In the 60-70s, gasification of the country began, the logical continuation of which was the development of a gas boiler for autonomous heating. It was designed for use in remote and small settlements lacking infrastructure.

The creation of such equipment was a revolution in the organization of everyday life. And today, AGV heating is still used in rural areas as an alternative to centralized heating.

About company

Before the Great Patriotic War, the Zhukovsky Machine-Building Plant produced a variety of metal structures, and in the post-war period, equipment for aviation maintenance. It still produces similar equipment for the domestic and foreign markets.

The company also produces heating equipment. Today, over 30 options are produced with a power from 11 to 68 kW. The most popular modification of the Zhukovsky MZ is the AOGV boiler. The remaining series - AKGV and KOV - are in demand among Russian consumers. The company has diplomas and distinctions for the high quality of its products.

Choosing an AGV (gas boiler) for a private home

Features of the house (area, building materials used) and the climatic characteristics of the area are one of the main criteria for the successful selection of a heating and hot water device. The second important feature is the power of the boiler.

The criterion that determines the choice is the price of the equipment, as well as the cost of materials necessary for operation. Compared to imported analogues, domestic devices are ≈ 35% cheaper, and the cost of maintenance is also three times lower.

Advantages of ZhMZ products

Any of the ZhMZ gas devices can operate independently of electrical networks - this allows you to expand the scope of their application. Advantages:

- Designed for the harsh Russian climate. Adapted to changes in water and pressure. Hardy, powerful, reliable, unpretentious.

- Can operate at very low pressure in gas and water supply systems.

- In severe frosts, they will ensure a comfortable temperature in the house.

- Highly reliable automation ensures high productivity of each unit and safe operation of all systems.

- Service life - 14 years or more. Warranty - 36 months.

- Capable of heating large areas.

- Some modifications can switch to liquefied gas.

Advantages and disadvantages of Zhukovsky plant products

The advantages of gas boilers are as follows:

- simplicity and ease of use;

- possibility of working in a system with forced circulation of coolant;

- affordable price;

- independence from power supply;

- service availability;

- ease of installation;

- economical gas consumption;

- long service life.

The disadvantages of Zhukovsky heating units include:

- weak automation;

- difficult to find spare parts;

- low efficiency = 80-86%;

- outdated appearance.

Standing out from the crowd are floor-standing gas boilers AOGV (gas water heating unit) with a round cylindrical shape. All products of the Zhukovsky plant are certified and adapted to domestic conditions. The presented units are not inferior in quality to foreign analogues, but are much cheaper. The manufacturer is confident in the reliability of its products and provides a 2-year warranty.

Design Features

- Fire adjustment is made in two ways: automatically and manually. The models differ not only in power, each of them has a certain range of capabilities.

- Some models have a pump to circulate water in the pipes. This allows you to effectively heat the room due to uniform heat distribution. Cheaper modifications do not have pumps, and water circulates according to the laws of physics. Therefore, when installing such boilers, the pipes are mounted at an angle.

- All modifications have an expansion tank. It allows you to achieve optimal pressure in the system, and if the liquid expands due to strong heating, it stores its excess.

Varieties

All boilers at the Zhukovsky Plant are floor-standing. There are three modifications:

In the first case, automation manufactured in the Russian Federation was used, in the other two - foreign ones. The brand presents only single-circuit versions - for heating buildings; double-circuit versions are not produced at ZhMZ.

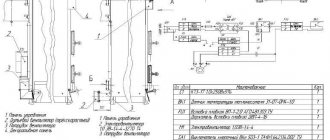

Device

The efficiency of the equipment is 89%, which is quite good for domestic products. This productivity can be achieved due to the original design of the heat exchanger. The cast iron heat exchanger is equipped with turbulators. The burner is atmospheric, air comes from the room. Thanks to automation, continuous operation for a long time is ensured.

Heaters from the Zhukovsky Plant have a number of innovations that increase their environmental friendliness. Developers are trying to keep up with global trends, but still, domestic products are far from achieving the indicators of European and some Asian competitors. But Russian products have an undeniable advantage - a low price that satisfies all consumers.

Heater parameters

The high efficiency of the AOGV - up to 92% - means that the installation of this equipment will bring maximum heating efficiency, and this is due to the original design of the jacket. Boilers can operate in heating systems with forced or natural circulation of coolant, provided that the pressure in the system is at least 1.4 Atm. Such conditions can ensure a liquid temperature of +40/+90 0 C.

The disadvantage of this equipment can be considered to be too much power - even the lowest-power boiler produced by the Zhukovsky plant is designed to heat an area of at least 200 m2, which means that in small houses its installation will be impractical and costly.

The burner in any modification and brand of boiler is made of stainless steel, so its durability is guaranteed. The jacket for hot water supply is made of copper, the body of the unit is coated with polymer or powder paint. Standard automation has temperature sensors and regulators to control the temperature of the coolant and prevent overheating of the boiler. The package also includes a thermocouple that controls gas flow and an air flow stabilizer, which serves to compensate for differences in air pressure during gusts of wind, and shuts off the gas in calm weather.

Certificate of conformity for gas boiler AOGB

| Names | AOGB-11.6 | AOGBK-11.6 | AOGB-17.4 | AOGBK-17.4 | AOGB-23.2 | AOGBK-23.2 | AOGB-29 | AOGB-35 | AOGBK-35 |

| Indicators | |||||||||

| Rated power, kW | 11,6 | 11,6 | 17,4 | 17,4 | 23,2 | 23,2 | 29,0 | 29,0 | 35,0 |

| Consumption of main or bottled gas | |||||||||

| Trunk, m/h | 1,19 | 1,19 | 1,75 | 1,75 | 2,32 | 2,32 | 2,95 | 3,56 | 3,56 |

| Balloon, kg/h | 0,865 | 0,865 | 1,215 | 1,215 | – | – | – | – | – |

| Heated area, square meters | 120 | 120 | 100-200 | 100-200 | 100-250 | 100-250 | 150-300 | 150-400 | 150-400 |

| Efficiency ≥ 90% | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 |

| DHW consumption when heating water at 35°C, liters per minute | – | 3,5 | – | 3,5 | – | 7,0 | – | – | 10,0 |

| Thread on fitting, inches | 1/2 | 1/2 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| Inlet/outlet | |||||||||

| To the heating system | 1/2 | 1/2 | 1/2 | 1/2 | 2 | 2 | 2 | 2 | 2 |

| To the DHW system | – | 1/2 | – | 1/2 | – | 1/2 | – | 1/2 | – |

| Diameter of gas outlet pipe, ≥ decimeters | 1,15 | 1,15 | 1,25 | 1,25 | 1,38 | 1,38 | 1,38 | 1,38 | 1,38 |

| Dimensions, cm | |||||||||

| Height | 86,5 | 86,5 | 86,5 | 86,5 | 85,0 | 85,0 | 85,0 | 85,0 | 85,0 |

| Width | 41,0 | 41,0 | 41,0 | 41,0 | 33,0 | 33,0 | 38,0 | 38,0 | 38,0 |

| Depth | 41,0 | 41,0 | 41,0 | 41,0 | 55,0 | 55,0 | 55,0 | 55,0 | 55,0 |

| Weight, kg | 43,0 | 47,0 | 49,0 | 52,0 | 56,0 | 72,0 | 65,0 | 80,0 | 82,0 |

| In models with a power of 23.2 29 and 35 kW - rectangular housing | |||||||||

About old-style boilers

AOGV is a later modification of the AGV brand. They, like their predecessors, do not have particularly high efficiency and do not have thermostat control. When gas was cheap, no one paid attention to low performance; today efficiency is one of the most important characteristics when choosing heating equipment. AGV models were distinguished by low-quality automation, which broke after one or two seasons of operation.

AGV and AOGV can work without automation: if it breaks down or is turned off on purpose, it will not interfere. When buying a heating boiler, you need to take care of a sufficient number of pipes - their diameter should not be less than two inches. If you take a smaller diameter, the circulation of the coolant may deteriorate - there will be additional costs for heating it.

What is the improvement?

The developers have made a number of improvements to the design:

- Glass thermometers were replaced with Italian, more modernized ones.

- German automation from Honeywell was installed.

- Piezo ignition.

- The appearance has improved thanks to the high-quality coating. The design has changed: the body can be round or rectangular. White color. Painting: powder.

What does the automation system for gas heating boilers AOGV consist of?

A standard automatic system must have several basic elements.

Ignition elements. In modern systems there is no burning splinter. The pilot burner is ignited by a piezoelectric element, which produces electrical energy as a result of mechanical pressure on the crystal. There are systems in which you need to open the gas supply valve with one hand and press the piezo ignition button with the other. In the most modern boilers, one button is responsible for the operation of both processes. The gas valve is then controlled in one of two ways:

- Due to the voltage that occurs when the thermocouple heats up.

- Due to heating of an additional thermal generator (more often used in imported boilers).

Automation of gas boilers AOGV most often operates using thermocouple energy.

In both cases, the generated energy creates a voltage that acts on the gas valve coil. It remains open, providing gas supply, as long as the gas burner is burning.

Thermoregulation system. These elements control the water temperature. They consist of a temperature sensor and a valve system that shuts off the flow of gas when the set temperature is reached. In the most modern boiler models, a room thermostat has been added to the control circuit, which, depending on the room temperature, sends a signal and the need to close or open the gas supply valve.

Control elements for efficient and safe removal of combustion products. This is a draft sensor that is mounted in the chimney. Wires connect the draft sensor to the gas valve. If there is no optimal draft, a signal is sent to the valve, it closes and stops the gas supply.

Automation for gas heating boilers does not allow you to turn on the gas supply if the equipment’s performance indicators go wrong or the slightest breakdown or depressurization of pipes occurs.

Additional elements and automation capabilities

In some models, automatic equipment for gas boilers AOGV is equipped with a thermostat that provides regulation of gas flow. The reason for reducing the intensity of work may be an increase in temperature outside or a signal from the thermostat in one of the rooms that the maximum permissible temperature has been exceeded.

Models that are installed in the Smart Home system offer the possibility of remote control of heating modes.

A modern, properly installed and adjusted automatic system on heating equipment helps reduce heating costs by 40%.

Nuances of operation

When using gas equipment from ZhMZ, you should know: the burner, when starting, creates noise - cotton. In some modifications it is minimized - it turns on more smoothly.

The chimney is installed outside the residential premises. The diameter of the chimney is 14 cm. Under its pipe there is a container for collecting soot, which needs to be cleaned from time to time.

Floor-standing devices are installed in separate rooms, on the lower level of the building. The new equipment comes with instructions, connection diagram and technical data sheet.

Principle of operation

The supply of cold water is carried out without forced circulation - by gravity. That is why the gas appliance is placed at the very bottom of the heating system. It happens that you even have to artificially lower its location.

The burner is ignited through the igniter. A prerequisite for combustion is draft. To control it, there is a special sensor. When the traction is lost, the gas supply automatically stops. If there is insufficient vacuum in the chimney or it is blown out by the wind, the gas is also turned off and the igniter goes out. The emergency situation is prevented.

The most common automation malfunctions and methods for eliminating them

Before setting up the automation on the boiler, it is necessary to diagnose it. As a rule, serious malfunctions occur that will require specialist intervention. The adjustment can also be entrusted to a gas technician. Or you can do it yourself by reading the instruction manual.

Attention! Before each seasonal operation, it is necessary to check the operation of the safety sensors.

Most often, the filter becomes clogged, problems arise with the valves, sensors burn out due to power surges, and a gas leak is detected. Proper cleaning of the filter should be done by a professional. You can try to replace electronic elements yourself by carefully studying the operating instructions for your boiler.

In order to replace the temperature sensor, you need to turn off the gas boiler and cool the water to a temperature of 40 degrees. Shut off the flow of coolant, remove the control knob by unscrewing the screw. Next, remove the PTV adjustment screw. Remove the sensor bellows with the support washer. Unscrew the union nut of the sensor thermal bulb. Install the thermal bulb of a working sensor into the boiler jacket and screw it tightly. Install the sensor bellows into the pipe socket, install the support washer on the bellows, install the PTB adjustment screw and adjust the temperature.

If problems arise with igniting the igniter, then one of the possible causes is a malfunction of the draft sensor. In this case, it must be dismantled, diagnosed, checked contacts, cleaned, and, if necessary, replaced with a new one.

Also, common reasons why the pilot light does not light may be:

- gas valve malfunction;

- clogging of the hole in the igniter nozzle (it can be cleaned with wire);

- strong air draft;

- low gas inlet pressure.

When the gas supply is turned off, it is necessary to check the chimney (it may be clogged), the electromagnet, and the gas pressure at the inlet to the gas boiler.

Attention! To diagnose and repair the gas boiler automation, you must invite a specialist. Inept actions can aggravate the problem and lead to undesirable consequences.

For the automation of AGUK, AGU-T-M, AGU-P systems, the most common problem is the burnout of the bimetallic plate, which is used as a sensitive element.

In Arbat and Orion, you can only replace the thermocouple and draft sensor, as well as the solenoid valve (rarely). The automation unit is practically beyond repair. In Arbat, the system shutdown button often breaks down.

Typical problems for SABC automation are damage to the main valve membranes and drying out of the thermostat stuffing box, resulting in gas leakage. Impulse tubes, bimetallic plates, and ball valves are subject to control.

In conclusion, I would like to emphasize once again that automation is designed to maintain the operation of heating equipment in a safe mode. Therefore, it is simply necessary for owners of gas boilers.

This video shows how to troubleshoot an automatic boiler AOGV, step-by-step assembly process and testing the result.

The most affordable energy resource with the lowest level of harmful emissions in the modern world is gas. The use of AGV for space heating is the most effective option in terms of efficiency and harmlessness. Independence from power supply and low cost of maintenance allow AGV water heating boilers to take their rightful place among similar devices.

Model overview

Any AOGV is a single-circuit floor-standing device designed for heating a room. There is no second circuit in them. If you need hot water supply, you need to connect an indirect heating boiler. Based on AOGV, AKGV is produced - they have a built-in heat exchanger for hot water supply.

The burner is designed for natural gas. To convert the device to liquefied gas, you will need to change it and need a special nozzle. The manufacturer produces heaters with power from 11 to 29 kW. You can choose a modification for heating an area from 45 to 250 m². The estimated cost of ZhMZ boilers is 18-23,000 rubles.

AOGV-11.6 Economy

Floor-standing version. Household versions - 11-29 kW. Features of version 11.6:

- Efficiency 90%

- Open camera.

- Heats 100 m².

- 11,600 W.

- One circuit.

- Mechanical control.

- Convection type.

- Weight - 45 kg.

AOGV-23.2-3 Comfort

- Efficiency 88%

- Open firebox.

- Heats 200 m².

- 23.2 kW.

- One circuit.

- Mechanical control.

- Convection type.

- Weight - 52 kg.

But 23 Universal can be made in two variations: single-circuit and double-circuit. The non-volatile device is equipped with imported automatic equipment. Works on any type of gas. Modest dimensions, light weight - an ideal solution for creating autonomous heating.

AOGV-17.4-3 Universal

AOGV 17 belongs to the convection type. Floor-standing version. Open firebox.

- Efficiency 88%

- Area - 140 m².

- Power - 17.4 kW.

- Weighs 49 kg.

The abbreviation stands for “Gas Water Heating Apparatus”. The Zhukovsky plant is not their only producer. They are released:

- JSC "Borinskoe" (Moscow region). It produces devices in an expanded power range; there are models for 5, 6, 7, 9 and 11 kW. Next: from 11 to 23 kW.

- CJSC "Rostovgazoapparat" Produces options 11.6-35 kW.

- There are also imported versions - Beretta (Italy).

Zhukovsky MZ does not produce parapet boilers, but they can be found from other domestic manufacturers, for example, a device from the ROSS company. Parapet models have a closed combustion chamber, so they can be installed in an apartment. They do not require a separate room.

Example of a parapet device: ROSS AOGV-13P. This is a 2-circuit option. Heats up to 130 m². 13 kW. Efficiency - 90%.

Gas boilers AKGV

The abbreviation of Borinsky gas equipment of the AKGV series stands for a combined gas and water circuit apparatus. In fact, this is the same AOGV only with a built-in second coil for the DHW system. Features of the line:

- leaky combustion chamber;

- two coils – heating + hot water supply;

- non-volatile automation.

This line is also equipped with sensors that prevent overheating of the coolant, turn off the boiler if the draft in the chimney disappears or the wick flame goes out. A gas pressure stabilizer and a mechanical cleaning filter are installed, which has a positive effect on the operation of the heater. The burner is made of stainless steel, both coils are copper. The characteristics, operating principle of the boiler and protective mechanisms are the same as in the Borino AOGV line of gas equipment. Fuel is only natural gas. All models are floor-standing.

The DHW circuit requires special attention. The product data sheet states that water for household needs should not be allowed to be heated directly from the water supply. That is, in transit, such as in parapet boilers, it will not be possible to heat water. Because of this, scale will form on the walls of the coil, as a result of which heat transfer will decrease, the nominal flow will decrease (up to the complete cessation of circulation), and the coil will burn out. There is only one way out - installing an indirect heating boiler in the heating system.

Reviews

AOGV-23.2-3 Comfort: Timofey U., Istra

It has been operating for six years now. Very cheap compared to what the Europeans offer. Quickly heats a house of 180 sq.m. It starts without problems. Over the 5 years of operation, the thermocouple had to be replaced once.

AOGV-11.6-3: Elena P., Kotlas

Cheap, that's why we bought it. Pros: compact, relatively quiet. Cons: everything is cheap, poor, as if it was assembled in a barn. Automation is just one name. The very next year it started to turn off on its own. And sometimes, on the contrary, it starts to “blaze” - something is burning inside, it smells of burnt plastic. And the masters cannot do anything. If I have money, I’ll buy something better, but not ZhMZ.

ZhMZ gas boilers are simple and reliable equipment, time-tested. They are adapted to Russian conditions and have an affordable price. In addition to the products of the Zhukovsky Metallurgical Plant, there are a lot of other manufacturers on the market that produce similar equipment, including double-circuit and parapet models. Everyone can choose the power that suits their home.

Old water heating units are known on the territory of the Russian Federation and other post-Soviet countries. Along with them, models such as the AOGV 11 6 boiler are widely used - devices produced by factories in Zhukovsky and Rostov. The device runs on natural gas - the cheapest modern fuel. The boiler is unpretentious in terms of operation and maintenance.

AKGV series

Floor-standing boilers with a double-circuit heating system are also presented here. Boilers of this series require high-quality ventilation, which will remove combustion products, and a separate room. True, as reviews of models in this series show, you can also buy a gas boiler for installation in the kitchen.

- The burner power in these units varies from 11.5 to 29 kW. The most popular model has a power of 17 kW and heats a room of 150 square meters. meters

- The boiler is equipped with a bithermic heat exchanger - a coil is installed inside the tank, which is responsible for heating the water to the desired temperature

- The burner of the device has anti-corrosion properties

- Heating equipment is equipped with a thermostat, temperature control system and control of gas supply and draft in the system

Also, the AKGV series is distinguished by the fact that the outer walls do not heat up during operation, and during sudden gusts of wind the draft will not disappear thanks to a special stabilizing element.

You can buy a Borinsky heating boiler of the AKGV series for $250, and you can buy Borinsky gas heating boilers with a higher power of 23 kW for $360. What do reviews say about the powerful heating boiler model AKGV 23?

Anastasia, 32 years old:

I’m glad that this model is non-volatile; constant power outages are always a problem for parents. It also heats the water quite well, but I can’t say that the pressure is enough for all needs – it’s enough to wash the dishes.”

3. AOGV series - here are gas single-circuit boilers designed for space heating. Devices in this series are floor-standing units that run on natural gas.

AOGV models are manufactured in a cylindrical body and are represented by several “subseries” - an economy version with a Russian-made control unit, a universal device with a control unit from Italian brands, and a comfortable unit, where the automation is presented by a German manufacturer.

- Borinsky AOGV floor-standing gas boilers have thermal power from 11.5 to 29 kW.

- Designed for heating rooms from 40 (at minimum power) to 250 sq. meters (maximum boiler power).

- Gas boilers are equipped with an automatic system for stopping the gas supply in the absence of draft and ignition on the burner.

- Equipped with a thermostat with a temperature range up to +95 degrees.

You can buy a Borinsky boiler of the AOGV series for 220 USD. – such a model will have minimal power; a unit for a large house with maximum power will cost $450-490. Let's look at the reviews of the mid-price model with a power of 23 kW.

Alexander, 37 years old:

In general, I bought a model with Italian automatic equipment for my 150 square meters. I want to say that the efficiency is really about 90%, and the gas consumption is small - about 1.7 kg/hour (cylinder). I’m happy with the device and I couldn’t be happier for six months now.”

4. The KOV series are single-circuit floor-standing boilers, which are distinguished by high power and are designed for heating large rooms.

- Borinsky KOV boilers have a power from 30 to 63 kW;

- Equipped with automatic equipment from an Italian manufacturer;

- Designed for heating areas from 250 to 750 square meters. meters;

- Gas boilers are equipped with a protection system in the absence of draft, gas supply interruption and absence of an igniter on the burner.

You can buy a Borino boiler with a power of 30 kW for 600-660 USD, a boiler with a power of 50 kW for a room of 500 square meters will cost 820-860 dollars.

Choosing a Borino boiler

Before you buy a Borino gas boiler, decide what you need it for - will it only perform a heating function, or do you need a double-circuit model.

- Look at the power - if your house is insulated, you can choose a boiler commensurate with the area of the house. If your house is “cold”, take a model with “power reserve”

- Look at the automation - all floor-standing boilers are equipped with a protection system, but the automation itself can be of domestic or foreign production

- Look at the combustion chamber and air outlet - the chamber can be closed or open, run on natural gas or from a cylinder. Some models may require replacement of injectors to operate on liquefied gas.

Features of AOGV

The abbreviation AOGV simply stands for gas-fired water heating apparatus. The number after the letters indicates the power of the model, that is, the AOGV 116 boiler is an 11.6 kW unit, respectively.

The technical characteristics of AOGV 11 6 3 indicate that the boiler is intended for heating a private residential house, garage or small utility room. The model is presented only in a floor-standing version; household units have a power ranging from 11-29 kW. The fuel used to operate the device is natural gas.

At the bottom of the boiler there is a heat exchanger, under which there is a gas burner. This is what heats the water. The unit can be converted to use liquefied gas. High quality steel is used to make the device body. The heat exchanger is made of tubes, which ensures a high efficiency of the device.

Advantages of AOGV and management

When deciphering the abbreviation, the advantages of the units become clear, namely:

- Simple and easy control of the heating gas unit allows you to organize safe and affordable control of the coolant temperature within the specified parameters;

- All devices, parts and components are manufactured using high-precision technologies, but what is this in practice? This is an absolute guarantee of the safety and reliability of gas equipment operation. In addition, some models have manual gas shut-off and coolant temperature adjustment;

- All AOGV brands are non-volatile, that is, they are not tied to electrical networks and are completely autonomous;

- Piping in the heating system can be done with any pipes - polypropylene, cast iron, steel or metal-plastic;

- The heat exchanger (jacket) is usually made of copper, which ensures long service life;

- Pressure drops in the gas pipeline do not affect the stability of operation;

- A high degree of thermal protection ensures maximum heat transfer of the unit and the system as a whole.

Installation of AOGV is only advisable in private residential buildings, and not in apartments due to their high power and large size.

Metal structures began to be produced at the Zhukovsky Mechanical Plant in 1939. Currently, it produces floor-standing gas boilers AOGV and AKGV with a capacity from 11 to 68 kW. The first are single-circuit and are intended only for heating, while the second are equipped with two circuits and can additionally produce hot water.

Distinctive characteristics of boilers

The Universal and Economy model boilers are especially popular among buyers. There are significant differences in the technical characteristics of AOGV 116 of these series. The Economy version is manufactured using Russian automation; this unit can be controlled using a solenoid valve and a temperature control knob. A draft sensor and a thermocouple are connected to them - one of the most important elements of the device.

The part looks like a thick rod made of copper. It is necessary to control the fire on the igniter. When the draft level decreases, the sensor is triggered, and the valve must shut off the natural gas supply at this time.

The boiler AOGV 11.6 of the Universal series is produced on the basis of Italian automatic equipment . The unit is distinguished by the presence of an automatic thermostat and piezo ignition. The device can be turned on by pressing just one button, and there is no connection to electricity networks.

There is another series of units - Comfort, it is equipped with American parts. These models also have a built-in piezo ignition, but it has a different design.

Flame and draft sensors

Flame and draft sensors work on this principle. The draft sensor reacts to deteriorating smoke draft and transmits an impulse to the control system. It is located in the smoke hood. Equipped with a plate made of an alloy of two metals: iron and nickel. When draft deteriorates, flue gases accumulate and heat the plate. It becomes deformed, the contacts open, and the flow of fuel into the combustion chamber stops. When the temperature decreases, the plate returns to its normal state.

The temperature sensor works on the same principle. When the water in the boiler heats above the set temperature, the lever mechanism is activated and the temperature regulator valve closes. The gas supply stops and the burners go out.

When the water cools, the sensor bellows contracts, the lever mechanism is activated, the temperature regulator valve opens, gas begins to flow, and the burners light up.