Protect your eyes | 10/06/2019

The technology of induction heating of workpieces is in demand not only in hot stamping shops. Compact inductors are necessary, in particular, for car service centers engaged in the manufacture and repair of steel parts from profiled rolled products. Purchasing an industrial inductor is expensive. Is there an alternative?

Induction heater circuit

Thanks to the discovery of the phenomenon of electromagnetic induction by M. Faraday in 1831, many devices that heat water and other media have appeared in our modern life.

Every day we use an electric kettle with a disk heater, a multicooker, and an induction hob, since it was only in our time that we were able to realize this discovery for everyday use. Previously it was used in the metallurgical and other metalworking industries. A factory induction boiler uses in its operation the principle of the action of eddy currents on a metal core placed inside the coil. Foucault eddy currents are of a surface nature, so it makes sense to use a hollow metal pipe as a core through which a heated coolant flows.

Operating principle of an induction heater

The occurrence of currents is due to the supply of alternating electrical voltage to the winding, causing the appearance of an alternating electromagnetic field that changes potentials 50 times per second at a normal industrial frequency of 50 Hz. In this case, the induction coil is designed in such a way that it can be connected to the AC mains directly. In industry, high-frequency currents are used for such heating - up to 1 MHz, so it is quite difficult to achieve operation of the device at a frequency of 50 Hz.

The thickness of the copper wire and the number of turns of the winding used by induction water heaters are calculated separately for each unit using a special method for the required thermal power. The product must work efficiently, quickly heat the water flowing through the pipe and not overheat. Enterprises invest a lot of money in the development and implementation of such products, so all problems are solved successfully, and the heater efficiency is 98%.

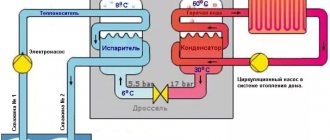

In addition to high efficiency, what is particularly attractive is the speed with which the medium flowing through the core is heated. The figure shows a diagram of the operation of an induction heater made in a factory. This scheme is used in units of the well-known VIN brand, produced by the Izhevsk plant.

Heater operation diagram

The longevity of the heat generator depends only on the tightness of the housing and the integrity of the insulation of the wire turns, and this turns out to be a fairly long period; manufacturers declare up to 30 years. For all these advantages that these devices actually have, you have to pay a lot of money; an induction water heater is the most expensive of all types of electrical heating installations. For this reason, some craftsmen have taken to making a homemade device with the goal of using it to heat a house.

Inductor in the kitchen

Induction hob

Induction hobs have become commonplace in the kitchen, see fig. According to the principle of operation, this is the same induction stove, only the bottom of any metal cooking vessel acts as a short-circuited secondary winding, see fig. on the right, and not just from ferromagnetic material, as the ignorant often write. Aluminum cookware is simply falling out of use; doctors have proven that free aluminum is a carcinogen, and copper and tin have long been out of use due to toxicity.

Household induction cookers are a product of the age of high technology, although the idea arose simultaneously with induction melting furnaces. Firstly, to isolate the inductor from the cooking, a durable, resistant, hygienic and EMF-free dielectric was needed. Suitable glass-ceramic composites have come into production relatively recently, and the top plate of the slab accounts for a significant portion of its cost.

Kitchen induction hob diagram

Then, all cooking vessels are different, and their contents change their electrical parameters, and the cooking modes are also different. A specialist will not be able to do this by carefully tightening the knobs to the desired fashion; you need a high-performance microcontroller. Finally, according to sanitary requirements, the current in the inductor must be a pure sinusoid, and its magnitude and frequency must vary in a complex way according to the degree of readiness of the dish. That is, the generator must have digital generation of the output current, controlled by the same microcontroller.

There is no point in making a kitchen induction hob yourself: more money will be spent on electronic components alone at retail prices than on ready-made good tiles. And it’s still quite difficult to control these devices: anyone who has one knows how many buttons or sensors there are with the inscriptions: “Stew”, “Roast”, etc. The author of this article saw a tile that separately listed “Navy Borscht” and “Pretanier Soup.”

However, induction cookers have many advantages over others:

- Almost zero, unlike microwave ovens, PPE, even if you sit on this tile yourself.

- Possibility of programming for preparing the most complex dishes.

- Melting chocolate, rendering fish and poultry fat, preparing caramel without the slightest sign of burning.

- High efficiency as a result of fast heating and almost complete concentration of heat in the cooking vessel.

Heating up cooking utensils on an induction hob and gas burner

To the last point: take a look at fig. on the right, there are schedules for heating up cooking on an induction stove and a gas burner. Anyone who is familiar with integration will immediately understand that an inductor is 15-20% more economical, and there is no need to compare it with a cast-iron “pancake”. The cost of money on energy when preparing most dishes for an induction cooker is comparable to that of a gas cooker, and even less for stewing and cooking thick soups. The inductor is so far inferior to gas only during baking, when uniform heating is required on all sides.

Induction heater: diagram and procedure for making it yourself

The uniqueness of man lies in the fact that he constantly invents devices and mechanisms that greatly facilitate work in one or another area of work or life activity.

For this purpose, as a rule, the latest developments in the field of science are used.

Induction heating was no exception. Recently, the principle of induction has been widely used in many areas, which can easily be attributed to:

- in metallurgy, induction heating is used to melt metals;

- in some industries, special rapid heating furnaces are used, the operation of which is based on the principle of induction;

- In the domestic sphere, induction heaters can be used, for example, for cooking, heating water or heating a private home. (You can read about the features of induction heating in this article).

Today there are a great variety of industrial-type induction installations. But this does not mean that the design of such devices is very intricate.

It is quite possible to make a simple induction heater for domestic needs with your own hands. In this article we will talk in detail about an induction heater, as well as various ways to make it yourself.

Do-it-yourself induction heating units are usually divided into two main types:

- vortex inductor heaters (abbreviated as VIN), which are mainly used for heating water and heating homes;

- heaters, the design of which provides for the use of various types of electronic parts and assemblies.

The vortex induction heater (VIN) consists of the following structural components:

- a device that converts ordinary electricity into high-frequency current;

- an inductor, which is a kind of transformer that creates a magnetic field;

- heat exchanger or heating element, which is located inside the inductor.

The operating principle of the VIN consists of the following stages:

- the converter transmits high-frequency current to the inductor, which is presented in the form of a cylinder made of copper wire;

- the inductor generates an electromagnetic field, which provokes the appearance of vortex flows;

- the heat exchanger located inside the inductor heats up under the influence of these vortex flows, and as a result, the coolant also heats up, which then enters the heating system in this form.

Specialist's note: since the induction coil is considered the most important element of a heater of this type, its manufacture must be approached quite scrupulously: the copper wire must be wound in neat turns onto a plastic pipe. The number of turns must be at least 100.

As can be seen from the description, the design of the VIN is not complicated enough, so you can easily make a vortex heater with your own hands.

Types of slabs

The household appliances market offers ovens of varying functionality and cost. Users can purchase both inexpensive induction cookers for the kitchen and multifunctional systems installed in cafes and restaurants.

The main types of this equipment include:

- compact tabletop induction cookers with one or more burners;

- built-in appliances or separate hobs;

- combined stoves - combine elements operating on the principle of magnetic induction and electric heating burners.

Combined induction-gas stove

When choosing a stove based on magnetic field energy, you should pay attention to the power capabilities and the number of modes. Intensive heating function allows you to cook food faster

It’s also worth thinking about the shape of the burner: it can be flat or recessed. The possibility of using dishes with different bottoms will depend on this. Multifunctional devices, such as induction cookers with an oven and a large number of burners, will allow you to cook several dishes at the same time.

Rules and recommendations for installation

- An induction heating system can only be equipped with a closed heating network with forced circulation provided by a pump.

- It is permissible to connect the device to a heating system with a plastic pipeline.

- A distance of at least 30 cm must be maintained between the surface of the walls, other appliances and the induction boiler, and a distance of more than 80 cm from the plane of the floor and ceiling.

- It is recommended to install a safety group behind the outlet pipe: a pressure gauge, an automatic device for air removal, and a blast valve.

Of course, you will have to tinker a lot with the production of the latter option, but the result and economic effect will undoubtedly bring pleasure. Factory induction equipment has been working like a clock for three decades, requiring no repairs. A homemade device will last at least 25 years, and if you make every effort, even more.

Productive vortex induction boiler for heating system - an economical option, with a 25-year term of impeccable service

It is possible that initially the manual production of an induction vortex boiler may seem quite labor-intensive and complex. But there will be a lot of benefits from it. In addition to the significant expense for the family budget on the purchase of expensive factory equipment, thanks to useful homemade products, the costs of expensive electricity will also be significantly reduced.

Appendix 3

Capacitors

| Capacitor type | Voltage, V | Reactive power, 103 var | Capacity, µF |

| ESP – 0.8 – 0.5 | 800 | 200 | 99,5 |

| ESV – 1 – 0.5 | 1000 | 200 | 63,6 |

| ESV – 1.6 – 0.5 | 1600 | 200 | 24,9 |

| ESP – 2 – 0.5 | 2000 | 200 | 15,9 |

| ESV – 0.8 – 1 | 800 | 250 | 62,2 |

| ESP – 1 – 1 | 1000 | 250 | 39,8 |

| ESV – 1.6 – 1 | 1600 | 250 | 15,5 |

| ESP – 2 – 1 | 2000 | 250 | 9,9 |

| ESV – 0.5 – 2.4 | 500 | 300 | 79,6 |

| ESV – 0.8 – 2.4 | 800 | 300 | 31,2 |

| ESV – 1.6 – 2.4 | 1600 | 300 | 7,8 |

| ESV – 1 – 2.4 | 1000 | 300 | 19,9 |

| ESV – 2 – 2.4 | 2000 | 350 | 4,9 |

| ESP – 0.5 – 4 | 500 | 350 | 55,7 |

| ESP – 0.8 – 4 | 800 | 350 | 21,8 |

| ESP – 1 – 4 | 1000 | 350 | 13,9 |

| ESV – 1.6 – 4 | 1600 | 350 | 5,4 |

| ESV – 2 – 4 | 2000 | 350 | 3,5 |

| ESP – 0.5 – 10 | 500 | 400 | 25,5 |

| ESP – 0.8 – 10 | 800 | 400 | 9,9 |

Self-production of an induction water heater

Remember, installing an induction water heater can significantly reduce energy costs. The design features of this mechanism ensure faster heating of the coolant compared to other analogues.

Manufacturing an induction device is a simple process that does not require significant labor costs or special skills. Even a novice specialist can perform this task.

However, before carrying out installation work, you should carefully study the technological sequence of work.

To make your own water heater, you need to prepare the following materials and equipment:

- — high-frequency inverter (as a rule, they use a mechanism from a welding machine);

- - a thick-walled piece of plastic pipe;

- — stainless steel wire with a diameter of no more than 7 mm;

- — adapters;

- - metal mesh;

- - enameled copper wire;

- — forced pump;

- - side cutters;

- - thermostat.

Remember, there are no standard heating elements in the design of an induction water heater. That is why there is no possibility of costly repairs if necessary. Also, the boilers do not have detachable connections, which often cause accidental leaks.

Recommendations that should be taken into account when installing induction-type water heating

Ensure that the welding current of the inverter matches its power.

The optimal current value is at least 15A.

Use five-centimeter pieces of steel wire. These elements will become the basis of the heated material, which will be located in the high-frequency field. To do this, the metal wire should be cut using side cutters.

- Make the heater body from a thick-walled plastic pipe. As a rule, this structural element must have an internal diameter of at least 5 cm.

- Connect the adapter to the pipe. The fittings should be installed on the side of the collector, which will be connected to the autonomous heating or water supply system.

- Place a metal mesh on the bottom of the plastic pipe. This will prevent the possibility of accidental spillage of wire rod.

- Place the prepared pieces of wire inside the plastic pipe. In this case, the procedure should be performed until the free space is completely covered.

- Install the transition element on the second end of the pipe.

- Wrap the prepared pipe with copper wire.

The number of turns should generally be between 80 and 90.

Remember, making the induction coil is the most important step in this job.

- Connect the structure to an autonomous heating or water supply system.

- Install a pump to ensure forced circulation of the coolant.

- Fill the manufactured structure with water and connect the inverter.

- Connect the thermostat in the main line break of the induction inverter.

Performing this operation makes it possible to adjust the water automatically.

Ground the manufactured installation.

Remember, you should turn on the induction water heater only after filling the structure with coolant. Failure to comply with this requirement leads to inevitable melting of the plastic housing of the device.

Channel melting device

The channel type induction steelmaking furnace has an electromagnetic core in its design. The operating principle of the device is the movement of an alternating magnetic flux through a magnetic circuit. An electric current is excited in a ring containing liquid metal, heating the charge to a predetermined temperature. The technology is used in foundries, mixers, and food serving tables. To increase the magnetic flux, a closed-type magnetic conductor made of transformer steel is used.

Channel furnaces got their name from the presence in the space of the unit of two holes with a channel forming a closed loop. Due to its design features, the device cannot operate without a circuit, thanks to which liquid aluminum is in continuous motion. If the manufacturer's recommendations are not followed, the equipment switches off spontaneously, interrupting the melting process.

Liquid bronze is poured through a siphon located on the end wall, additives and slags are loaded and removed through special holes. The finished product is dispensed through a V-shaped drain channel made in the lining according to a template, which is melted during the working process. Cooling of the winding and core is carried out by air mass, the temperature of the housing is regulated using water.

Assembly diagram and order

Electrical circuit of an induction water heater. (Click to enlarge) Constructing an induction heater with your own hands should proceed according to the following sequential steps:

A heating element. One of the ends of the plastic pipe is fixed with a metal mesh. Then the stainless wire is cut with wire cutters into small pieces that fit tightly inside the pipe

It is very important to avoid voids. The second end of the pipe is also fixed with a metal mesh.

Inductor

Copper wire is wound over the plastic pipe, which will create vortex flows. It is very important to know that the number of turns must be at least 90.

Inverter. This device is designed using thyristors, which allow you to efficiently convert ordinary electricity into high-frequency current. The thyristor inverter is the most important component of an induction heater. It is also worth noting that the thyristor converter has electronic control, which allows you to smoothly regulate the current supply and also reliably protects against emergency situations.

Connection. When the induction water heater is fully installed, it is directly connected to the heating system using ball valves and adapters.

You may be interested in an article on how to make an induction heater from a welding inverter.

Read an article on how to make an induction heater with your own hands here.

By following all of the above recommendations, you can easily construct an induction heater with your own hands.

Watch the video in which a specialist shows in detail the process of assembling an induction water heater with his own hands:

Vortex induction heaters VIN: design, pros and cons of use in heating systems

Induction heater: diagram and procedure for making it yourself

Induction heating boiler: advantages of use and do-it-yourself manufacturing technology

Appendix 2

Power supplies ITP (thyristor frequency converters)

| Type | Output parameters | ||

| Rated power, kW | Rated frequency, Hz | Rated voltage, V | |

| SCHI – 100/3 | 100 | 3000 | 400 |

| SCHI – 250/3 | 250 | 3000 | 800 |

| TFC – 160 – 2.4 | 160 | 2400 | 800 |

| TFC – 250 – 2.4 | 250 | 2400 | 800 |

| TFC – 250 – 8 | 250 | 8000 | 500 |

| TFC – 320 – 1 | 320 | 1000 | 800 |

| TFC – 500 – 2.4 | 500 | 2400 | 800 |

| TFC - 1 | 630 | 500 or 1000 | 800 |

| TFC – 800 – 0.5 | 800 | 500 | 800 |

| TFC – 800 – 1 | 800 | 1000 | 800 |

| TFC – 1000 – 2.4 | 1000 | 2400 | 800 |

| TFC – 1600 – 0.5 | 1600 | 500 | 800 |

| TFC – 1600 – 1 | 1600 | 1000 | 800 |

| TFC – 2400 – 0.5 | 2400 | 500 | 800 |

| TFC – 2400 – 1 | 2400 | 1000 | 800 |

| TFC – 3200 – 0.5 | 3200 | 500 | 800 |

| TFC – 3200 – 1 | 3200 | 1000 | 800 |

Design features and operation of the heat generator

To organize individual heating, a transformer consisting of two windings can be used as an induction heater for this system:

- Primary.

- Secondary short-circuited.

Vortex flows here are formed in the internal component. They direct the resulting electric field to the secondary circuit. It is he who performs the simultaneous role of a housing and a heating element for the coolant. With an increase in the density of eddy currents that are aimed at the core, its entire surface initially begins to heat up, and then the entire element.

An example of installing an induction current water heater for heating

For the supply of cold water and the outlet of heated coolant, induction boilers are equipped with two pipes.

For those who want to make such equipment with their own hands, you need to provide that:

- The lower pipe is mounted on the inlet main section;

- The upper one is on the supply section of the pipeline.

How the system works

The heat generated by the boiler is transferred to the coolant circulating in the heating system. Due to hydrostatic pressure, heated water enters directly through the supply pipe into the general heating system and is constantly removed by pumping coolant into it. Therefore, the possibility of equipment overheating is completely excluded here.

Comparison of energy consumption of an induction water heater with others

Constant vibration during operation of the induction system prevents the formation of scale and its hard deposits on the internal walls of the pipeline. Induction heaters do not have standard electric heating elements, so the likelihood of costly breakdowns is reduced to zero. In addition, there are no detachable connections that could threaten unplanned and unpleasant leaks. A positive feature of this boiler is the absence of noise during operation, which allows it to be installed in any residential premises.

Annex 1

Thermal characteristics of metals

| Metal | Melting temperature ?WITH | Temperature pouring ?C | Heat content/(enthalpy) in the molten state J/kg (kWh/kg) | Cold resistivity Ohm*m | Resistivity in molten condition Ohm*m | Density at casting temperature t/m3 |

| Aluminum | 660 | 730 | 1,44*106/(0,4) | 3*10-8 | 24*10-8 | 2,5 |

| Copper | 1085 | 1230 | 0,79*106/(0,22) | 2*10-8 | 21*10-8 | 8,3 |

| Steel | 1400 | 1600 | 1,42*106/(0,39) | 0,2*10-6 | 1,37*10-6 | 7,2 |

| Cast iron | 1100 | 1300 | 0,9*106/(0,25) | 0,25*10-6 | 1,5*10-6 | 6,7 |

What is an induction boiler?

Induction heating systems began to be used in the 80s of the last century in industrial enterprises. Household appliances appeared only in the mid-nineties. Over the past decades, they have been refined and some updates have been made to their design, however, the principle of their operation remains unchanged.

The name of these heating systems and devices in itself indicates that their operation is based on electromagnetic induction. The essence of the operating principle is that if an alternating current is passed through a wire of a sufficiently large diameter cross-section, wound in the form of a coil, then a powerful electromagnetic field is created around this primary winding. If there is a conductor in this field, then voltage will be induced (induced) in it. Well, if the field lines intersect a core made of an alloy with magnetic properties located in it, then a kind of short-circuited circuit is obtained. And due to the appearance of stray Foucault currents on it, very fast and strong heating of this material occurs.

The simplest diagram of the operating principle of an induction heater

This principle is widely used, for example, in the steel industry. They also found a use for it for fast and high-temperature heating of water. It is clear that the core in this case will be a pipe or other channel through which the coolant circulates.

And the most understandable example of an induction heater is a wire wound around a pipe made of a dielectric, which will insulate a magnetic core placed in its interior.

The wire coil is connected to the power supply and creates an electromagnetic field. As a result of exposure to an alternating electromagnetic field, the metal core rod will heat up, transferring heat to the coolant, which then enters the pipes and radiators of the heating circuit. Oil, water or ethylene glycol can be used as a coolant in autonomous heating systems.

Instead of a core, modern boilers use a whole labyrinth of channels and pipes for heat exchange. Their walls, made of a ferrimagnetic alloy, provide a large area of contact with water and therefore very intense heating of the coolant circulating through them

This is, of course, a very simplified explanation. In industrial induction boilers, the heat exchange ferromagnetic core can be a whole labyrinth of pipes or channels, and often, for example, in vortex heaters, the body of the device is also involved in this process.

One induction boiler of correctly selected power is capable of providing heated coolant to several circuits of an extensive heating system. Naturally, with proper placement of collectors and circulation pumps.

In heating systems of short length, the coolant, when heated, will rise upward, and the created natural pressure is usually sufficient for its natural circulation. If the heating main is quite long and branched, connected to collectors with further distribution of coolant flows along separate circuits, then one or more circulation pumps are installed in the system, since without them the required coolant movement will be impossible to achieve.

The best electric built-in hobs in the premium segment

Premium solutions look great and are easy to use. But similar units are offered for sale at a more affordable price. So why should you choose premium models? Of course, because of their reliability. The final category of our rating includes devices only from German manufacturers. Design, functionality, assembly - everything is top notch here. However, for these advantages the consumer will need to pay an appropriate amount.

Kuppersberg FA6IF01

We decided to start with the most affordable glass-ceramic hob in the premium segment. Model FA6IF01 will cost you about 30 thousand rubles. For this amount you will receive two large and the same number of small heating zones, a burner timer, convenient touch-type controls, a residual heat indicator and a safety shutdown. Also, the device from Kuppersberg provides the possibility of parental control, and the presence and diameter of dishes on the surface of the FA6IF01 can be automatically recognized.

Advantages:

- high heating speed;

- protective functions;

- original design;

- quality of assembly and parts;

- determining the diameter of the dishes;

- boiling function;

- reasonable cost.

Flaws:

square burners.

Siemens EH651FFB1E

If you are looking for a reliable 4-burner cooktop with an oval heating zone and a reasonable price, then we recommend taking a closer look at the EH651FFB1E. It is made of glass ceramics, has a rated power of 7.4 kW, and also has touch slider switches that allow you to conveniently adjust the heating of the burners.

After switching off, the heating zones cool down quickly enough, and the panel itself is able to display the residual heat of each of them. If there are small children in the house, then for their safety the device has a control lock button. The device is also protected from failures, automatically turning off when operating in abnormal mode.

Advantages:

- excellent power;

- the ability to pause a specific burner;

- ease of care;

- low noise level;

- smooth adjustment;

- durable surface;

- beautiful appearance.

Flaws:

demanding on dishes.

Bosch PIF679FB1E

If you dream of a bright kitchen, then black appliances can disrupt the integrity of your chosen interior. In this case, the ideal option for purchase would be a good electric hob PIF679FB1E, manufactured by Bosch. This unit has 4 burners and a convenient control panel. The latter allows you to select one of 9 heating modes for each zone, lock the buttons and set an automatic shutdown timer. If necessary, the user can use a short pause, as well as the oval burner in the upper left corner.

Advantages:

- silver color;

- oval heating zone;

- convenient control;

- tableware recognition;

- chic appearance;

- high-quality glass-ceramic surface;

- There is a pause function.

Bosch PXV851FC1E

The premium model from Bosch leads the list of the best electric hobs. The PXV851FC1E's design and functionality are truly impressive. However, the recommended price tag for this unit is no less impressive - 88,000 rubles. To embed the device, you need a rectangular slot in the tabletop with a width of 75 and a depth of 49 centimeters.

Among the useful functions of the device are protective shutdown and detection of the presence of dishes on the surface. The latter is made of durable glass ceramics, which heats up quickly after the stove is turned on. The device can turn off not only manually, but also automatically. For this purpose, there is a sound timer.

Advantages:

- flawless assembly;

- stylish appearance;

- large heating zone;

- presence of a metal frame;

- precise touch control;

- high power;

- sleep timer.

Flaws:

high price.

Operating principle

If you disassemble an induction type boiler, you will find the core, electrical and thermal insulation, then the body. The difference between this heater and those used in industry is the toroidal winding with copper conductors. It is located between two pipes welded together. These pipes are made of ferromagnetic steel. The wall of such a pipe is more than 10 mm. As a result of this design, the heater has much less weight, higher efficiency, and is also small in size. A pipe with a winding acts as a core here. And the other serves directly to heat the coolant.

The induction current, which is generated by a high-frequency magnetic field from the external winding to the pipe, heats the coolant. This process causes vibration of the walls. Thanks to this, scale does not deposit on them.

Heating occurs due to the fact that the core heats up during operation. Its temperature rises due to eddy currents. The latter are formed due to the magnetic field, which, in turn, is generated by high voltage currents. This is how an induction water heater and many modern boilers work.

What are the differences from other plates?

Induction cookers compare favorably with other types of stoves (gas and electric).

A number of points are worth highlighting:

The efficiency of induction furnaces reaches 90%. For comparison, in gas stoves this figure is only 30-60%, and in electric stoves - no more than 70%; High heating rate (devices with heating elements or gas burners cannot boast of this feature); Efficiency. After removing the dishes, you do not need to turn off the work area manually - this happens automatically. In electric or gas stoves, the burner continues to work, which leads to excessive consumption of gas and electricity

In the summer, this is especially important, because there is additional heating of the air, which complicates the process of air conditioning (cooling) the room; Precise temperature control. On stoves with heating elements or gas-fired, temperature control occurs “by eye”

In the case of induction cookers, you can maintain the same setting throughout the entire cooking time;

Safety. If a person accidentally mixes up the cookware and places a product with a non-magnetic bottom, the burner will not work. To activate the burner, the cookware must cover its area as much as possible, 50% or more; Many additional functions that classic gas or electric stoves cannot boast of.

Water boiler with transformer

To get started, get or buy an inexpensive welding inverter (transformer) with current regulation of 18-25 amperes. Small pieces of wire rod or stainless steel are used as elements for heating water in a water heater. The wire is cut into pieces of length from 3.8 to 5.5 cm (if a wire rod with a diameter of 6-8 mm is used). Then the heater body is made from a thick-walled plastic pipe with a diameter of 45-50 mm. One end of this section of pipe is covered with a fine mesh and cut wire is poured from the free open end of the body.

induction heater design diagram.

Having filled the pipe to the top with scraps, they begin to manufacture the inductor coil. Take an enameled copper wire of at least 1.5-2 mm and wind it around the made body. The number of turns varies (depending on the amperage of the welding inductor) and is 85-95. The coil is placed in the center of the body (pipes with scraps). The heater is connected to the water supply system or heating network using adapters.

To make a vortex induction boiler-water heater based on the resulting heater, you need to weld a structure resembling a donut from two pipes. This is a water heating element. Take any tank of suitable diameter and insert the inlet (in the upper part of the tank) and outlet pipes for water into it. The previously made induction coil is inserted into this housing. Then attach the heater (donut) to the nozzles so that it passes inside the inductor strictly in the center. The output ends of the coil are insulated and connected to the transformer. To prevent heat from leaving the water heater, it is covered with a heat-insulating screen.

Water, passing through the pipes inside the coil, heats up and comes out of the outlet pipe hot.

Such an induction boiler-water heater can also be connected to a system made of plastic pipes. To ensure safety, the boiler is installed at a distance of 80-90 cm from the floor and ceiling and 30-40 cm from the wall. This water heater must be equipped with a valve installed on the pipe to bleed air from the system. Such a boiler can also be used as a heater for a small room by adding a heating radiator.

Arc furnace

Arc furnaces are devices powered by electricity. In this case, electrodes are used to heat the contents of the chamber, creating a thermal arc that heats the metals. The arc temperature can reach 1800˚, as a result of which an extremely high temperature is created inside the chamber, melting non-ferrous and ferrous metals.

Components of an arc furnace

- Melting bath.

- Power regulator.

- The mechanism for closing, opening and sealing the chamber.

- Slag collections.

- Removing liquid metal from the furnace.

Regulation of the thermal intensity of the electric arc is carried out using special software that moves the electrodes in vertical space. Previously, electromechanical regulators were used, but today they are practically not used, because they have a large inertia.

In order for the device to show the expected results, it is customary to use a kind of “furnace” transformer connected directly to high-voltage wires or a transformer with a power of up to 300 MVA.

The advantages of an arc furnace are:

- Ability to melt metals of any composition.

- You can manually adjust the heating temperature of the furnace.

- It is permissible to produce alloys from several combinations of metal using such equipment.

To use an arc furnace for smelting, you must first load the raw material inside through the furnace charge located on top. Loading of raw materials is carried out using a special basket - a loading tub. To avoid damage to the device by large pieces of metal, small parts are loaded onto the bottom, and then 2-3% of lime is introduced (of the total mass of the loaded raw materials).

After the arc furnace is fully loaded, electrodes are placed inside the chamber and a high-voltage switch is turned on, resulting in the formation of a high-voltage hot arc that transfers heat to the metal loaded inside.

Application of arc furnace

Arc furnaces for melting steel, aluminum, gold, copper, bronze, nickel, tungsten are used in various industries, such as foundries, jewelry manufacturing plants, as well as the metallurgical, mechanical engineering, and chemical industries. Such furnaces are also used for research in laboratories experimenting with metals by exposing them to extremely high temperatures.

Power calculation

Since the induction method of steel melting is less expensive than similar methods based on the use of fuel oil, coal and other energy sources, the calculation of an induction furnace begins with calculating the power of the unit.

The power of an induction furnace is divided into active and useful, each of them has its own formula.

As initial data you need to know:

- the capacity of the furnace, in the case considered for example, it is 8 tons;

- unit power (its maximum value is taken) – 1300 kW;

- current frequency – 50 Hz;

- The productivity of the furnace plant is 6 tons per hour.

It is also necessary to take into account the metal or alloy being melted: according to the condition, it is zinc. This is an important point, the heat balance of cast iron melting in an induction furnace, as well as other alloys, is different.

Useful power transferred to liquid metal:

- Рpol = Wtheor×t×P,

- Wtheor – specific energy consumption, it is theoretical, and shows the overheating of the metal by 10C;

- P – productivity of the furnace installation, t/h;

- t – overheating temperature of the alloy or metal billet in the bath furnace, 0C

- Rpol = 0.298×800×5.5 = 1430.4 kW.

Active power:

- P = Ppol/Yuterm,

- Rpol – taken from the previous formula, kW;

- Yuterm is the efficiency of a foundry furnace, its limits are from 0.7 to 0.85, with an average of 0.76.

- P = 1311.2/0.76 = 1892.1 kW, the value is rounded to 1900 kW.

At the final stage, the inductor power is calculated:

- Rind = P/N,

- P – active power of the furnace installation, kW;

- N is the number of inductors provided on the furnace.

- Rind =1900/2= 950 kW.

The power consumption of an induction furnace when melting steel depends on its performance and the type of inductor.

Application

Heating based on eddy currents created by electromagnetic fields can find its application in:

- heating a residential property, house, bathhouse, garage, industrial or administrative building;

- in the hot water supply system;

- heating of buildings and structures that have certain requirements for heat sources (for safety).