What are the benefits of heaters from this company?

- Reasonable price;

- Excellent quality;

- Ease of use;

- Long service life;

- A large assortment;

- Minimum fuel consumption;

- The use of a piezoelectric element makes it practically independent of electricity;

- It is possible to choose the appropriate power;

- Has a highly durable design;

- There are models that provide hot water to several points of intake;

- Automatically controlled;

- In double-circuit designs, the circuits are made of copper;

- Ease of system management;

- They work silently;

- Manufactured using an automatic welding process;

- They have a modern design;

- They have two types of heat exchanger: steel and cast iron;

- Can be used with forced water circulation.

There are nine main models of the Siberia brand:

| Model | 11 | 11k | 17 | 17k | 23 | 23k | 29 | 29k | 35 |

| Power, kWt | 11,6 | 11,6 | 17,4 | 17,4 | 23,2 | 23,2 | 29 | 29 | 35 |

| Natural gas consumption, m 3/h | 1,18 | 1,18 | 1,76 | 1,76 | 2,3 | 2,3 | 2,94 | 2,94 | 3,75 |

| Liquefied gas consumption, kg/h | 1 | 1 | 1,21 | 1,21 | – | – | – | – | – |

| Maximum area of heated room, m2 | 125 | 125 | 200 | 200 | 250 | 250 | 300 | 300 | 400 |

| Weight, kg | 52 | 56 | 56 | 59 | 65 | 70 | 70 | 76 | 90 |

general description

Natural gas is used as fuel for AOGV Siberia boilers. The abbreviation AOGV stands for gas-fired water heating unit. These heating complexes are provided with a reliable, durable design, are characterized by low fuel consumption and high efficiency.

AOGV models are made of durable steel, but the weight of the structure is light. All types of gas boilers are energy independent and can operate in difficult conditions. AOGV Siberia tanks are made of steel using automatic welding, which ensures trouble-free heating of the coolant.

Main characteristics

- Can be configured to operate from a gas cylinder;

- The range includes models that do not depend on electricity;

- Stainless steel burner;

- Piezoelectric ignition uses fuel until complete combustion;

- Italian automatics;

- The case is protected from heat;

- The circuits are made of copper alloy. This prevents heat loss. 8. In addition, copper does not corrode;

- The cast iron heat exchanger ensures uninterrupted operation for 25 years, heats up quickly and retains heat for a long time.

Gas boilers are:

- Wall-mounted;

- Floor-standing.

Both of them can be: single-circuit and double-circuit.

Double-circuit heaters are used when there is a need to combine heating with water heating. They have two circuits that simultaneously work for both needs. In addition, the temperature for heating buildings and heating water can be set differently. And in the summer, the boiler can be used as a boiler. Single-circuit boilers, for space heating only.

Advantages and disadvantages of boilers

Independence from power supply is one of the advantages of Siberia boilers.

The advantages of Siberia boilers include:

- reliable and time-tested design and clear operating principle;

- the cost is quite acceptable for the average user;

- compliance of technical characteristics with the requirements of regulatory documents;

- independence from power supply;

- the presence in the range of combinations of not only single-circuit, but also double-circuit models.

A description of the advantages of Siberia boilers will be incomplete without mentioning the compactness and perfect design of the wall and floor samples offered by the company. In addition, users are attracted by the presence in the model range of products equipped with an almost “eternal” cast iron heat exchanger.

The disadvantages of the design and operation of some models include the following points noted by the owners in their reviews:

- noise of ignition and subsequent operation of the gas igniter;

- the need for maintenance of boiler equipment (regular cleaning of the burner, igniter and heat exchanger);

- not very high productivity for FGP in dual-circuit systems.

Wall-mounted boilers Siberia

The mounted gas boiler is designed for heating water in heating and hot water systems. Its capacity is from 7 to 12 l/m.

The main feature is its small size. There are two types of wall-mounted boilers:

- With an open combustion chamber;

- With a closed combustion chamber - makes it possible to reduce heat loss.

Its type is indicated by the presence or absence of the letter “C” in the marking. If this letter is present, then the combustion chamber is sealed and a coaxial chimney is needed here.

The combustion process is controlled smoothly using an automatic system manufactured by Eurosite and Honeywell

Operating principle of wall-mounted boilers

- Gas automatics.

- The burners are made of stainless steel , which are produced by such manufacturers as Polidoro, Worgaz.

- The combustion process is controlled smoothly using an automatic system manufactured by Eurosite and Honeywell. Thanks to an imported manufacturer, the heater lasts for a long time, despite frequent pressure changes.

- Energy control.

- Since the boiler operates using electricity , for safety, in case of a power outage, it contains a circulation pump, a controller, and also has a system for self-diagnosis of possible faults. The point is to stop the gas supply in unusual situations.

- Heat exchanger.

- Heat loss is minimal. This is justified by the fact that it is insulated with thermal insulation, and its design is unique and patented.

Specifications

- They have two circuits;

- Efficiency 90%;

- The heat exchanger is made of copper;

- Coolant temperature maximum 80°;

- Consumes electricity 85, 130 W/hour.

Siberia boilers: features, advantages, disadvantages, model range

An important advantage of units from Rostov manufacturers is their high efficiency. This figure reaches 90%. Depending on the model, produced under the Siberia brand, they can be used to heat houses with an area of 100 to 500 square meters. m and several floors.

The units are available with open and closed heat exchangers. The coolant heated in the heat exchanger in single-circuit boilers enters a three-way valve, and in double-circuit boilers into a secondary heat exchanger. A design feature of Siberia boilers is the separate regulation of water and heating. This allows them to be used in the summer only for domestic hot water.

All models of Siberia boilers are non-volatile and are configured to operate with low gas pressure. If necessary, they can be easily converted to use liquefied gas. Gas burners have pilot and main stages. The first is used for ignition, which is done manually using a special piezo button.

The manufacturer provides a guarantee of up to 25 years for its equipment. The units have a floor-mounted installation option and can be single- or double-circuit.

They are presented on the market in two heat exchanger versions:

- steel;

- cast iron

The power of the boilers included in the model range can range from 11 to 50 kW. The power range of models with a steel heat exchanger is from 11 to 35 kW, with a cast iron one - from 16 to 50 kW.

The latter are produced only in a single-circuit version and are intended only for heating rooms. The heat exchanger material and unit power are displayed in the boiler markings.

The Siberia line of cast iron boilers includes 4 types of units:

- KCHGO 16;

- KCHGO 25;

- KCHGO 40;

- KCHGO 50.

The letter “H” indicates the material used to make the heat exchanger, and the numbers indicate the power of the unit. A similar type of marking is used for boilers equipped with a steel heat exchanger.

In addition to them, the manufacturer produces Siberia floor-standing boilers with a block of electric heating elements operating from a single-phase electrical network with a voltage of 220 V. Such equipment is marked with the letter “E”.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

All models of Siberia gas boilers are equipped with atmospheric gas burners with natural smoke removal. Such designs require high-quality ventilation in the room. A mandatory requirement for the room where a gas boiler is installed is the absence of drafts.

Floor standing boilers Siberia

The peculiarity of such boilers is that their heat exchanger is made of cast iron. This simplifies its operation, since it does not care about water hardness.

Such heaters are single-circuit. And there are also those that have an electric power supply, that is, they are dependent on the mains at approximately 4.4 W/hour.

In terms of power, floor-standing boilers are:

- 16 kW;

- 25 kW;

- 40 kW;

- 50 kW.

But only those with a power of 16 kW run on regular gas. The water temperature at the outlet is maximum 90°. They are all 86 cm in height.

Width:

- 16 kW, 25 kW – 57.5 cm;

- 40 kW, 50 kW – 61 cm.

By depth:

- 16 kW – 41 cm;

- 25 kW – 49.5 cm;

- 40 kW – 66.5 cm;

- 50 kW – 75 cm.

Thanks to an imported manufacturer, the heater lasts a long time, despite frequent pressure changes

Operation of floor-standing boilers

They are more powerful, which affects their large dimensions. For installation, you will need to prepare a place on the floor and be sure to install a foundation.

Possible malfunctions of the Siberia boiler and methods for eliminating them

- If the panel fuse is damaged , it can be replaced.

- If the room thermostat is set to a lower temperature or the timer is off, you need to adjust the settings.

- If the gas does not correspond to the specified data , then you need to contact the service center.

- The gas valve has been found to be defective and needs to be replaced.

- If the fan of the boiler with a closed gas chamber has stopped and there is power, then it needs to be replaced.

- The relay setting is out of order - replace it.

- Tubes are clogged - clean.

- Broken ignition electrode - replace.

- The electrode is installed incorrectly - install correctly.

- Defective ignition device - replace the device with the help of a specialist.

- Air in the pipes is blocking the burner - ignite several times in a row.

- Incorrect polarity of the power line can also block the burner - check the polarity and, if necessary, connect correctly.

- The monitoring electrode is not connected - contact service.

- If the flame is of an unusual color or height , then you need to adjust the gas supply.

Main components of the Siberia gas boiler

Design and principle of operation

The main idea used by the creators of Siberia is to develop a completely energy-independent floor-standing gas boiler Siberia. It can work in difficult situations without requiring electricity. This approach became correct, and the low cost of the units created great consumer demand.

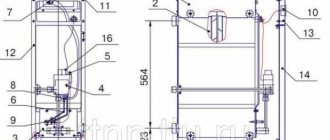

The structure of Siberia. Photo source: mtbwn.us

The Siberia gas boiler is made with an open-type atmospheric burner, which places increased demands on air exchange in the room where it is located.

Smoke removal is carried out in a natural way; for this reason, drafts or a sudden change in air movement are dangerous, since they contribute to an emergency situation due to the separation of the gas flame from the burner or smoke in the room.

An internal highly efficient heat exchanger, made of steel or cast iron, makes it possible to heat water with an efficiency of 90%, which corresponds to the performance of many popular Western analogues.

Design of floor-standing gas boilers Siberia:

- Internal heat exchanger of the heating circuit, for single-circuit devices.

- Secondary heat exchanger for heating DHW, for dual-circuit devices.

- Multifunctional three-way valve for adjusting coolant flows.

- Set of gas elements: shut-off valve, torch combustion stabilizer, fine filter.

- Automatic piezo ignition.

- Gas burner device in the form of two burners - main and ignition.

- Automatic regulation and protection system.

The basic functions of the Siberia gas boiler are performed by the burner device and heat exchangers, where the water coolant is heated. The heated water directly enters the three-way valve for single-circuit modifications or flows through the secondary boiler, heating the water for domestic hot water.

In the mixing unit, the coolant acquires the specified temperature and enters the heating circuit. The movement of streams occurs by gravity, under the influence of natural circulation of layers of water.

Similarly, using the natural circulation of air layers, smoke combustion products are discharged into the atmosphere.

How to choose a gas boiler

- First you need to decide on its power. The larger the room, the more power the speaker will need.

- For every 10 sq. m. needs 1 kW of energy. In order for the device to work longer, you should not purchase it one-on-one with the calculated power. It is better to take with a reserve of 1/3.

- It is important to take into account climatic conditions, as well as the decoration of the house. If the house is insulated, then heat loss will be less. Accordingly, a less powerful boiler will do.

- You also need to take into account what it is needed for. Only for heating or for the availability of hot water.

- If the equipment will be installed in an apartment, it is recommended to use a wall-mounted speaker, and if in a house, then it is better to use a floor-standing speaker. But it still depends on preferences, and, of course, on the size of the heated area.

- For long-term operation, the type of heat exchanger is important. If it is cast iron, then this is only a guarantee of durability.

Compliance with operating rules

The heater, like any other equipment, will last longer and be of better quality if you follow the established rules during use:

- Do not turn on if the burner is faulty;

- Do not use if the chimney is dirty;

- The case must be grounded;

- It is necessary to ensure that the water in the system does not reach a boil;

- The boiler must be installed in a safe place to prevent the surrounding materials from catching fire;

- Before turning it on, you should make sure that the system is full;

- Maintenance should be carried out once a year:

- Chimney cleaning;

- Filter cleaning;

- Burner flushing;

- Checking the tightness of connections.

Equipment installation

Equipment installation must be carried out by a specialist. To do this, you will additionally need to obtain permission to install:

- Registration of permission;

- The gap between the wall and the equipment must be at least 3 cm;

- For a floor-standing unit, you will need to prepare a foundation;

- To prevent gas leakage, all connections must be carefully insulated;

- The boiler should be started up for the first time by a specialist;

- must provide the equipment with a warranty upon first start-up

- If you connect an electric boiler , you will need to install the electrical network and water supply;

- When connecting heaters that are not volatile , additional equipment will need to be installed separately;

- If you connect it to the network using the “cascade” principle, you can increase the power several times. Thus, it is possible to connect all types of boilers;

- A piezoelectric element is used for ignition;

- Initially, the igniter lights , and then the main burner.

If condensation appears on the heat exchanger during the first start-up, this is not a problem. When the unit heats up, it will disappear.

Installation rules

In order to create an autonomous heating system and install equipment, you must have a project and permits that are prescribed by the gas company. According to the manufacturer's requirements, the installation of Siberia floor-standing boilers must be carried out in accordance with SNiP standards and the requirements of GOST and SanPin, only by certified specialists who have permission to conduct such activities.

After you buy the equipment and have the permit in hand, you need to take care of additional devices. You need to purchase an expansion tank, a circulation pump, which is responsible for the forced movement of the coolant along the heating circuit. This equipment must be purchased separately, because It is not included in the boiler package.

The next stage is preparing the boiler room. Floor-standing boilers can be installed in a kitchen or in a specially designated non-residential premises that has a supply and exhaust ventilation system and a waste gas removal system. Utilities must be installed in the firebox.

Next, we pay attention to the location of the boiler unit - you need to choose an area near fireproof walls. Be sure to place the floor heating device on the foundation.

You can connect the pipeline and heating circuit yourself, without the help of specialists. Gas industry employees must connect the installation to the gas main.

Pricing policy for Siberia heaters

The price depends primarily on the power. The more power, the higher the price. A boiler with a cast iron heat exchanger will also be more expensive.

Approximate prices in relation to the model:

- 11 – 19-22 thousand rubles;

- 17 – 21-24 thousand rubles;

- 23 – 25-30 thousand rubles;

- 25 – about 34 thousand rubles;

- 29 – about 31 thousand rubles;

- 35 – about 36 thousand rubles;

Approximate prices for KCHGO:

- 16 – approximately 32 thousand rubles;

- 25 – approximately 41 thousand rubles;

- 40 – approximately 54 thousand rubles;

- 50 – approximately 58 thousand rubles

Main varieties

Siberia gas boilers are presented in three categories:

- Floor-standing - autonomous heating units that do not require connection to the electrical network.

- Floor-mounted ones with cast iron heat exchangers are characterized by an increased level of strength and reliability.

- Wall-mounted – a whole segment of double-circuit units built on a modern element base.

Gas boilers of the Siberia brand are assembled in Rostov, from where they are distributed throughout Russia. By the way, the company is the manufacturer of the legendary AOGV-80 boiler. Although outdated, it still works in some homes.

Reviews from equipment owners

“When choosing, we were guided by price and power. We decided to install a double-circuit boiler with a power of 20-25 kW. We paid attention to the Siberia company. Reasonable price and good quality. Installed without any problems, we've been using it for two years now. So far there are no problems. Very pleased". Alexander, St. Petersburg

“Excellent producer. No problem. I only call a professional for routine cleaning at the end of the season. When I bought it, I felt somehow uneasy, I doubted it. And now I’m glad I didn’t choose the Chinese. Now the equipment is more than 3 years old and no problems have been found in operation. The cost is quite low, and the quality is excellent!” Anatoly, Krasnodar

“The Siberia boiler is a great thing. I have a very large house, but it does the job of heating it and providing hot water. I have two bathrooms, which are located in different corners, but the device quickly supplies water, and its temperature corresponds to the set one. I’m very glad that I chose Siberia 17. I’m also glad for our country that it can make cool equipment!” Alexander, Nizhny Novgorod

“I’m not one to be easily surprised, but Siberia did it. The boiler operates silently, without interruption and is also economical. It's inexpensive. But what I like most is that the boiler operates automatically; you don’t have to constantly stand near it and adjust anything. In general, it copes with the task perfectly.” Ivan, Volgograd

“Siberia works great. There are promised savings and warmth. I've been using it for 4 years now. But I would like to advise you not to forget to periodically clean the filter, otherwise the temperature sensor will not work. I encountered this, but they fixed it quickly and at no cost. No matter how good the technology is, its care must be decent. Good luck to all!" Mikhail, Kazan