Comfortable living conditions in winter depend entirely on the adequacy of the heat supply to residential premises. If this is a new building, for example, on a summer cottage or personal plot, then you need to know how to calculate heating radiators for a private house.

How to calculate heating radiators for a private house

All operations boil down to calculating the number of radiator sections and are subject to a clear algorithm, so there is no need to be a qualified specialist - every person will be able to make a fairly accurate thermal calculation of their home.

Specified and actual heat transfer of the radiator

The parameters of any heating device are indicated in the technical passport.

Typically, manufacturers declare the power of 1 standard section with an interaxle size of 500 mm within the range of 170...200 watts. The characteristics of aluminum and bimetallic radiators are approximately the same. The trick is that the heat transfer rating cannot be stupidly used to select the number of sections. According to clause 3.5 of GOST 31311-2005, the manufacturer is required to indicate the battery power under the following operating conditions:

- the coolant moves through the radiator from top to bottom (diagonal or side connection);

- temperature difference is 70 degrees;

- the flow rate of water flowing through the device is 360 kg/hour.

Let’s explain the essence of the problem; to do this, substitute the known values of ΔT = 70 °C and room temperature – plus 20 °C into the formula, and perform the reverse calculation:

- tsupply + treturn = (ΔT + tair) x 2 = (70 + 20) x 2 = 180 °C.

- According to the standards, the calculated difference in coolant temperatures between the supply and return lines should be 20 degrees. This means that the water coming from the boiler needs to be heated to 100 °C, the return water will cool to 80 °C.

- The 100/80 °C operating mode is not available for domestic heating installations; the maximum heating is 80 degrees. In addition, maintaining the specified coolant temperature is not economically profitable (remember, we took the average value of 65 °C).

Conclusion. In real conditions, the battery will give off much less heat than specified in the operating instructions. The reason is the lower value of ΔT - the temperature difference between water and ambient air. According to our initial data, the ΔT indicator is 130 / 2 - 22 = 43 degrees, almost half the declared norm.

Adjustment depending on heating system mode

Manufacturers indicate the maximum power of radiators in the passport data: in high-temperature mode of use - the coolant temperature in the supply is 90 o C, in the return - 70 o C (indicated by 90/70) in the room there should be 20 o C. But in this mode, modern systems The heating works very rarely. Typically, a medium power mode of 75/65/20 or even a low temperature mode with parameters of 55/45/20 is used. It is clear that the calculation needs to be adjusted.

To take into account the operating mode of the system, it is necessary to determine the temperature pressure of the system. Temperature pressure is the difference between the temperature of the air and the heating devices. In this case, the temperature of the heating devices is considered as the arithmetic average between the supply and return values.

It is necessary to take into account the characteristics of the premises and climate in order to correctly calculate the number of radiator sections

To make it clearer, we will calculate cast iron heating radiators for two modes: high temperature and low temperature, standard size sections (50cm). The room is the same: 16m2. One cast iron section heats 1.5 m 2 in high temperature mode 90/70/20. Therefore, we need 16m 2 / 1.5 m 2 = 10.6 pcs. Round up - 11 pcs. The system plans to use a low temperature mode of 55/45/20. Now let’s find the temperature difference for each of the systems:

- high temperature 90/70/20- (90+70)/2-20=60 o C;

- low temperature 55/45/20 - (55+45)/2-20=30 o C.

That is, if a low-temperature operating mode is used, twice as many sections will be needed to provide the room with heat. For our example, a room of 16 m2 requires 22 sections of cast iron radiators. The battery turns out to be big. This, by the way, is one of the reasons why this type of heating device is not recommended for use in networks with low temperatures.

With this calculation, you can also take into account the desired air temperature. If you want the room to be not 20 o C, but, for example, 25 o C, simply calculate the thermal pressure for this case and find the desired coefficient. Let's do the calculation for the same cast iron radiators: the parameters will be 90/70/25. We calculate the temperature difference for this case (90+70)/2-25=55 o C. Now we find the ratio 60 o C/55 o C=1.1. To ensure a temperature of 25 o C you need 11 pcs * 1.1 = 12.1 pcs.

How to correctly calculate the actual heat transfer of batteries

You should always start with the technical data sheet that is attached to the product by the manufacturer. In it you will definitely find the data you are interested in, namely the thermal power of one section or panel radiator of a certain standard size. But do not rush to admire the excellent performance of aluminum or bimetallic batteries; the figure indicated in the passport is not final and requires adjustment, for which you need to calculate the heat transfer.

You can often hear the following judgments: the power of aluminum radiators is the highest, because it is well known that the heat transfer of copper and aluminum is the best among other metals. Copper and aluminum have the best thermal conductivity, this is true, but heat transfer depends on many factors, which will be discussed below.

The heat transfer stated in the heating device’s passport corresponds to the truth when the difference between the average temperature of the coolant (supply t + return t)/2 and in the room is 70 °C. Using the formula, this is expressed as follows:

For reference. In the documentation for products from different companies, this parameter can be designated differently: dt, Δt or DT, and sometimes it is simply written “at a temperature difference of 70 °C”.

What does it mean when the documentation for a bimetallic radiator says: the thermal power of one section is 200 W at DT = 70 °C? The same formula will help you figure it out, but you just need to substitute the known value of room temperature – 22 °C – into it and carry out the calculation in reverse order:

Knowing that the temperature difference in the supply and return pipelines should not be more than 20 °C, their values must be determined as follows:

Now it is clear that 1 section of the bimetallic radiator from the example will give off 200 W of heat, provided that there is water heated to 102 °C in the supply pipeline, and a comfortable temperature of 22 °C is established in the room. The first condition is impossible to fulfill, since in modern boilers heating is limited to 80 °C, which means that the battery will never be able to deliver the declared 200 W of heat. And it is a rare case that the coolant in a private house is heated to such an extent; the usual maximum is 70 °C, which corresponds to DT = 38-40 °C.

Calculation procedure

It turns out that the actual power of the heating battery is much lower than stated in the passport, but to select it you need to understand how much. There is a simple way to do this: applying a reduction factor to the initial value of the heater’s thermal power. Below is a table that shows the values of the coefficients by which you need to multiply the heat transfer rating of the radiator depending on the DT value:

The algorithm for calculating the real heat transfer of heating devices for your individual conditions is as follows:

- Determine what the temperature in the house and water in the system should be.

- Substitute these values into the formula and calculate your real Δt.

- Find the corresponding coefficient in the table.

- Multiply the rated heat transfer value of the radiator by it.

- Calculate the number of heating devices needed to heat the room.

For the example above, the thermal power of 1 section of a bimetallic radiator will be 200 W x 0.48 = 96 W. Therefore, to heat a room with an area of 10 m2, you will need 1 thousand W of heat or 1000/96 = 10.4 = 11 sections (rounding always goes up).

The presented table and calculation of the heat transfer of batteries should be used when the documentation indicates Δt equal to 70 °C. But it happens that for different devices from some manufacturers the radiator power is given at Δt = 50 °C. Then you can’t use this method, it’s easier to dial the required number of sections according to the passport characteristics, just take their number with a margin of one and a half.

For reference. Many manufacturers indicate heat transfer values under the following conditions: supply t = 90 °C, return t = 70 °C, air t = 20 °C, which corresponds to Δt = 50 °C.

Calculation of different types of radiators

If you are planning to install sectional radiators of a standard size (with an axial distance of 50 cm in height) and have already chosen the material, model and desired size, there should not be any difficulties in calculating their number. Most reputable companies that supply good heating equipment have on their website the technical data of all modifications, including thermal power. If it is not the power that is indicated, but the coolant flow rate, then it is easy to convert to power: the coolant flow rate of 1 l/min is approximately equal to the power of 1 kW (1000 W).

The axial distance of the radiator is determined by the height between the centers of the holes for supplying/removing coolant.

To make life easier for customers, many websites install a specially designed calculator program. Then the calculation of heating radiator sections comes down to entering data on your premises in the appropriate fields. And at the output you have the finished result: the number of sections of this model in pieces.

The axial distance is determined between the centers of the coolant holes

But if you’re just evaluating possible options, then it’s worth considering that radiators of the same size made of different materials have different thermal power. The method for calculating the number of sections of bimetallic radiators is no different from calculating aluminum, steel or cast iron. Only the thermal power of one section can be different.

To make it easier to calculate, there are averaged data that you can use as a guide. For one radiator section with an axial distance of 50 cm, the following power values are accepted:

- aluminum - 190W

- bimetallic - 185W

- cast iron - 145W.

If you are just figuring out which material to choose, you can use this data. For clarity, we present the simplest calculation of sections of bimetallic heating radiators, which takes into account only the area of the room.

Example Method

A simplified version of the calculations is based on taking several indicators as a standard:

In a room with ordinary ceilings, 1 section of the battery will heat 1.8 m2. For example, if the room is 14 m2. 14: 1.8 = 7.7. Round up = 8 sections.

Or like this:

In a room with 1 window and 1 external wall, 1 kW of radiator power can heat 10 m2. Example: room 14 m2. 14:10 = 1.4. That is, for such a room you need a heater with a power of 1.4 kW.

Such methods can be used for approximate calculations, but they are fraught with serious errors.

If the results of the calculations are a long radiator of more than 10 sections, then it makes sense to divide it into two separate radiators.

Practical example of calculating thermal power

Initial data:

- A corner room without a balcony on the second floor of a two-story cinder block plastered house in a windless region of Western Siberia.

- Room length 5.30 m X width 4.30 m = area 22.79 sq.m.

- Window width 1.30 m X height 1.70 m = area 2.21 sq.m.

- Room height = 2.95 m.

Calculation sequence:

| Room area in sq.m.: | S = 22.79 |

| Window orientation – south: | R = 1.0 |

| Number of external walls – two: | K = 1.2 |

| Insulation of external walls is standard: | U=1.0 |

| Minimum temperature – up to -35°C: | T=1.3 |

| Room height – up to 3 m: | H=1.05 |

| The upstairs room is an uninsulated attic: | W=1.0 |

| Frames – single-chamber double-glazed windows: | G=1.0 |

| The ratio of window and room areas is up to 0.1: | X = 0.8 |

| Radiator position – under the window sill: | Y=1.0 |

| Radiator connection – diagonally: | Z=1.0 |

| Total (remember to multiply by 100): | Q = 2,986 Watts |

Below is a description of calculating the number of radiator sections and the required number of batteries. It is based on the obtained results of thermal power, taking into account the dimensions of the proposed installation locations of heating devices.

Regardless of the results, it is recommended to equip not only window sill niches with radiators in corner rooms. Batteries should be installed near “blind” external walls or near corners that are subject to the greatest freezing under the influence of street cold.

Simple area calculations

You can calculate the size of heating batteries for a specific room based on its area. This is the easiest way - to use plumbing standards, which stipulate that a thermal power of 100 W per hour is needed to heat 1 sq.m. We must remember that this method is used for rooms with standard ceiling heights (2.5-2.7 meters), and the result is somewhat inflated. In addition, it does not take into account such features as:

- number of windows and type of double-glazed windows on them;

- the number of external walls in the room;

- the thickness of the building walls and what material they are made of;

- type and thickness of insulation used;

- temperature range in a given climate zone.

The heat that radiators must provide to heat the room: the area should be multiplied by the thermal power (100 W). For example, for a room of 18 sq.m the following power of the heating battery is required:

18 sq.m x 100 W = 1800 W

That is, 1.8 kW of power is needed per hour to heat 18 square meters. This result must be divided by the amount of heat that the heating radiator section produces per hour. If the data in his passport indicates that this is 170 W, then the next stage of the calculation looks like this:

1800 W / 170 W = 10.59

This number must be rounded to the nearest whole number (usually rounded up) - it will be 11. That is, in order for the temperature in the room to be optimal during the heating season, it is necessary to install a heating radiator with 11 sections.

This method is only suitable for calculating the battery size in rooms with central heating, where the coolant temperature is not higher than 70 degrees Celsius.

There is a simpler method that can be used for normal apartment conditions in panel houses. This approximate calculation takes into account that one section is needed to heat 1.8 square meters of area. In other words, the area of the room must be divided by 1.8. For example, with an area of 25 sq.m., 14 parts are needed:

25 sq.m / 1.8 sq.m = 13.89

But this calculation method is unacceptable for a radiator of reduced or increased power (when the average output of one section varies from 120 to 200 W).

How to calculate radiator sections by room volume

This calculation takes into account not only the area, but also the height of the ceilings, because all the air in the room needs to be heated. So this approach is justified. And in this case the technique is similar. We determine the volume of the room, and then, according to the standards, we find out how much heat is needed to heat it:

- in a panel house, heating a cubic meter of air requires 41 W;

- in a brick house per m 3 - 34 W.

You need to heat the entire volume of air in the room, so it is more correct to calculate the number of radiators by volume

Let's calculate everything for the same room with an area of 16m2 and compare the results. Let the ceiling height be 2.7m. Volume: 16*2.7=43.2m3.

Next we will calculate for options in a panel and brick house:

- In a panel house. The heat required for heating is 43.2m 3 *41V=1771.2W. If we take all the same sections with a power of 170 W, we get: 1771 W/170 W = 10,418 pcs (11 pcs).

- In a brick house. The heat needed is 43.2m 3 *34W=1468.8W. We count the radiators: 1468.8W/170W=8.64pcs (9pcs).

As you can see, the difference is quite large: 11 pieces and 9 pieces. Moreover, when calculating by area, we got the average value (if rounded in the same direction) - 10 pcs.

The most accurate calculation option

From the above calculations, we saw that none of them is perfectly accurate, because... Even for identical rooms, the results, albeit slightly, are still different.

If you need maximum calculation accuracy, use the following method. It takes into account many coefficients that can affect heating efficiency and other significant indicators.

In general, the calculation formula is as follows:

T=100 W/m2 *A *B * C * D * E * F * G * S,

- where T is the total amount of heat required to heat the room in question;

- S – area of the heated room.

The remaining coefficients require more detailed study. Thus, coefficient A takes into account the characteristics of the glazing of the room.

Features of room glazing

The values are as follows:

- 1.27 for rooms whose windows are glazed with just two glasses;

- 1.0 – for rooms with windows equipped with double glazing;

- 0.85 – if the windows have triple glazing.

Coefficient B takes into account the insulation features of the walls of the room.

Features of insulation of room walls

The dependency is as follows:

- if the insulation is low-effective, the coefficient is taken equal to 1.27;

- with good insulation (for example, if the walls are laid with 2 bricks or are purposefully insulated with a high-quality heat insulator), a coefficient of 1.0 is used;

- with a high level of insulation - 0.85.

Coefficient C indicates the ratio of the total area of window openings and the floor surface in the room.

The ratio of the total area of window openings and the floor surface in the room

The dependency looks like this:

- with a ratio of 50%, coefficient C is taken as 1.2;

- if the ratio is 40%, use a coefficient equal to 1.1;

- with a ratio of 30%, the coefficient value is reduced to 1.0;

- in the case of an even smaller percentage, coefficients equal to 0.9 (for 20%) and 0.8 (for 10%) are used.

Coefficient D indicates the average temperature during the coldest period of the year.

Heat distribution in a room when using radiators

The dependency looks like this:

- if the temperature is -35 and below, the coefficient is taken equal to 1.5;

- at temperatures up to -25 degrees, a value of 1.3 is used;

- if the temperature does not drop below -20 degrees, the calculation is carried out with a coefficient of 1.1;

- residents of regions where the temperature does not drop below -15 should use a coefficient of 0.9;

- if the temperature in winter does not fall below -10, count with a coefficient of 0.7.

The E coefficient indicates the number of external walls.

Number of external walls

If there is only one external wall, use a factor of 1.1. With two walls, increase it to 1.2; with three – up to 1.3; if there are 4 external walls, use a coefficient of 1.4.

The F coefficient takes into account the features of the room above. The dependency is:

- if there is an unheated attic space above, the coefficient is taken equal to 1.0;

- if the attic is heated - 0.9;

- if the neighbor above is a heated living room, the coefficient can be reduced to 0.8.

And the last coefficient of the formula - G - takes into account the height of the room.

Room height

The order is as follows:

- in rooms with ceilings 2.5 m high, the calculation is carried out using a coefficient of 1.0;

- if the room has a 3-meter ceiling, the coefficient is increased to 1.05;

- with a ceiling height of 3.5 m, count with a factor of 1.1;

- rooms with a 4-meter ceiling are calculated with a coefficient of 1.15;

- when calculating the number of battery sections for heating a room 4.5 m high, increase the coefficient to 1.2.

This calculation takes into account almost all existing nuances and allows you to determine the required number of sections of the heating unit with the smallest error. In conclusion, all you have to do is divide the calculated figure by the heat transfer of one section of the battery (check in the attached data sheet) and, of course, round the found number up to the nearest integer value.

Heating radiator calculator

For convenience, all these parameters are included in a special calculator for calculating heating radiators. It is enough to indicate all the requested parameters - and clicking on the “CALCULATE” button will immediately give the desired result:

Energy Saving TipsEnergy Saving Tips

Happy calculations!

Determining the number of radiators for single-pipe systems

There is another very important point: all of the above is true for a two-pipe heating system, when a coolant with the same temperature enters the input of each radiator. A single-pipe system is considered much more complex: there, increasingly colder water flows to each subsequent heating device. And if you want to calculate the number of radiators for a one-pipe system, you need to recalculate the temperature every time, and this is difficult and time-consuming. Which exit? One of the possibilities is to determine the power of the radiators as for a two-pipe system, and then, in proportion to the drop in thermal power, add sections to increase the heat transfer of the battery as a whole.

In a single-pipe system, increasingly colder water flows to each radiator

Let's explain with an example. The diagram shows a single-pipe heating system with six radiators. The number of batteries was determined for two-pipe wiring. Now we need to make an adjustment. For the first heating device everything remains the same. The second one receives coolant with a lower temperature. We determine the % drop in power and increase the number of sections by the corresponding value. In the picture it turns out like this: 15kW-3kW=12kW. We find the percentage: the temperature drop is 20%. Accordingly, to compensate, we increase the number of radiators: if 8 pieces were needed, there will be 20% more - 9 or 10 pieces. This is where knowing the room will come in handy: if it’s a bedroom or a children’s room, round up, if it’s a living room or other similar room, round down. You also take into account the location relative to the cardinal directions: in the north you round up, in the south you round down.

In single-pipe systems, it is necessary to add sections to radiators located further along the branch

This method is clearly not ideal: after all, it turns out that the last battery in the branch will have to be simply enormous in size: judging by the diagram, a coolant with a specific heat capacity equal to its power is supplied to its input, and in practice it is unrealistic to remove all 100%. Therefore, usually when determining the power of a boiler for single-pipe systems, they take a certain reserve, install shut-off valves and connect radiators through a bypass so that the heat transfer can be adjusted and thus compensate for the drop in coolant temperature. One thing follows from all this: the number and/or size of radiators in a single-pipe system must be increased, and more and more sections must be installed as you move away from the beginning of the branch.

Technical characteristics of cast iron radiators

The technical parameters of cast iron batteries are related to their reliability and endurance. The main characteristics of a cast iron radiator, like any heating device, are heat transfer and power. As a rule, manufacturers indicate the power of cast iron heating radiators for one section. The number of sections may vary. As a rule, from 3 to 6. But sometimes it can reach 12. The required number of sections is calculated separately for each apartment.

The number of sections depends on a number of factors:

- room area;

- room height;

- number of windows;

- floor;

- presence of installed double-glazed windows;

- corner placement of the apartment.

The price given for cast iron heating radiators is per section, and may vary depending on the manufacturer. The heat dissipation of batteries depends on what material they are made of. In this regard, cast iron is inferior to aluminum and steel.

Other technical parameters include:

- maximum operating pressure – 9-12 bar;

- maximum coolant temperature – 150 degrees;

- one section holds about 1.4 liters of water;

- the weight of one section is approximately 6 kg;

- section width 9.8 cm.

Such batteries should be installed with a distance between the radiator and the wall of 2 to 5 cm. The installation height above the floor should be at least 10 cm. If there are several windows in the room, the batteries should be installed under each window. If the apartment is corner, then it is recommended to insulate the walls externally or increase the number of sections.

It should be noted that cast iron batteries are often sold unpainted. In this regard, after purchase, they must be coated with a heat-resistant decorative composition and must first be stretched.

Among domestic radiators, one can distinguish the ms 140 model. For cast iron heating radiators ms 140, the technical specifications are given below:

- heat transfer of the MS section 140 – 175 W;

- height – 59 cm;

- The radiator weighs 7 kg;

- capacity of one section - 1.4 l;

- section depth is 14 cm;

- section power reaches 160 W;

- section width is 9.3 cm;

- the maximum coolant temperature is 130 degrees;

- maximum operating pressure – 9 bar;

- the radiator has a sectional design;

- crimping pressure is 15 bar;

- the volume of water in one section is 1.35 liters;

- Heat-resistant rubber is used as a material for intersection gaskets.

It is worth noting that MS 140 cast iron radiators are reliable and durable. And the price is quite affordable. Which determines their demand in the domestic market.

Features of choosing cast iron radiators

To choose which cast iron heating radiators are best suited for your conditions, you need to take into account the following technical parameters:

- heat dissipation Select based on the size of the room;

- radiator weight;

- power;

- dimensions: width, height, depth.

To calculate the thermal power of a cast iron battery, you need to be guided by the following rule: for a room with 1 outer wall and 1 window, you need 1 kW of power per 10 sq.m. room area; for a room with 2 external walls and 1 window - 1.2 kW; for heating a room with 2 external walls and 2 windows - 1.3 kW.

If you decide to buy cast iron heating radiators, you should consider the following nuances:

- if the ceiling is higher than 3 m, the required power will increase proportionally;

- if the room has double-glazed windows, then the battery power can be reduced by 15%;

- If there are several windows in the apartment, then a radiator must be installed under each of them.

Modern market

Imported batteries have a perfectly smooth surface, they are of higher quality and look more aesthetically pleasing. True, their cost is high.

Among domestic analogues, we can highlight cast iron radiators Konner, which are in good demand today. They are characterized by a long service life, reliability, and fit perfectly into a modern interior. Konner heating cast iron radiators are available in any configuration.

- How to fill water into an open and closed heating system?

- Popular floor-standing gas boiler made in Russia

- How to properly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes for malfunctions

Recommended reading

2016–2017 — Leading heating portal. All rights reserved and protected by law

Copying site materials is prohibited. Any copyright infringement will result in legal liability. Contacts

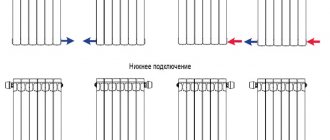

Dependence of radiator power on connection and location

In addition to all the parameters described above, the heat transfer of the radiator varies depending on the type of connection. A diagonal connection with a supply from above is considered optimal; in this case, there is no loss of thermal power. The largest losses are observed with lateral connections - 22%. All others are average in efficiency. Approximate percentage losses are shown in the figure.

Heat loss on radiators depending on connection

The actual power of the radiator also decreases in the presence of obstructing elements. For example, if a window sill hangs from above, the heat transfer drops by 7-8%; if it does not completely block the radiator, then the loss is 3-5%. When installing a mesh screen that does not reach the floor, the losses are approximately the same as in the case of an overhanging window sill: 7-8%. But if the screen completely covers the entire heating device, its heat transfer is reduced by 20-25%.

The amount of heat depends on the installation

The amount of heat depends on the installation location

Heat transfer of one section

Today there is a wide range of radiators. While most are similar in appearance, thermal performance may differ significantly. They depend on the material from which they are made, on the dimensions, wall thickness, internal cross-section and on how well the design is thought out.

Therefore, it is possible to say exactly how many kW in 1 section of an aluminum (cast-iron bimetallic) radiator only in relation to each model. This data is provided by the manufacturer. After all, there is a significant difference in size: some of them are tall and narrow, others are low and deep. The power of a section of the same height from the same manufacturer, but of different models, may differ by 15-25 W (see the table below STYLE 500 and STYLE PLUS 500). There may be even more noticeable differences between different manufacturers.

Technical characteristics of some bimetallic radiators

Please note that the thermal power of sections of the same height may have a noticeable difference. However, for a preliminary assessment of how many battery sections are needed for space heating, we calculated the average thermal power values for each type of radiator

They can be used for approximate calculations (data are given for batteries with an interaxial distance of 50 cm):

However, for a preliminary assessment of how many battery sections are needed for space heating, average thermal power values were calculated for each type of radiator. They can be used for approximate calculations (data are given for batteries with an interaxial distance of 50 cm):

- Bimetallic - one section produces 185 W (0.185 kW).

- Aluminum - 190 W (0.19 kW).

- Cast iron - 120 W (0.120 kW).

More precisely, how many kW can you have in one section of a bimetallic, aluminum or cast iron radiator when you choose a model and decide on the dimensions. The difference in cast iron batteries can be very big. They are available with thin or thick walls, which causes their thermal output to change significantly. Above are the average values for batteries of the usual shape (accordion) and those close to it. Retro-style radiators have significantly lower thermal output.

These are the technical characteristics of cast iron radiators from the Turkish company Demir Dokum. The difference is more than significant. She could be even bigger

Based on these values and average standards in SNiP, the average number of radiator sections per 1 m2 was calculated:

- the bimetallic section will heat 1.8 m2;

- aluminum - 1.9-2.0 m2;

- cast iron - 1.4-1.5 m2;

How to calculate the number of radiator sections using this data? It's still simpler. If you know the area of the room, divide it by the coefficient. For example, a room of 16 m2, to heat it you will need approximately:

- bimetallic 16 m2 / 1.8 m2 = 8.88 pcs, rounded - 9 pcs.

- aluminum 16 m2 / 2 m2 = 8 pcs.

- cast iron 16 m2 / 1.4 m2 = 11.4 pcs, rounded up - 12 pcs.

These calculations are only approximate. Using them, you can roughly estimate the costs of purchasing heating appliances. You can accurately calculate the number of radiators per room by choosing a model, and then recalculating the number depending on the temperature of the coolant in your system.

Dependence of the degree of heat transfer on the connection method

The heat transfer of heating radiators is affected not only by the material of manufacture and the temperature of the coolant circulating through the pipes, but also by the chosen option for connecting the device to the system:

- The connection is direct one way

. It is the most favorable in relation to the thermal power indicator. For this reason, the calculation of the heat transfer of a heating radiator is performed precisely with a direct connection. - Diagonal connection

. It is used if you plan to connect a radiator to the system in which the number of sections exceeds 12. This method allows you to minimize heat loss. - Bottom connection

. It is used when the battery is connected to a floor screed in which the heating system is hidden. As the calculation of the heat transfer of the radiator shows, with such a connection, the loss of thermal energy does not exceed 10%. - Single pipe connection

. The least profitable method in terms of thermal power. Heat transfer losses with a single-pipe connection most often reach 25 - 45%.

Specific thermal power of battery sections

Even before performing a general calculation of the required heat transfer of heating devices, it is necessary to decide what material the collapsible batteries will be installed in the premises from.

The choice should be based on the characteristics of the heating system (internal pressure, coolant temperature). At the same time, do not forget about the greatly varying costs of purchased products.

How to correctly calculate the required number of different batteries for heating will be discussed further.

At a coolant temperature of 70 °C, standard 500 mm sections of radiators made of dissimilar materials have unequal specific thermal power “q”.

- Cast iron - q = 160 Watt (power density of one cast iron section). Radiators made of this metal are suitable for any heating system.

- Steel - q = 85 Watt . Steel tubular radiators can operate in the harshest operating conditions. Their sections are beautiful in their metallic shine, but have the lowest heat transfer.

- Aluminum - q = 200 Watt . Lightweight, aesthetic aluminum radiators should be installed only in autonomous heating systems in which the pressure is less than 7 atmospheres. But their sections have no equal in terms of heat transfer.

- Bimetal - q = 180 Watt . The insides of bimetallic radiators are made of steel, and the heat-dissipating surface is made of aluminum. These batteries will withstand all pressure and temperature conditions. The specific thermal power of bimetal sections is also high.

The given values of q are rather arbitrary and are used for preliminary calculations. More accurate figures are contained in the passports of the purchased heating devices.

Image gallery

Photo from

Advantages of the sectional assembly principle

Basic rules for assembling heating devices

Sections of an obsolete cast iron battery

Powder coated colored sections

Steel radiator: how many kilowatts in 1 section

Steel radiators are fundamentally different from cast iron, aluminum and bimetallic ones. They are not made in separate sections, but in the form of a solid heating device.

The thermal performance of a steel radiator depends on its height, width, and number of convectors. There are three types of radiators:

- Type 11 – one convector;

- Type 22 – two convectors;

- Type 33 – three convectors.

For convenience, we provide a table of the thermal power of steel radiators (values are given in W).

Heat transfer table for steel radiators.

As in the previous case, the values given are nominal. For a coolant with a temperature of 55-60 °C, the actual heat transfer will be 75-85%, for 65-70 °C - 85-90%.

In the article we give real values of how many kilowatts of heat one radiator section can produce. They are less than the numbers indicated by manufacturers, but we do not deceive our readers.

Don't forget to share the post on social networks!

How to calculate

Different climatic zones of our country for heating apartments according to standard building codes and regulations have their own values. In the middle zone at the latitude of Moscow or the Moscow region, heating 1 square meter of living space with a ceiling height of up to 3 meters will require 100 watts of thermal power.

For example, to heat a room of 20 square meters, you will need to spend 20 × 100 = 2000 Watts of thermal energy. If one section of a cast iron battery has a heat output of 160 watts, then the calculation of the number of sections will look like this: 2000:160=12.5. This means, rounding up, 12 sections or two batteries of 6 sections each.

Similar calculations can be made for other types of radiators:

Disadvantages of simplified calculation

Calculations are carried out based on formulas

A simplified calculation assumes ideal sealing conditions for our apartments. However, here it is necessary to take into account the specific features of the winter period, namely:

- Up to 50% of the heat entering the apartment can evaporate through window openings. Therefore, installing modern double-glazed windows will significantly reduce heat loss.

- Corner apartments require more heat for heating, since their two walls face the street.

- During the heating season, the central heating system does not always work like clockwork. Sometimes fluctuations in coolant temperature, extreme frosts, unplanned gusts or other technical force majeure situations occur. Batteries installed according to calculations will not provide their full heat transfer power. Therefore, when installing radiators, their number should be 20% higher than calculated.

How to take into account effective power

When determining the parameters of a heating system or its individual circuit, one should not discount one of the most important parameters, namely the thermal pressure. It often happens that the calculations are done correctly, and the boiler heats well, but somehow the heat in the house does not work out. One of the reasons for the decrease in thermal efficiency may be the temperature regime of the coolant. The thing is that most manufacturers indicate the power value for a pressure of 60 °C, which occurs in high-temperature systems with a coolant temperature of 80-90 °C. In practice, it often turns out that the temperature in the heating circuits is in the range of 40-70 °C, which means that the temperature pressure value does not rise above 30-50 °C. For this reason, the heat transfer values obtained in the previous sections should be multiplied by the actual pressure, and then the resulting number divided by the value specified by the manufacturer in the data sheet. Of course, the figure obtained as a result of these calculations will be lower than that obtained when calculating using the above formulas.

It remains to calculate the actual temperature difference. It can be found in tables on the Internet, or calculated independently using the formula ΔT = ½ x (Tn + Tk) – Tvn). In it, Tn is the initial temperature of water at the inlet to the battery, Tk is the final temperature of water at the outlet of the radiator, Twn is the temperature of the external environment. If we substitute into this formula the values Tn = 90 °C (high-temperature heating system, which was mentioned above), Tk = 70 °C and Tvn = 20 °C (room temperature), then it is not difficult to understand why the manufacturer focuses on this particular thermal pressure value . Substituting these numbers into the formula for ΔT, we get the “standard” value of 60 °C.

Taking into account not the nameplate, but the real power of thermal equipment, it is possible to calculate the parameters of the system with an acceptable error. All that remains to be done is to make an adjustment of 10-15% in case of abnormally low temperatures and provide in the design of the heating system the possibility of manual or automatic adjustment. In the first case, experts recommend installing ball valves on the bypass and coolant supply branch to the radiator, and in the second, installing thermostatic heads on the radiators. They will allow you to set the most comfortable temperature in each room without releasing heat to the street.

Heating radiator sizes

The standard height of the most popular models of heating devices with the center distance along the connections is 500 millimeters.

These are the batteries that in most cases could be seen about two decades ago in city apartments. Cast iron radiators

. A typical representative of these devices is model MS-140-500-0.9.

The specifications for it include the following overall dimensions of cast iron heating radiators:

- the length of one section is 93 millimeters;

- depth - 140 millimeters;

- height – 588 millimeters.

Calculating the dimensions of a radiator from several sections is not difficult. When the battery consists of 7-10 sections, add 1 centimeter, taking into account the thickness of the paronite gaskets. If the heating battery is to be installed in a niche, it is necessary to take into account the length of the flushing tap, since cast iron radiators with side connections always require flushing. One section provides a heat flow of 160 watts at a temperature difference between the hot coolant and the air in the room of 70 degrees. The maximum working pressure is 9 atmospheres.

Aluminum radiators

. For aluminum heating devices on the market today, with the same center-to-center spacing of the connections, there is a significant variation in the parameters (for more details: “Dimensions of aluminum heating radiators, section volume, preliminary calculations”).

Typical sizes of aluminum heating radiators are:

- the length of one section is 80 millimeters;

- depth 80-100 millimeters;

- height - 575-585 millimeters.

The heat transfer of one section directly depends on the area of its fins and depth. Typically it ranges from 180 to 200 watts. The operating pressure for most models of aluminum batteries is 16 atmospheres. Heating devices are tested with one and a half times higher pressure - this is 24 kgf/cm².

Aluminum radiators have the following feature: the volume of coolant in them is 3 and sometimes 5 times less than in cast iron products. As a result, the high speed of movement of hot water prevents silting and the formation of deposits. Bimetallic radiators

. The steel core in such devices does not in any way affect their appearance and the size of the heating radiators, but the maximum operating pressure increases significantly. Unfortunately, the increased strength of the bimetallic battery leads to high costs. And the price of such a product is already inaccessible to a wide range of consumers.

Bimetallic heating radiators have the following section dimensions:

- length 80-82 millimeters;

- depth - from 75 to 100 millimeters;

- height – minimum 550 and maximum 580 millimeters.

In terms of heat transfer, one bimetallic section is inferior to an aluminum section by about 10-20 watts. The average heat flux is 160-200 watts. Due to the presence of steel, the operating pressure reaches 25-35 atmospheres, and during testing - 30-50 atmospheres.

When arranging a heating structure, you should use pipes that are not inferior in strength to radiators. Otherwise, using durable devices loses all meaning. For bimetallic radiators, only steel liner is used.

A quick way to calculate the number of sections

If we are talking about replacing cast iron radiators with bimetallic ones, you can do without scrupulous calculations

Taking into account several factors:

- The bimetallic section gives a ten percent increase in thermal power compared to cast iron.

- Over time, battery efficiency decreases. This is due to deposits that coat the walls inside the radiator.

- It's better to be warmer.

The number of elements of a bimetallic battery must be the same as that of its predecessor. However, this number increases by 1 - 2 pieces. This is done to combat future decreases in the heater's efficiency.

For a standard room

We already know this method of calculation. It is described at the beginning of the article. Let's analyze it in detail, referring to a specific example. Let's calculate the number of sections for a room of 40 square meters. m.

According to the rules of the 1st quarter. m requires 100 W. Let's assume that the power of one section is 200 W. Using the formula from the first section, we will find the required thermal power of the room. Let's multiply 40 square meters. m. at 100 W, we get 4 kW.

To determine the number of sections, divide this number by 200 W. It turns out that a room of a given area will require 20 sections. The main thing to remember is that the formula is relevant for apartments where the ceiling height is less than 2.7 m.

Cast iron radiators MS-140

i http-equiv="Content-Type" content="text/html; ″>d=”breadCrumb”> Home page»Radiators»Cast iron radiators» MS-140

| MS-140-500 price list MS-140-300 price list |

MS-140 is a two-channel heating device consisting of separate cast iron sections connected to each other by nipples with rubber or paronite gaskets. The large cross-section of the channels allows the coolant to circulate inside the radiator without additional effort, which makes it possible to use it in systems with natural circulation, in the so-called gravity heating systems.

Cast iron radiators have significant thermal inertia, i.e. They react poorly to changes in coolant temperature, take a long time to heat up and take a long time to cool down, so the use of this type of heating devices in heating systems where a weather-dependent or other thermoregulation mode is used is inappropriate.

MS-140 heating radiators are quite heavy and have a rather unattractive design, however, the demand for these heating devices does not weaken due to their availability, both in terms of price and in terms of ease of maintenance and durability. They are supplied primed or painted on pallets with 10 radiators each: 9 radiators in 7 sections and one radiator in 4 sections. If it is necessary to assemble heating devices with a different number of sections from the base, subsequent pressure testing of the radiators is required. Depending on the manufacturer, MS-140 radiators can have an operating pressure of up to 12 atm, a test pressure of up to 18 atm, a nominal heat flux of one radiator section of up to 175 W, and a maximum coolant temperature of up to 130°C.

The main manufacturers and suppliers of cast iron radiators MS-140 to the Russian market are the following enterprises:

Minsk Heating Equipment Plant - the most popular product on the Russian market is Minsk cast iron radiators MS-140. However, in addition to standard radiators, the plant produces heating devices of the following modifications: cast iron design radiators 1K60P-500, radiators with reduced front clearance between sections and improved design 2K60, 2K60P, 2K60PP, 2KPM-90x500, 2KP100-90x500. The above heating devices differ from traditional MS-140 radiators, in addition to their design, in their smaller depth, capacity and higher operating pressure.

Lugansk Foundry-Mechanical Plant is an enterprise that also produces a wide range of competitive products of European quality: traditional cast iron radiators MS-140 with center-to-center distances of 500mm and 300mm; compact, similar in design to KONNER cast iron radiators, heating devices RK-1-100-500; compact and lightweight three-channel cast iron radiators MS - 100 M1 3KP 500 and MS - 100 3KP 300 with center-to-center distances of 500 mm and 300 mm, respectively.

Cheboksary Cast Iron Radiator Plant - the plant produces both traditional MS-140 radiators and modified CHE.RAD radiators, which have a more attractive design, compact size and lower capacity. A special feature of these heating devices is the presence in the model range of 2- and 3-channel radiators with a depth of 102 mm and 120 mm, respectively.

Lyubokhonsky Iron Foundry - produces cast iron radiators MS-140, MS-110, MS-85. A special feature of the model range is the presence of radiators with a depth of 110mm and 85mm. These are compact heating devices with a higher - 12 atm - excess pressure and an updated design. Radiators are supplied primed and painted.

Nizhny Tagil Boiler and Radiator Plant - the enterprise produces traditional radiators MS-140 with a center-to-center distance of 500mm and 300mm - MS-140M2-500 and MS-140M-300 with heat output of 160W and 117W, respectively, as well as a model of cast iron sectional radiators T90 - heating devices with improved design, depth 90mm, center distance 500mm and heat output 127W per section. All NTKRZ radiators are supplied assembled in 4 and 7 sections in a primed form.

| Conner | Guratec | Sti | Che.Rad |

| Home | 2003 kck20 |

Painting

It can be carried out using any type of composition, but under one condition: the solution must be resistant to high temperatures.

The surface of the heating radiator is painted using a regular or curved brush. First, gloves are put on your hands and gauze, foam rubber or rags are placed nearby. They can be used to wipe off paint that has flowed down the brush handle.

The dyeing process is as follows:

- Use a flexible brush to update the appearance of hard-to-reach places (they are located between the pipes of the sections). In some parts the brush will not touch the cast iron. You can use gauze folded into a tourniquet. It is placed between the sections, paint is applied to the middle and then the ends are pulled in turn. This way the paint will adhere to the alloy.

- Paint the top and easily accessible places.

- Always moving from top to bottom. It is better to apply the paint in several layers.

Types of heat exchangers

A heating radiator is a device that consists of sections combined into a single device through which a heated coolant moves—usually water. Compartment - a battery element, usually a cast two-tubular structure, capable of radiating heat, which is transferred to the surrounding air, which allows you to create a comfortable atmosphere in the apartment.

According to their design, heating devices are divided into panel and sectional. There are also registers - a tubular product with a large diameter, or a shaped coil (a heated towel rail in the bathroom), they cut into the system.

Heating devices are: steel, cast iron, aluminum, copper. Cast iron products, which we are used to seeing in our homes, need painting to give a good appearance.

Cast iron

Products made of cast iron are the most common; they have a simple shape and design. They are mounted and on legs.

Manufactured by casting. These are massive structures that store heat for a long time; in terms of operation, they are the most profitable.

Pros:

- transfer heat well;

- resistant to corrosion;

- durable, last at least 30 years;

- not picky about water quality.

Minuses:

- heavy, difficult to install;

- bad design.

Steel

Steel heat exchangers come in panel and tubular types.

Panel models are made of metal 1.5 mm thick, so they have a small thermal capacity. This quality allows you to quickly adjust the temperature. They are efficient in operation, their efficiency reaches 75%. The advantages also include low cost and simple operation. Disadvantage: poor corrosion resistance.

Tubular varieties have all the advantages of the panel type, but unlike them, they have a high pressure level of 9 - 16 bar, the first 7 - 9. And the heating power (120 - 1600 W) and water heating (120) are equal for both models.

Aluminum

Aluminum heat exchangers are recommended for private buildings with autonomous heat supply. This model is not intended for use in centralized heating, as it is exposed to low-quality coolant. Presented on the Russian market.

Aluminum batteries are cast and extruded:

- cast - have several compartments, they are durable, with thicker walls and wide channels for water;

- extrusion - according to production technology, the device is extruded from an aluminum alloy mechanically, resulting in a solid product, but the number of compartments cannot be increased.

All aluminum batteries have high thermal output, they are lightweight and easy to install. Externally they look presentable. In terms of pressure and temperature levels, they can be equated to steel products.

Bimetallic

Bimetallic heat exchanger - tubular steel core and aluminum body. It is durable and reliable, able to withstand high pressure. Despite its low inertness, it has increased heat transfer with low water consumption. Outwardly it looks presentable and is not difficult to care for.

The main disadvantage is the high price.

Copper

Copper has been used for the manufacture of heat exchangers for a long time, but such models have become widely used recently. Since heating systems require a refined type of copper, and new technologies have made its production inexpensive.

With the same technical indicators as other models, they weigh less and heat transfer is higher. This property significantly reduces electricity costs.

Copper has increased mechanical strength, so pipes can be used in combination with water heated to 150 degrees, at a pressure of 16 atmospheres.

Tips and tricks

The efficiency of a heating system depends on many factors

But, as is clear from the information above, heating costs can be optimized by paying attention to the following factors:

- It has been established that the main losses of thermal energy occur in the upper part of the house and range from 25-30% with an uninsulated roof.

- Losses due to insufficiently insulated floors are also significant.

- The material from which the walls are made matters. Being installed from concrete blocks or cast walls, enclosing structures quickly lose heat to the outside space, which requires additional costs to warm them up and maintain them in this condition for a long time.

- Floor insulation is of particular importance. Being constantly cold, it creates uncomfortable living conditions and creates a lot of inconvenience. In addition, heated floors significantly reduce the temperature of the main heating circuit, which saves fuel resources. But it should be remembered that the surface temperature of the heated floor should not exceed 30 degrees. Otherwise, rising convection currents arise, raising dust from the floor, which is harmful to humans.

Thus, after reading this article, you will be able to independently calculate the required number of sections for radiators using formulas and check the correctness of the information received using a calculator.

Bimetallic radiators features

Bimetallic radiators are becoming increasingly popular today. This is a worthy replacement for the hopelessly outdated “cast iron”. The prefix “bi” means “two”, i.e. In the manufacture of radiators, two metals are used - steel and aluminum. They are an aluminum frame with a steel pipe inside. This combination in itself is optimal. Aluminum guarantees high thermal conductivity, and steel guarantees a long service life and the ability to easily withstand pressure drops in the heating system.

It became possible to combine seemingly incompatible things thanks to a special production technology. Bimetallic radiators are made by spot welding or injection molding.

Advantages of bimetallic heating radiators

If we talk about advantages, then bimetallic radiators have many of them. Let's look at the main ones.

- long life span. High build quality and a reliable “union” of two metals turns radiators into “long-livers”. They can serve regularly for up to 50 years;

- strength. The steel core is not afraid of pressure surges characteristic of our heating systems;

- high heat transfer. Thanks to the presence of an aluminum body, the bimetallic radiator quickly heats the room. In some models this figure reaches 190 W;

- resistance to rust formation. Only steel comes into contact with the coolant, which means that the bimetallic radiator is not afraid of corrosion. This quality becomes especially valuable during seasonal cleaning and water dumping;

- pleasant appearance". The bimetallic radiator is much more attractive in appearance than its cast-iron predecessor. There is no need to hide it from prying eyes with curtains or special screens. In addition, radiators differ in color and design. You can choose what you like;

- light weight. Significantly simplifies the installation process. Now installing a battery will not require much effort and time;

- compact size. Bimetallic radiators are valued for their small size. They are quite compact and easily fit into any interior.