Many owners of modern buildings, especially suburban ones, use stoves to heat their premises. The market for thematic devices offers a wide range of products that vary in size, function and dimensions, as well as technical characteristics.

Unfortunately, not all homeowners know that the height of the firebox in a stove must be of a certain size, and this element is present in all designs without exception; it also differs in configuration and size, which depends on the type of device and the type of fuel used. Taking this fact into account, it is necessary to consider in detail the question of what size of the firebox will be ideal in a given case.

Ready to use oven

How to fold a stove firebox with your own hands

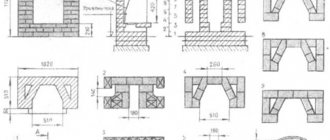

The furnace firebox consists of a ashpit (ash pan) with a door, a grate and a combustion chamber (firebox) with a door.

Dimensions are determined based on the volume of firewood for simultaneous loading. The width of the combustion chamber is equal to its door or slightly wider on both sides.

The height of the firebox should facilitate complete combustion of fuel, which is achieved by having free space in the chamber after loading firewood. Recommended height 80-100 cm.

Reference. The depth of the furnace firebox must accommodate the length of the combustible material; there are no other restrictions.

The combustion chamber is connected to the ash pan via a grate . The latter is designed to supply air during combustion and collect ash. When installing the grate, it must be buried below the level of the fire door to prevent burning coals from falling onto the floor.

The firebox must have bevels in the direction of the grate to move the ash into the ash pit. The gap between the masonry and the grate must be at least 5 mm to prevent brick rupture as a result of the difference in expansion of the brick material and metal at high temperatures.

The choice of materials for masonry and flooring, how to process the structure

The structure is made of red clay brick with lining (lining) of fire-resistant material. When choosing a brick material, you need to pay attention to ensure that it is not burnt or cracked. High-quality brick, suitable for stove masonry, has smooth edges, sharp edges and a uniform color; when tapped, a clear, almost metallic sound is heard.

Attention! Sand-lime brick is not suitable for the construction of the device.

The following materials will be required:

- red brick - for walls;

- refractory and wedge-shaped (fireclay) bricks - for lining and forming the ceiling;

Photo 1. Refractory brick used for laying the furnace firebox. Before using the material, you must ensure its integrity.

- clay, sand, water - for solution;

- cast iron grate;

- doors of the combustion chamber and ash pan;

- steel strips or wires - for fastening doors;

- asbestos sheet - for a fireproof gasket between the masonry and the doors.

To connect the stove masonry, you can buy a ready-made mixture or prepare the solution yourself. In high-temperature zones, compositions made exclusively of red clay, sand and clean water are used. The quality of the solution depends on the viscosity, plasticity and fat content of the clay. Sand for construction must be free of dirt and impurities.

Preparing tools

will allow you to make a structure with your own hands :

- furnace hammer;

- trowel - for applying the solution;

- large container - for preparing the solution;

- building level - to control the correctness of the masonry;

- measuring instruments - ruler, tape measure, square;

- plumb lines - to determine the outer contour.

How to properly cover the firebox and make a roof for a brick oven

the exact layout must be determined and a foundation with a layer of waterproofing must be laid.

Before laying on the mortar, you need to assemble the structure without it - to accurately adjust the bricks to size.

The phased construction looks like this:

- Prepare a solution.

- The first row is laid on the foundation without gaps and formed under the stoves.

- On the second row, the formation of the ash pan and the fastening of its door begin. To do this, mark the center of the future firebox and place the blower strictly under it. A flexible wire is passed through the holes in the door frame and its ends are twisted into a bundle. Wire bundles are fixed in the masonry layer.

- of the blower and the location for laying the grate are formed

- Secure the combustion door with wire. The door frame is insulated with a gasket made of non-combustible material.

- of the firebox and the vault with a hole for connecting the chimney are formed

- is lined with refractory bricks.

Important! During construction, you cannot combine simple bricks and refractory bricks due to different expansion coefficients. When heated, such masonry will burst.

Dimensions for firewood

Given the high flame trunk, experts recommend making a firebox for wood with a height of 80 cm to 1 m. If these parameters are not observed, the combustion of volatile substances will not occur, as a result of which these particles will settle in the chimney system.

Over time, a significant layer of soot will accumulate, which will lead to a decrease in the efficiency of the entire furnace. In order for the coals to roll, it is necessary to slightly bevel the corner parts of the firebox, which are in direct contact with the grate.

Good to know: How to paint a red brick stove, what composition to use

Error correction

When building a stove firebox, there are several common mistakes that can be corrected during the process:

- When forming the walls, the solution must be applied and leveled by hand to avoid the formation of cavities.

- be moistened with water during laying so that they do not draw moisture from the mortar.

- If one brick block has moved, cannot be moved to the desired position. It must be removed, cleaned of the mortar and re-installed.

Cracks in the masonry caused by temperature changes are repaired with mortar. The cracked brick is removed from the structure, the area is cleared, it is moistened and a suitable brick is laid back. If the fastening of the door is not secure, remove it by disassembling the seams nearby, and if necessary, replace the brick blocks with new ones.

Manufacturers of ceramic bricks

The increase in construction volumes in our country in recent years has had a positive impact on companies producing relevant materials.

Fireclay bricks whose technical characteristics meet the requirements of standards and are produced at affordable prices by the following companies:

- TEREX Group of Companies;

- Bogorodsky plant of ceramic wall materials;

- Verkhnevolzhsky brick factory;

- Wienerberger Brick;

- Kerma;

- "Ceramics" (Lomintsevsky brick;

- Brick factory BRAER.

The named enterprises produce fire-resistant bricks in a wide range and of adequate quality. The products of these plants are in demand among builders and the population of both the regions where they are located and in neighboring areas. Competition between manufacturers of building materials has a positive effect on quality and range.

If you notice an error, a non-working video or link, please select a piece of text and press Ctrl+Enter.

Design safety

Violation of stove masonry technology at any stage of construction can lead to danger when using the firebox. The main mistake can be incorrect laying of the foundation.

The main signs of malfunctions that occur when the foundation is laid incorrectly:

- The roof of the firebox is destroyed.

- The doors fall out.

- Burning coal spills out.

- The brickwork is cracking right through the entire area of the stove.

- Chimneys become unusable.

It is impossible to heat the stove in this condition - there is a high risk of fire and poisoning of people from flue gases . Damage caused by an unsuitable foundation cannot be corrected. You will have to disassemble the entire stove and rebuild all the elements.

In past centuries, the only means of heating for households was a stove, and stove specialists lived in good prosperity and enjoyed great respect among people. Today, stoves have not gone into oblivion and are still very popular in homes, baths and saunas.

With the development of the Internet, anyone can become a stove maker. To do this, you just need to set a goal, purchase the necessary materials and find the necessary tools. You can fold the oven yourself.

Fireplace stove efficiency

An indicator of the efficiency of fireplace stoves (as well as other heating devices operating on solid fuel) is the efficiency factor (COP). It is determined based on the heat balance, that is, the equality between the heat generated by burning fuel and the consumption of this heat for useful heating. The efficiency of furnaces mainly depends on the amount of oxygen entering the firebox and at the same time the volume of warm air leaving the pipe. For example, a fireplace stove produced 24,000 kcal per day, and the thermal energy contained in the fuel amounted to 34,000 kcal. In this case, the efficiency is 70% (24,000 : 34,000 = 0.7 x 100%). Some of the heat went into the chimney with hot gases, while some remained in the coals and ash. The efficiency of the device is also affected by the volume of the combustion chamber (the larger it is, the better the heating), the intensity of the air supply and the height of the chimney. GOST R52133-2003 “Fireplaces for residential and public buildings” classifies devices according to the method of heat transfer: class 1 - with thermal power expended on heat transfer by radiation; class 2 - with thermal power expended on heat transfer by radiation and convection; class 3 - with an additional function of heating the water coolant. Fireplace stoves belonging to the second class must have an efficiency of at least 50%. At optimal performance, the oven can operate with energy efficiency of up to 70%.

What types of brick ovens are there?

Building a brick stove is not the easiest thing. To begin with, careful preparation of materials, tools, and plans is necessary. But first of all, you need to decide which of the many types of stoves you want to make.

- Heating stoves. As the name implies, their main task is to heat the room. Furnaces of this type are extremely simple, have a simple design and do not take long to construct.

- Combined ovens. A more universal type of stove than the first. They are somewhat more difficult to construct, but have not only the function of heating the room. You can cook food on such stoves. In some versions, even ovens are built into them.

- Stoves and fireplaces. The ideal type of stove for a private home or cottage. With their unrivaled appearance, they do a great job of heating your building. A well-built and well-finished fireplace will become the interior highlight of your home.

Some masters rank stoves not by their main function, but by the shape of the unit: square, rectangular, round, etc.

Of course, almost any homeowner can make a stove with their own hands. Numerous diagrams and guides will help you do this efficiently and with minimal time. The oven can be of any size, shape and purpose. However, it should be remembered that the main condition for its successful construction will be fire safety.

Laying a square stove with bottom heating

The stove in the photo has a combined or mixed smoke circulation system. The parameters of this design are 102x102x238 centimeters. Its heat output is 4200 kcal/hour.

The design of square-shaped heating stoves with bottom heating suggests that the firebox in it has a relatively large height. Side openings located symmetrically on both sides (2 pieces each) serve to drain gas into the chambers. They are located in the outer side walls of the structure. The gas then descends through chambers connected by a channel under the firebox behind the ash compartment.

If it is planned that the stove will operate on hard coal or anthracite, the walls of the firebox should be laid exclusively from refractory bricks.

The main advantages of a brick oven

With the widespread development of private households, conventional brick kilns are increasingly being used. They are often preferred to modern heating devices: gas and other boilers. Not to mention metal stoves. Among the main positive features of brick kilns are:

- Long-term heat conservation. A brick oven is a real heat accumulator. Thanks to the material it is made of, it maintains its temperature almost throughout the day. Accordingly, it needs to be heated much less often, and firewood needs to be added no more often than once every

- Economical. As mentioned earlier, the stove stays warm longer, which means you heat it less often and waste less fuel.

- Environmental friendliness. The stove consists of natural materials and is heated primarily with wood.

- Safety. The outer surfaces of the furnace are not subjected to strong heating. The brickwork gradually takes excess heat from the firebox and transfers it to the surrounding space. This means that the thermal radiation will be softer than from an iron “potbelly stove”.

- Breath. During combustion, the stove releases moisture from the brick, which softens the air. When cooling, the masonry is moistened again. Air humidity is always at a level that is beneficial for the human respiratory system.

What to consider

In addition to the direct dimensions of the working chamber, such indicators as the power of the firebox and the volume of the heater are taken into account, which is most often measured in the mass of loaded stones. The power of the stove determines what size steam room it will effectively heat, and the volume of the heater affects the amount of steam produced.

For kilns made independently, it is very difficult to calculate the optimal ratio of power to the number of loaded stones. Most often this is done experimentally. In factory-made models, everything is calculated, so the stones are guaranteed to warm up to the required temperature for the release of “white steam”.

Where is the best place to install a stove in the house?

Before starting work, you need to decide where in your house it will be located. For example, if you place a heating structure in the middle of a large room, it will give off much more heat.

If you build a stove near the wall, and this is what most people do, then cold air will flow near the floor near it. Some prefer to place the stove between several rooms, so that the plane of the stove falls on the dining room, living room and bedroom. However, only relatively small rooms can be heated in this way.

It is necessary to provide in advance for the placement of the combustion door and other parts of the stove. During operation, you must freely use all components of the stove. Most often, the door is placed in uncrowded rooms, for example, in the kitchen or in the hallway.

What is a grate and why is it installed?

The grate is a grate that allows the air flow to penetrate directly to the combustion site from below, and the ash to fall through the holes into the compartment reserved for it. It can be cast iron or steel. Installing this accessory solves a number of problems. in particular, he:

- Divides the firebox into two zones - the combustion chamber itself and the ash pan.

- Used for placing and drying fuel.

- Distributes the air flow from the ash compartment.

- Provides high-quality traction.

- In combination with the door, it allows you to control and adjust the flame.

It is not possible to make a grate intended for installation in a furnace from every metal. After all, it is exposed to high temperatures and under the influence of atmospheric oxygen can oxidize quite quickly. Only cast iron can resist such a complex destructive influence for as long as possible.

What materials are used for laying a brick oven?

Preparing for the construction of a furnace is a troublesome, but enjoyable undertaking. You will need to decide what material you will use to build the oven, what solution to use, what doors and other elements to purchase.

First you need to decide which brick will be used. There are several types of it:

- Ceramic is the most common and popular material for laying a stove.

- Silicate is a type of brick that is categorically unsuitable for the construction of stoves.

- Fireproof - well suited for the construction of furnaces. Most often they are used to lay the firebox of brick stoves and fireplaces. They can be refractory, fireclay and others.

IMPORTANT! When choosing the type of brick, avoid hollow and hollow types. They are not strong enough.

The next thing you need to decide on the solution. Most often, clay is used for these purposes. For ceramic bricks - red, for fireproof bricks - special fireclay clay. You can purchase ready-made mixtures at construction stores and dilute them according to the instructions.

Some kiln craftsmen still prepare masonry mortars with their own hands. To do this, they mix river sand of a fraction of one to one and a half millimeters, clay and water. The proportion of sand and clay is 2.5 to 1.

Additional accessories include grate bars (special grates, which in the future will be located between the firebox and the ash pit); doors for the firebox and vent, soot cleaners, valves and dampers.

To build your stove you will need the following tools:

- plumb line;

- measuring tape;

- trowel;

- spatulas of different sizes;

- metaba;

- wire;

- level;

- metal pieces;

- containers for solutions.

Preparatory work

Before starting work, it is necessary to decide where the heating structure will be located. The choice of location determines its configuration and size.

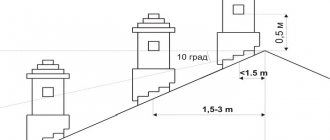

When planning, you should remember that the chimney should not be located near the rafters - closer than 15 centimeters. Otherwise, trouble may arise.

For inexperienced stove makers: it is recommended to first build a model of your future stove from bricks without mortar. This will allow you to notice design flaws in time and correct them.

An important element of any furnace is its foundation. It should be larger in area than the oven itself. The base must also be provided with preliminary waterproofing.

Making the foundation for the stove

The foundation can be made from any brick; some stove makers use crushed stone to make it.

The most durable stove will be the one whose foundation was laid along with the house in which it is located. It is worth noting that both foundations are laid separately from each other. Otherwise, settlement of the building walls will lead to a violation of the geometry of the heating device and damage its integrity.

If the stove is built in an already finished house, then several difficulties will have to be overcome. If wooden floors are installed indoors, they will be dismantled at the construction site. The possible offset from the external contours of the future furnace is 15 centimeters.

- A foundation pit is being dug. Its depth depends on climatic conditions and the level of soil freezing. For the middle latitudes of Russia, the optimal depth will be 0.8 meters. The bottom of the pit is covered with a layer of sand 15 centimeters high. A layer of crushed stone is poured on top. Both layers must be compacted thoroughly.

- The next step is to stick wooden stakes into the corners of the future stove, and attach the lathing to them. It turns out to be a kind of formwork for the foundation. Its wall joints must be covered with polyethylene so that cement does not leak into the cracks.

- Let's move on to pouring the foundation. Concrete mortar is mixed from M-400 cement, sand and crushed stone. It is important not to overdo it with water; the consistency of liquid concrete should be of medium fluidity. Otherwise, the strength of the foundation will be less.

- The mixture is poured into the formwork, compacted and the surface is leveled using the rule.

IMPORTANT! The upper edge of the stove base should be located centimeters below floor level.

A few hours after the initial setting, the formwork is wrapped in film. It is necessary to wait until the concrete solution dries completely, this takes several weeks.

Parameters for hard coal

Experts note that the combustion process of wood fuel occurs when a smaller volume of oxygen is consumed than required by coal. Based on this, it is necessary to take into account the fact that the dimensions of the grate area in furnaces that use this type of fuel must be larger.

In the combustion area, in the combustion chamber, conditions for maximum oxygen penetration must be created. That is why a grate of the same size as the bottom part of the chamber is installed for coal.

Definitely a big coal fire.

As for the material used to make this element, it must be resistant to high temperatures, and also have a thickness of at least 4 cm. Experts note that if the stoves have cooking surfaces, then fuel can be added through the holes in them.

A characteristic feature of Anthracite coal is that the volume of volatile substances is significantly less than that of other coal or firewood. Accordingly, under such conditions, a small flame burns inside the furnace, which makes it possible to reduce the size of the firebox by almost half.

The immersion depth of the grate should be 30 cm, and to increase the efficiency when using coal of this grade, it is necessary to narrow the firebox in the area of the lower part of the grate. The fuel layer will be larger, which means heat transfer will increase.

How to fold a simple small stove

This compact and easy-to-build stove is perfect for heating a small country house, cottage or garage. Its design is extremely simple and does not have gas circulation, the level of heat transfer is not very high. It will heat a room of a maximum of 16 square meters.

For such a furnace there is no need for a powerful foundation. You just need to lay crushed stone to a depth of centimeters and fill it with concrete.

The oven dimensions will be 2 by 2.5 bricks, which is approximately 51 by 64 centimeters. Due to the absence of a blower chamber, it is necessary to drill holes in the door for the firebox.

Construction Features:

- Setting up such a stove is not difficult. Make sure the bricks are arranged so that the brick on top covers the seam between the two bricks below it.

- On row No. 8 the firebox begins to narrow. For this, use ¾ of a brick. And as a result, the exit from the combustion chamber has an area of one brick.

- The ninth level is placed in the same way as the seventh. That is, a whole brick is used.

- The tenth tier will be specific. The bricks on it are not placed flat, but on an edge, strictly along the contour of the recess on the row below.

- On top of the tenth tier, bricks are again laid traditionally - flat. To lay it out you will need two solid bricks and four ¾ bricks. Thanks to this arrangement, you will narrow the smoke channel.

- Next, the bricks are again placed on edge, and the smoke channel is divided in half. In cross-section, the masonry of this level will resemble a figure eight on a calculator. On the next tier the bricks are flat again. Alternating the laying method in this way, lay out five rows.

- On the next four rows, the bricks are placed flat.

- In the last two rows, the chimney is narrowed so that its cross-section is exactly half the size of a brick (12 by 12 centimeters).

- A smoke damper is installed and a steel chimney pipe is attached to it.

Furnace construction procedure

The layout of the stove in question is carried out in accordance with the order. This, as already noted, is a special diagram on which the order of laying out each row of the structure is indicated. There are standard procedures. If you do not have the skills to lay out ovens, it is strongly recommended to use one of the standard schemes.

A well-designed order will allow you to significantly reduce the time and money spent on stove construction. The work will be carried out in a precise and easy to understand manner to ensure maximum efficiency.

Having figured out the order of the Swedish stove before the start of construction, you will be able to lay out the unit yourself, without involving third-party craftsmen in the work and without spending money on paying for their labor.

The detailed order additionally indicates which materials should be used and at what stage of the work.

Study the proposed order and additionally pay attention to the following points:

- The design of the Swedish stove includes a blower. This point must be remembered in the process of independently arranging the stove;

- The first row of bricks must be laid perfectly evenly. Any displacements will lead to various violations that will negatively affect the quality and reliability of the finished furnace unit. To check the evenness of the masonry, use a building level;

- The correctness of the angles must be checked - they must be strictly 90 degrees. Check the angles using a suitable tool called a square.

The reliability, efficiency and durability of a Swedish oven largely depends on the correct layout of the first row; remember this.

How to fold an oven with a hob

You can also build a stove equipped with a hob with your own hands. The simplest option will have dimensions of 78 by 53 centimeters. That is, it is 2 bricks wide and 3 bricks long. Despite its small dimensions, such a unit can accommodate one burner.

The base of such a stove should be 10 centimeters larger than its dimensions. And the foundation is made in such a way that the first row of bricks comes from the floor level.

If there is an underground space under the house that is more than half a meter high, then there is no need to dig a foundation for the stove. You can make formwork on the ground and lay two layers of roofing material on the bottom (this will protect the structure from moisture). Next, concrete is poured and the foundation is given at least a week to dry. After which you can begin installation.

IMPORTANT! Stove makers recommend laying out each new tier first without mortar. In this case, you will have the opportunity to properly fit the bricks to each other.

- The starting row is installed on a clay solution, 5 millimeters thick. Having leveled it, proceed to the second. It is necessary to leave space on it for the blower door.

- Before installation, a wire is screwed to the door, the ends of which are placed in the seams between the bricks. This will provide better hold.

- Since metal expands when heated, it is necessary to leave a gap between the edges of the masonry and the door. The frame of the door itself is wrapped with asbestos cord before installation.

- The third row is laid in such a way that the bricks overlap the seams of the previous tier. At the same time, the installation of grates takes place.

- Row number four differs from the previous one, since the walls of the firebox are formed on it. The bricks on it are laid on edge, and it is important to observe the “bandaging” of the seams.

- Behind the combustion chamber there is a smoke circulation. In order to be able to remove ash from it in the future, the brick is placed in the back without mortar.

- In the chimney, two stands are made from fragments of bricks so that the internal partition rests on them.

- The stones of row No. 5 are placed flat; do not forget to leave room for the door to the firebox.

- When laying smoke channels, be sure to clean their insides from protruding clay with a wet rag. Otherwise, the flow of smoke will be disrupted.

- On the eighth tier it is necessary to reposition the door into the combustion chamber. Don't forget to place the wire from it into the seams. On the same tier it is recommended to install a “smoke tooth”. This is a brick with a beveled end, thanks to which it enhances heat transfer and slows down the escape of smoke into the street through the chimney.

- When laying the ninth row, it is necessary to install an asbestos cord covered in a clay solution. It will seal the joint between the cast iron slab and the brickwork.

- On the tenth row, a cast iron stove with a burner is placed on top of the firebox.

- Row No. 11 is notable for the fact that a smoke valve is installed in the pipe, the contour of which is also sealed with asbestos cord and clay.

- On the last two rows of brickwork, the walls of the chimney are formed. The pipe is then placed there.

Primary requirements

As mentioned above, furnace fireboxes are available in any design. If the combustion chamber meets all regulatory and technical requirements, then the home owner does not have to worry that the design will consume a lot of fuel or poorly heat the house.

If you install modern stoves for a bathhouse or home, then they already have a properly thought-out system for convection of air flows in the area where the combustion process itself occurs. Moreover, they are equipped with spacious fireboxes that allow maximum storage of wood and coal, thereby saving fuel used, and at the same time being able to maintain a comfortable temperature in the house for as long as possible.

This product is made of cast iron, and is subsequently installed inside the combustion chamber. It serves to maintain the poured volume of solid fuel used during the combustion process. The grille has holes located along its base, which facilitate the penetration of air flows into the chamber. To improve traction, there is a blower, through which ash is also removed.

Typical firebox design

The location of the grate should be in the middle of the firebox of a stove for a bathhouse or a country house, slightly below the firebox door, approximately two bricks apart, and the horizontal holes are directed along the combustion chamber.

The slope of the grate is from two to five centimeters, which is determined by the size of the ovens. For better kindling and creation of proper draft, the element is mounted with a slope towards the chimney pipe. It is in this way that ideal conditions are created for uniform combustion of fuel inside a metal or brick stove, when the smoke flakes off the fire without collecting inside the firebox.

It is also important to observe this point: if the heating device is made of metal, then it is necessary to additionally design protection for the firebox so that it does not overheat, but in stone products, in order to build a chamber, it is better to use fireclay bricks that are resistant to high temperatures. As for the fuel used, to purchase the required volume of material for the cold season, it is worth correctly calculating the number of days when the stove will burn, the area of the house and taking into account the thermal conductivity of the material

The highest indicators are coal (5500-6500 kcal/kg), peat gives off heat a little worse (2500-3500 kcal/kg), as well as firewood, but the latter must be dried in natural conditions

As for the fuel used, to purchase the required volume of material for the cold season, it is worth correctly calculating the number of days when the stove will burn, the area of the house and taking into account the thermal conductivity of the material. The highest indicators are coal (5500-6500 kcal/kg), peat gives off heat a little worse (2500-3500 kcal/kg), as well as firewood, but the latter must be dried under natural conditions.

Use of firewood

To correctly calculate the size and shape of the heating chamber, you need to focus on the height of the flame that comes from a particular type of fuel. If you can make a small firebox for coal, then larger dimensions are extremely necessary for peat and wood, since these substances burn actively.

Order or diagram of the construction of your stove

In the construction of furnaces, everything is exactly the same as in any other construction work. You need to start by preparing a drawing. In this case, it is called “ordering” and is a schematic representation of each row of brickwork with a top view.

Roughly speaking, if your stove from the base to the end of the chimney consists of 20 rows of bricks, then before installation work you need to make yourself 20 diagrams. Without order, the successful construction of a furnace is almost hopeless.

You can find hundreds of different drawings on the Internet and specialized literature. You can make them yourself - to suit the size of your home and your needs.

To do this, you should know that each oven consists of the following parts:

- The firebox is a furnace chamber into which fuel is placed. The combustion process also takes place in it. It is separated from the ash pit by grates. It has a direct connection to the internal channels of the stove, through which smoke is directed from it to the street.

- The ash chamber is the cavity of the stove through which the oxygen necessary for burning wood is supplied to the firebox. Burnt fuel residues also get into it through the seals.

- Devices for cooking and heating water are built in optionally, depending on the purpose of the stove device.

- Cleaning chambers are cavities necessary for collecting and removing soot.

Furnace device for peat.

The height of the firebox can be 70 - 80 cm. The dimensions of the grate depend on the degree of moisture content of the peat: when using dry briquettes, you can use the same grate as for firewood; for wet peat, the grate should be larger. The gaps in the grille should be no more than 8 - 10 mm.

The walls of the firebox should be inclined towards the grate. Since the combustion of peat produces a lot of ash, the ash pan should be larger.

For peat with high humidity, two grates are installed, this provides greater air flow. The height of the firebox in this case must be at least 80 cm, the width at least 40 cm. Holes are drilled in the valve.

Firebox size in a heating furnace

Firebox dimensions The width of the firebox in small stoves must be at least 20 cm, in large stoves - at least 30 cm. The height of the firebox, counting from the grate, must be at least 65 cm for peat, at least 80 cm for firewood, for coal - at least 70 cm. Place so much fuel in the firebox that there is at least 30 cm of free space between it and the top. If these conditions are not met, unburned fuel particles (soot) enter the chimney and settle there, becoming saturated with carbon monoxide. If a sufficient amount of soot accumulates in chimneys, poisoning (“burning”) with carbon monoxide is possible when the valve is closed.

Cladding a metal stove with bricks

Metal stoves, unlike stone ones, are not as heavy and are quite easy to install. Their disadvantage is that they overheat during the heating process and quickly release heat to the surrounding room. They also cool down quickly.

Moreover, according to scientists, the thermal radiation emanating from them does not affect humans as favorably as the soft heat emanating from their brick counterparts. Moreover, you can’t lie on such a stove and you can’t dry your laundry.

In Russia, the practice of lining metal stoves with brickwork is popular. Of course, the properties of such a heating structure will not be as outstanding as those of a full-fledged stone stove. True, there will be fewer negative effects in the form of overheating and radiation.

IMPORTANT! Most often, iron stoves are lined in a bathhouse. This allows you to save both time and money.

- The same brick and mortar is suitable for cladding iron stoves as for the construction of their “ceramic” counterparts.

- The construction of the foundation is optional, and depends on the dimensions and weight of the future furnace. If the floor is concrete, a continuous row of bricks is laid on it. Allow to dry.

- If you want to build a stove up to the ceiling, you need to dig a pit and pour a foundation.

- The site for the construction should be centimeters around the perimeter larger than the building below.

- 4 beacon bars are placed at the corners of the base; they will be your marks when laying bricks.

- The brick “cover” around the iron stove should be centimeters larger than it. There should be free space between them.

- After completing the lining, the structure should dry well without extraneous heating.

Furnace device for peat.

The height of the firebox can be 70 - 80 cm. The dimensions of the grate depend on the degree of moisture content of the peat: when using dry briquettes, you can use the same grate as for firewood; for wet peat, the grate should be larger. The gaps in the grille should be no more than 8 - 10 mm.

The walls of the firebox should be inclined towards the grate. Since the combustion of peat produces a lot of ash, the ash pan should be larger.

For peat with high humidity, two grates are installed, this provides greater air flow. The height of the firebox in this case must be at least 80 cm, the width at least 40 cm. Holes are drilled in the valve.

Firebox dimensions The width of the firebox in small stoves must be at least 20 cm, in large stoves - at least 30 cm. The height of the firebox, counting from the grate, must be at least 65 cm for peat, at least 80 cm for firewood, for coal - at least 70 cm. Put enough fuel into the firebox so that there is a free space of at least 30 cm between it and the top.

Preparing the base

When erecting a brick screen, it is necessary to fulfill all the conditions specified in SNiP 21-01-97 (Fire safety of buildings and structures).

SNiP 21-01-97. FIRE SAFETY OF BUILDINGS AND STRUCTURES. File for download

Installation of a sauna stove in a brick case

Although brick does not heat up as much as metal, it should not be laid close to the wooden walls of a bathhouse or on unprotected floorboards. It is also necessary to leave a gap between the walls of the stove and the brick, 5 to 10 cm wide. If there is no gap, the stove will overheat and, as a result, its service life will noticeably decrease. If the distance is made more than 10 cm, heating of the steam room will slow down and fuel consumption will increase.

When constructing a brick screen, remember the necessary clearances

The base for the stove and the brick screen must be common, otherwise uneven distribution of the load will cause subsidence of individual elements. If, when installing the furnace, the heat-resistant base was made with a margin of area, additional preparation for the brickwork is not required. If there is no such reserve, and the edges of the platform protrude from under the stove body no more than 2-3 cm, it is necessary to disconnect the chimney pipe, dismantle the stove, and carefully and according to all the rules prepare a new base.

Base for stove and screen

For the lining of stoves, solid red brick is usually used, which is characterized by heat resistance and durability. Fireclay brick is also suitable for these purposes, but it is more difficult to process and is more expensive. There is a ceramic refractory brick with a decorative surface, which has the same properties as ordinary bricks, but it looks much more impressive. With its help, you can not only improve heat transfer and protect yourself from harsh radiation, but also make the stove a decoration for your steam room.

Bricks for lining a metal sauna stove

It is also acceptable to use hollow red brick, especially if you want to reduce the load on the base. It just holds the temperature worse and cools down faster. And the most budget option is to use used red brick, you just need to thoroughly clean it of the remnants of the old mortar.

Used red brick

Please note that building material must be taken in reserve, since brick waste is inevitable during the laying process.

First you need to calculate the total weight of the stove and brickwork. The easiest way to find out how many bricks are needed for one row of screen is to lay them around the stove at a distance of 4-5 cm. Usually you get a square of 3x3 or 4x4 bricks, that is, from 9 to 16 pieces in one row. To calculate the number of rows, the height of the stove must be divided by the height of the brick - 65 mm. On average, this is 11-12 rows of masonry. Next, we multiply the number of bricks in a row by the number of rows and the weight of one brick, and we get the weight of the screen. Now all that remains is to add the weight of the stove and the water tank to this value.

Primary requirements

As mentioned above, furnace fireboxes are available in any design. If the combustion chamber meets all regulatory and technical requirements, then the home owner does not have to worry that the design will consume a lot of fuel or poorly heat the house.

If you install modern stoves for a bathhouse or home, then they already have a properly thought-out system for convection of air flows in the area where the combustion process itself occurs. Moreover, they are equipped with spacious fireboxes that allow maximum storage of wood and coal, thereby saving fuel used, and at the same time being able to maintain a comfortable temperature in the house for as long as possible.

This product is made of cast iron, and is subsequently installed inside the combustion chamber. It serves to maintain the poured volume of solid fuel used during the combustion process. The grille has holes located along its base, which facilitate the penetration of air flows into the chamber. To improve traction, there is a blower, through which ash is also removed.

Typical firebox design

The location of the grate should be in the middle of the firebox of a stove for a bathhouse or a country house, slightly below the firebox door, approximately two bricks apart, and the horizontal holes are directed along the combustion chamber.

The slope of the grate is from two to five centimeters, which is determined by the size of the ovens. For better kindling and creation of proper draft, the element is mounted with a slope towards the chimney pipe. It is in this way that ideal conditions are created for uniform combustion of fuel inside a metal or brick stove, when the smoke flakes off the fire without collecting inside the firebox.

It is also important to observe this point: if the heating device is made of metal, then it is necessary to additionally design protection for the firebox so that it does not overheat, but in stone products, in order to build a chamber, it is better to use fireclay bricks that are resistant to high temperatures. As for the fuel used, to purchase the required volume of material for the cold season, it is worth correctly calculating the number of days when the stove will burn, the area of the house and taking into account the thermal conductivity of the material

The highest indicators are coal (5500-6500 kcal/kg), peat gives off heat a little worse (2500-3500 kcal/kg), as well as firewood, but the latter must be dried in natural conditions

As for the fuel used, to purchase the required volume of material for the cold season, it is worth correctly calculating the number of days when the stove will burn, the area of the house and taking into account the thermal conductivity of the material. The highest indicators are coal (5500-6500 kcal/kg), peat gives off heat a little worse (2500-3500 kcal/kg), as well as firewood, but the latter must be dried under natural conditions.

Use of firewood

To correctly calculate the size and shape of the heating chamber, you need to focus on the height of the flame that comes from a particular type of fuel. If you can make a small firebox for coal, then larger dimensions are extremely necessary for peat and wood, since these substances burn actively.

Making the solution

Most often, when lining a furnace, a solution of clay and sand is used in a ratio of 1:2. Many home craftsmen recommend the following proportions for mixing: 4 parts clay, 8 parts sifted sand and 1 part water. It is advisable to take clay from a depth of 1.5-2 m, clean, without various impurities. In order for the clay to acquire the desired viscosity, it must be soaked in water for 2-3 days and then rubbed through a sieve. If this is not done, small pebbles or plant debris may end up in the solution, which will not only complicate the laying process, but will also negatively affect the strength of the structure.

The following solution is also used for masonry: 1 part clay, 1 part sand and 100 g of table salt per bucket of solution. The clay must be pre-soaked in water and the sand must be sifted. When kneading, water is added in small portions so that the mixture does not become too liquid. The finished solution holds its shape well, does not stick to the trowel, and easily slides off the walls of the container.

Clay mortar mixed with fireclay powder and cement has excellent qualities. To prepare it, take 60% of the total mass of clay, 35% fireclay powder and at least 10% cement. If you do not want to select the proportions for the mortar, use a ready-made masonry mixture, which only needs to be diluted with water to the desired consistency. The solution should be mixed in small portions so that it does not have time to dry out before application.

What to look for when choosing?

Let's start with the fact that, no matter how perfect a fireplace stove is, you shouldn't rely on it as the main heating device. A potbelly stove is not able to heat a house; its task is to properly heat one room. So you need to choose a model based on the area of this room.

True, the figures given in the documentation by foreign companies should be approached with a certain degree of skepticism. Perhaps a tiny stove will be able to provide heat to a room of 50 m², but only in a mild European climate. Most fireplace stoves come from France and Italy, and experiments to determine their effectiveness were carried out there. Needless to say, our winters are much harsher. Therefore, it is wiser to focus on the declared power of the product.

Sometimes during the first firing of the fireplace stove an unpleasant odor appears. This burns through the metal dust. But you shouldn’t be afraid of this - after a few days of use, the smell of scale disappears

There is a simple formula: 1 kW per 10 m² with a ceiling height of 2.7-2.8 m. But these are optimistic figures, implying that the device will work in a well-insulated house. If the building suffers some heat loss during the cold season, it is better to proceed at a rate of 1 kW per 7 m², and when things are really bad with thermal insulation, then 1 kW per 5 m².

Another point to pay attention to is the size of the firebox.

The area of its opening must correspond to the size of the heated room in a proportion of at least 1:75. In general, the larger the chamber, the more efficient the heating. Small ones are inconvenient because you have to heat them with short logs - they burn quickly, which means you will need to add firewood every 3-4 hours.

It is strictly forbidden to burn fireplace stoves with coal. It generates a huge amount of heat and the glass door may not withstand the heat

Features of choosing cast iron grates

When choosing a particular model, you must first of all take into account the type of fuel used. Let’s say, if you plan to heat the stove with coal, then give preference to a design with dimensions of 30 (35) x 20.5 centimeters, but if with wood briquettes or firewood, then the dimensions of the product should be from 14 x 12 centimeters to 33 x 25.2 centimeters.

Note! In addition, when choosing a grate, it is necessary to focus on the calculation that the rods of the product will be able to withstand the maximum weight of one portion of loaded fuel. In order to find out exactly how many kilograms a particular option can withstand, talk to a sales consultant

If in doubt, it is better to consult a specialist.

Another important point is the width of the gaps. In order for you to easily clean the grate from ash in the future, the area of these gaps must correspond to at least 40 percent of the total area. If this indicator is lower, then the combustion chamber will not function as efficiently, because the volume of incoming oxygen will not be enough for proper combustion. And if there is little ventilation, then gases can also accumulate there. And on the contrary, if the area of the cracks exceeds 40 percent, then incompletely burned fuel will fall into the cracks along with the residues.

Classification of grate

Cast iron grates for stoves were and are still the best option. Steel is less resistant to this mode of operation and is not able to accumulate heat, as cast iron does. Therefore, despite the heaviness of the material, it is cast iron wood-burning stoves - Harvia, for example, and cast iron grates that are considered the best. Moreover, this applies to models both for baths and for heating living quarters.

However, this classification exists:

- steel gratings are lighter. If you know how to handle a welding machine, they can be made with your own hands - for a bath structure, for example. However, the material burns out faster because it is less resistant to chemically aggressive substances.

- Cast iron grates for sauna stoves or other structures are much more stable and, therefore, have a long service life.

Another classification of devices is related to the type of device.

- Fixed - usually a lattice with different sizes for different types of construction. This element does not change its parameters and does not move. There are several types of grating: tiled flat - lattice flat rectangle. This is the most popular option and is used for any wood-burning sauna stoves, solid fuel heating boilers, fireplaces, and so on. The photo shows the Harvia model.

- basket - designed for open fireboxes and originally developed for cooking. This device is no longer used, and there are almost no open fires, so the popularity of this model is not great;

- beam - in appearance they resemble a construction beam. The lattice of them is assembled with your own hands, choosing the appropriate size and quantity. This is the best method for fireboxes of non-standard sizes.

The chain grate belongs to the same category: its elements are connected by chains. However, in practice it is extremely rare, since it does not ensure complete combustion.