This is a classic mechanical pump for pressure testing. They can fill the outline

In country houses and where the heating circuit is turned on only from time to time, ordinary water cannot be filled. It freezes, which leads to rupture of pipes and batteries, and the boiler may break down. Therefore, in such cases, special antifreeze compounds are used, which are popularly called by a beautiful foreign word - antifreeze. We talked about whether it is possible to pour antifreeze into the heating system in one of our articles. In short, you can, you can read more here.

Today we will talk about how to add antifreeze to the heating system. Let's look at the technique step by step. We will help you determine which pump to use and where to connect it. There are some tricks that you can use to cope with the task yourself.

Signs of a critical coolant shortage

Not all owners of private houses monitor the technical condition of their water heating; it works - and that’s okay. When a hidden leak occurs, the system continues to function for some time until the amount of coolant drops to a critical level. This moment is monitored by the following criteria:

- In an open system, the expansion tank is first emptied, then the main riser rising from the boiler is filled with air. Result: cold batteries when the supply pipeline overheats; turning on the maximum speed of the circulation pump does not help.

- The lack of water during gravity distribution manifests itself in a similar way; in addition, the gurgling of water in the riser can be heard.

- On a gas heater (open circuit), frequent starts/turns of the burner are observed - clocking, the TT boiler overheats and boils.

- The lack of coolant in a closed (pressure) circuit is reflected on the pressure gauge - the pressure gradually decreases. Wall-mounted models of gas boilers automatically stop when they fall below a threshold of 0.8 Bar.

- Floor-standing, non-volatile units and solid fuel boilers continue to regularly heat the remaining water in a closed system until the volume vacated by the coolant is filled with air. The circulation will stop, overheating will occur, and the safety valve will operate.

Important clarification. When a TT boiler operating in an open gravity system boils, there will be no explosion, since the coolant communicates with the atmosphere. The water heated by the heater will evaporate, and then a fire will start in the boiler room. Although the described process takes a lot of time, such situations are far from uncommon.

We will not explain why the system needs to be recharged - this is an obvious measure to maintain the functionality of the heating. All that remains is to choose a method for replenishing the heating network.

FAQ

Which booster pump manufacturers are the best?

+

If you prefer to use foreign equipment, then Wilo (Germany), Valtec (Italy), Jemix (China), Grundfos (Denmark) are considered the best. On the domestic market, we should highlight Gilex, Valfex, and Whirlwind.

Which pump should I get for my apartment?

+

Take a quiet centrifugal pump - you can make an approximate calculation of its main characteristics using the method given in our article. As for specific series, the most popular are Wilo PB, Grundfos UPA, Jemix W15GR.

Selecting a refueling option

Several methods are used to replenish the coolant supply:

- Manual recharge is the cheapest and most versatile option, suitable for all types of wiring.

- Automatic replenishment from the water supply is practiced only in systems operating under pressure.

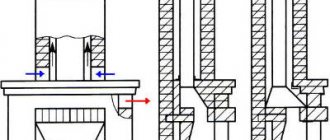

- To fill a closed network with non-freezing coolant, a manual pressure test pump is also used. The design of an automated circuit with an electric pumping station connected to a container with antifreeze is practiced in industrial boiler houses.

At home, antifreeze is pumped into the heating network using a pressure test pump

Note. If the radiator network and heated floors are filled with antifreeze, simple replenishment is done with a small hand pump. But most often, filtered tap water is used in the heating system, because of the price of non-freezing coolants (especially harmless propylene glycol).

The operating principle of the automatic make-up unit is based on the operation of a pressure reducing valve that responds to a decrease in pressure in the heating network. When it drops below the set value, the valve mechanism opens and releases water from the main line. A pumping station operates in a similar way, pumping antifreeze from a separate tank.

Unit with gearbox (left) and station pumping coolant from the tank (right)

Let us take the liberty of recommending the use of a manual recharge scheme. Causes:

- The unit consists of 2-3 inexpensive elements and will never turn on without the knowledge of the homeowner.

- No matter how reliably and efficiently the heating network is installed, there is a possibility of leakage and valve operation.

- Situation: pipe break, prolonged leakage of coolant in the absence of the owners. A completely autonomous “smart” recharge will flood the entire house, ruining the flooring and causing expensive repairs.

- Imagine an identical situation in an apartment building - a leak from an individual system and the activation of automated replenishment will flood the neighbors below.

- Fine sand will accumulate under the valve seat and the element will lose its seal over time. Under pressure from the water supply of 4-7 bar, spontaneous replenishment will begin. The most harmless scenario is the release of excess coolant through the fuse on the boiler safety group.

To eliminate the consequences of the described troubles, it is better to allocate a little time for personal control over your heating. Having discovered signs of loss of coolant, you will make your own decision - to recharge the system immediately, look for a leak, or make repairs. For a negative example of using such automation, watch our expert’s video:

Conclusion on the topic

Automated make-up is a practical option for a large house with a complex multi-circuit heating system. The financial costs of organizing it will be a small percentage of the total investment in heat supply. A small closed autonomous heating system is easier and cheaper to maintain yourself. In addition, there is no point in installing equipment whose operation requires power supply on a gravitational one.

Most homeowners connect a water pipe to the heating circuit through a shut-off valve, and manually refill the water using pressure gauge readings.

Video on the topic:

Manual recharge scheme

The simplest option for filling the system is implemented in 90% of double-circuit wall-mounted boilers, where a cold water supply pipe is a priori connected. A manual valve is installed inside the housing, connecting this line with the heating return line. Often, a boiler feed tap is found on solid fuel heat generators with and without a water circuit (for example, heating units of the Czech brand Viadrus).

Reference. On some models of gas heaters equipped with a DHW heat exchanger (in particular, Beretta), instead of a manual tap, manufacturers install an automatic make-up valve with an electromagnetic drive. If the coolant pressure drops below 0.8 Bar, the boiler itself draws water to the required level.

In wall-mounted double-circuit heat generators, the make-up valve is located at the bottom, where the pipelines are connected

. To assemble a classic make-up unit suitable for any type of system, you will need the following parts:

- tee with side outlet DN 15-20, corresponding to the material of the heating main pipe - fitting for metal-plastic, polypropylene, and so on;

- poppet (spring) check valve;

- ball valve;

- couplings, fittings.

The purpose of the check valve is to prevent water from the heating network from flowing back into the water supply system. If we are talking about pumping antifreeze using a pump, you cannot do without a valve. The fittings are installed in the order listed:

- The tee cuts into the heating return after the circulation pump.

- A check valve is connected to the outlet pipe of the tee.

- Next is a ball valve.

Advice. If there is no fine filter at the entrance of the water supply to a private house, it is advisable to provide one on the make-up line. The element will protect the heating system from the entry of fine sand and rust particles that accumulate on the check valve plate and in the seats of three-way valves.

The operating principle of the unit is simple: when the tap is opened, water from the centralized main flows into the heating pipelines, since its pressure is higher (4-8 Bar versus 0.8-2 Bar). The filling process of a closed system is monitored by a boiler or safety group pressure gauge. If you accidentally exceed the pressure, use the Mayevsky tap on the nearest radiator and bleed off excess water.

To control the amount of coolant in the expansion tank of an open heating network located in the attic of the house, the tank must be equipped with 2 additional tubes with a diameter of ½ inch:

- The control line, ending with a tap in the boiler room, cuts into the side wall at approximately half the height of the tank. By opening this valve, you can determine the presence of water in the tank without climbing into the attic.

During the replenishment process, air bubbles escape through the tank lid, the maximum level is monitored by the flow of water from the upper fitting through the pipe - The overflow tube is inserted 10 cm below the tank lid, the end is discharged into the sewer or simply onto the street under the roof overhang. Being in the furnace room and opening the feed tap, you should see this pipe; when water flows from there, filling stops.

Comment. If you are interested in calculating the minimum volume of the expansion tank, follow the dedicated link.

The circuit with a check valve and shut-off valve is also applicable for filling solar systems (solar collectors) and geothermal circuits of heat pumps with antifreeze. How to use the boiler make-up valve is described in the video:

Standards according to SNiP

Building codes and regulations (SNiP) are based on statistical research, testing theoretical calculations in practice - that is, the ease of use of plumbing fixtures in the bathrooms of apartments and public institutions. At the same time, collections of rules standardize the basic requirements for the design of certain building structures.

According to SNiP 3.05.01-85, the installation height of a sink in a bathroom (regardless of whether it is a private bathroom or a public one) is 800...850 mm from the floor, the permissible deviation is +/-20 mm. For schools, kindergartens, hospitals and clinics, places of visit for the disabled or people with temporarily limited mobility, the parameter may vary. Data on other plumbing fixtures are presented in the table.

Important: when installing a joint mixer for a sink and bathtub, its position is determined by a higher-lying plumbing fixture, usually the sink. Thus, the height of the sink in the bathroom from the floor (standard) along the top of the side and the installation height of the faucet in the bathroom (along the bottom edge of the body) are the same.

The RF standard is focused on devices installed by builders during mass construction

Thus, the installation height of the bathtub from the floor in the table is given for a typical cast iron or steel product with legs. For acrylic, modern cast iron and steel bathtubs, glass models, the position is determined individually, in accordance with the geometry of the model and the method of its installation. If the product is installed on a podium, the distance from the finished floor to the top of the side is calculated from the top plane of the podium. Thus, the height of an acrylic bathtub is determined by the height of the podium, the type of supports and linings under the bowl

The RF standard is focused on devices installed by builders during mass construction. Thus, the installation height of the bathtub from the floor in the table is given for a typical cast iron or steel product with legs. For acrylic, modern cast iron and steel bathtubs, glass models, the position is determined individually, in accordance with the geometry of the model and the method of its installation. If the product is installed on a podium, the distance from the finished floor to the top of the side is calculated from the top plane of the podium. Thus, the height of an acrylic bathtub is determined by the height of the podium, the type of supports and linings under the bowl.

In addition to the height of the bathtub from the floor (standard) and the position of the sink side, the required free area in front of the plumbing fixtures and the distance between them are standardized.

It is important to understand: the standards for the placement of plumbing fixtures are justified, but are not indisputable. If there are no other options, you can change the relative position of the devices so as to provide users (taking into account their physical characteristics) a comfortable stay in the bathroom.

Automatic make-up unit

If you are firmly confident in the reliability and quality of the system, you can install an automated circuit that adds water from the cold water pipe. What you need to buy:

- pressure reducing valve (simpler - reducer);

- 3 ball valves;

- 2 tees;

- pipe for the bypass device.

Important point. The water entering the reducer must be pre-cleaned with a coarse strainer, otherwise the valve will quickly become clogged. If such a filter is not provided at the entrance to the building, install it in front of the make-up unit.

In this diagram, the pressure gauge shows the pressure on the side of the heating network; bypass and taps are needed to service the recharge module

The main executive element of the circuit - the gearbox - consists of the following parts:

- fine filter on the inlet pipe;

- spring seat valve with rubber seals;

- pressure regulator handle with a printed scale, range – 0.5…4 Bar (or higher);

- manual shut-off valve;

- check valve at the outlet.

Note. There are more expensive models of make-up reducers with a built-in pressure gauge that measures the pressure on the side of the heating system. Since this device is already in the safety group or boiler, there is no point in spending extra money and duplicating it. The exception is the situation when the make-up is installed far from the heat source (read the next section).

As you can see, the pressure reduction machine already contains all the necessary elements - a filter, a check valve and a regulator. All that remains is to assemble a simple circuit with a bypass and service taps designed for removing and servicing the gearbox.

Operating the valve is simple - use the regulator to set the minimum pressure threshold in the heating network, open the direct line taps, and close the bypass. How to properly adjust the automatic valve is shown in a short video:

Advice. If you plan to install a coarse filter in front of the gearbox, provide an additional service tap in order to clean the mesh without turning off the water in the entire house.

To organize the automatic addition of antifreeze to the system, you can adapt a “hydrofor” - a water station with an electric pump designed for water supply from a well. The pressure switch of the unit must be reconfigured to a minimum pressure of 0.8 Bar, a maximum pressure of 1.2...1.5 Bar, and the suction pipe must be directed into a barrel with non-freezing coolant.

The appropriateness of this approach is highly questionable:

- If the “hydrofor” works and starts pumping up antifreeze, you will still have to look for and eliminate the cause of the problem.

- If the owners are absent for a long time, replenishment will also not save the situation in the event of an accident, since the size of the container is limited. The pumping station will extend the heating operation for some time, but then the boiler will turn off.

- Placing a large barrel is dangerous - you could flood half the house with toxic ethylene glycol. Non-toxic propylene glycol is too expensive, as is spill cleanup.

Examples of organizing automatic refueling from containers of different capacities

. Conclusion. Instead of additional pumps and automatic gearboxes, it is better to purchase an electronic unit of the Xital type. After a relatively inexpensive installation, you will be able to control the heating operation via a cell phone or computer and quickly respond to emergency situations.

Preparatory stage

After installation of heating networks, they are flushed. This will remove chips and solid particles that got into the pipes during installation. If you ignore flushing, debris will damage the pump or heating boiler.

Before pumping in coolant, the system is pressure tested. To do this, a special compressor pumps air into it, filling the pipes and radiators with it. The pressure is injected 25% higher than the standard one, about 2 atmospheres. Pressure gauge readings are taken periodically; the pressure drop should not exceed 1% in 15 minutes. You can pressurize the heating with water; you need to pump it under a pressure of 1.5-1.8 atmospheres and monitor it throughout the day. If no leaks are detected, water is drained and antifreeze is pumped in.

Good sealing means not only the absence of liquid loss, it eliminates airing of the circuit. The entry of air provokes the formation of traffic jams, making the heating operation ineffective.

How to connect to the heating system

With a closed circuit, there is not much difference where to connect the make-up pipeline - to the supply or return. We recommend using the classic proven method - the insertion point should be located on the return line next to the boiler, after the circulation pump and expansion tank. Causes:

- the unit is located in the combustion room, next to the equipment and instruments;

- pumping water into the return line is immediately reflected on the pressure gauge installed in the supply behind the boiler;

- the insert is located at the lowest point, the flow is distributed in 2 directions - into the boiler and radiators, the air is squeezed out evenly.

Classic scheme for inserting a recharge module

The piping of solid fuel units involves the installation of a condensation protection circuit with a three-way valve. You cannot make makeup in front of this valve - cold water will immediately close it and the boiler pressure gauge will begin to lag in readings. Cut inside the circuit, between the 3-way valve and the heat generator.

In a similar way, the make-up flows into the return line of the open system. The second option is to add coolant directly to the tank; the disadvantage of this method is to lay the supply pipe into the attic.

The correct connection is shown on the left - inside the primary boiler circuit

Connecting the make-up line is also allowed at other points:

- to a separate fitting of a solid fuel boiler, provided by the manufacturer;

- to the bottom of the hydraulic arrow;

- to the return manifold of the distribution comb;

- to the outlet of the indirect heating boiler.

These options are usually implemented in complex and extensive systems of country cottages. Connecting the make-up to the boiler is demonstrated in the next video:

Pressure testing with water and/or air: what is it?

There are several tests designed to detect leaks in a water or gas pipeline system, and their use depends on what is being carried through the pipeline and how safe the tests are. Practically used:

- Hydraulic testing with high pressure water flow.

- Pneumatic tests with compressed air.

- Ultrasonic integrity control.

- Pumping bubble solution.

For most domestic gas pipelines, the pipes are tested under air pressure. Non-destructive testing measuring systems are more accurate because they allow you to accurately diagnose areas of loss of tightness. But they require specialized equipment, which is not always available to organizations in the housing and communal services sector, and even more so to individuals.

Regarding industrial production related to the processing of flammable and flammable materials, pressure testing will be needed to assess the stability of the fire extinguishing systems.

All of the above types of pipe crimping are performed with water or air.

Finally, about the safe addition of coolant

When filling water or partial replenishment, follow our recommendations:

- Replenish the heated system slowly by opening the valve a quarter of the lever stroke. In this way, it will be possible to avoid the formation of air locks and protect the boiler heat exchanger from temperature shock.

- Refill from scratch with the heat generator not working and the circulation pump turned off.

- Check the pressure in the expansion tank and go through all the radiators, opening the Mayevsky valves to release air.

- If your boiler is equipped with modern electronics, be sure to study the instructions regarding make-up. Often it is necessary to activate a special service mode in the unit.

- Excess pressure is easily released through the nearest air vent.

The complex system make-up module can be connected to a hydraulic separator and a comb

Reference. Cast iron heat exchangers easily crack from sudden temperature changes, and steel fireboxes become covered from the inside with condensation. The latter mixes with soot and forms a dense coating.

Injecting antifreeze with a hand pump does not have any pitfalls. Pressure testing units are equipped with their own pressure gauge, which allows you to monitor the current pressure at the insertion point.

The best pumping units to increase water pressure

Grundfos

The Grundfos UPA_15-90(N) is rightfully considered the most convenient, high-quality and reliable, simply the best wet rotor pump. Made in Denmark, Grundfos has a durable cast iron stainless steel body and can operate with different pressures. There are several operating modes available in the control, which can be selected by the consumer at will. Grundfos can raise water to a level of eight meters. In this case, the minimum inlet pressure will be 0.2 bar, and the electricity consumption will be high - only 0.12 kilowatts.

Grundfos pump Source valves-msk.ru

The noise level is an important point for a pump installed inside a small apartment. For Grudfos it is no more than 35 decibels. The pump is lightweight, easy to install, durable (can operate for at least ten years, according to the established official service life).

What to look for when buying - main characteristics

Productivity or feed

This is a value showing how much liquid the pump moves through itself per hour. Measured in m3/h. These data can be found in the technical document for the pump.

Multiply the volume of liquid in your pipes by three - and you will find out the approximate value of productivity.

Those. an approximate figure for a small village house will be 1 - 2 m3/h.

Performance of circulation pump Askoll ES2 70

A more accurate calculation is made using the formula:

Q=Qn/Dt

Q - desired feed

Qn – how many kilowatts of energy are needed for a given area (in kW)

Dt is the temperature difference between the boiler outlet and return.

Pressure

The second, no less important indicator. The more complex and longer the pipeline (the more turns, radiators, fittings and taps it has), the greater the pressure the pump should have.

It is clear that if there is insufficient pressure, the pump simply will not perform its functions, and if there is excessive pressure, noise will appear in the system from the rapid movement of liquid.

Pressure and flow characteristics of the pump

The pressure can be calculated using the following formula:

Hpu =R x L x ZF / 10000

R – losses caused by pipe friction (Pa/m)

L – pipeline length

ZF – coefficient for valve (1.7), fittings (1.3)

If all these calculations seem too difficult and confusing to you, there is a plan B. Buy a pump with a reserve of pressure and flow (which, of course, leads to unnecessary expenses), but you can always simply switch the unit to a lower speed if it is working too hard.

Connection size

The diameter of the pipes and the diameter of the inlet holes on the pump may not match. This, of course, can be corrected with the help of adapters, but it will be less troublesome if the section sizes are chosen to be the same. In the specifications for heating circulation pumps, the diameters are indicated in inches.

Power

Remember that your heating circulation pump will be turned on quite often and for a long time, so high power can be ruinous. Nowadays they make very economical units that consume electricity like a regular light bulb.

Selection of a circulation pump based on power parameters

Other nuances

Automation for the heating circulation pump (automatic regulator) will help save electricity. Then the pump will work “according to the needs” of the system.

When buying an imported pump on the Internet, it is a good idea to make sure that it operates on a 220 V network (and not 380, for example).

And look at the service life of the pump - it should not be less than 10 years.