A heating structure project is a drawing of a future fireplace design on paper. Before starting masonry, you need to carefully think through all the points and draw up a sketch correctly.

When studying designs of houses with a fireplace, you should know the following parameters:

- what size of foundation to pour under the fireplace;

- room height;

- the strength of a tall brick structure;

- compliance with fire safety measures;

- the appearance of the attractiveness of the fireplace.

A correctly drawn up diagram of a brick fireplace will save time and effort, and will make it possible to carry out the planned construction in the best possible way, as well as avoid difficulties during operation. Brick fireplace projects

Corner fireplace and its uniqueness

Let's look at a detailed drawing of the masonry of a corner brick fireplace and the order with a description. Today there are a huge variety of fireplace designs, but at the moment we offer you a convenient fireplace built into the corner, which can be installed in a small room of at least 12 m2, since there will not be enough oxygen to heat it. To create it, you should find a mason of the 4th - 5th category, so that he has the intricacies of constructing this structure or delve into the intricacies of this process on his own.

It should be remembered that the internal structure of fireplaces is created almost identically, and the combustion of fire in the firebox is the same.

Corner fireplaces have their advantages:

Its peculiarity is that it is not located in the center of the building, but in the corner, and has small dimensions. In addition, it evenly transfers heat energy throughout the room.

Folded neatly, with the smallest deviations and tolerances in construction, the corner fireplace is a heating equipment, carries a certain decorative beauty and shows the status of the owner of this building.

Its disadvantage is the expensive, decorative finishing.

The brick for the construction of this structure needs a high grade; of course, you can lay it out with grade 100, but you should remember that this material is of poor quality for laying it out. In this case, if you build a fireplace from this brick, then, according to fire safety regulations, it should be plastered.

This brand of brick is used for laying out the outer part of the building and for constructing the pipe. And the inside of the firebox is made of refractory bricks.

- Under this brick structure, it is necessary to pour a separate foundation so as not to disturb the main foundation, since the heating device has its own shrinkage.

- It is required to attach a special heat-insulating material between the wall and the future fireplace or lay the masonry in a quarter of a brick, that is, on an edge (it is advisable to lay wire through two rows, for the strength of the structure).

It is advisable to maintain the horizon level, vertical surface and equal diagonal points. With this observance of the rules, the quality of the removal of combustion products to the outside depends.

Safety rules for the construction of a bathhouse

It has already been written above how important it is when planning and constructing a bathhouse to strictly adhere to all standards and recommendations to ensure fire safety. Brick is the best material for fire protection, but despite this, it is necessary to maintain the minimum distance from the stove to the walls - no closer than 25 cm

A special base for the stove is laid on wooden floors to avoid fire. The ash compartment is located at a height of at least 14 cm from the floor

Brick is the best material for fire protection, but despite this, it is necessary to maintain a minimum distance from the stove to the walls - no closer than 25 cm. A special base for the stove is laid on wooden floors to avoid fire. The ash compartment is located at a height of at least 14 cm from the floor.

Following the simple rules described in the article will help you install the stove in the bathhouse correctly and protect yourself from unforeseen situations.

Rectangular fireplace diagram and drawing

Its size is 5x2.5 brickwork order consists of 33 rows

This structure is used without a door on the firebox. The designer, when creating this drawing, used a smoke exhaust through channel, which provides good draft. In this regard, its heat capacity decreases in order to increase the efficiency of this structure. To do this, you should use standard methods, such as laying empty channels along the firebox and chimney.

- The inside of the firebox should be made of refractory bricks that can withstand temperatures of 1100 degrees.

The main massive part of the fireplace is laid out with high-quality solid ceramic bricks, it must correspond to grade 125 and higher, its heating temperature is 750 degrees.

You should remember that refractory and ceramic bricks are prohibited from being tied, but they can be tied using 3 mm wire placed in the seam between the bricks.

Order diagram of a rectangular fireplace 5×2.5 made of brick

When laying out this structure, you should maintain the same thickness between bricks, equal to 5-7 mm. If the material contains flaws, for example oblique corners, then they should be trimmed apart from each other, this way you will achieve the desired thickness of the seam.

Rows should be checked with a level or plumb line to achieve the correct geometric shape of the structure.

This drawing is used by master stove makers, and even with extensive experience, they consult it.

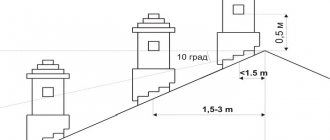

Features of chimney installation

The inner surface of the chimney pipe is a straight channel, but its outer part has design features.

Design features keep you warm

At the intersection of the floor beam, the chimney has an expansion. This design element is important because it reduces the temperature of the outlet streams. As a result, there is no need to make additional thermal insulation in this place.

At the level of the intersection of the roof, the chimney has an extension. This feature protects the brickwork from the harmful effects of precipitation.

The smoke channel is also protected in the form of a metal cap. It is recommended to equip the chimney with a spark arrester.

Mini fireplace drawing

It is recommended to install this heating device in a room of at least 16 m2. It is built into a partition to heat two rooms. To increase heat transfer, the firebox is laid out without refractory bricks. Thus, ceramic brick heats up much faster because it retains less heat capacity of the mass than refractory brick.

- In this case, to protect the firebox from high temperatures, the stove maker uses a metal sheet 3 millimeters thick instead of a stone tooth.

A drawing of a brick fireplace is attached below in the description. If the master has little qualifications in this direction, then instead of the portal arch, you can build a horizontal ceiling. To do this you will need 2 metal corners of the required length.

A positive characteristic of this fireplace is that when purchasing materials for its construction, you spend minimal money.

For construction you will need:

- ceramic bricks 235 pieces;

- clay – 0.12 m3;

- sand – 0.3m3;

- cleaning door – 1 piece;

- stove valve – 1 piece;

- grate – 1 piece;

- choke tubes – 2 pieces;

- steel sheet thickness - 3 mm and size 0.25 m 2;

- roofing material - 1.5 m2;

- cement - 15 kilograms.

“Mini” fireplace and its sequential masonry scheme

To maximize the efficiency of this structure, the side walls of the firebox are laid out at an angle of 25 degrees.

The back wall is laid out in 10 rows in the usual way, that is, horizontally. Starting from the 11th row, the brick extends a quarter at an angle of 30 degrees into the inside of the firebox. With this action, a chimney tooth pass is formed, metal pins are then inserted into the seams between the bricks, and a sheet of metal will be attached to them.

Below is a metal drawing for a firebox.

Due to the absence of fireclay bricks in this building, the space in the room heats up much faster, since side air channels are laid out.

In the lower part there are holes through which cold air enters, and the hot air heated from the fireplace insert through the “ventilators” located in the 13th and 14th rows exits into the room as hot air. Thus, its efficiency increases by 15, 20%

Varieties

With a bed

The volumetric shape of such a stove is not suitable for all buildings. A miniature country house will be too small for a full-fledged heating system. But in a spacious room it will look harmonious. The stove and fireplace can be lit alternately - the combined option allows this. On the one hand, this is a cozy space with a crackling fireplace, and on the other, a full-fledged stove.

Most often, stoves with a stove bench are dacha installation options. In winter, massive stoves heat the house completely: the heat from the knee walls warms the whole night. Hence the understanding of why it is called a long-burning furnace. And if there is an option to install this design in your home, it’s worth taking advantage of.

Swedish oven

Another design of a combined stove is the Swedish one. It is distinguished by its compactness and the possibility of the same alternate use. If you touch the name, it immediately becomes clear that it comes from the country of origin - Sweden. The fireplace itself heats up quickly, since the mechanism with a heat exchanger has a hob. The Swedish oven is located between the walk-through room and the kitchen - this allows you to quickly heat a small space. The disadvantages include easy cooling, therefore, the inability to retain heat.

Wall furnace

A stove in which one side is in the wall is called a wall stove. This is a space saving option. It can be built in a small cottage to heat two rooms at once. Built-in structures allow it to be used in different ways - as a stove, and as a fireplace for aesthetic relaxation. It will heat the adjacent rooms behind the wall. The disadvantage of this mechanism is the lack of a cooking unit.

BBQ oven

Ordinary street barbecues are becoming a thing of the past. The stove can be used for barbecuing, and in this case it will be divided either into several separate planes and located directly on the street, or it will be built into the wall of the house, representing a single whole with the adjacent gazebo.

A barbecue stove refers to a mechanism that will be used alternately as a kitchen unit and as an outdoor fireplace. The structure is installed either on the outdoor gazebos of the dacha, or in the kitchen, which is made in high-tech style.

Mini ovens

Minimalism now is about earthiness and adherence to planes. A consistent minimalist style means the absence of protrusions.

Medium sized English fireplace

A DIY English brick fireplace is one of the oldest ever built. It is also called a classic open-type brick fireplace.

The parameters include the following features:

- protruding tooth;

- open firebox;

- rear wall of an inclined fracture.

The internal recess of the firebox or hearth is lined with refractory bricks in a mortar containing clay and fireclay chips, as well as a little cement. The external contour of the structure is created from ceramic, solid material.

Elements and diagram of an English-type fireplace

This scheme is relevant for most English-type models.

To build it you will need:

- solid ceramic brick – 350 pieces;

- fireclay bricks – 125 pieces;

- sand-clay solution – 215 kg;

- fireproof mortar – 155 kg.

Below is a detailed drawing of an English heating device 5x3 made of brick

The first four rows of the base are laid out of ceramic bricks of grade 100, then higher quality material of grade 150 and higher is used.

This structure is installed in a room with at least 80 m 3 of total space. Having studied its order, the following points should be noted; note that there is no blower and grate.

If a small room has hermetically sealed windows on all sides, you should install an oxygen supply from the street to the firebox for better combustion.

To create a ceiling for the firebox, a corner of steel and 2 strips of the same material are laid on the twelfth row.

In this design, a cleaning door is provided on rows 16–17, which is installed on the rear wall. This hole limits the placement of the fireplace against a load-bearing wall or wall. In this case, this heating device will not be able to warm the second room.

To maintain the elasticity of the mortar and its natural setting, ceramic bricks should be soaked in a container of water for 5 minutes before laying the masonry structure. Heat-resistant bricks are wiped with a damp cloth to remove dust.

After completing the construction of an English fireplace, you should gradually heat and dry it for 3 weeks, and only after this time has passed, you can fill the firebox up to half. After another month, you can turn on the heating device at full power.

By following this rule, you will allow the solution to set naturally; if it is violated, then you expose your structure to a limited service life. The decision is yours.

Features of operation

There are a number of conditions that are very important to observe when installing the stove. Neglecting these rules will make further operation of the fireplace stove difficult.

- The structure cannot be installed close to the wall. The required distance should be indicated in the instructions that come with the fireplace.

- There must be cladding on the surfaces of nearby walls. A ceramic stove is perfect for this.

- Do not install the structure on a bare floor. It is advisable to lay ceramic tiles or make a podium from bricks.

- The stoves weigh quite a lot, so additional racks should be installed to prevent the floor from sagging.

Conclusion

In conclusion, it is worth noting that no matter what efforts are spent on choosing, purchasing and installing a fireplace stove, they will more than pay off with positive emotions and a feeling of comfort that comes from a burning fire.

Laying a three-level fireplace with a grate

This design is a Russian version, but the main elements are taken from the themes of English and Swedish modeling.

photo of a fireplace consisting of three levels

The draft in the chimney of this building is consistently good, even at a height of three meters, due to the large cross-section of the internal part of the chimney.

It should be remembered that this structure is used in rooms where there is high air humidity.

Drawing diagram of a three-level fireplace with a grate

For masonry you will need the following materials:

- ceramic brick – 620pcs;

- fireclay brick (fireproof) – 220 pcs;

- grate 420x200mm – 2 pcs;

- smoke valve 260x260 mm – 1 piece;

- steel corner No. 40 – 150cm;

- steel corner No. 60 – 100 cm;

- steel strip 4x60 mm – 300 cm;

- clay mortar – 750 kg.

Having studied the above-described procedures and drawings of brick fireplaces for DIY construction, you should know how to calculate all the dimensions of this structure.

Be patient for self-construction or find a skilled stove maker with good qualifications to install this heating equipment.

Dimensions of the fireplace in the house: calculation according to the area

If we talk about creating a fireplace yourself, then you need to know the parameters that it must meet. More specifically, you need to draw up drawings of the firebox, chimney, arrangement and, of course, write down the materials that will be required in the process.

So, for example, to calculate the size of the combustion hole, you need to know the size of your room. The ratio of the firebox to the area of the room should correspond to 1 to 50. For example, if you have established that the area of the room is 25 m2, then we calculate 25 to 50 and get 0.5 m2, this is the size of your future firebox hole. As for the width and height, they are determined by the ratio of 2 to 3. That is, taking into account the size of our firebox, we can calculate that the width will be 80 and the height 63. Incorrect calculations are fraught with impaired draft, smoke in the room and poor heat transfer.

If we talk about the chimney, it depends on the area of the portal; its size should be 15 times smaller. If this is not taken into account when calculating, the carbon monoxide produced will enter the room, and this is life-threatening.

The third thing you need to pay attention to is order. It is necessary to complete the drawings as accurately as possible. We carry out the order on paper and be sure to indicate the materials that will be needed, in what quantity and for what purpose. The order may look like a standard table where all dimensions are indicated. The plan must also indicate depth, width and height. Also on the drawings, the rows should be numbered, in the future this will help you not get lost when laying.

If we talk about material, for example, brick is calculated based on the order, but its exact quantity cannot be determined, only approximate. To determine the exact quantity, you need to take into account how much brick will be used for laying and joining seams, and add all this into an intermediate calculation.

We count materials. In the process of preparing drawings and purchasing materials, you need to know not only the future dimensions of your fireplace, but also how many bricks will be needed to build it. This approach will help calculate all possible costs for laying out an object.

What are modern sauna stoves like?

Experts divide all modern stoves into two categories based on the type of energy used: wood stoves and electric heaters. Each of them has certain advantages, which you should definitely know about in order to avoid mistakes when choosing the right model.

The design of a metal stove can be very different. Some of them are made using handicraft methods, from scrap materials and using gas welding. Others are created in factories and have a special design developed by professionals. But they all differ in how quickly the temperature rises. It is enough to lay dry, high-quality firewood and set it on fire, so that after 30-40 minutes the temperature in the bathhouse rises to a level suitable for washing.

The danger of carbon monoxide poisoning is completely eliminated. The stove is covered on all sides with metal, preventing smoke from entering the bathhouse. The stones from which the heater is made heat up as a result of the flame transferring heat to the iron, and the iron conducts them to the stones and gives off heat to them.

Alas, the classic metal sauna stove has a serious disadvantage. The heat capacity of such furnaces is not too high. They heat up quickly and, rapidly transferring heat to the room, quickly cool down. Because of this, conditions suitable for uniform heating of the body are not created. To correct this, experts recommend lining them with brick, leaving only a gap of a few centimeters for a layer of air. This not only allows you to retain heat for a long time (brick has a high heat capacity), but also reduces the risk of burns.

Some stoves even line the inside of the firebox with refractory bricks. This makes it possible to increase the heat capacity of the furnace and increase its service life.

In the manufacture of heater stoves, sheet iron with a thickness of about 5 millimeters is most often used. The water tank is located on either side - it depends on the installation location and the size of the bath.

Some models are made of stainless steel or regular zinc-plated steel. Their main advantage is their low weight and quick warm-up. Unfortunately, their durability is relatively short, and, even worse, they are not able to accumulate heat. It will be hot in the bathhouse as long as the fire is burning in the stove. But it is enough for the wood to burn out, and after just 10-20 minutes the temperature in the steam room will begin to rapidly decrease, which does not please users at all.

An alternative could be a cast iron stove. Yes, it weighs significantly more - sometimes up to 200 kilograms, which significantly complicates the installation process. But it is practically eternal. High temperature, high humidity - all this cannot cause the slightest harm to cast iron. Just look at the drawings of sauna stoves to be convinced that this is a truly monumental thing.

But such a furnace also takes much longer to heat up, that is, it has high thermal inertia.

Of course, another integral advantage of a classic stove-stove is the subtle smoke. Many people cannot imagine a real sauna without this smell.

Electric heaters are significantly different from conventional stoves. At the same time, they differ for the better. They are safe, convenient to use and very easy to operate. They have only one serious drawback - electricity tariffs are rapidly rising, and to maintain good heat in the steam room, an electric heater must work continuously.

The main design advantage of electric heaters is the multi-layer body made using sheet steel. It allows you to increase heat capacity and also reduce the risk of burns in case of accidental contact

When choosing an electric heater, be sure to consider the operating voltage of the specific model. It can be 220 or 380 volts. Models with power exceeding 7 kilowatts usually have a voltage of 380 volts. Don't forget that although stoves with a stainless steel body are more expensive than galvanized ones, they can last much longer.

Fireplace calculation: size advantages

Regardless of what model of fireplace is installed, many people perceive it only as a decoration, and, unfortunately, do not even think about why this installation has not changed after so much time. But a fireplace can be an excellent attribute for room ventilation. With its help you can not only ventilate, but also dry the room. Moreover, all these actions can be performed in a very short period of time; many heating devices cannot do this. Fireplaces are an advantageous solution for those rooms that do not have central, constant heating. For example, if you light a fireplace in a country house that is rarely used, you can quickly dry and warm the house.

Please note that all these benefits are only available if all dimensions have been correctly compared.

It is no secret that when installing a fireplace in a house, most people worry first of all about its appearance and location in the room, and only then about such an important fact as its size. In order for the fireplace to perform all its functions at full capacity, you need to correctly make calculations and drawings that will meet all the assigned tasks. Only in this case will the installation work with maximum efficiency.

Calculating a fireplace with an open firebox: important aspects of its creation

When organizing the construction of any fireplace, we must not forget about the important recommendations of experts. The most important thing is to follow all the dimensions, since they play an important role in the characteristics of the fireplace. When you start making preliminary calculations, follow all formulas and take into account possible factors and aspects.

Important aspects include the following:

- The size of the firebox of almost any fireplace should not be less than 25 cm and no more than 40 cm. Such dimensions are considered optimal for household fireplaces with average power. These varieties are the most common. If we talk about a sauna stove, then the width of the firebox can be a little more than 40 cm.

- If you doubt the correctness of the calculations for your fireplace design, you can check them in a simple way. The width of the firebox must match the width of your firebox door.

- Please note that the difference in size will significantly reduce the heat flow, and the fuel will burn much more slowly than it should. Either way, improper sizing will reduce the use and efficiency of your fireplace.

Experts always try to pay special attention to the firebox, because its parameters are the most important indicator. The minimum size of the firebox should be 80 cm, the maximum 100 cm. Very often, when building a fireplace, it is impossible to achieve this indicator, and the way out of this situation is to increase the level of the afterburner chamber. If the size does not match, then all the flammable gases that were formed in the process will not burn.

Standard fireplace dimensions (video)

The dimensions of the fireplace are a very important detail during construction. As you can see from the article, failure to match the dimensions leads to irreversible consequences, all your efforts become in vain and most likely the structure will be dismantled. Don't neglect the rules. If you are not confident in your capabilities, it is better to contact a professional who will certainly create an ideal and correct model of your fireplace.

08/24/2017 3738 Pechnik (Moscow)

Not many people know how important it is when choosing either a ready-made purchased model or when preparing an assembly diagram to indicate and pay attention to the dimensions and design parameters.

The efficiency of the device, its position and viewing angle in the interior directly depend on this aspect. Due to its location, a corner fireplace does not always look equally good and advantageous; it requires preliminary selection of the most suitable location and other parameters.

Knowing the dimensions of the corner fireplace, you can easily choose a unique design for it that is most harmonious and compatible with the overall interior of the room, calculate its power and purchase all materials and accessories.

For detailed information, we also recommend watching the video in this article.

Correct definition of parameters

A corner fireplace, the dimensions of which have already been calculated, can be made of any materials and have a certain lining of the hearth. Before making your choice, we recommend that you familiarize yourself with the following selection rules:

The dimensions of a corner fireplace largely depend on the type of hearth chosen for installation and the fuel used for its operation.

If you are looking for a purely decorative solution or a firebox that will serve as an additional source of heating for a house or apartment, we recommend that you pay attention to fireplaces that operate using bioethanol or electricity.

Installation instructions for the finished model are always included in the basic package. The most effective fireplaces that can become the main source of heating in rooms are gas and classic wood-burning structures.

If installing a gas boiler is possible both in a private and apartment building, then wood-burning fireboxes require a chimney, which is only possible in your own home.

It should be noted that the installation of such installations is more complex, costly and time-consuming.

The chosen finish, materials for making the hearth and portal also play a big role.

The most inexpensive and budget coatings are plasterboard, metal profiles, ceramic tiles, and decorative plaster.

Due to their low cost, the design of portals, fireplaces or such cladding provides lower efficiency and efficiency.

The price of materials and coatings that form and provide the furnace with additional heat capacity, efficiency, and heat transfer is quite high.

This category includes tiles, natural minerals, cast iron, and steel. The distinctive features of the materials are practicality, durability, fire resistance, easy maintenance and environmental friendliness.

Tip: a corner fireplace, the dimensions of which are selected individually, must be thought out to the smallest detail. Before you start assembling or purchasing, determine for yourself the optimal price range, the list of installation and installation work that you will need to perform. This will greatly facilitate the work process and help determine the dimensions, type of fuel and other features of the fireplace.

Preparation for construction

The beginning of any construction is the preparation of a sketch and carrying out calculation work. First, you should draw the future fireplace by hand in relation to the room. You should also carefully draw the location of the firebox, the shape of the portal, chimney and other elements. The dimensions should first be indicated in advance, and then calculations should be made using formulas.

Based on the approximate drawing, a detailed drawing should be made. It must indicate the dimensions of all parts, the side section of the building and other elements. Particular attention must be paid to the ordering scheme according to which construction will be carried out. There are many such schemes. You can choose the best option or come up with your own. You can also use one of the ready-made fireplace drawings, having previously adjusted it taking into account the size and features of the room.

Dimensions of decorative fireplace

The dimensions for which a corner fireplace is determined according to the area of the room for decorative installations can also be determined based on the following tips and recommendations:

- The room chosen for installation and installation of the structure must have suitable dimensions. As a rule, the dimensions of the stove should not exceed one twenty-fifth of the living room;

First of all, it is recommended to buy the firebox itself

Electric fireplaces are universal

Miniature corner fireplace for a home or apartment

Example: for a room of 25-30 square meters, the size of the corner heating installation should not exceed one square. Moreover, each of its sides, which is adjacent to the wall ceiling, is about 1.4-1.6 meters.

- Since there is no real flame burning in the hearth of false fireplaces and the structure does not heat up, it is quite possible to make it not only an addition and decoration to the interior, but also add a certain functionality. To do this, equip the frame with various racks, tabletops or shelves on which you can place books, accessories and other necessary, useful little things;

- If you want to install a purchased electric or bio firebox into a decorative portal, all calculations are made according to the existing installation dimensions. If the portal is purchased, you can find its installation dimensions in the instruction manual included with the purchase. For home-made frames, all measurements are taken by hand; choosing a hearth of suitable size in this case is quite difficult and it is quite possible to make it only to order.

You can also view photos of corner fireplaces in various interiors in this article.

How to calculate the dimensions of the combustion chamber

In order to calculate the size of a corner fireplace and its combustion chamber, adhere to the following rules:

- To calculate such a parameter as width, you will need to add up the width of the firebox itself and its side parts, as well as add up the frame consoles;

- To calculate the height, add up the height of the firewood, mantelpieces and other decorative elements;

Metal corner fireplace: dimensions

The size of a corner fireplace made of metal is calculated based on a list of other criteria and rules:

- The overall dimensions of metal fireplaces are calculated based on the characteristics of the firebox, which can have either a completely separate floor-mounted or built-in arrangement;

- The size of the firebox depends on the type of fuel chosen - it can be either gas, wood, coal or purchased pellets;

- The height, width and depth of the model are selected based on the area of the room selected for installation, as well as the power of the heating unit itself. You can learn more about the power and other technical features and functionality of the model from the supplied passport, manual or instructions;

- In order for the power and efficiency of the finished fireplace to be optimal, first of all, calculate the area of the house or apartment you want to heat, then multiply the resulting numerical value by the footage of the ceiling height and divide by twenty.

This hearth is equipped with a firewood rack and a hob.

Ready-made models do not require careful calculations

Steel wall-mounted model with a chimney and a spacious firewood rack

Dimensions of the finished metal corner hearth

Example: if the area of your house is 70 square meters and the ceiling height is 2.7 meters, we get a value of 189 cubic meters. When we divide 189 by twenty, we get 9.45. This means that the power of the heating device to create high-quality and uniform heating must be at least 9-10 Kilowatts.

Corner fireplaces, the dimensions of which are shown in the photo in this article, depending on their dimensions, are suitable for installation in rooms with different areas and design features.

Important: built-in corner fireplaces, the dimensions of which are no less important when choosing and installing, are calculated according to the scheme of decorative hearths and portals. An exception in this case would be fireboxes, which are installed in a frame made of brick (the parameters of the bricks themselves are taken into account).

Types of Kuznetsov furnaces

As mentioned above, the caps can be positioned in different ways, which is why there are a lot of options. The ability to install any heat exchange device in the second dome without damaging the combustion process also contributes to the presence of many different thermal units. At the same time, devices with any type of combustion can be designed according to this principle: upper, lower, pyrolysis, layer-by-layer, etc. They all have some specifics, but can be implemented. On Kuznetsov’s website, projects for various purposes are posted in order. They can be downloaded freely for personal use, but republication is not encouraged.

Fireplaces built on the principle of bell-type stoves

There are Kuznetsov stoves for two-story houses, and they heat both levels. Moreover, there are such units with beds. Heating can be of the convection type (only from the walls of the stove) or a water heat exchanger can be inserted inside. Then such a unit is called a boiler and is designated KIK. Four ready-made water-heating brick boilers with a capacity of 16 kW, 17 kW, 34 kW, 64 kW are publicly available on Kuznetsov’s official website. They can have a built-in tank for heating water for domestic needs. The boiler needs to be tied with metal corners, if necessary, it can be insulated, a reinforcing mesh should be laid on top and plastered.

Heating stove. Beautiful

There are many more options for convection ovens. In the section of heating and cooking furnaces without the use of fireclay bricks, OVIC, there are 25 different projects. There are three options for a heating and cooking stove with a fireplace. The fireplace can be located on the side (right or left). Such options are marked OVIK BK (side fireplace), there is an option with a stove bench and an OVIK BK 13l fireplace. For a fireplace located at the rear, the marking is OVIC ZK (rear fireplace).

Kuznetsov’s heating and cooking stove looks very decent

Purely heating thermal units are marked IOC. Orders that have a bed have the letters “lie” or “L” in their names; if there is an oven, the letter “D” is added. Heating stoves also have options with fireplaces. They are marked OIK K. There are calorific furnaces PKIK1X. A separate category includes ovens for greenhouses and bread ovens.

Heating stove Kuznetsov OIK. Impressive

Kuznetsov's Russian stoves are marked RTIC; a total of 10 models are laid out, two of which have stove benches. They have the usual configuration of a cooking chamber, the mouth of which must have a sealed valve. If the chamber is not sealed, the oven will not work normally.

Russian bell stove with stove bench

In the section of stoves for baths, Kuznetsov immediately offers an option for planning the premises, indicating the dimensions and showing how suitable models can be “fitted” there. After all, bathhouses are usually small, and while a metal stove can be placed in it easily, a large brick stove is already problematic. And you need to take into account many factors: where will the fire be fired from, where will the steam come out and the hottest part of the stove. And here are ready-made options. Very convenient and worth saying a big thank you to the author! The stoves themselves are placed in a separate category and are marked with BIC.

Kuznetsov's sauna stoves are marked with BIC. They look presentable and, according to reviews, have excellent characteristics

This video offers a design of a furnace designed according to the principle of constructing furnaces proposed by Kuznetsov. The first half talks about the movement of gases and how it works, about the principles of controlling the operation of a particular model. The second comments on the masonry process. Very useful and educational video.

Dimensions of brick structures

If you want to assemble a corner fireplace with your own hands, the drawings and dimensions for it must be selected with additional precision. The following rules and recommendations will help you with this:

- In order for such a brick oven to have suitable dimensions and appropriate efficiency and functionality, it is necessary to make very careful calculations. To do this, it is important to note the ratio of the combustion chamber to the portal, the area of the house and the room in which it will be located. It is equally important to select a brick of a certain size so that the installation corresponds to the stated dimensions and fits well into the specified angle;

- The calculation is made using the following formula: the area of the room selected for installation is determined, the specified numerical value is divided by one hundred (the area of the combustion hole is determined);

The combustion hole must gradually narrow to create good heat transfer

The brick frame can be equipped with a purchased metal firebox

Brick structures are considered the most difficult to calculate and implement.

Advice: in order for the heat transfer of the corner heating unit to be as high as possible, the combustion chamber is made in the shape of a trapezoid or triangle, while its rear part gradually narrows.

- In order to determine the width of the combustion hole in the shape of a triangle, you need to determine its area, then take the square root from it and multiply by two units;

- A parameter such as depth is calculated as follows: for this, the width is divided by 1.4. The height of triangular figures often corresponds to its width (maybe a little more);

An example of calculating the diameter: in order to calculate the diameter of the chimney (on average 1:10-16), you need to use the following diagram. The dimensions of the fireplace are calculated and the area of the room is determined. With a footage of 40 square meters, this value is divided by 100, and thus we get 0.4 square meters. The width of the firebox is found by taking the square root of the number 0.4, after which it is multiplied by two units. It turns out 1.2 meters, this distance allows you to fit 4-5 bricks. The sides are 1.2/1.5=0.80 (3-4 units of brick, depending on the original size chosen).

Important: if you want to fold a firebox that has a trapezoidal shape, we recommend that you do not perform your own calculations, but use the help of a professional or a ready-made, proven order diagram. These recommendations also apply to combustion chambers that have convex or rounded outlines.

Foundation

The foundation is an important and responsible stage of work. When laying the foundation for a fireplace, it is worth considering the following points:

- the foundation of the fireplace should not be in contact with the main foundation of the house;

- the dimensions of the foundation should be approximately 10 cm larger than the dimensions of the fireplace on each side;

- the depth of the pit should be 50 - 60 cm;

- the level of the foundation must be lowered from the floor level by the height of one brick - 6 - 7 cm;

- The fireplace should be laid on a completely finished, solidified foundation.

The foundation is made of brick or concrete.

Concrete is more difficult to make, so we’ll focus on it.

Crushed stone 10–15 cm thick is poured onto the bottom of the pit. The formwork is installed, treated with resin or upholstered with roofing felt. Fill the foundation with sand-cement mortar (3 parts pitch and 1 part cement). Having leveled the poured foundation, leave it to dry for a week under plastic film.

Immediately before laying, it is necessary to provide additional waterproofing with two or three layers of roofing material.