In Russia, for at least 5 months a year (in the northern regions, there is a heating system in every living room of the house. And in the open air at this time there is a noticeable cold. And, if we are talking about the attic, which has the largest contact area with the open atmosphere large, then you should take this seriously. After all, in winter there is a serious temperature difference on both sides of the roof and the gables of the attic, which is why the heat flow always moves to the source of the cold - out. And the task of insulating the attic is to stop this flow and minimize heat loss, with the purpose of which is to use materials with low thermal conductivity.

there is a heating system in every living room of the house. And in the open air at this time there is a noticeable cold. And, if we are talking about the attic, which has the largest contact area with the open atmosphere large, then you should take this seriously. After all, in winter there is a serious temperature difference on both sides of the roof and the gables of the attic, which is why the heat flow always moves to the source of the cold - out. And the task of insulating the attic is to stop this flow and minimize heat loss, with the purpose of which is to use materials with low thermal conductivity.

First of all, it is important to decide which insulation is best for the attic - based on the materials of manufacture, planned operation and expected internal temperature. Let's try to figure it out.

Rating of roof insulation

The traditional technology for thermal insulation of attic floors of the second half of the twentieth century is backfilling with a layer of expanded clay or sawdust. The effectiveness of these materials is low, which often led to the appearance of frost and icicles on the inside of the slopes. In the spring, frozen condensation melts, the wood becomes damp and this reduces the service life of the rafters. To prevent this from happening, a more advanced insulation was required.

Architects designing houses with mansard roofs have also made new demands on thermal insulation materials. The popularity of these structures is due to the reduction in costs of building a cottage and the opportunity to get additional usable space instead of a cold attic. Insulation for an attic roof must differ in its technical characteristics from the materials used to insulate the attic floor or the used flat roof.

The variety of requirements for thermal insulators has led to the emergence of products with very different properties. Our Vyborexperta.ru team decided to weed out low-quality materials and understand the question of which roof insulation is best to use for different roof designs. To be included in our rating, products must have the best technical parameters. Performance characteristics, installation features, and cost were analyzed. Feedback from property owners and expert opinions were taken into account, and professional testing was performed.

Experts analyzed:

- Thermal conductivity - the lower the indicator, the less insulation thickness is required for effective insulation against heat loss;

- Density - low characteristics reduce the weight of the insulator and the load on rafters and supporting structures, but loose material tends to caking and losing its properties. A dense insulator retains its shape and thermal parameters well, but increases the pressure on the walls and foundation. We chose a compromise solution;

- Hygroscopicity - the ability to absorb moisture leads to a decrease in thermal conductivity.

- Thermal stability - the thermal insulator must maintain performance characteristics over a wide temperature range.

- Fire resistance - the flammability of the material, resistance to ignition and ability to support combustion were taken into account;

- Durability - the thermal insulation “pie” is subject to biological, chemical, and static effects;

- Environmental friendliness – the emission of harmful substances into the air is not allowed;

- Installation technology – affects the cost of insulation work;

- Price – when insulating, a large volume of materials is used; high cost can lead to a sharp increase in the estimate.

Not all analyzed insulation materials were suitable for effective thermal insulation of roof slopes or flat roofs. Complex installation, delamination, low biological stability, high fire hazard - materials with these characteristics were excluded from the rating.

Why do you need attic insulation?

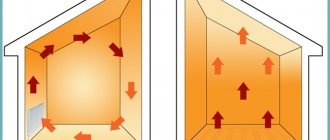

In winter and autumn, the temperature difference between indoors and outdoors is strong. All warm air currents tend to the source of cold. This means that in the house they will move towards the walls and roof. Condensation forms at the point of contact between warm and cold masses. It accumulates, causing the material of the walls and ceiling to deteriorate.

In the attic room this is even more noticeable. The pediment and slopes, on one side, are in contact with cold outdoor air, and on the other, with warm indoor air. Thermal insulation is necessary to limit the penetration of warm flow onto cold surfaces.

Choosing insulation for the attic is not difficult. Insulation can be external or internal. External insulation of the building is performed on top of the rafters. The thermal insulation material is covered with a film for waterproofing, and then the roofing material is installed. Such insulation is installed only during construction.

Film for waterproofing Source nohoho.ru

Internal insulation is carried out directly in the room. The insulator is mounted between the rafters and then covered with hydro- and vapor barrier. Installation can be carried out at any time.

The best insulation for an attic roof

There are increased requirements for the thermal insulation of attic roofs. The slopes act as external enclosing structures and must ensure minimal heat loss. Installation of insulation when arranging an attic is often carried out from the inside, for example, if you want to turn the attic into a full-fledged living space. Insulation should not be difficult. We analyzed the products of 8 brands and settled on three that had good thermal characteristics and easy installation.

Isorok Ultralight P-33

The slabs are made from cotton wool, the threads of which are obtained as a result of the melting of basalt rocks. This is an environmentally friendly material with good vapor permeability. Using Isorok Ultralight will help create a cozy microclimate in the attic.

Density 33 kg/cub.m. allows you to reduce the load on rafter structures. Recommended for insulating non-load-bearing structures located on a slope. A slight static load does not lead to mineral wool caking and a decrease in thermal conductivity.

Advantages:

- Low thermal conductivity – 0.038 W/(m*K);

- High elasticity simplifies the installation of slabs between rafters;

- Mineral wool does not burn, retains its properties at a temperature of 600-650 ºС;

- Not subject to biological effects;

- Resistant to aggressive substances;

- Low price.

Flaws:

- Fiber delamination.

The developers reduced the water absorption coefficient to 1% by treating the fibers with compounds and water-repellent properties. This allows you to maintain performance characteristics throughout the entire service life.

Rockwool Light Butts Scandic

The slabs are made of basalt wool. Density 35 kg/cub.m. allows you to reduce the load on supporting structures. Treatment of mineral fibers with a water repellent reduced the water absorption coefficient to 1-1.5%. Thermal conductivity of 0.036 W/(m*K) allows you to reduce the thickness of the slabs used when insulating the attic. The insulation is easily cut with a stationery or construction knife, which simplifies installation work.

Advantages:

- One of the edges is flexible, which allows the insulation to be compressed when installed in a spacer;

- Compression is used during packaging;

- Service life – 100 years;

- Non-flammable material.

Flaws:

- It crumbles during installation.

- High price.

Paroc eXtra

The slabs are made of stone wool. The thickness of 100 mm allows you to increase the pace of installation work. Density – 30 kg/cub.m. reduces the load on supporting structures and foundations. Thermal conductivity 0.040 W/(m*K) meets the requirements for regions with cold climates.

Advantages:

- Good vapor permeability;

- High fire retardant characteristics;

- Provides effective sound insulation of the attic;

- Low water absorption – 1%.

Flaws:

- Low density leads to delamination.

Efficiency of single-layer insulation

As for the method of laying insulation, for a long time there was an opinion that cross-insulation is more effective.

id1932564FORUMHOUSE Member

Tell me what to do: the roof is attic, the insulation is 200 mm in size for the rafters, I bought rolled mineral wool insulation for the roof. There is an idea to add 50 mm cross-insulation from the inside. The builders did not approve. Does this make sense? Tatarstan region.

Anatoly Zemyanko Technical Specialist

It is better to insulate in one layer than in several. Increasing the speed of work by reducing the number of technological operations, reducing waste due to cutting layers when performing run-ups.

Six fragments of walls with stone wool slabs were tested in the climatic chamber of NIIMosstroy:

- In three layers and in one layer - the plates are joined without a gap (good installation).

- Three layers and one layer - slabs with a gap of 2 mm (normal installation).

- In three layers and in one layer - a gap of 5 m (everything is bad - it needs to be redone).

A seam width of up to 2 mm is acceptable in most building structures and appears in the standards. This is due to the fact that under climatic conditions, convection at a seam of such width is not intense. Therefore, it is not detected by a thermal imager as a cold bridge. Previously, there were studies on the uniformity of two-layer and single-layer insulation while maintaining the width of the seam.

The research revealed the following:

- Single-layer and multi-layer insulation used in external enclosing structures are equivalent in their effectiveness.

- A gap of 2 mm between adjacent insulation boards has virtually no effect on heat transfer resistance.

Anatoly Zemyanko Technical Specialist

Advantages of minimizing thermal insulation layers (2x100 mm and 1x150 mm are better than 4x50 mm and 3x50 mm):

- reduction of labor costs during the preparation and installation of insulation;

- reduction of material scraps during work;

- insulation with a thickness of 100 mm or more is less prone to deflection than a thickness of 50 mm, due to which it is more securely held in the frame, which is important when installing on vertical and inclined surfaces;

- A single-layer solution is ultimately cheaper than insulation with two or more layers.

The best insulation for a pitched roof

Additional insulation of the attic floor is not always possible due to the low load-bearing capacity of the ceiling. In this situation, pitched roof insulation is used, which is laid between the rafters on the sheathing. The material is subject to lower requirements for thermal conductivity and density. Cold attics and attics can be insulated with thermal insulation. The VyborExperta.ru project analyzed 9 types of insulation from popular brands and chose 3 brands that attracted attention due to their price, simple installation and stable characteristics.

Rockwool Light Butts Extra

Stone wool slabs with a density of 40-50 kg/cub.m. Thermal conductivity of 0.038 W/(m*K) allows you to maintain a comfortable microclimate in the house in winter at minimal cost. A universal material used not only for insulating slopes, but also partitions, floors with joists, and other non-load-bearing structures. Has high linear tensile strength.

Advantages:

- Refers to non-combustible materials;

- High strength allows installation in vertical frames up to 6 m high;

- Reliable fixation between rafters;

- Good resistance to wind loads.

- Long service life.

Flaws:

- Not found.

Isover C-000176898

Rolled roof insulation made of mineral wool based on limestone and quartz. Density 15 kg/cub.m. allows you to reduce the load on the rafters and supporting structures. The roll rolls out easily, which has a positive effect on the speed of installation work. The packaging has markings for easy cutting to size. The thickness of 150 mm and the long length of the roll reduces the risk of heat loss through the joints. The thermal conductivity coefficient of 0.037 W/(m*K) provides a high level of thermal insulation.

Advantages:

- Improved water resistance;

- Elastic insulation does not require additional fasteners;

- Environmentally friendly material;

- Does not burn, does not lose its properties at high temperatures;

- Allows you to reduce the amount of insulation waste.

Flaws:

- Noticeable level of dust during operation.

The insulation format allows the material to be used when insulating roofs with different rafter pitches. This is relevant for restoration work and major repairs of old houses.

HeatKnauf TR 037 Aquastatik

Professional roof insulation for a private house with high hydrophobic characteristics. Aquastatik technology effectively protects against water. A universal material for vertical and horizontal structures in which the load on the insulator is not provided. Thermal conductivity of 0.037 W/(m*K) allows you to reduce heating and air conditioning costs. High air flow resistance increases service life. It has a low content of phenol-formaldehyde resins.

Advantages:

- Environmentally friendly material;

- High elasticity simplifies installation work;

- Low percentage of waste;

- Light weight;

- Good vapor permeability;

- No unpleasant odors.

Flaws:

- Requires caution when slicing.

What is more convenient: rolls or mats?

In fact, in what form this or that insulation is sold plays a big role for many ordinary people. Some people prefer to work only with slabs as they are more convenient, but for the majority, rolls seem rational: rolled out and secured, what could be simpler?

Roll material is really convenient to work with. They rolled it out to the required length, cut it, and rolled the cut piece. They brought a new skein to the right place, rolled it out again, straightened it and secured it. Roll insulation is also convenient because, with a standard distance between rafters of 61 cm, the roll can be easily cut in half with a regular knife, and its halves will fit perfectly into their niches - just roll them out:

Less convenient in practice for many is the packaging of rectangular slabs, which leaves the most waste. But it is easier to transport, and the insulation in it does not bend, like in a roll, which is a critical issue for many materials:

And finally: when buying insulation, be sure to pay close attention to the integrity of the packaging, otherwise you won’t end up with problems later. The insulation packaging must be completely sealed, slightly compressed, without a single scratch or torn film. This is the only way to prevent moisture from getting to the insulation before installation begins.

Now imagine what happens to insulation in poor-quality packaging: moisture and water vapor penetrate the material through holes and slits, the insulation gets wet in places and changes its geometry and properties. On site, you unpack the roll or slabs and begin installation, and then it turns out that the insulation, swollen and heavy in places, does not fit together in any way, the cracks are visible even to the naked eye. Having somehow suffered, you cover all this stuff with clapboard or drywall. As a result, undried insulation ends up in a closed and dark space - an ideal place for mold to grow. The consequences are usually not at all pleasing to the eye, and you will recognize their presence by the unpleasant smell within a few weeks.

Therefore, follow our recommendations, study our website - and you can avoid problems.

The best insulation for a flat roof

Thermal insulation for a flat roof must withstand high snow loads. Waterproofing materials are applied on top of the insulation; if defects appear in the membrane, the insulation should not absorb water. Extruded polystyrene foam and high-density stone wool meet these requirements. Our experts analyzed the products of 6 brands and chose 2 brands. These products comply with SNiPs and strict requirements for flat roofs in use.

Penoplex Comfort

Extruded polystyrene foam with high strength characteristics. At a density of 25 kg/sq.m. can withstand a load of several tons per square meter. Supplied in the form of slabs with grooved edges, which simplifies installation and reduces heat loss through gaps. It has low thermal conductivity - 0.033 W/(m*K), which makes it possible to reduce the thickness of the insulator layer. Maintains operating parameters over a wide temperature range.

Advantages:

- Water absorption does not exceed 0.4%, which is 3-4 times lower than that of clinker bricks;

- Non-flammable material;

- Low load on supporting structures;

- Long service life;

- Can be used on existing and green roofs.

Flaws:

- Overcharge.

Extruded polystyrene foam was developed as insulation for submarines. The material does not lose its properties even when directly exposed to moisture.

TechnoNIKOL Carbon Eco

Extruded polystyrene foam boards with a density of 26 kg/sq.m. They have high bending strength and can withstand increased loads. Operation is allowed at temperatures from -70 to +70 degrees. Thermal conductivity of 0.034 W/(m*K) makes it possible to reduce the thickness of the insulation compared to using stone wool. It does not lose its properties under load and can be used to insulate existing roofs.

Advantages:

- Easy installation;

- No shrinkage;

- Does not attract rodents and birds;

- Durability;

- Low price.

Flaws:

- Low resistance to ultraviolet radiation.

Video description

The insulation of an ecowool frame house is shown in this video:

The wet application process begins with fixing the vapor barrier film, in which holes are made. Through them, the necessary holes are filled with ecowool.

Insulation with polyurethane foam

To insulate an attic with polyurethane foam, you also need professional tools. The material can be sprayed onto any surface. The mass fills all the gaps without leaving seams.

Typically, polyurethane foam is applied to the inner surface of the roof, and the top is covered with decorative finishing. If the house is located in a temperate climate zone, then such a layer of insulation will be sufficient.

How to choose roof insulation

The scope of work requires the use of a large amount of thermal insulation materials. This causes high demand for rolled roof insulation, which has a low price. But does this material always meet the requirements of heating engineers and installers? Let's consider the main criteria for choosing a heat insulator, which will help you buy the best products on the market.

Thermal insulation

Thermal conductivity coefficient is the main selection parameter. The lower the value, the better the heat transfer resistance ability. Choosing products with low thermal conductivity not only ensures the maximum level of comfort, but also allows you to reduce, if necessary, the thickness of the roofing “pie”. A high level of thermal insulation is provided by a layer of insulation made of stone wool or mineral fiber 150-200 mm thick. The exact values depend on the climatic characteristics of the region and are calculated by heating engineers.

Environmental friendliness

Phenol-formaldehyde and acrylic resins are used to bind mineral fibers into a board. The fewer of these substances in the composition, the safer the material is for human health. Insulation materials made from fibers obtained as a result of molten rocks are environmentally friendly products. Materials made from fiberglass have an increased emission of dust, which causes skin irritation. It is better not to use this product.

Insulation materials based on sawdust and other organic substances are very popular. These products do not cause allergic reactions or skin irritations, but have a significant drawback - a low level of fire safety.

Durability

The design features of the flat roof and the slopes of the attic floor make planned repairs difficult. To replace the heat insulator, it is necessary to remove the finishing materials and open the leveling layer of plasterboard. This makes repairs expensive. To ensure that the insulation does not have to be changed every 10-15 years, it is necessary to choose the right products.

The material for pitched roofs must be elastic, not cake under its own weight, and not accumulate moisture in its structure. These factors ensure durability. The best manufacturers produce stone wool and extruded polystyrene foam with a service life of 50-100 years.

Hygroscopicity

The ability to absorb water is one of the main criteria that has a negative impact on thermal performance. If the fibers well adsorb drops of water that are present in the water vapor released during life, then within 1-2 years the material will increase its density, and the thermal conductivity coefficient will increase by 2-3 times.

The attic floor will become cold in winter and heating costs will increase. Products with low hygroscopicity have an advantage. To reduce it, fibers are treated with hydrophobic impregnations. The cells of extruded polystyrene foam, unlike conventional polystyrene foam, have a closed structure. This allows for minimal hygroscopicity throughout the entire service life.

Fire safety

Fireplace chimneys and heating boiler chimneys lead to the roof of the building. An accidental spark can cause a fire. The materials used in the construction of the roof are subject to special fire resistance requirements. Wooden rafters are treated with fire-retardant impregnations, and when insulating, thermal insulation is used that meets the strict requirements of fire safety rules. The best characteristics are found in slabs made of basalt fiber, which are used as a fire barrier when protecting load-bearing structures.

Conclusion

In order for a pitched roof to fulfill its purpose and reliably protect the house not only from external influences, but also from increased operating costs due to heat loss, it must be well insulated. In this case, living in the attic will be as comfortable as possible without overpayments, and the need for major repairs will not arise soon.

About single-layer insulation - in the previous material. Owners of wooden houses will find the article about insulating a timber house with stone wool useful. The video shows how to choose and lay stone wool correctly.

Subscribe to our Telegram channelExclusive posts every week

Which roof insulation is best?

Manufacturers offer roofing materials with different design features. Which insulation from our TOP-8 turned out to be better? There is no universal solution. When choosing, it is necessary to take into account thermal characteristics, operating conditions and the construction budget. Our experts recommend:

- Isorok Ultralight P-33 - for insulating the attic floor;

- Rockwool Light Butts Scandic - for construction sites located far from shopping centers - a small volume will help save on transportation costs;

- Isover C-000176898 – rolled roof insulation 150 mm thick will help reduce the time required to complete the work;

- HeatKnauf TR 037 Aquastatik is the best material for working in conditions of high humidity;

- Penoplex Comfort is reliable protection against heat loss on existing roofs.

What should be the perfect insulation for a home? Only materials with low thermal conductivity and long service life are worthy of the status of the best in their segment.

Reviews

There is no consensus on the best type of insulation for such roofs, but most owners recommend insulating attic slopes with mineral wool with a density of 45-50 kg/m³ and a layer thickness of 200 mm.

The best reviews are from specialized roofing brands Rockwool and TechnoNIKOL . Among fiberglass-based roll materials, Ursa is rated positively.

In addition to brands, construction forums often discuss the permissibility of combining different materials (in particular, mineral wool and polystyrene foam or polystyrene foam) and the choice of the best materials for closing the insulating layer from the inside.

On the first question, there is again no general opinion, but most owners do not consider combining heat insulators a good solution (with the exception of heating zones and contact with chimneys). According to the second, plasterboard is recognized as the optimal material.

You can get acquainted with the opinions of builders about various insulation materials here, here and here.

Glass wool

A product of processing glass waste, from which the structure of fragile fibers is subsequently formed. The material is simple and inexpensive, but effective in heat conservation. Partly, the good thermal insulation effect is achieved due to the high density of the products. The form of glass wool insulation is usually tiled, so installation is carried out according to the general technology of fastening mineral wool, but with some differences. Since glass fibers are very fragile, the material requires external protection in the form of film and structural layers. Some time after installation, especially at a large slope, the slab will shrink, so the fixation must be rigid and not allow the slightest deformation.

Despite the hassle of installation, glass wool is widely used in the construction industry as an insulator. It has a lot of other advantages in addition to heat conservation, which include environmental friendliness, fire resistance and biosecurity. But if you plan to live in the attic, then the glass wool insulation will need to be carefully insulated. Its dusting with the release of small particles is dangerous to human and animal health. In addition, it is important to install a waterproofing barrier, since glass wool is sensitive to moisture.

Sawdust

Insulating the attic roof with sawdust is not recommended due to the low performance characteristics of this material. The only advantage is the price. According to other criteria, sawdust is inferior to modern insulation.

- Relatively high thermal conductivity coefficient;

- Spontaneous changes in density under the influence of gravity, the likelihood of voids appearing in the roof structure;

- Combustible material. The effect is reduced when using a solution with gypsum, cement or lime;

- Rotten;

- Habitat for rodents and insects.

The best materials for insulating an attic are basalt wool and polyurethane foam. They have high thermal insulation properties, reduce noise levels and are harmless for use in residential areas.

Common Mistakes

The lack of vapor barrier during insulation leads to the formation of dampness in the floors.

Most often, novice craftsmen make the following mistakes:

- ignoring the installation of vapor barriers, which leads to the formation of dampness in the floors;

- improper installation of the drainage system;

- installing a thin layer of insulation, which leads to overheating and freezing of the attic;

- leaving the joints of waterproofing sheets open;

- excessive tension of the vapor-permeable film, which leads to its rupture during cooling.

To avoid mistakes, you need to follow the instructions of the material manufacturers, the recommendations of professionals and the construction plan.

Polyurethane foam

Spraying polyurethane foam is a good way to insulate an attic. In addition, the material has the following properties:

- Excellent degree of thermal protection.

- Possibility of insulation without a frame and special fastenings.

- The absence of seams, which are always conductors of cold.

- Creating tightness in hard-to-reach places.

- No reaction with any roofing material, excellent resistance to moisture and vapor permeability.

- Good grip on any surface.

- Polyurethane foam is not afraid of rodents and insects, and is also not affected by mold and rot.

But polyurethane foam still has a drawback: it cannot be applied independently without special equipment.

Ecowool

A relatively new insulating material that appeared with the wave of fashion for green construction. The main set of components for the production of ecowool includes recycled waste paper, cellulose and, in general, waste from the wood processing industry. This attic insulation will be beneficial due to its structure, which adapts to any conditions of use. The material is produced in the form of loose filler, which requires manual laying or spraying. In other words, there are no design restrictions for installation.

The optimal installation option involves filling the niches in the sheathing. It may be difficult to insulate a broken mansard roof from the inside with ecowool, but a blow molding tool for wet laying the material will help make the process easier. In this case, the filler is pre-mixed with water and glue, which allows it to be applied as polyurethane foam without any additional fastening operations. Next, all that remains is to cover the work area with finishing materials.

Expanded polystyrene

Belongs to the group of rigid foam plastics. According to production technology, there are two types - pressed (PS) and pressless (PSB).

Thermal conductivity in dry form is almost the same as that of mineral wool. But in real operating conditions it’s a little lower. Therefore, it is usually noted that polystyrene foam has better thermal insulation properties.

One of the most inexpensive thermal insulation materials. Easy to install.

Low water absorption - from tenths of a percent to 2 - 4%. But it is capable of accumulating moisture, which, when frozen, destroys the fragile bonds between the individual “capsules” of the material.

The main disadvantage in operating conditions of an attic roof is low vapor permeability. When insulating in several layers, some of the wooden structural elements may end up between the insulation and the vapor barrier (for example, sheathing or counter-lattice). This can lead to the wood getting wet and the appearance of rot, which can already “infect” the supporting structure.

The second disadvantage is flammability. Although they produce “self-extinguishing” polystyrene foam PSB-S with fire retardant additives (it is a low-flammable material), it also emits toxic gases upon contact with fire.

Foam plastics are not noise-absorbing materials. Under certain conditions (as part of structures with thin-sheet cladding) they can even amplify noise at certain frequencies.

Styrofoam

The cheapest insulation option for the attic is polystyrene foam. It is lightweight, so the work can be done independently, without the involvement of experienced craftsmen. This property is especially important when insulating sloping roof walls.

Polystyrene foam is an excellent soundproofing material, as it has several levels of density. In addition, it is not characterized by shrinkage during operation.

The density of insulation for an attic roof in this case shows the degree of its resistance to mechanical loads, but denser foam plastic is less resistant to fire. Therefore, to insulate the attic roof, you can choose materials with less rigidity, since in this place significant loads will not be placed on the insulation.

Natural wool

In some regions, natural wool or felt is used as roof insulation. These materials have good vapor permeability and excellent thermal insulation properties.

Wool can be used independently, but its use in a roofing pie is considered more effective.

For the Caucasian region, wool is the most affordable insulation material, which gives a great advantage over ready-made, more expensive materials. But in this case, do not forget about insects and rodents that can live in natural material.