One of the fastest and most practical ways to insulate a house is to cover it with foam plastic. Polystyrene foam (expanded polystyrene) has long established itself as a good insulation material. This material is the most affordable in terms of price and availability in stores and is considered one of the best solutions for facades in terms of price-quality ratio. In this article we will look at how to properly insulate a facade with polystyrene foam, its main characteristics (density, thickness), point out the main mistakes and watch a video with step-by-step instructions on the technology of insulating the walls of a house with your own hands.

What's better - is polystyrene foam safe?

In Russia and the CIS countries, there is a certain prejudice towards polystyrene foam facing material. But you can check how safe this material is based on approved documents. Thus, environmental and fire safety are confirmed by many studies and results:

- Research Institute named after Erisman under No. 03/PM8;

- Republican level Scientific Research Center of Hygiene, Republic of Belarus;

- Research Center for Fire Safety of the Russian Federation;

According to the material safety scale approved by BREEM, the material is assigned the highest class A+. All these indicators taken together allow us to speak about its high quality and practicality of use in many construction areas and areas.

You can find out about the percentage of harmful substances in the composition of the building material itself from the available certificates - every conscientious manufacturer attaches them to their product. And even if the material is in doubt, it will still be located outside the house, but not inside. Therefore, cladding with foam plastic and decorative coating is the right choice. The main thing is to correctly calculate the number of slabs, the density of the insulation layer itself and select the adhesive composition - you should not be afraid of poisoning with harmful compounds released into the air from this insulation.

Advantages and disadvantages of polystyrene foam

Figure 2. Installation of facade foam plastic

The presented insulating material has a number of advantages and disadvantages in its characteristics. Which ones exactly? There are several of them, and according to the manufacturer, they are what make the material itself highly sought after.

Styrofoam and rodents

The advantage of this material is that rats, mice and other rodents simply do not eat it. But even here there is a controversial point - as practice shows, rodents willingly gnaw at it, even going so far as to use it to insulate their own burrows. That is why it is so important to install thermal insulation efficiently, blocking access to it for rodents at the joints of the fabric.

Foam and ultraviolet

When insulating a facade with polystyrene foam, you must remember that it reacts negatively to ultraviolet radiation, especially to direct sunlight. Rays, affecting the material at the chemical level, reduce its stability of the PPS - the material seems to age, soften and lose its own technical characteristics.

But such a disadvantage can be called relative - the main thing is not to expose the material to direct sunlight, covering it with finishing material, a layer of protective plaster, practicing decorative cladding with protective sheets

About the soundproofing ability of PPS

The seller's claims about its high soundproofing qualities are questionable. In practice, many users, like the manufacturer himself, talk about its low ability to absorb noise and the whole point is that it consists of 90% air. Its porous structure, to a greater or lesser extent, has certain density characteristics. Therefore, you should not undermine its high ability to absorb noise when insulating the facade and finishing.

About the vapor permeability of foam

A low percentage of vapor permeability in practice means that in the path of steam flow from the house there is an obstacle in the form of sheets of PPP. But the weather outside is often cool, lower than indoors. Accordingly, the steam itself condenses inside, at the junction of the material - therefore, it is important to correctly calculate the dew condensation point, sufficient to finish the thickness of the sheets of insulation used.

Important! Therefore, it is important to install a reliable and effective ventilation system in the house, which will not lead to stagnation of moisture in the room.

How to choose high-quality insulation in a large assortment on the market

- Ask the seller for a product certificate. The quality of the purchase must be confirmed not only visually, but also documented. Reliable manufacturers of building materials who value their reputation are always ready to provide the necessary quality certificates.

- Assess the storage conditions of the material where it is sold. For example, under the influence of the sun's rays, polystyrene foam may acquire a foreign odor, turn yellow, and its properties deteriorate.

- Examine the packaging. A quality product is marked; if the packaging material does not have the appropriate markings, then it is better to buy polystyrene foam elsewhere.

- Inspect the material granules. They should be uniform, approximately the same size, and evenly distributed across the sheet. If voids or peeling of granules are noticeable, then this is a sign of a low-quality product.

- Rate the sheets. Visually, they should be without bumps or deformations, and to the touch - soft and elastic. The rigidity of the sheets indicates that the production technology has not been followed.

- Don't chase the cheap. Polystyrene foam, purchased at a low price and initially pleasing with this fact, may later turn out to be worthless. Cheap material absorbs water, freezing and thawing between the granules, it destroys the foam.

There are more advantages to using polystyrene foam than disadvantages: it is inexpensive, easy to install and operate, and non-toxic. To enjoy the quality of your new insulation for longer than one season, you should carefully consider purchasing the material.

Classes and grades of foam plastic

Foam plastic as a material for finishing and insulating facades can have different brands and corresponding classes - each of them has its own purpose, composition and characteristics.

Foam classes

There are two classes of finishing materials on the modern construction market:

- Pressed – it is made by pressing equipment.

- Non-pressed - materials are sintered at high temperatures.

Which particular class a particular finishing material belongs to can be determined, so to speak, by eye, visually. Thus, unpressed sheets of material are round or oval-shaped granules firmly glued together with a special composition, while the structure of the sheet itself is porous. The overwrought sheets are smooth, but the density can be different, depending on the brand of the product itself.

Foam brands

Figure 3. Storage of façade foam.

Unpressed foam is abbreviated as PSB, but pressed foam is called PS. Although the material itself has different letter designations.

- A – the canvas is made in the correct geometric shape, namely in a parallelepiped format, with a smooth edge;

- B - the edge of the sheet itself has a cut in the shape of the letter L;

- R - cutting of blades is carried out using a hot jet;

- F – façade type or can be used using decorative finishing elements;

- C – self-extinguishing type of finishing material;

- N – the material is suitable for exterior finishing.

So the numbers in the name of the PPP will coincide with the density indicators.

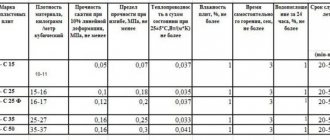

Brands of unpressed foam

picture 3 – BPP brands

- PSB-15 is the most expensive material with high brittleness. It is used as a thermal insulation and packaging material, characterized by low hygroscopicity. Used for finishing and insulating balconies, cottages, and outbuildings.

- PSB - 25, often supplemented with the letter F in the marking and is applicable for façade insulation. Due to its density, it is also suitable for the manufacture of decorative elements.

- PSB-35 is a material widely used in construction and finishing. For example, for insulation of heat and gas-carrying lines, it is used in the process of manufacturing multi-layer panels as a heat-insulating gasket.

- PSB-50 has the highest density, perfectly insulates heat and sound, therefore it is used in all objects, regardless of purpose.

Pressed foam brands

The presented finishing material is durable and rigid, looks like plastic with closed cells, and is widely used in the field of finishing and insulation of a wide variety of buildings. Thus, brands PS-1, PS-2, PS-3, PS-4 are foam plastic with a closed porous structure and are resistant to external negative influences.

Foam plastic with increased hardness characteristics is labeled as PS - 1-35O and PS-1 - 150 - applicable in the field of radio electronics, due to its resistance to electric current breakdown. It is often used when insulating facades; the main thing is to choose high-quality material.

Rules for choosing polystyrene foam for facade insulation

The task posed in the field of finishing and insulating the facade is perfectly handled by PSB - S - 25 and there are several reasons for this.

- the material itself is dense and does not crumble during installation due to its strength;

- has low thermal conductivity in its characteristics and at the same time does not allow heat to escape outside during the installation process;

- It is light in weight and easy to transport;

- has a low price and is durable, self-extinguishing.

But its main quality is the density achieved by pressing the granules and the stronger the pressing, the stronger the final result.

Insulation characteristics

The first thing people pay attention to when choosing a thermal insulation material is its technical characteristics. So, we will begin our study of polystyrene foam with this:

- Low thermal conductivity, which makes the material an excellent heat insulator.

- Large temperature range of use from -50 to +75 degrees Celsius.

- Soundproofing properties. Manufacturers also indicate this characteristic, but after installing the foam, the noise reduction effect is insignificant.

- The material withstands sudden temperature changes well.

- Moisture-repellent properties.

- Flammability class 3–4 - this means that the material does not support combustion, but melts at high temperatures. There are options that are coated with special flame retardant compounds. Then the class increases and becomes G1 or G2.

- Resistant to chemical and biological influences. Foam plastic is not afraid of a variety of chemicals, be it solutions of salts, acids or alkalis. In addition, pathogenic bacteria, fungi and mold do not form on the surface of the insulation.

- High tensile and compressive strength, but mechanical stress in the form of impacts is detrimental to foam plastic.

Manufacturers indicate in quality certificates only the positive characteristics of their products and do not say a word about the disadvantages of the material. Everything is connected with the fact that everyone wants to earn as much as possible, which means they need to sell large volumes of insulation.

How to find out the density of foam plastic

The density indicators themselves are calculated as follows: weigh a cubic meter of material, and the resulting result will be an indicator of density. For example, PSB-25 will weigh 25 kg, although in practice this is very rare. Often slabs are sold under this brand, the density of which varies between 16.1 – 16.5 kg/m3.

Potto, a sheet of foam plastic of the appropriate thickness is taken and its volume is calculated - the length of the sheet itself is multiplied by the width and height. Next, absorb the weight of the sheet and divide the resulting number by the volume indicators themselves.

Extruded polystyrene foam

A facade made of extruded polystyrene foam is the right choice for finishing and insulation. Since the material itself has higher density characteristics than PSB-50. Brands such as Penoplex, Technoplex, Ursa are represented on the Russian construction market.

All of them are of high quality, although they have their own characteristics. For example, Technoplex brand products add graphite to the canvas to increase density, due to which the canvas comes out grayish. Sheets from Penoplex have a specific bright, carrot shade. And the product of the Ursa company has a beige color. The quality parameters are the same for everyone, the only thing is that the dimensions of the expanded polystyrene sheet may vary.

Technology of facade insulation with foam plastic

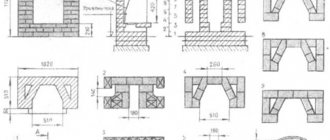

Insulation of the facade is carried out by laying sheets in a continuous layer, using either special glue or another adhesive base, dowels. Work is carried out in the following technological sequence:

- Cleaning the base from dust and strengthening it. At this stage, priming work is carried out by applying a deep penetration priming composition using a brush.

- Marking is carried out, as well as fastening the base profile. It is recommended to fasten the corners at a 45 degree angle to the profile using self-tapping screws and plates. The profile is attached along the entire bottom of the wall, the perimeter of the erected building - this is a kind of support.

- The adhesive composition itself is prepared from dry mixtures, plus it is recommended to use reinforcing compounds applied to the reinforced surface of the EPS mesh itself. This method is applicable if a solution of cement and sand is used to plaster the facade.

- Apply the PPS solution to the inner surface of the slab and level it using a wide spatula - the thickness of the adhesive layer depends on the glue itself, but on average it is 0.5 - 1 cm.

- Glue the slabs by placing the sheet itself on the base profile and hold it in this position for several seconds. The remaining glue is removed using a spatula, and then the canvas is fixed with dowels - fungi. The seams themselves are filled with polyurethane foam to increase the level of integrity.

- An adhesive is applied and the reinforcing, strengthening mesh is fixed with it. The excess is cut off using special metal scissors.

- Next, apply a reinforcing solution to the mesh and a leveling compound, level it with a wide spatula. Finish with plaster.

- Finally, a layer of a special protective primer is applied. It protects the sheets themselves from ultraviolet radiation and wind, moisture and other external, negative natural factors.

In conclusion, it is worth saying that insulating facade walls with foam sheets is not a complicated process and even a beginner can handle it. The main thing is to follow simple tips, instructions for preparing adhesives and walls for finishing, installation and finishing.

Thickness calculation

Before purchasing a material, you need to not only select its strength and dimensions, but also calculate the required thickness of insulation for walls or other structures. When designing a building, specialists perform a special thermotechnical calculation manually or using programs, after which they assign the dimensions of the heat insulator.

The thickness for a private building can be selected without making calculations. But it is necessary to take into account the climatic features of the area and the operating conditions of the facility. In the vast majority of cases, the following sizes can be recommended:

- wall thermal insulation thickness - 100 mm;

- thickness for the attic floor - 150 mm;

- thickness for the floor of the 1st floor and roof - 200 mm.

But in any case, it is better to assign dimensions accurately. You can calculate the required amount of insulation using fairly simple programs. For example, the calculation can be done in the Teremok program. It is freely available on the Internet. There are two versions: online and desktop application.

Insulation thickness depending on the wall design

To perform the calculation in the program, you will need to know the composition of the enclosing structure and the thermal conductivity of the materials used. Some types are in the program database, but it is better to check the thermal conductivity with the manufacturer of a particular product. Calculating a thermal insulator using this application is quite simple.