Home » Classification of gas boilers » Operating principles » Setting up Proterm gas boilers

Gas boilers Proterm are popular among consumers due to their reliability, European quality and reasonable price. Among floor-standing devices, the Bear series is known, and among wall-mounted devices, the Cheetah is considered the most universal line. Models with the letter designation MOV are equipped with an open combustion chamber, while MTV is equipped with a closed combustion chamber. Let's look at how to configure Proterm gas boilers.

…

- 1 Heating modes Proterm Cheetah

- 2 How does Proterm Cheetah work when connecting thermostats?

- 3 Setting up the Proterm Medved gas boiler

Comparison of the most popular boiler models Baxi, Vaillant, Viessmann, Buderus, Protherm

BAXI Eco Four 24

Advantages:

- The boiler design combines two circuits - heating and DHW - with a water heater.

- Unification of energy resources used from natural to liquefied gas.

- Automation clearly controls the specified operating mode, adjusting the work to possible changes.

- Low noise from the operating unit, coupled with a stylish design and simple installation.

Flaws:

The “smart” system is extremely dependent on the stability of the power supply, which requires that the unit be connected through a voltage stabilizer.

All Baxi gas boilers

Buderus Logamax U052-24K

Advantages:

- The design has compact dimensions, allowing you to solve problems of heating and hot water supply in an apartment or house in limited space.

- The closed combustion chamber does not make any changes to the air conditioning mode.

- LED display with temperature indication makes it easy to control.

- A number of protective systems – from pump anti-blocking to “Anti-freeze”.

Flaws:

To ensure the normal functioning of all boiler systems, its installation must be carried out by qualified specialists with mandatory verification of all operating modes.

All gas boilers Buderus

Protherm Cheetah 23MTV

Advantages:

- A new product on the Russian market with forced removal of combustion waste.

- Heating modules are made of chromium-nickel steel for more durable service.

- The presence of a modulating burner ensures smooth adjustment of the boiler power, guarantees efficient use of fuel and favorable efficiency.

- The adjustable bypass is combined with a closed expansion tank, safety valve and three-way valve to protect against overheating and blocking of systems.

- Work in three modes - summer, winter and holiday.

Flaws:

Effective for heating rooms with a total area of up to 200 sq.m. When calculating power in conjunction with domestic hot water, it is recommended to use a reduction factor.

All Protherm gas boilers

Viessmann Vitodens 100-W

Advantages:

- Wall-mounted condensing boiler with an attractive power range.

- Modern matrix cylindrical burner.

- The automation has a power limitation option with the possibility of installing a room temperature sensor in combination with an electronic control unit for DHW parameters.

- Maximum noise level 38 dB.

- Self-cleaning effect from scale thanks to the smooth surface of the stainless steel heat exchanger and the ability to redirect the movement of exhaust gases.

Flaws:

More complex installation of a condensing boiler with features of the arrangement of a coaxial chimney (angle of inclination).

All Viessemann gas boilers

Vaillant VUW INT 242-5-H

Advantages:

- Wall-mounted condensing boiler with an attractive power range.

- The choice of consumers who value comfort and increased safety.

- The presence of a modulating burner improves the adjustability of power parameters.

- Disposal of combustion waste is carried out through a coaxial chimney.

- Service with frontal access to the main components.

- Intelligent pressure control in the heating system with automated troubleshooting through a diagnostic system.

Flaws:

The electronic filling of the boiler is very sensitive to power supply fluctuations, and its repair is expensive.

All Vaillant gas boilers

When choosing the best option for you, we recommend focusing on the technical characteristics of the boilers and compliance with the requirements.

For apartment heating, gas boilers Protherm and BAXI are more effective. They are also suitable for heating a private home, but Vaillant, Buderus and Viessmann will cope better with this.

Our advantages:

- We work around the clock

- we exist since 1999

- own emergency service

- own service department

- heating repairs of any kind

- repair of water supply systems

- restoration of boiler equipment

- redevelopment and replacement of pipes

LLC DESIGN PRESTIGE reliable partner

Removing air pockets in the system

Simply filling the heating system with water is not enough; in order to fully start the heating system, it is necessary to release the accumulated air from it. Most modern heating boilers are equipped with an automatic air release system, but, as a rule, they work inefficiently and therefore, at least from the main components, it must be removed manually. Starting the heating system involves eliminating air pockets in the radiators and circulation pump.

It's better to start with batteries. To remove air pockets, a Mayevsky tap is usually installed on them. We open it and wait for the water to run. Did you run? Let's close. Such manipulations must be done with each heating device separately.

How to start a boiler with your own hands photo

After the air is removed from the batteries, the pressure in the system will decrease and the pressure gauge needle will drop. At this stage of work, the solution to the question of how to start the boiler involves re-filling the system with liquid.

Now, the most difficult thing is that starting gas boilers requires bleeding air from the circulation pump. To do this, the boiler needs to be disassembled a little. We remove the front cover and look for a cylindrical object with a shiny lid in the middle, which has a slot for a screwdriver. After we have found it, we put the boiler into operation - we supply it with electrical power and set the water heating controls to the operating position.

Relieving air from the circulation pump when starting the boiler photo

The circulation pump will immediately turn on - you will hear a faint hum and loud gurgling and many incomprehensible sounds. This is fine. As long as the pump is aired, it will be so. Take a screwdriver and slowly unscrew the cap in the middle of the pump - as soon as water starts seeping out from under it, screw it back. After two or three such manipulations, the air will come out completely, the strange sounds will subside, the electric ignition will work and start working. Check the pressure again and add water to the system if necessary.

Basically, that's it. While the system is warming up, you can begin to study the instructions in detail (if, of course, you have not already done so) and start debugging the system that involves starting the boiler. Everything is simple here - the batteries closest to the boiler need to be screwed on, and the ones farther away need to be turned on to their full potential. This debugging is carried out using control valves installed on the supply connection pipe to the heating radiator.

Where to buy a boiler

In order to choose a Protherm gas boiler, you need to go to the official online store page: protherm.ru.

On the website you can find the nearest sales and service points of Protherm Gepard models, for example for Moscow:

- "GK PROJECT"

- .

- UniEnergoTech Trade LLC.

- LLC "ThermoStream"

- LLC "Incomplex"

- LLC "Comfort-Eco"

- LLC "Levada"

- STI Service LLC.

- LLC "Energobyt Service"

- LEX plus LLC.

In addition, on the website you can get acquainted with all the new boilers, their technical characteristics and production instructions.

The site’s specialists will help you choose the Protherm Gepard model that best suits the thermal loads of a heating supply facility.

Conclusions and useful video on the topic

The nuances of connecting a Protherm turbocharged boiler are described in detail by a professional master in a short and understandable video:

The heating system with Proterm boilers is reliable and durable. The wall-mounted equipment has an attractive design and is intuitive to operate: all information is displayed on the display, thanks to which you can easily control every stage of the equipment’s operation. A gas boiler installed by specialists, subject to operating standards, will delight its owners with stable operation and a comfortable microclimate.

Would you like to supplement our material with useful tips for installing a boiler? Or tell us about the problems you encountered when deciding to independently connect gas-using equipment? Write about your experience, participate in discussions - the comment block is located below.

Parapet boiler Gepard and its technical data

The Cheetah gas boiler has two models that are especially popular. The technical designation of the boiler may contain the following inscriptions - 23MOV or 23MTV. Boiler home heating is very popular, so you need to choose equipment wisely.

The decoding of these designations is simple, but you need to know it:

- 23 - rated power of the heating boiler;

- MOV is a natural method for removing combustion products;

- MTV is a forced method of removing combustion products.

The created gas boiler Proterm Gepard 23 MTV is intended for installation on the walls of apartments, private houses, cottages and dachas. The boiler is double-circuit, so there will be no problems with hot water. The presence of a liquid crystal display allows you to continuously monitor the operating process, the health of the boiler and the heating system.

The Protherm Cheetah 23 MTV wall-mounted gas boiler saves gas thanks to the ability to connect a temperature sensor or room thermostat. This model does not require connection to a chimney, which means it can be connected in almost any room, since it has a closed combustion chamber, and the waste combustion products are discharged through a horizontal coaxial chimney, led outside through the outer wall of the room.

Main technical characteristics:

- maximum hot water supply - 11 l/min;

- efficiency (efficiency) - 93.2%;

- range of manual adjustment of boiler power - 8.5 - 23.3 kW;

- rated boiler power - 23.3 kW;

- boiler type - parapet, wall-mounted, double-circuit;

- manufacturer - Czech Republic, Protherm company;

- recommended heating area - 240 sq.m.;

- approximate price - 38,892 rubles;

- warranty from the manufacturer - 24 months;

- gas operating pressure level - (0.5 - 3.0) bar.

In addition, the Proterm Cheetah 24 kW boiler, the instructions for which describe in detail the operating rules and temperature adjustment, is equipped with a display. The display shows information about the current status and malfunctions of the product.

What's wrong with too much power?

Let's look at setting the power of a gas boiler using the example of a double-circuit device Protherm Gepard 23 MTV. This model is an analogue of the Protherm Panther unit. The same manufacturer that produces Protherm gas appliances produces Vaillant brand boilers in another production facility. Their price is much more expensive, since they use higher quality components. In design and settings, Vaillant gas devices are very similar to Protherm models.

The operating instructions say that the useful thermal power of the Protherm Gepard 23 MTV boiler is adjustable from a maximum of 23.3 kW to a minimum of 8.5 kW. In production, the units are set to a power of 15 kW.

It is good if the heating system to which the gas boiler is connected has a power within the capabilities of the burner device, in our case - from 8.5 to 23.3 kW. But what if the existing radiators require less performance?

For example, let's take an apartment with an area of 50 m². For its heating there are radiators with a thermal power of 4 kW. The installers installed a gas boiler, but did not set the appropriate power. A 4 kW heating system will not be able to accept the installed unit performance of 15 kW. The large difference between the produced and the required indicator makes it impossible to automatically adjust the boiler. Then you need to adjust the device yourself.

Note! Experts categorically do not recommend installing a gas boiler whose power significantly exceeds the required one. This leads to cyclical operation of the unit and its rapid failure.

The characteristics of the gas boiler Protherm Gepard 23 MTV indicate that the efficiency of the device when operating at full thermal power is 93.2%, and at minimum - 79.4%. If the unit operates at a capacity of 4 kW, its efficiency will decrease even more. It turns out that almost a quarter of the thermal energy will “fly down the drain.”

Cyclicity of a gas unit and its consequences

Cycling or “clocking” of a gas boiler means that the burner, after being turned on, quickly turns off when the liquid reaches a given temperature in the pipe at the outlet of the unit. But the batteries do not have time to warm up. After a short period, the circulation pump pumps cold water from the heating system into the unit circuit, and the burner turns on again.

Another difficulty lies in the fact that low-power heating pipes have a smaller diameter and higher hydraulic resistance; accordingly, the coolant flows in them more slowly. If you heat the liquid in the heat exchanger with high power, it will reach the set temperature very quickly and the burner will turn off. At the same time, the rest of the water that did not have time to reach the burner will remain cold.

Automation without human intervention will not be able to react to the situation and adjust the optimal power of the device.

Note! With the correct settings of the heating system, the temperature difference between the inlet and return should be no more than 15ºC. Cycling of a gas boiler significantly reduces the service life of the unit and increases fuel consumption

It is known that the components suffer the most wear at the moment of switching on. Also, when ignited, a maximum portion of gas is supplied to the burner, most of which evaporates into the pipe. Frequent re-ignition of the burner further increases fuel consumption and reduces efficiency. To avoid this, it is necessary to adjust the power of the unit, that is, to equalize the performance of the gas boiler and heating system

Cycling of a gas boiler significantly reduces the service life of the unit and increases fuel consumption. It is known that the components suffer the most wear at the moment of switching on. Also, when ignited, a maximum portion of gas is supplied to the burner, most of which evaporates into the pipe. Frequent re-ignition of the burner further increases fuel consumption and reduces efficiency. To avoid this, it is necessary to adjust the power of the unit, that is, to equalize the performance of the gas boiler and heating system.

Variety of gas equipment Proterm

This manufacturer offers consumers gas equipment of the following modifications:

- Boilers "Gepard". In these wall-mounted units, the coolant moves forcibly.

- Double-circuit devices "Tiger". They are also placed on the wall, but they are equipped with an electronic control system.

- Heating devices “Grizzly” and “Bear” have automatic control of the combustion process and a special ignition system.

- The Lynx and Leopard boilers are equipped with bithermal heat exchangers. They are also double-circuit.

- Wall-mounted “Panther” devices are capable of functioning in closed heating systems.

Basic faults

All possible malfunctions are immediately detected by the sensor system and displayed on the display in the form of an alphanumeric code.

Unit errors occur for various reasons, including:

- Break or short circuit of one or another sensor.

- No flame.

- Lack of water.

- Stopping smoke output.

- Circulation pump failure.

- Fan stop, etc.

Most errors cause immediate blocking of the boiler for safety reasons. Situations are possible when there is no one in the house, and there is no one to respond promptly to the appearance of signals.

NOTE!

Therefore, the security system produces an emergency lock, which is reset by the owner when restarted. A complete list of error codes is available in the user manual.

It is a rather lengthy list, and there is no point in listing it in its entirety.

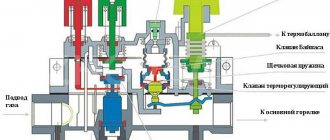

Device

The design of the Protherm Gepard 23 MTV boiler has a basic composition of components and structural elements that is typical for most convective installations of this type.

The main components of the unit include:

- Gas burner made of chromium-nickel alloy.

- Primary heat exchanger made of copper.

- A hydraulic group that includes a three-way valve, water replenishment and discharge devices, and other elements.

- Secondary heat exchanger made of stainless steel.

- Grundfos circulation pump.

- Turbocharger fan.

- Expansion tank with a capacity of 5 l.

- Electronic control board with microprocessor attached to an external display panel.

- A system of self-monitoring sensors that continuously monitors the condition of all boiler elements and signals the occurrence of errors.

The boiler operates according to a typical pattern. The coolant enters the heat exchanger, where it is heated to maximum temperature.

It is then removed and enters a secondary heat exchanger where hot water is heated. After this, the liquid enters the three-way valve, partially mixes with the return flow and acquires the set temperature corresponding to the set heating mode. After this, the OB goes into the external heating circuit.

Heating is provided by a gas burner, which automatically starts or turns off when the specified coolant temperature limits are reached.

The air supply for optimal combustion is provided by a fan, which simultaneously creates draft to remove gas combustion products. Air intake is made from the external compartment of the coaxial chimney, purchased separately.

The operation of all components is monitored by a system of sensors that monitor the presence of flame, gas or water pressure, and signal any failures or malfunctions. The occurrence of any problems is immediately displayed on the display with an alphanumeric code indicating a particular error.

A complete list of codes is available in the user manual.

About company

The Protherm company appeared on the heating equipment market back in 1991 and since then has been pleasing consumers with a high-quality and practical product. The range of products promoted on the market is very wide: the products are represented by 95 items, including gas, solid fuel, electric boilers and much more.

The company places special emphasis not only on the high level of quality of its products, but also on guaranteed professional service.

Proterm produces both gas and electric boilers

All products manufactured by the company have appropriate quality certificates and are absolutely safe from a hygienic point of view.

Series

Protherm products are divided into series and model lines, which are united by a common name and design features.

For simplicity, the series are named after animals - for example, wall-mounted boilers belong to the “cat” group and consist of the following series:

- Jaguar. Basic inexpensive two-circuit convection model with a power range from 11 to 24 kW.

- Lynx. Convection, later - a condensation apparatus with two circuits. Power models are 11, 24 and 28 kW.

- Panther. consists of 4 models with a power of 12, 25, 30 and 35 kW. There are single- and double-circuit options with atmospheric and turbocharged burners.

- Cheetah. Two models with a power of 12 and 23 kW. Compact and low-cost installations with record low noise levels.

- Leopard. The entire series is represented by one dual-circuit 24 kW model.

- Tiger. One of the newest models. Combined with a built-in storage boiler. Power 12 and 24 kW.

Floor standing boilers:

- Wolf. A non-volatile single-circuit boiler that does not require connection to the network. one of the cheapest and most reliable models.

- Bear. A series of several lines with different design features, including piezo ignition of the burner, the presence of one or two circuits, etc. Model power ranges from 17 to 49 kW.

- Grizzly. A series of devices with increased power from 65 to 150 kW. They are used in large residential buildings and can be installed in shops or public buildings.

- Buffalo. A series of universal floor-standing boilers that can operate on gas, fuel oil or diesel fuel. can be assembled in a cascade with high power of industrial significance.

The series and model lines of Protherm boilers are constantly expanding, new ones are being developed and existing devices are being improved.

Technologies are moving forward, making it possible to create more advanced types of heating equipment.

Heating boilers Gepard for heating

All units of this model range are practically no different from similar middle-class products. They have a low level of functionality, but are also relatively inexpensive. To regulate their power, there is a modulation burner. The efficiency of "Cheetahs" during the entire heating season can be 92%. The heating boiler has an i-BAS communication bus.

Among the advantages of these devices are:

- the ability to select the desired operating mode (winter or summer);

- making adjustments using the monitor;

- heat exchanger made of stainless steel;

- presence of a coolant pressure sensor;

- burner made of chrome-nickel steel;

- ability to diagnose the system state.

User manual

Control panel A user manual is supplied with the unit. The document contains the basic rules for operating the boiler:

- If there is a burning smell in the room, do not turn on the lights, smoke, or use the phone. The device is immediately turned off from the network, and the boiler room is ventilated.

- There must be a place for servicing next to the device. A gap of 30 cm is needed above and below the structure. 10 cm remains on the side and 60 cm near the front.

- When leaving for a long time, the valves for heating, hot water supply and gas supply are closed.

- The recommended coolant pressure is from 1 to 2 bar.

- Explosive and flammable substances and paint and varnish products must not be stored near the boiler.

- To select the heating mode, press MODE. To go to “Summer” - the same button twice, to “Vacation” - three times.

- Water temperature parameters are adjusted using the plus and minus keys.

- To set the temperature indicator of the heating main, you will need to press MODE, and then “plus” or “minus”.

Pros and cons of these boilers

Gepard boiler units have 2 heating circuits for heating and hot water supply, through separate heat exchangers. The basic heating heat exchanger is made of copper, and the second high-speed plate heat exchanger is made of stainless steel. The heating speed of hot water does not exceed 2-4 seconds.

The main advantages of Gepard dual-circuit units:

- European quality standard ISO 9001;

- good consumer quality of the boiler structural elements;

- innovative technologies with a modern functional set of management functions;

- LCD control display with anti-glare protection;

- developed trade and service network for the sale and maintenance of boilers.

Disadvantages of Gepard units:

- weak hydraulic group made of plastic materials;

- small volume of the expansion tank;

- high level of price offers from 45,000 rubles;

- a short warranty period of no more than 2 years, which is provided for the boiler only if it is installed by specialists who have factory Proterm certificates.

Advantages

This is an innovative technology that meets European safety and quality standards. Developers are introducing advanced technologies and modern technical solutions. On the Russian market and in the CIS countries, boilers of this brand have affordable prices, but at the same time they are not inferior in performance properties to world analogues.

Main advantages of boilers:

- a large selection of standard models of convection and condensation units;

- high efficiency with efficiency indicators in the range of 90-94%, achieved through a proven design and high-quality elements;

- ease of maintenance of the wall-mounted device;

- high degree of adaptation to Russian utility networks, boilers can heat water even at low pressure in the main gas and water networks.

Disadvantages of gas boilers "Proterm" "Cheetah":

- plastic hydraulic system;

- small expansion tank.

Important! The warranty period is valid for two years when installation and commissioning work is performed by specialists certified with Protherm diplomas

Setting up the Proterm Jaguar boiler

All custom boiler operation settings are set on the front control panel of the boiler. There is also an LCD display to display the necessary information.

- Rotary switch for setting the boiler operating mode and adjusting the temperature of the coolant in the heating system.

- Rotary switch for setting the DHW temperature and turning the boiler on/off

- Reset button and mode switching - economical/comfortable

- LCD display to display information

When the boiler is connected to the mains, the LCD display shows the current pressure. When the boiler is on, to find out the current pressure, you need to press and hold the “eco/comfort” button for two seconds.

Setting the temperature on the Proterm Jaguar boiler

Rotary switches

The coolant temperature is changed by turning the right knob located on the control panel. When using radiators as the main heating source, the temperature can be from 38°C to 85°C. If underfloor heating is used as the main heating system, the temperature of the coolant is in the range from 30°C to 50°C. The maximum and minimum temperature parameters are set by the technician depending on the type of system.

To change the DHW temperature, use the rotary switch, which is located to the left of the LCD display. The temperature range can be from 35°C to 64°C.

Changing the boiler operating mode - economical and comfortable

To switch from economy mode to comfort mode or vice versa, you need to press the “eco/comfort” button once. After pressing, the display will show the selected operating mode - with the symbol “C” if the comfortable mode is selected or “E” when the economy mode is selected.

Changing the operating mode - comfortable or economical

When switching to economy mode, the boiler will turn off every time the water in the heating circuit heats up to the required temperature. In comfortable mode, when the set temperature is reached or exceeded, the boiler does not turn off, but modulates the flame.

F29.

The error appears during boiler operation and indicates loss of flame.

Recommendation: first you need to make sure that the gas line is not blocked by a tripped shut-off valve (for example, due to voltage instability) and that the pressure is normal.

Probable Causes

- Ionization sensor is dirty. It does not “see” the flame and does not provide a signal to the Proterm Gepard electronic module about stable operation of the burner. Cleaning clears the error.

- The grounding is broken. You should check the reliability of the contacts of the wires suitable for the sensor.

All other reasons causing boiler error F29 (gas fittings, control board, electrode corrosion) must be diagnosed and eliminated by a service technician. It is better for the user not to figure it out on his own.

Advantages and disadvantages

The advantages of Protherm gas boilers include:

- High quality manufacturing and assembly of all components and parts.

- Large selection of design and configuration options.

- The presence of many modifications that are optimally suited for working in difficult conditions.

- Environmental cleanliness, equipment safety.

- A self-diagnosis system is used that monitors the condition of all units of the unit.

- Economical consumption of gas and electricity. Non-volatile models are available.

There are some disadvantages:

- Dependence on the availability and correct connection to the power supply network, sensitivity to power surges or surges.

- High cost of spare parts, difficulties with supply in some regions.

- Low level of professionalism among technical personnel of service organizations.

IMPORTANT!

Complaints about the lack of training of service workers should not be understood as a design flaw in Protherm boilers, since the problem is of an organizational and administrative nature.

Clocking reduces the service life of the boiler and increases gas consumption

Putting the equipment into operation is the most difficult moment. At this time, components and mechanisms are maximally loaded. At this moment, starting currents operate, and an increased portion of fuel is supplied to the burner, part of which escapes through the chimney. During clocking, switching on/off occurs frequently, which means that wear on components increases, gas consumption increases, and efficiency decreases. Therefore, it is necessary to eliminate the cyclic operation of the gas unit immediately after detection. To do this, it is necessary to equalize the power of the boiler and heating system.

Regular maintenance of the boiler will extend its service life. How to do this correctly is described in the video

Model range of Protherm boilers - single-circuit and double-circuit

Gas equipment Proterm is produced by a European manufacturer in several modifications, which allows you to choose the model that is optimal in terms of functionality, as well as practical and most convenient to use.

Wall type

Wall-mounted gas equipment has undeniable advantages, including compact size, external aesthetics, excellent performance properties, the ability to adapt to operation with different energy carriers through a standard replacement of the nozzle, as well as cost-effectiveness.

"Panther". Inexpensive model with two heat exchangers for space heating and water heating. A modern heating device with the ability to operate in a closed system. It has reliable protection against freezing, automatic shutdown of gas supply and control of pump operation.

Inexpensive heating device option in the Protherm line

"Jaguar". A budget option for equipment that does not have a winter/summer mode. Double-circuit unit with a closed combustion chamber and control via handles.

A simple model with the minimum required set of functions

"Cheetah". Double-circuit turbocharged boiler with a power of 11–23 kW and a closed combustion chamber. Even low-power models can heat 10–11 liters of water in one minute. A wall-mounted device in which the movement of the coolant is forced.

Turbocharged boiler with high efficiency

"Tiger". It features a neat appearance, an informative LCD display and very simple controls. It is possible to program it for different operating modes or operate in automatic “comfort” mode. It is possible to automatically regulate the combustion process and is distinguished by a special ignition system.

Compact equipment with different operating modes

Main characteristics of the boiler

Floor type

Floor-standing single-circuit and double-circuit boilers have several advantages that make this type of equipment in demand among consumers. It is impossible to ignore high performance indicators, maximum thermal efficiency, economical fuel consumption, wide functionality and guaranteed durability.

"Bear". A high-quality cast iron heat exchanger makes the unit durable and very reliable. The model has a “Winter-Summer” mode and convenient traction control. It has automatic regulation of the combustion process and is distinguished by a special ignition system.

The cast iron heat exchanger ensures long-term operation of the boiler

"Buffalo". Easy to use and durable boiler with high efficiency, capable of operating on different types of fuel. A very powerful unit with a high degree of reliability.

Powerful equipment that can operate on different types of fuel

Main characteristics of the Bison model

Floor-standing boiler with a reliable heat exchanger

Main characteristics of the model

Stationary heating gas boiler

Main characteristics of the model Bear KLOM17

Specifications

The devices are characterized by a high level of operational availability. The LCD display helps to control thermal processes automatically.

- individual processes for adjusting the temperatures of the heating circuit and DHW;

- advanced software and setting codes for individual heat supply parameters;

- possibility of operation in low-temperature heating systems;

- possibility of equithermal regulation using an outside air temperature sensor;

- flame control;

- protection against freezing and overheating;

- anti-blocking system for the network pump;

- control of the gas-air path of the boiler.

Note! To maintain the guarantee during operation of the Gepard gas boiler, it is necessary to pay attention to the quality of the water before filling the boiler circuit

- external for the presence of precipitating substances that can be removed through a regular water filter;

- for the presence of iron oxide or magnetite, cleaning is carried out using a magnetic filter;

- the pH value of the selected water at 25°C should be in the range of 8.2-10.0, otherwise it is necessary to replace the source or carry out routine cleaning work with the involvement of specialists.

Important! The manufacturer prohibits the addition of unsuitable additives, antifreeze and corrosion protection agents, biocides or sealants to the water. In this case, the warranty terms will be canceled, and equipment repairs will be carried out at the expense of the owner.

Proterm devices with bithermic exchangers

This class is represented by only two models; let’s take a look at each of them.

Model "Lynx"

Protherm gas boilers of this model are dual-circuit combined equipment intended for both heating residential premises and supplying hot water. Known for their uninterrupted and reliable operation, excellent quality/price ratio, excellent efficiency, ease of operation and low noise output.

Here are the main properties of the structural elements that the Lynx is equipped with:

- smooth power adjustment;

- display of basic operating parameters on a special display;

- protection of the device from severe frosts;

- built-in microprocessor;

- valve for additional supply of working fluid to the system;

- regulated using a bypass valve;

- separate filters for heating fluid and hot water supply;

- effective protection against overheating.

The approximate cost starts from 30.5 thousand rubles.

Model "Leopard"

The average power of Leopards ranges from 8-24 kilowatts. All devices in this line are characterized by high efficiency and cost-effectiveness. Produced in two variations:

- with an open combustion chamber;

- with closed.

The productivity in terms of hot water supply is 12.5 liters per minute, and the area of the heated room can reach 220 square meters. You can adjust power, as well as other operating parameters, directly from the panel

Excellent performance even in low pressure conditions, which is especially important in today's times when fluctuations in gas supply occur quite often

Each of the Leopards, if necessary, can be converted from natural gas to bottled gas. To do this, you do not need to perform complex manipulations; you just need to change the gas valve and nozzle.

Protective functions include:

- antifreeze;

- anti-cyclicality of the heat generator;

- anti-inertia of thermal energy.

This also includes cessation of gas supply in such cases as:

- exceeding the temperature of the device set value;

- burner goes out;

- craving disorder;

- interruption of electricity supply.

Note! Each of the described functions only works if Protherm gas boilers are connected to the mains

The cost of “Leopards” starts from 13 thousand rubles.

Specifications

Installation options:

- individual processes for adjusting the temperatures of the heating circuit and DHW;

- advanced software and setting codes for individual heat supply parameters;

- possibility of operation in low-temperature heating systems;

- possibility of equithermal regulation using an outside air temperature sensor;

- flame control;

- protection against freezing and overheating;

- anti-blocking system for the network pump;

- control of the gas-air path of the boiler.

Note! To maintain the warranty during operation of the Gepard gas boiler, it is necessary to pay attention to the quality of the water before filling the boiler circuit. Type of control:

Type of control:

- external for the presence of precipitating substances that can be removed through a regular water filter;

- for the presence of iron oxide or magnetite, cleaning is carried out using a magnetic filter;

- the pH value of the selected water at 25°C should be in the range of 8.2-10.0, otherwise it is necessary to replace the source or carry out routine cleaning work with the involvement of specialists.

Important! The manufacturer prohibits the addition of unsuitable additives, antifreeze and corrosion protection agents, biocides or sealants to the water. In this case, the warranty terms will be canceled, and equipment repairs will be carried out at the expense of the owner.

Manufacturer Protherm

Vaillant Group began producing boilers in 1992 at a plant in the Slovak city of Skalica, which became the main production site for Proterm thermal units.

Today the company is known in 26 countries, 400 plant specialists produce about 350 thousand boiler units annually. The quality management system is carried out according to ISO 9001 standards, the technology is subject to annual inspection by expert European companies.

The assembly of the product is organized using two modern technologies:

- container method for heavy floor structures;

- according to the “one piece flow” system, when one device is assembled from start to finish by one professional who is responsible for the quality of the assembly.

The plant has a research laboratory that carries out technological tests of boilers and tests innovative solutions in domestic heat and power engineering.

How to connect and configure

Basic conditions for installing gas heating equipment from:

- installation of the boiler and the necessary auxiliary equipment is carried out in accordance with the design documentation, taking into account the requirements of SNiP and the manufacturer’s recommendations;

- installation of equipment is carried out in a room specially designed for these purposes, and in case of special modification of the unit - exclusively in well-ventilated outbuildings;

- the installation and commissioning process is carried out by specialists who have completed a training course in the installation and maintenance of gas equipment;

- any boiler malfunctions are repaired by a service organization authorized by the manufacturer of heating and water heating equipment;

- independent installation work entails deprivation of the consumer's warranty on the unit and its repair;

- When unpacking heating equipment, the supplied boiler must be checked for completeness and compliance with the type of fuel used.

Before proceeding with installation, you must carefully read the instructions supplied with the gas boiler, and during the installation process all recommendations given in the accompanying documents must be followed. Markings on equipment must not be damaged or removed.

Standard technology for connecting and setting up a gas boiler:

- the unit is fixed to the wall using screws with appropriate spacers;

- connection pipes should not be loaded with a pipe heating system, hot water supply system or gas supply elements;

- the installation size of the tube connections, including their height and the required distance from inlet to outlet, must be strictly observed;

- the hydraulic group is placed on the lower part of the gas equipment, and the system is necessarily equipped with a filler valve and safety relief valves;

- when the maximum pressure inside the system is exceeded, steam or water is released from the safety valve;

- connecting the unit to the heating system presupposes the ability to carry out the full scope of maintenance and repair work;

- water is delivered to the heating system via a filling valve, and a drain device is used to reduce pressure or partially drain the coolant;

- special outlets installed in designated areas of the heating system have full drain and fill functions;

- the pressure of hot water supply to the equipment must exceed similar indicators in the heating system;

- in the “Filling” tap position (hydraulic group), the operation of the system must be monitored using a boiler pressure gauge;

- The valve opens counterclockwise and closes strictly clockwise.

Boiler equipment maintenance items covered by the warranty do not include activities such as deaeration and adjustment of the expansion tank.

Rules for using the equipment

- Image

- Text

0020096579_00 01/10

— 16 —

RULES FOR USE OF EQUIPMENT

water in the heating system (see installation design documentation).

Safety valve

8.11

The safety valve is located on the left, on the hydraulic group located at the bottom of the boiler. Water may flow out of the safety valve outlet (if the maximum pressure in the heating system is exceeded) or steam may escape. Therefore, it is recommended to organize a drain at the outlet of the safety valve, which must be connected to the sewage system of the given facility.

Warning:

It is prohibited to manipulate the safety valve while the boiler is operating. In addition, it is not permitted to use the safety valve to drain water from the boiler or heating system. Valve malfunctions caused by clogging from the heating system are not covered by the warranty.

Gas connection

8.12

The design of PANTHER series boilers is designed to operate on natural gas with a nominal pressure in the distribution network of 2 kPa, for which the specific calorific value is most often given from 9 to 10 kWh/m3. The internal gas distribution network and gas meter must be designed taking into account the user’s use of other types of gas appliances.

Warning:

It is recommended to seal the gas connection point to the boiler by tightening the union nut placed on the end of the gas valve pipe, placing a suitable gasket under it (see Boiler delivery set).

a

After completing work on supplying gas to the boiler, it is necessary to carefully check the gas tightness (tightness) of the connection made.

The lineup

It should be noted that Protherm gas wall-mounted and floor-standing boilers are available in different modifications. Therefore, it is worth considering widely used models in more detail.

Among the wall ones is the Jaguar model. The boiler is used for heating country houses and cottages, the area of which does not exceed 220 sq.m. It also provides the organization of hot water supply. Heat exchangers are separate. The equipment mainly runs on main gas. Although the unit can be converted to run on liquefied fuel. For this you will need to buy a set of jets.

The technical characteristics of the Proterm Jaguar wall-mounted gas boiler are as follows: closed combustion chamber, efficiency is 90.2%, maximum net power is 25.3 kW, minimum net power is 10.5 kW, power consumption is 98 W, liquefied gas consumption ranges from 2.73 cubic meters/hour to 1.02 kg/hour.

The Panther model is also widely used. Hydraulic blocks of boilers are made of composite materials. This allows the strength of the structure to be increased significantly. The unit is equipped with a tank and pump. There is a “Comfort” option, which allows you to heat the water in just 5 seconds. Equipment power ranges from 12 to 35 kW. Many owners prefer to install a Protherm Panther 30 ktv gas wall-mounted boiler in their home to create an effective heating system.

The Lynx model is also chosen by many users. The series is characterized by two separate heat exchangers. It is possible to separately regulate the temperature level in each of them. There is an expansion tank with a volume of 7 liters. The Proterm double-circuit gas wall-mounted boiler is also equipped with a circulation pump. There are two versions of devices: with a power of 24 kW and 28 kW.

Among the floor-standing modifications are the “Bear” series of gas boilers. This is a single circuit type. Power is 18-44.5 kW. It can operate on main gas or liquid fuel. No electrical connection required. Most often used for heating industrial buildings. You can learn more about this model from our article “Gas boiler Proterm Bear - model range and advantages”

The Grizzly model is also widely used. The series is easy to operate. Designed for heating structures with an area of up to 15,000 sq.m. Productivity is 150 kW. Operates on main gas. It is considered the most environmentally friendly equipment among boilers with similar power. But this series is dependent on the power source. There are also floor-standing models “Wolf” and “Beaver”.

To summarize, we can say that Proterm gas boilers are widely in demand among domestic consumers. All products are distinguished by high performance characteristics, reliability, durability, and at the same time, affordable prices. Which model to choose depends on the parameters of the heated room and the preferences of the owner of the house.

Connection diagram

Almost all thermostats existing on the modern market are relay. This means that they operate via a relay that opens and closes contacts based on a temperature preset by the user. As a theoretically connected thermostat, we will use an electric relay-type thermostat with dry contacts. Dry contacts are a term that means that in any state, closed or open, there is no voltage across the contacts.

READ How to connect unlimited mini opera to MTS

To connect to the boiler, there are terminals on the thermostat; you need to connect the open and common ports. If they are not indicated in the manual for your specific model, you just need to ring the contacts with a tester. Next, we need to make sure that the thermostat can be connected to the boiler. Usually this is indicated directly in the technical documentation; if there is none, then the information can be easily found in any of the search engines.

The found electronic circuit diagram of the board indicates the location of the very jumper into which the thermostat will be connected to the boiler. Depending on the boiler model, you will have to unscrew several bolts to get to the required part. The block can be installed either on the control board or taken out separately. Connecting the thermostat for any of these options will be no different.

Next, you need to pull out the jumper, and in its place put the cable supplied with the thermostat (or purchased separately). This is a two-core wire with a cross-section of at least 0.75 square millimeters. The polarity when connecting does not matter. The cable is connected to the thermostat control unit into the normal open and common ports, as described above. The ports are located on one side of the control unit, and on the other there are ports for connecting the power supply cable. You can either purchase a new cable of the desired cross-section or use the complete one.

This completes the connection of the thermostat to the gas boiler. All that remains is to check the functionality of the system. On the thermostat we set the required air temperature in the room, the signal is transmitted to the control unit and, depending on the set temperature, the relay contacts close or open. When setting a temperature that is lower than the current one, the burner starts heating the water in the system; when setting a temperature higher, the burner, on the contrary, starts working.

Common errors and malfunctions

Some of the most common malfunctions of gas boilers can be eliminated independently, but the correction of the most complex errors must be entrusted to service center professionals.

| Error/malfunction | Code/designation | Remedies |

| Reduced pressure level in the unit or heating system | F0 | Check the functionality of the pressure sensor, make sure there are no cable damages and the integrity of the boiler control board |

| No flame in the burner | F1 | Check the operation of the emergency thermostat and ignition transformer, make sure the gas supply and the integrity of the gas valve, restart |

| Rapid overheating of a gas boiler | F3 | Eliminate blockages in the water filter and pump, check the functionality of the heat exchanger, replace the antifreeze mixture |

| Open circuit in the temperature sensor circuit | F4 | Check the resistance readings on the sensor, make sure the integrity of the cables connecting the control panel and the sensor |

| Input signals are not recognized | F7 | Make sure the information panel is working, check the panel connectors |

| Opening the NTC sensor circuit and grounding the DHW boiler | F8 | Check connections, disconnect and reconnect elements, or completely replace the sensor |

| There is a short circuit on the traction sensor | F15 | Disassemble and clean the terminal connections, clean the tubes, and, if necessary, completely replace the unit |

| Low pressure level inside the heating circuit | F22 | Top up the coolant to the required level, make sure the system is completely sealed and there are no leaks |

| Rapid increase in coolant temperature | F24 | Replace insufficiently efficient pumping equipment and get rid of air in the system. |

| Unsuccessful initial ignition | F28 | To eliminate the error/malfunction, it is necessary to involve specialists from the service center |

| Activating fan anti-freeze protection | F33 | |

| Pressure sensor error repeat | F75 |

Modern heating equipment from a manufacturer from Slovakia, the category of which includes single- and double-circuit gas boilers Protherm, is distinguished by its high reliability and variety of models. These high-quality and inexpensive boilers of European quality from the “middle class” are deservedly popular and are invariably in demand by domestic consumers.

Boiler elements as standard from factory

- turbine;

- membrane tank;

- water supply pressure sensor;

- hydrogroup;

- electronic control unit;

- electric ignition;

- electrode protection system;

- burner;

- boiler.

On a note! The manufacturer strongly recommends the use of coaxial chimneys of its brand. This is a condition for maintaining the warranty.

The model provides for the connection of low-temperature appliances in Eco mode, including the “warm floor” system.

Hydraulic group equipment:

- automatic air vent;

- OS pressure sensor;

- stainless steel plate heat exchanger for the secondary circuit;

- pump;

- SIT valve;

- safety valve 3 atm;

- three position valve.

Gas boilers from Protherm

The Protherm company appeared in 1991 in Slovakia.

Today it is part of the same holding with the recognized flagship company Vaillant, which allows us to confidently speak about powerful technological and consulting support. This condition has a positive effect on the product - with an average price range designed for the mass buyer, the quality of the equipment is not inferior to other representatives of this direction.

Gas boilers are one of the types of heating equipment produced by Protherm for export. All units undergo adaptation to the technological conditions of the area where they will be operated.

They are able to withstand power fluctuations and operate at low pressures of water and gas.

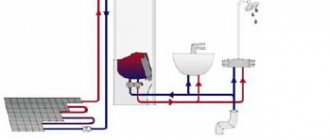

How does Proterm Gepard work when connecting thermostats?

When the Protrem Cheetah gas boiler operates without a room thermostat , heating of the rooms depends on the coolant temperature settings.

When connecting a Proterm thermostat , it becomes possible to set the desired heating temperature. It must be such that the unit can maintain it, regardless of the outside temperature. The controller will only control heating within the selected range.

Note! In the room where the room regulator is located, radiators cannot be equipped with thermostatic valves.

The Proterm unit with a two-position regulator is capable of maintaining a given heating temperature. The boiler will receive a signal to turn on or off depending on the temperature in the room in which the regulator is located.

When connecting a continuous regulator , the power will change smoothly to maintain the set room temperature.

The room regulator will control the temperature in the room and send a signal to the unit to turn off if the heat level has reached the set value or to turn on if the temperature decreases.

The most modern and accurate is equithermal regulation . This is done by a thermostat with an outside temperature sensor. When such a device is connected to a gas boiler, the latter will regulate the temperature of the coolant depending on the conditions outside.

If the operation of the unit is controlled by an equithermal regulator, it is not recommended to set the maximum coolant temperature - this will significantly reduce the efficiency of the system.

Find out here how to make a gas boiler more economical?

Malfunctions of Proterm gas boilers and their elimination

Features of ignition of different models of gas boilers

Efficient gas boilers Protherm and features of their installation

After purchasing the boiler, you must check that there is no external damage to the body and that the supplied product is complete. The instructions directly prohibit connecting the Proterm Cheetah double-circuit gas boiler on your own. The installation has the right to be carried out by licensed specialists, so you cannot do without calling a specialist to connect the boiler. The initial start-up of the device and connection to the heating network must be carried out under the supervision of a specialist. You can read how to legally connect individual heating in an apartment here.

Attention! Violation of the rules for installing and connecting the boiler may lead to the manufacturer's warranty being revoked.

Read with this

- Types and principle of operation of a gas boiler for heating a private house

- Turbocharged or atmospheric gas boiler? which one should I take?

- The operating principle of a double-circuit gas boiler. classification and advantages

- Characteristics of gas boilers Proterm Bear

- Review of Siberia gas boilers

- Wall-mounted, non-volatile gas boilers

- Ariston double-circuit gas heating boilers

- How to choose a wood-electricity combi boiler

- How to correctly calculate the power of a gas boiler

- Review of the electrolux basic gas boiler

Advantages

This is an innovative technology that meets European safety and quality standards. Developers are introducing advanced technologies and modern technical solutions. On the Russian market and in the CIS countries, boilers of this brand have affordable prices, but at the same time they are not inferior in performance properties to world analogues.

Main advantages of boilers:

- a large selection of standard models of convection and condensation units;

- high efficiency with efficiency indicators in the range of 90-94%, achieved through a proven design and high-quality elements;

- ease of maintenance of the wall-mounted device;

- high degree of adaptation to Russian utility networks, boilers can heat water even at low pressure in the main gas and water networks.

Disadvantages of gas boilers "Proterm" "Cheetah":

- plastic hydraulic system;

- small expansion tank.

Important! The warranty period is valid for two years when installation and commissioning work is performed by specialists certified with Protherm diplomas