

Gas stove with cylinder

It is a more compact unit that operates without an intermediate link in the form of a coolant. The space is heated directly from the burner flame. Due to the fact that it is isolated from contact with the user, the equipment is safe. Many devices use infrared wave technology in their work. To do this, they are equipped with a ceramic plate, which, when heated to a high temperature, begins to generate infrared radiation. Its peculiarity lies in the targeted impact not on the air, but on specific objects, people, walls.

You can use garage heating with an IR heater from a gas cylinder at any temperature, which is especially important in the winter. Periodic activation as needed is also acceptable. This will significantly reduce fuel consumption. At the same time, it will be possible to warm up the room to the required temperature using infrared technology extremely quickly.

Gas furnaces are available in a wide variety of models with mobile floor or wall, ceiling stationary installation. This will allow you to choose the best option for a building of any size.

Homemade heater

DIY equipment is also suitable for a small garage space. It will provide heating due to convection and infrared radiation at the same time. To assemble it you will need

- burner

- galvanized steel sheets

- steel mesh

- hemispherical metal sieve

To assemble gas equipment for heating a garage, you need to prepare a hacksaw or grinder, as well as fasteners for connecting elements, for example, rivets, bolts.

Two circles are cut out of the sheets, the diameter of which corresponds to the size of the sieve with a margin. Their edges are folded to allow the attachment of other elements. The burner is fixed on one of the workpieces. The entire structure is then covered with a sieve, whose function is to dissipate heat. A cylinder is rolled up from the mesh to act as a body. On one side, the first circle with a burner is attached to it, on the other, the second workpiece. The resulting unit is connected to a propane cylinder through a hose.

Homemade gun

Its manufacturing technology is even simpler. To do this, you will need a fire extinguisher, from which you need to cut the bottom, or a pipe with a diameter of approximately 200 mm, a fan with a switch, a burner, and a steel mesh. A flame generator is mounted inside a cylindrical container. A fan is installed at one end, and a mesh is installed at the other to protect against open fire. The burner is connected to the cylinder through an adapter pipe.

Convector

When answering the question of how to effectively heat a garage with gas in winter, you should pay attention to this equipment. It heats the space due to the constant movement of air currents: heated ones rise to the ceiling, cooled ones fall to the floor. Its virtues

- high power. One unit is enough to heat the entire room

- compactness. The cylinders to which it is connected can be placed outside behind a wall

- efficiency. Convectors make maximum use of the heat generated during combustion

- minimum amount of emissions into the atmosphere

- easy installation with wall mount

The disadvantages of the devices include the fact that they create additional dust in the room due to the circulation of air flows.

Features of operation

It is important before using gas stoves in the garage to make sure that the ventilation is working properly and that there is no gas pollution in the room. The valve on the gas cylinder or on the stove must be closed after each switching off of the equipment, even if it is equipped with its own shut-off valves.

Therefore, having opened the gas, we light the burner flame. If a cannon is used, the fan is turned on before the fire is lit. A reducer must be installed on the cylinder, which protects it from backlash and regulates the gas pressure.

Otherwise, the operation of a gas furnace is similar to other types of furnaces. The main thing is to be responsible and careful about the maintenance and care of equipment and your garage will always be warm.

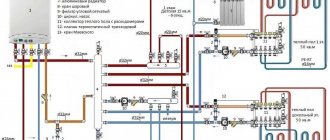

How to install gas heating for a garage

First of all, it is important to properly prepare the room for the operation of fire-hazardous equipment. To operate a stove or boiler, it is necessary to allocate a fenced nook with an area of 4 m2 and a height of 2 m. It must have natural lighting from a window or artificial lighting from electricity. It is also necessary to organize air access from the street through a hole in the wall or a ventilation system. Cover the walls of the boiler room with non-flammable material.

To install the floor unit, a low platform is built from brick or concrete mortar. Wall-mounted devices are hung on brackets. In order for heating a garage with a gas boiler to be effective, the heating pipes must be laid at a slight slope towards the movement of the coolant. The second option for providing circulation is integration into the pump system. Installation of any type of device must be carried out with an accurate level check of the housing location. The slightest distortion will affect performance. It is important to maintain a distance of at least 30 cm from the unit to the nearest objects.

Connection to the gas main must be carried out with the involvement of a specialist from the relevant farm. Unauthorized connection to the system is fraught with a fine and forced shutdown. The supply of fuel from the cylinder is not regulated by utility services.

Best models

Based on customer reviews, we have compiled our rating of the best models of gas furnaces for the garage.

| Model | Characteristics | Price |

| Gas heat gun MASTER BLP 33 M | Most suitable for heating a large box. Heater power 18 to 33 kW. Provides an air flow of 1000 m3 for 60 minutes. Resistant to power surges. Manual flame ignition system. Under normal operating conditions, gas consumption is from 2.4 kg per hour. The minimum pressure of suitable gas is from 0.75 Bar. Gun weight 9 kg | Average price from 15,700 rubles |

| Convector for heating a large garage. Model "Alpine Air NGS 50 F" | Average power 4.9 kW. Gas consumption during operation for an hour is from 0.5 m3, chimney outlet diameter is 80 mm. Weight 31 kg. Dimensions – length 220 mm, width 600 mm, height 630 mm. Designed for wall mounting. Closed gas combustion chamber. Comes with built-in fan and coaxial pipe. | 22700 |

| Gas infrared heater “BALLU BIGH-3”

| Maximum power 3 kW. Powered by propane - butane. The flame ignition system is manual. In 60 minutes of operation, 200 mg of fuel is consumed. Incoming gas pressure – 30 Bar Weight 2 kg | 1179 |

| Ceramic gas oven "NEOCLIMA UK-20". | Maximum power 4 kW. Minimum thermal power 1.5 kW. Powered by propane - butane. In 60 minutes of operation, up to 0.3 kg of gas is consumed. Weight 400 g. | 5290 |

| Gas convector, model “Alpine air NGS-20”. | Wall mounted. Maximum power 2 kW. Mechanical control with manual ignition. Room area 22 m2. Weight 22 kg. | 22300 |

The simplest designs can be made independently from scrap materials.

Heating system cost

As already mentioned, heating a garage with natural gas mains is the most profitable in terms of operating costs. Liquefied propane is more expensive. The equipment itself also varies significantly in price depending on the type, power, functionality, etc. Boilers have the highest cost; a low-power model with simple configuration will cost from 10,000 rubles. Convectors and infrared heaters cost approximately the same, from 3,000 rubles. The cheapest way is to make the unit yourself using scrap materials.

Oil device

A homemade oil heater is a fairly functional and safe device. It has high efficiency and is therefore suitable for those rooms where various household appliances are repaired.

Its design consists of a sealed housing, inside of which there is oil and heating elements.

Before making a heater with your own hands, you need to prepare the following materials:

- Sealed container. You can use an aluminum or metal battery or a car radiator as it.

- Technical or transformer oil.

- Heating element 4 pcs.

- Electric motor with a power of 2-2.5 kW. Instead, you can use a pump with the same power.

- Switch.

- Set of drills.

- Corners or profile pipe with dimensions 40x40 mm.

- Two tubes. Must withstand temperatures of 100-150 °C.

You will have to work with a drill and a welding machine.

Algorithm for manufacturing an oil heater

Frame welding. Before this, draw a diagram of the frame. To do this, you should start from the size of the selected container and the height at which the case should be placed. The frame can be made in the form of two rectangles. The width of the rectangle should be greater than the depth of the selected container, and the length should be greater than the height of the container. The main part will be inserted into rectangles. These parts of the frame should be at the ends of the container. Each rectangle must have two legs. It is advisable to connect them with one corner, which will run along the body.

At the beginning of frame manufacturing, the corners or profile pipe are cut into pieces of the required length. Next, weld the rectangles and weld the legs to them. The longitudinal angle can be fixed with bolts. Thanks to this, the frame can be disassembled and hidden in a convenient place until the start of the next winter season.

- Cutting 7 holes in the selected container. 4 of them must be such that a heating element can fit in one hole. They can be located in the corners of the radiator. 2 holes are needed for the pump. They are made at the bottom of the radiator. Another hole is needed to fill the oil. It needs to be done at the highest point of the radiator. You can use a grinder or welding to cut holes. The best option is autogen.

- Making a mount for fixing the pump. To do this, metal plates with holes cut in them for bolts are welded to the container. These plates should be located close to the pump holes.

- Fixing the pump and connecting it to the radiator. To connect it you need to use two tubes. They can be welded to the radiator and connected through shut-off valves to the pump. You can weld fittings to the holes intended for the pump and attach tubes to them.

- Mounting heating elements. They are secured using bolted connections. The easiest way to mount those heating elements is the base of which has a thread and is a kind of large bolt. In this case, a fitting with internal thread is welded to the holes in the radiator. A nut may also work. A heating element is screwed into it.

- A fitting with an external thread is placed and welded onto the oil filling hole. There will be a lid on it. It can be made from a pipe. To do this, an internal thread is cut at one end. It should be the same as the thread on the fitting. The pipe must have a larger diameter than the fitting. A metal square plug is welded to the second end.

- Check the tightness of all holes. To do this, create a lot of pressure in the middle of the oil heater.

- Heating elements are connected. To do this, use the parallel connection method.

- Connect the voltage regulator and cable with plug.

- Place the housing on the frame and ground it.

- Pour oil.

Economical heating with electric batteries

The oil heater is now ready and can be used. Over time, it may fail and require repair. Repair comes down to replacing heating elements or pumps. Sometimes it may be necessary to improve the tightness of connections. This type of repair is not very difficult.

- https://trubexpert.ru/heating/kak-sdelat-samodelnyj-obogrevatel-dlya-garazha/

- https://ventcondition.ru/obogrevatel-radiatora-avtomobilya-svoimi-rukami/

- https://oventilyacii.ru/otoplenie/kak-sdelat-obogrevatel-iz-chugunnoj-batarei-svoimi-rukami.html

- https://sovet-ingenera.com/otoplenie/radiator-obogrev/samodelnyj-obogrevatel-dlya-garazha.html

- https://poluchi-teplo.ru/radiatoryi/drugie-rad/izgotavlivaem-svoy-obogrevatel.html

Gas or electricity

This question is faced by everyone who is considering various analogues of heating sources.

To make a decision, it is important to compare them based on key indicators

Gas

The cost is 1.5–2 times cheaper than electricity. The financial side of the issue will be especially noticeable if the building is large.

Autonomous heating works through a gas tank located underground. It can hold thousands of liters of gas. The gas tank is refilled by specialists twice a year.

An underground reservoir does not interfere with the full use of the territory and does not emit an attention-grabbing odor

Electricity

The costs are high, since this energy source is considered one of the most expensive.

Sometimes the power consumed by the heating system is too high for a suburban electrical network; the energy is not enough to heat the entire house.

In bad weather, power surges often occur, which leads to a failure in the heating system.

It follows that liquefied gas is a more profitable, economical and reliable option.

Types of boilers

First, it’s worth considering what types of boilers there are.

- Gas boilers - it is advisable to purchase when in the utility room there is a possibility of diverting a pipe from the gas main. This fuel is considered the most budget-friendly. The heat carrier is a liquid that is heated by the boiler. Heating is provided by the convection method using a fan.

- Electric boilers - it is advisable to install them in a room where the coolant is heated by electricity. The operating principle of such a device is that the liquid in the heat exchanger is heated thanks to electric heating elements.

Is it possible to reduce gas consumption

This is not only possible, but necessary. Since several simple elements in the gas cylinder system help to significantly reduce gas consumption.

- Install special sensors that indicate the presence of gas in the room. This allows you to timely identify a leak (which leads not only to an explosion, but also to excessive overspending) and eliminate it.

- Without fail, the gas heating system should be automated. Only with the use of automation elements can lower fuel consumption be achieved.

- Use only high-quality and real fuel, without additives. If there are impurities in the gas, its consumption increases significantly.

- Monitor the temperature in the room in which gas equipment is installed. It, like the rest of the rooms, should be heated. Insufficient temperature in the combustion chamber may cause a gas boiler to fail.

In addition to the above measures, the outside of the house should be insulated. High-quality insulation will help achieve minimal gas consumption and a more comfortable temperature in the house.

Portable tile heater

Small rooms, a garage, a greenhouse, a tent can be conveniently heated with a portable tabletop gas heater. Such a device is constructed from a quadrangular flat tile equipped with a metal grid.

Assembling this device involves attaching part of the gas stove to a metal casing. Due to the installed combustion chamber, the air is heated to the desired temperature, and several or one fan ensures the supply of warm air and its circulation throughout the room. The assembly of such a device consists of several stages and does not require special technical knowledge.

A gas heater made according to this design is more powerful than the previous version. With the help of such a device it will be possible to heat small rooms even in winter.

The first stage is working with measuring tools. You need to use a ruler or tape measure to take accurate measurements from the quadrangular tile. This will be required to determine the parameters of the heater housing. After taking measurements, you need to cut out blanks from a tin sheet using scissors. Next, the blanks are fastened with rivets into a casing.

Then the casing is fixed with hook strips on the tile. In order for it to be quickly removed and mounted back, you need to make a movable bar. Such a bar can be easily made using a small spring, which is connected to a lifting lever.

Thanks to this solution, in the future it will be possible to easily remove the casing for cleaning or transportation. The homemade scheme under consideration assumes the presence of a special ventilation system. To install it you will need a simple fan without any additional complex devices or materials.

Instead of tiles, you can also purchase a ceramic infrared burner. The infrared heating system provides heat distribution similar to solar radiation. Such heating does not heat the air, but objects, which then radiate heat

A small fan from any home device is suitable for installing ventilation. You can use scissors to adjust the size. Trimming and giving the desired shape and size to the fan blades takes about half an hour. After carrying out these steps, you need to install a ready-made fan behind the heater housing so that there is draft inside the housing.

You also need to install a metal combustion chamber. The combustion chamber body must be studded with many small holes. They can be made using an electric drill and a metal drill or using a hammer and nail. The holes should be a short distance from each other.

You also need to purchase a rubber hose with an adapter to connect the flat tile to a gas pipe or gas cylinder. A fan installed at the rear of the casing ensures the supply and distribution of warm air over a fairly wide range in the heated space.

The gas flows through the hose to the burner. The burner burns the resource and heats the heat emitter, which releases thermal energy to the room. At night, such a heater illuminates a small area around itself

Such a homemade gas heater copes well with the task of heating a room not only in the autumn-spring period, but even in winter. Also, such a device consumes gas economically and has a high efficiency.

Method thirteen, well, this is really for extreme sports enthusiasts

If you often find yourself in situations where you have to fight the cold in the car (for example, you are a traveler), then you can take a regular wood stove with you on the road. If you don't believe me, look:

A real oven in the car

So how? Did you believe it? You can stock up on firewood or brushwood for free, for example, if your forced stop occurred in the forest or next to an old and dilapidated building with a lot of boards.

If your car stalls in winter, don’t despair. Armed with any of the heaters listed above and having studied all the tips described, you will not freeze and survive in harsh weather conditions. Even if you find yourself in a car at night, face to face with a cold and harsh winter, you can create all the conditions in the cabin that are similar to the comfort of home. So, don't worry, motorists!

The best prices and conditions for the purchase of new cars

It has long been known that a comfortable temperature for a driver is the range from +21...23 degrees Celsius. Low temperatures negatively affect concentration and alertness while driving, causing irritability. And safety is affected by driving with limited visibility due to icy windows.

If you have at least once had to get to your car in a parking lot in severe frosts or simply get into an icy car interior after leaving a warm home, then you know firsthand that this feeling is not a pleasant one. And how I would like to warm up at this moment. You can, of course, run around the car or leave the snow while the interior warms up, but there are also less radical methods. As always, there is a solution, and it has long been known among motorists - an autonomous interior heater, which will happily provide comfort.

What should you prepare for?

The main advantage of operating gas equipment is the affordable cost of fuel. However, there are some difficulties to keep in mind:

- Installation problems. Not everywhere there is a real possibility of connecting to the main line for fuel intake. Of course, there is an alternative in the form of liquefied gas cylinders, but this technique will certainly lead to increased costs.

- For installation it is necessary to involve specialists from the relevant services, these are the safety requirements. It will not be possible without obtaining numerous permits.

- In some situations, the boiler is installed exclusively in a separately equipped boiler room or, at least, in a special reinforced metal cabinet (according to fire safety regulations, liquefied fuel cylinders are stored in it).

Fire safety requirements for a garage heating system

Before starting the installation of heating equipment, you will have to draw up a detailed diagram - this will allow you to identify vulnerable areas, including:

- wooden surfaces next to which the equipment will be located. They are covered with galvanized sheet metal;

- the location where the chimney pipe passes through a hole in the ceiling or wall;

- fuel storage areas. Flammable substances are located as far as possible from the heating device and always above the level of the floor covering.

The main thing is to ensure safety

The future locations of fire extinguishers and other fire protection equipment must be marked. If the system is planned to use flammable fuel, it would be useful to place a box with asbestos fabric near the boiler - it will help localize the fire in the event of an emergency.

But in such a box there are plenty of problems even without heating

A little theory

Before installing gas equipment in your home, you should find out its operating principle, as well as familiarize yourself with the structure of the entire system.

Propane-butane is pumped into the cylinders.

In order for gas to be transported and used in cylinders, it must be converted from a gaseous to a liquid state. Therefore, before filling the tank, the gas is diluted, this allows it to be pumped in larger quantities.

Lukoil cylinders in warehouse ready for shipment

After connecting the cylinder to the main line and opening the tap, the gearbox starts working. The reducer reduces the pressure several tens of times, because of this the gas returns to its original state and can be used as fuel for heating rooms. The reducer allows you to use the entire capacity of the cylinder.

It should be remembered that any gas cylinder has high pressure inside and therefore requires appropriate handling and maintenance.

Refueling

Cylinders undergo mandatory certification once every 3 years - this is necessary for the user’s own safety.

Such containers can serve for about 10 years. A standard home consumes about 10-12 cylinders per month, so they will have to be refilled weekly - you cannot transport more than 3 cylinders at a time without special permission. Before filling, the vessels need to be prepared. To do this, you need to remove condensation, which artificially reduces the useful volume and harms the steel walls. Removing condensate is the prerogative of specialists; doing such work yourself is always a risk. If for some reason it is difficult to find a specialist, you will have to carry out the procedure yourself. The cylinder is taken out to an open space without sources of fire, grounded and then the reducer is removed. Leave for 2 hours to allow any remaining gas to evaporate. After two hours of inactivity, the vessel turns over and the water flows into the ground. You can take it to a gas station.

It is worth choosing a gas station that organizes both transportation and a guarantee for the work. It is better not to contact car stations, because their equipment does not have a special cut-off valve that regulates the filling of household gas cylinders. They also do not have a special connector for connecting the cylinder to station equipment.