Despite the ongoing debate about the environmental safety of modern means of protecting objects under construction, not a single construction project can be completed without the use of various insulating materials. This trend does not mean that humanity is not concerned about its own environmental well-being.

New thermal protection products, such as extruded polystyrene foam, comply with existing standards, and their use is approved by the relevant standardization bodies and sanitary and epidemiological services. The periodic resumption of discussions in the media about whether penoplex is harmful or not is reminiscent of the elementary desire of competitors to create conditions for changing the market situation.

Is it true that foam insulation is harmful to health?

Increasingly, modern builders recommend that buyers use penoplex to insulate their homes.

Penoplex with penoplex glue gained its popularity not so long ago, because it was invented only in the middle of the last century, but during this time it has spread throughout the world and began to occupy a position on a par with mineral wool, ordinary polystyrene foam and other well-known materials for thermal insulation.

Penoplex in original packaging

However, you can often hear that there is harm from penoplex, and very significant. Is it really? Let's try to figure it out.

Pros and cons of the material

Currently, many homeowners choose penoplex to insulate their homes. This material is very popular due to its good performance characteristics. In addition, it is quite possible to carry out the installation work yourself, which allows you to significantly save money, because the services of professionals today are not cheap.

Penoplex, or extruded polystyrene foam, has many positive qualities that have made it a leading product in the insulation materials market. Let's take a look at the main list of positive qualities of this type of insulation:

- The main advantage of penoplex can be considered its increased strength. In this regard, this thermal insulation material is ahead of its competitors.

- In addition, penoplex has almost zero absorption of dampness and moisture. Thanks to this advantage, such material does not necessarily need to be supplemented with a vapor barrier membrane after installation.

- This thermal insulation product comes into contact with any other materials without problems. In this case, no chemical reactions occur. The only exception is contact with solvents or acetone.

- As mentioned above, penoplex is installed on walls (and other surfaces) quite simply and quickly. To do this, you do not need to have any special education - you just need to follow the step-by-step instructions.

- Penoplex belongs to the mid-price category products.

- This popular material effectively retains heat in the house. Thanks to this quality, a comfortable microclimate is maintained in the home.

Currently, several varieties of penoplex are sold in stores. This suggests that you can choose the best option for any conditions.

In addition to this, a number of positive properties stand out;

- Penoplex is considered an environmentally friendly and safe material: it does not emit hazardous substances that can harm the health of household members. Unfortunately, today not every material can boast of such advantage.

- Extruded polystyrene foam is a vapor-permeable material. A home with such insulation will remain “breathable”, so fungus or mold will not appear on the floors, which can be very difficult to get rid of.

- Such insulation is lightweight, so its installation cannot be called energy-intensive. In addition, transporting penoplex will not be expensive.

- High-quality penoplex is a durable material: it will not require replacement or repair in the coming decades.

- Penoplex has an anti-corrosion composition, so it can be safely laid on substrates consisting of a variety of materials.

- This thermal insulation material does not cause allergic reactions, even if the room temperature is high.

- Penoplex does not rot or deform over time.

- This insulation can be used both during the construction of a new home and during the restoration of an old one.

- Thanks to its excellent strength characteristics, extruded polystyrene foam can easily withstand heavy loads. It is difficult to damage during operation.

Harm of penoplex: myth or reality?

- 1. What is extruded polystyrene foam

- 2. Harm of penoplex

Among all the modern thermal insulation materials on the market, Penoplex takes the lion's share, thanks to a large number of advantages. The strength of this material is much higher than that of ordinary polystyrene foam; it is not interesting to rodents. Due to its special anti-corrosion composition, penoplex can be used in all situations. In addition, this material is very light, which makes it possible to use it without harm for various structures.

As for the shortcomings, they also exist. Although many are mostly interested not in the disadvantages of penoplex, but in its harm when insulating the internal walls of a house. How harmful is extruded polystyrene foam? Can it be used as internal insulation for walls and floors inside the house? This is exactly what will be discussed in this article from the construction magazine samastroyka.ru.

What is extruded polystyrene foam

This insulation appeared relatively recently, around the middle of the last century. In Russia, the first company to produce this thermal insulation material began its activities in 1998. Therefore, we can say with confidence that Penoplex is a relatively new and, of course, modern thermal insulation material.

Penoplex is produced from polystyrene by extrusion - a technological process during which molten polystyrene is pressed through special molds. The output is a fairly dense material with a maximally homogeneous structure, having microscopic pores. It is due to this that penoplex does not absorb moisture, it has a high density and a sufficient degree of strength.

The main area of application of Penoplex is thermal insulation. Extruded polystyrene foam is used to insulate not only walls, floors and other surfaces in the house, but also roofs, foundations, and all kinds of building structures. This thermal insulation material copes well with its main task, but many developers are interested in how harmful it is in operation.

Harm of penoplex

The ancestor of extruded polystyrene foam can rightfully be considered ordinary polystyrene foam, which is made from polymers and gas fillers. There are many rumors about the dangers of polystyrene foam, but all of them are unconfirmed. The fact is that modern thermal insulation materials have been brought to an ideal state in their composition, and pose little threat to the human body.

Of course, no one is saying that penoplex is not harmful when it burns, or that polystyrene foam completely lacks a component such as styrene. The main thing here is the percentage of these most harmful substances, and in materials from well-known and certified manufacturers it is kept to a minimum. In this case, you need to take into account this fact that we are talking about large and well-known manufacturers of thermal insulation materials, which have made their name thanks to the high quality of their own products.

Such products are absolutely harmless when used even indoors. Plus, walls insulated with penoplex are still finished, so it’s pointless to talk about the dangers of this material or the release of something into the air. It’s a completely different matter when products from little-known manufacturers are chosen to insulate a house, and even at a low price. There is a kind of roulette here, since there are absolutely no guarantees about the quality of the purchased materials.

The main disadvantages of penoplex are its inability to withstand high temperatures and its rather expensive cost. In addition, the material is susceptible to chemical attack from solvents. In all other respects, it is excellent thermal insulation for walls and foundations, which is many times superior to polystyrene foam and some other thermal insulation materials.

Disadvantages of insulation?

When purchasing insulation, you must remember that all manufacturers, when advertising their products, emphasize only the positive aspects of their product.

The myths about orange insulation discussed below are those facts that you will not find in advertising brochures, but which have a direct impact on human safety and health.

Fireproof or not so much?

Insufficiently high fire resistance is one of the main disadvantages of orange insulation. In general, the issue of flammability of foam plastics is not as simple as it might seem if you do not delve into the essence of the matter.

For the reason that their various modifications have different degrees of fire safety and, in terms of flammability, belong to materials of different categories - from G1 (low-flammable) to G4 (highly flammable).

Pure polystyrene foam is a flammable material, which is its main disadvantage. It ignites easily from any open flame - a lit match, a burning blowtorch, even welding sparks. Therefore, unmodified foam plastic is rarely used in construction.

To increase its fire safety, combustion inhibitors are added to it - flame retardants (substances that prevent fire). Foams with fire retardant additives are called self-extinguishing.

Burning or smoldering of polystyrene foam produces thick black smoke, which can be very toxic due to the additives it contains.

In addition to carbon monoxide, it may contain hydrogen cyanide, phosgene, hydrogen bromide, etc. Inhalation of such substances has a detrimental effect on the respiratory system and nervous system of a person and can lead to rapid death.

It would seem that the issue with the fire resistance of polystyrene foam is easily resolved: add more fire retardant - and the problem is solved. But, firstly, this makes the material more expensive, and secondly, some types of fire retardants contain toxic substances.

Such, for example, as hexobromocyclododecane, which is a bioaccumulative toxin and has been banned for use in the European Union since 2015.

Insulation service life

One of the requirements for insulation materials is that their service life must be commensurate with the durability of the object that is insulated with it. Domestic standards provide for insulation materials to operate for at least 25 years.

If you believe the manufacturers, their polystyrene foams more than provide this period.

Some sources indicate the durability of foam plastics to be 50 years or more. But objective research does not confirm this. The experiments carried out revealed that after 10 years of operation, signs of destruction begin to appear in polystyrene foam.

Speaking about the durability of polystyrene foam, you need to pay attention to one more aspect - the safety of the material that is insulated with it. Although polystyrene foam is a vapor-permeable material, its vapor permeability is low.

Moisture that penetrates into wooden structures from the inside or outside is unable to completely leave them through the insulation layer to the outside. This lack of insulation contributes to the formation of fungi and mold on the wood, leading to its rotting.

Although polystyrene foam is not a breeding ground for fungi, they feel quite comfortable on its surface, especially if this surface interfaces with wood.

Safety and environmental friendliness

As for pure polystyrene, it is truly safe, but the same cannot be said about the components and additives used in the production of expanded polystyrene.

As mentioned above, fire retardants added to polystyrene foam can pose a direct threat to human health and the environment. But the matter is not limited to them alone.

In the production of expanded polystyrene, at the foaming stage, sometimes not only safe CO2 and isopentane are used, but also chlorine- and bromine-containing freons. When heated, the latter are capable of releasing toxic substances, in particular, the well-known phosgene, which is the main component of some types of chemical weapons.

In addition, freons have a detrimental effect on the ozone layer, which protects the Earth from solar radiation. In addition, their greenhouse activity is more than 1000 times higher than that of carbon dioxide. It is not for nothing that the use of freons has been prohibited in the European Union since 2010.

Conclusion from all of the above

When choosing a thermal insulation material for your home, pay attention to the entire range of its characteristics, and not just the heat-insulating properties. Not only the comfort and economy of your home, but also the health of all family members depends on the right choice.

Is polystyrene foam harmful or not to human health?

What insulation should you use to avoid turning your home into a time bomb? After all, any thermal insulation material, with the exception of moss or flax, which is used to insulate wooden log houses, is a synthetic material, which means it contains toxic substances that are potentially dangerous and can harm human health. Particular discussions among users are caused by such questions as “is polystyrene foam harmful as insulation indoors” and “does the harm of extruded polystyrene foam exceed the harm caused by compressed polystyrene foam (ordinary polystyrene)”?

Is the buyer doing the right thing by giving preference to such an easy-to-use, relatively cheap and popular polystyrene foam?

It is dangerous for health to insulate a balcony from the inside with polystyrene foam

Vapor barrier

Before insulating a wooden house, it is necessary to make a high-quality vapor barrier. These manipulations are especially important for a house made of timber.

To perform a vapor barrier, it is necessary to attach wooden slats vertically to the walls, the thickness of which must be at least 25 mm.

It is on them that the vapor barrier materials will be attached using staples or nails.

After that, the attachment points should be protected with tape. These manipulations allow you to create ventilation between the walls and the heat-insulating material, as well as an optimal microclimate in the room.

Is extruded polystyrene foam harmful to people?

We suggest you find out whether extruded polystyrene foam is harmful to human health? To do this, let’s break down the composition of the material into its components and consider the main dangerous component – styrene.

- Styrene – 0.05%. This figure is tens of times less than what is allowed by sanitary standards for residential premises in the Russian Federation. At the same time, the maximum permissible concentration of styrene in the EU countries is at the level of 0.002 mg/m3. But, do not forget that styrene tends to accumulate in the body. It demonstrates a cumulative effect (concentration increases 600 times over 20 years). And styrene is released already at a temperature of 25°C.

- The damage to polystyrene foam when exposed to high temperatures is another important aspect. In this case, toxic substances are released: vapors of styrene, benzene, carbon monoxide, carbon dioxide and soot. In this case, the combustion temperature of styrene is 1100°C. At this temperature, even metal melts, which leads to the destruction of the building.

- Time is another indicator. The decomposition period of expanded polystyrene is more than a century. During intensive use (20-25 years), its harm to health increases. After all, during this time, about 60% of the decomposed styrene is released.

- Oxygen, upon interaction with which formaldehyde and benzaldehyde are formed.

Why is styrene harmful?

- phenylethylene (styrene) accumulates in the liver and is not excreted from the body;

- adversely affects the functioning of the heart;

- exposure to styrene is critical for pregnant women, in particular for the fetus;

- entails irritation of the mucous membranes and respiratory tract.

Where is it safe to use polystyrene foam?

- in places where there are no potential sources of fire;

- in non-residential premises;

- use for external insulation of the base, foundation, insulation of a frame house with polystyrene foam from the outside.

As you can see, insulation inside the house is unacceptable, and polystyrene foam installed under the slate will not cause harm only if it is installed in a non-residential attic with good ventilation.

Let us note once again, answering the question of whether polystyrene foam is harmful indoors, it is not the styrene itself that is harmful, but its concentration. Expanded polystyrene is a completely safe decor, but is not recommended as insulation for residential premises.

Conclusion

Sellers of expanded polystyrene have the right to refer to GOSTs and SNiPs when offering their goods, because these standards do not regulate the environmental aspect of the use of this heat-insulating material.

Is penoplex harmful inside the house? Insulation of walls from the inside with penoplex and plasterboard

If you want to insulate the walls of your apartment or house with penoplex and plasterboard from the inside, then see the comments on this page about this insulation method. Insulating walls inside a house with penoplex and plasterboard is possible, but some nuances should be taken into account and not violate the work technology.

So, let's see what the pros and cons of this method are, and also take into account the specialists they leave under this publication.

Advantages of insulation from the inside

The biggest advantage when we insulate walls with penoplex and plasterboard from the inside of a room is the ability to carry out work in winter at negative outside temperatures.

Indeed, it’s winter outside, but it’s cold inside the house. And there is no way to wait for warmer weather to do any work outside.

In such conditions, it is quite possible to increase the level of thermal resistance of the walls by insulating them on the inside with extruded polystyrene foam.

The second big advantage of this method is that it is the only method that allows you to insulate individual apartments in an apartment building at any time.

Moreover, you can insulate the walls from the inside with penoplex and plasterboard yourself. And such work outside on the facade of a multi-apartment high-rise building would require complex lifting equipment and skills in high-rise installation work.

Disadvantages of internal wall insulation

The biggest disadvantage of insulating walls from the inside with penoplex and plasterboard is that we trap moisture inside the room. Extruded polystyrene foam has minimal vapor permeability. This means that all the moisture that should escape through the walls in the form of water vapor will remain in the premises.

However, there are two points that mitigate this disadvantage:

- This minus is valid only for vapor-permeable walls. These include wooden, aerated concrete, foam concrete, and brick walls.

If your house walls are made of concrete panels or expanded clay concrete blocks, then this minus does not matter to you - even before EPS insulation, your walls did not allow water vapor to pass through and did not “breathe.”

- Even in a house with “breathable” walls, you can avoid the appearance of moisture on the inner surface of the insulation sheets, under the gypsum board, if you reconfigure the ventilation system so that it removes a larger volume of air from the premises.

In this case, the volume of air that was previously removed through the walls of the house will be removed through exhaust ventilation.

Practical lesson on wall insulation and plasterboard covering

Next, we will look at how to insulate a wall with penoplex and cover it with plasterboard.

If you don’t understand something or have any questions, leave yours in the answer form at the bottom of the page. We hope that this material was useful to you.

Foundation insulation

Using penoplex you can also perform thermal insulation of the foundation of a wooden house. In this case, the slabs should be installed from the inside to prevent the formation of condensation on the inner surface of the wall.

Thermal insulation of the foundation also allows you to create an optimal basement microclimate. In addition, the room will become much warmer and heating costs will be reduced.

Video to help:

Additionally, you can make thermal insulation of the floor in a wooden house.

Heat loss is one of the main problems when maintaining a building. The lost heat requires large additional heating costs, so high-quality thermal insulation of the house is very important for the owner of an apartment and a private house.

Penoplex is rightfully considered the best thermal insulation material. It has a wide range of applications - it is used to insulate almost all types of buildings, as well as roads, both automobile and railway in cold regions.

When insulating a house with penoplex, certain rules must be followed:

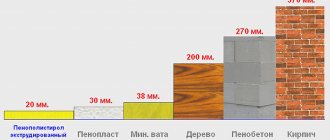

- The thickness of the sheet should be more than 12.4 cm. By the way, this is the minimum thickness among all used thermal insulation materials.

- The thermal conductivity coefficient of penoplex should be 0.03 W/(mx°K). When choosing this material, you need to pay attention to this, as well as to the density of penoplex.

- When installing, the penoplex must be pressed with maximum density.

- In addition to the walls, it is necessary to insulate the foundation, roof and facade. This will significantly reduce heat loss at home, especially in winter.

Is extruded polystyrene foam harmful indoors? What is polystyrene foam or expanded polystyrene?

First you need to understand what polystyrene foam is and how it behaves under various influences. And understand whether polystyrene foam is harmful to health?

Expanded polystyrene is a gas-filled material. They are made by steam heating polystyrene granules. These granules are first filled with gas. The gas used is different: in ordinary polystyrene foam, natural gas is used, in fire-resistant foam, carbon dioxide is used. When heated, the gas expands, and the granules increase many times in size (15 - 30 times the original).

Polystyrene foam poisoning. Is polystyrene foam as insulation harmful to human health?

To retain heat in a private house or apartment, external or internal wall insulation is performed. It is important that all materials used in the construction or renovation process are environmentally friendly.

For example, polystyrene foam is used as insulation. How safe is it for humans and can it be used for insulation?

Is polystyrene foam as insulation harmful to human health?

Many users, in particular owners of apartments on the upper floors, prefer to carry out thermal insulation work from the inside of the room. What does this mean? Which insulation material should you prefer and what is the difference between polystyrene foam and polystyrene? Is polystyrene foam harmful to human health? If it is dangerous, then why and what are the harmful properties of polystyrene foam?

What harmful substances does foam release?

To determine whether polystyrene foam emits harmful substances, you need to consider the composition of the foam; among the harmful components it includes:

- styrene (0.01-0.2%) is a substance harmful to human health that can be released into the air for another 20 years after installing the insulation. Released when the temperature exceeds 25 °C;

- phenol is another chemical compound in foam that is released when exposed to direct sunlight or at temperatures exceeding 20 ° C;

- formaldehyde (formaldehyde, methanal) is a toxic gaseous substance that is released at high temperatures (over 160 ° C).

It should be remembered that substances released by polystyrene foam tend to accumulate, causing deterioration in the health of people living in the room.

So, on the one hand, the balance is: ease of installation, convenience of further finishing, low cost, and on the other hand, the safety of the house and its occupants.

Is polystyrene foam harmful as insulation?

It is possible to answer unequivocally only taking into account the location of its installation and operating conditions, in particular the temperature regime.

When talking about the harmfulness of polystyrene foam, you need to consider at what temperature the foam releases harmful substances. As already noted, styrene and phenol are released at room temperature.

Many are convinced that the harm of polystyrene foam manifests itself regardless of the installation location. However, is foam plastic harmful indoors or is there no health risk when installing it on interior walls? Experts say that polystyrene foam installed on external walls is absolutely safe, since the small amount of vapors of harmful substances that can penetrate through the ventilation, even if accumulated, cannot cause significant harm.

How to eliminate the harmful effects of polystyrene foam

You can reduce or neutralize the harm of polystyrene foam as follows:

- do not install in residential premises, inside rooms of a house or apartment;

- when insulating walls in a house, attach polystyrene foam only to external walls and install ventilation correctly;

- if it is necessary to install foam plastic on the ceiling, this should be done from the attic side (provided that it is non-residential). Installation on the balcony ceiling (from the inside) is also excluded;

- do not purchase polystyrene foam produced by handicraft methods. Each seller must have a certificate confirming the styrene content;

- Use only for its intended purpose, namely as external insulation. The construction of playhouses for children is, of course, unacceptable. But is polystyrene foam dangerous for animals and birds, in particular for chickens (who love to peck at it)? Manufacturers say no. After all, the lifespan of chickens is short and harmful substances simply do not have time to accumulate in their bodies.

Installation of insulation

The slabs are glued to the wall, secured with disc dowels, the joints are foamed.

Penoplex slabs are laid on the insulated surface using adhesive or combined technology. In the second case, they are additionally fixed with disc-shaped dowels. To fix the slabs, a special glue is used, which is diluted before starting work. The surface of the penoplex is passed with a grater or a needle roller to reduce smoothness. The solution is applied to it with a notched trowel. Depending on the size of the insulated surface, the glue is distributed over the entire slab or along the perimeter and middle.

The insulation is installed using a frame or frameless method. Under plasterboard or wooden lining, a frame is assembled from wooden blocks or special guides. Installation begins with marking the ceiling, then the lines are transferred to the walls. The guides are attached in increments of 600 mm - this is the width of the foam boards. When using wooden blocks, the material is pre-treated with an antiseptic. The heat insulator will fit tightly between the sheathing. The frameless method is less expensive and labor-intensive. The finishing material is attached directly to the insulation.

On the walls

Adhesive for penoplex

The technology for installing penoplex depends on the wall material. For concrete structures that do not have external insulation, the use of vapor barrier is recommended. Freezing of the walls will cause condensation and constant dampness. This problem does not arise in wooden houses.

Laying the insulation begins from the bottom corner. In each subsequent row, it is advisable to move the slabs by half the width. Installation in a checkerboard pattern reduces the length of the seams. Fastening to the wall occurs using various compounds:

- Bitumen mastic - used as a fixative and waterproofing in rooms with high humidity.

- Cement-based mineral adhesive is the most common option. The composition hardens quickly, so it is mixed in small portions. Thorough mixing is required until the solution is homogeneous.

- Polyurethane adhesive in cans is easy to use, one package is enough for 12-15 square meters. m.

- Polyurethane foam - a universal composition that will ensure reliable adhesion to brick, concrete, and aerated concrete. The foam dries quickly and creates a sealed seam.

Penoplex with glue applied is pressed tightly against the wall and held for 40-60 seconds. For reliability, the slabs are fixed with 5 dowels, the fasteners are hammered in the corners and center.

To obtain a smooth surface, a bubble level is periodically applied to the thermal insulation. By increasing or decreasing the layer of adhesive solution, you can adjust the plane.

The gaps between the penoplex are filled with foam. After drying, the protruding parts are cut off. When insulating using the frame method, the slabs are laid in a similar way.

To the ceiling

The technology for insulating the ceiling is no different from the walls.

Ceiling insulation is carried out from the inside or outside. In a private house, to reduce heat loss, penoplex is laid on the floor of the attic. Fixation occurs with an adhesive composition. Boards are attached to the sheathing on top of the heat insulator. In apartments this is not possible, so insulation is done from the inside. The surface is prepared in the same way as walls - cleaned, leveled and primed.

Glue is applied to the surface of the slabs, then they are pressed firmly to the ceiling. Fixing with dowels securely fastens the insulation. If a frame is provided, penoplex is placed between the guides. All seams are filled with construction foam.