Home / Solid fuel boilers

Back

Published: 02/24/2020

Reading time: 5 min

0

1671

In modern heating systems, a three-way valve for a solid fuel boiler performs the function of adjusting the temperature of the coolant.

The heat supply to the heating device must be carried out in accordance with the outside air temperature and ensure a sanitary regime inside the room.

Then you can get an economical, efficient heating system, avoid underheating or boiling of the coolant, which are considered the most pressing problems of a solid fuel unit.

- 1 Design and functionality of the device

- 2 Types of valve actuators and operating principle

- 3 Selection criteria 3.1 Capacity assessment

- 3.2 Necessity of placement

How does the valve work and what is it for?

The desire to save energy resources leads to the creation of ever new types of equipment that allow us to solve this problem. By design, three-way valves combine a pair of two-way devices. However, they do not block the flow of the coolant, but perform the function of adjusting the intensity of the water flow to achieve the desired temperature regime.

Important. A three-way valve makes it possible, without changing the area of the radiators, to provide the room with the required amount of heat, exclusively within the power characteristics of the heating system.

A three-way valve has externally different configurations and different types of actuators, but the task is the same: to mix two streams of water of different temperatures into one stream with a set temperature level. In this case, the liquid will move from one pipe to another until the temperature reaches the required value. After this, the drive will gradually admit coolant from the third pipe to maintain the temperature at the required temperature level. That’s why they call it a “three-way valve”, since all actions occur in three steps.

The main purpose of a three-way mixing valve for a boiler is to consistently maintain a comfortable thermal balance in the room. Moreover, this problem is solved not by reducing the temperature of the coolant, but by changing the amount of liquid. This is especially true in cases where it is impossible to lower the temperature of the coolant in any other way. Despite the fact that the device performs such a complex task, its design is quite simple.

Basic design

Several designs of three-way valves have been implemented, which, however, do not affect the performance of the device’s main functions.

Three-way globe valve

The main element of the device is a movable rod, which has a significant power reserve. A valve is installed on the rod, blocking one of the two pipes. If the rod is in its extreme upper or lower position. Regardless of the position of the shutter, the intensity of coolant supply from the main pipe “AB” does not decrease.

The design is used for both mixing and separating flows. Depending on the type of coolant or other type of working environment, the configuration of the valves, the freedom of movement of the rod, the shape of the seats, etc. may change. Such models are characterized by the use of electric drives for remote automatic control.

Three way rotary valve

The device has a radially rotating rod. The rotation angle is strictly 90° and covers only two pipes. In the extreme left or right position, one of the pipes is completely blocked. In the range between these two positions, the coolant is supplied and mixed. Rotary drives can be used as automatic control devices.

Design differences of the device

Based on their design differences, three-way valves are divided into the following types:

- Mixing valve with up and down adjustable stem (“stem-seat”). The rod moves using an electromechanical drive. In fact, here we are talking about extreme automation of the work and adjustment of the system. The mixing valve is designed to connect water flows and thermoregulation. For incoming streams that have different temperatures, two inputs and one output are provided. These valves are often used when installing underfloor heating to prevent the system from overheating.

- The second type is a separating valve that operates on a ball-socket system. The location of the ball changes due to its rotation. This valve is used if the coolant needs to be supplied in several directions at once. In essence, it is a mixer that forms a water flow at the required temperature. The device has good wear resistance, as it is designed to withstand sudden changes in fluid temperatures. It is classified as a shut-off valve. In households where water is consumed in a small volume, it can also be used as a regular mixer.

The shape of the valve is similar to a regular tee. However, its functionality is completely different. The three-way valve is also used as a mixer, as well as an air or hot water distributor.

Education

The buyer's employees can undergo training in servicing boiler houses produced by Alliansteplo. Although all of our boiler room systems are automated and do not require the constant presence of maintenance personnel, there are always subtleties and features in servicing specific equipment. During the process of commissioning and operational adjustment work, our specialists will talk in detail about the features of servicing boiler houses, explain and show what to do if non-standard situations arise and how to most optimally maintain operation in normal mode.

What types of three way valves are used

The thermostatic mixing valve for the boiler is equipped with two inlet pipes and one outlet. The types of drives by which liquid is distributed are as follows:

- pneumatic;

- hydraulic;

- manual;

- electromechanical.

Electromechanical, in turn, are of the following types:

- thermostatic;

- capitate.

Thermostatic type of drives is usually used in everyday life. Under the influence of high temperature, the sensing element expands, presses on the rod of the device and opens it. In this way, cold and heated liquids are mixed. The thermostatic head is equipped with a remote temperature sensor, which is installed instead of a thermostat.

Important. The most convenient, simple and accurate way to regulate the flow of coolant is considered to be a thermostatic drive, which does not use electricity.

Electrically driven devices receive signals to mix the liquid from the control unit. Valves with servo drives are simplified versions of models with controllers, where the valve is controlled directly.

If the drive of a three-way thermal mixing valve for a boiler is a head one, then the valve is controlled by pressing the head on the stem. This type is successfully used in underfloor heating systems. The manual drive is activated by rotating the cap, which is placed on the valve.

Important. If you purchase a three-way thermostatic valve for the boiler, to which you can connect a servo drive, then the auto mode will be especially useful with a water heated floor system.

Alternative ways to connect heated floors

There are other options for connecting warm water floors:

- When installing a heated floor in a room whose size is no more than 10 m2, the temperature level can be adjusted using a simple valve. To increase the heating level, the valve must be unscrewed, to decrease it, screw it in. The disadvantage of this method lies in manual adjustment. When installing an additional two-way valve on one side, the adjustment will be made automatically, the same as when using a three-way valve.

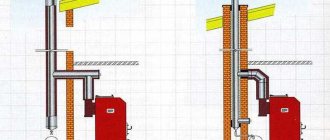

- It is possible to connect a warm hydrofloor directly from the boiler. But then, the presence of a heat generator, safety fittings and a pump is required. Water from the tank is supplied to the collector unit, and then sent to the floor branches, after bypassing the main line it returns to the boiler. It needs to be adjusted to the temperature of the underfloor heating fluid.

If the heated floor is equipped according to this scheme, then it is better to install a condensing boiler, since it is able to operate at full capacity in low temperature mode. A conventional boiler operating at low temperatures will cause heat exchanger failure. When using a solid fuel boiler, a buffer exchanger is required to regulate the temperature.

Connecting a heating floor to a pumping and mixing unit - this diagram is intended for a combined heating system with a radiator and a heated floor. In the mixing unit, waste water is mixed with hot water coming from the heating source.

All pumping and mixing units have a balancing valve; it dispenses cooled liquid. Thus, it is possible to obtain the strictly required water temperature for the reproductive system at the outlet of the equipment, which increases its efficiency.

There are different models of pumping and mixing units, they are equipped with: a bypass, which has a bypass valve, a balancing valve or ball valves, they are located at the edges of the pump.

Connecting a floor with heating from a radiator - this requires a special kit, with temperature limiters for the coolant and air, and an air vent. Water is directed into the floor pipes directly from high-temperature radiators, where it is cooled to the desired degree, and the next batch is supplied. But with this scheme, there are overheating zones.

When planning to install a warm water floor at home, you should think through all the design elements in advance. And most importantly, how the required temperature of the coolant in the heating system will be achieved. Of course, a pumping and mixing unit is a more advanced device, but it costs more, and not everyone can install it themselves.

An excellent option is a thermostatic valve. It is inexpensive, its connection is simple, and at the same time, it copes perfectly with the function of adjusting and controlling the water temperature.

How to choose a thermostatic mixing valve

The thermostatic mixing valve for solid fuel boilers should be selected according to parameters that relate to both the control valves and the characteristics of a particular heating boiler:

- According to the material of manufacture. This is an extremely important selection criterion that affects the technical and operational characteristics of the device. A copper or cast iron valve is considered the best.

- By volume of coolant consumption. This indicator can be found from the technical data sheet for the boiler or from the design documentation for the heating system. The coolant flow rate must be known in order to correlate it with the throughput capacity of the valve.

- A three-way thermostatic valve for a solid fuel boiler is selected based on the modification of the drive and the piping diagram. In a simplified version, the diagram is as follows: the valve supplies coolant from the third pipe to the first. As soon as the liquid in the boiler heats up to the required temperature, a flow of unheated coolant will come out of the second pipe. Essentially, an exchange will occur when the cold liquid from the heat accumulator tank is replaced by hot one. If there is a controller on the crane, then the piping is more complex. Here you will need dual-circuit and dual-drive mixers. The first (thermostatic) is placed next to the heat source. The second drive is electric and is controlled by a controller that supplies signals from the sensor. The thermostatic valve for solid fuel boilers maintains the set water temperature. Important. The choice of drive is an extremely important component when purchasing a thermal mixing valve for a solid fuel boiler. Manual ones are much cheaper, more reliable, but less functional; electric ones break down faster and cost much more, but they solve the problem radically.

- The most important operating parameter of a three-way mixing valve for a solid fuel boiler is the maximum permissible temperature of the coolant. It should be from 35 to 60 degrees. If we are talking about valves for hot water supply or water heated floors, the requirements for devices with a thermostatic drive are different, since the temperature reaches 90 degrees.

- When purchasing a valve, you need to take into account the dimensions of the internal and external diameters for connection to the heating system. If you cannot find the right size, you can use a regular adapter to solve the problem.

Boiler repair

In case of leakage, we repair fire tube boilers in the following sequence:

- We study the documentation and diagrams of the device.

- We search for the problem area and localize it.

- We clean the surface near the crack to bare metal to a width of 15-20 mm.

- We carry out welding work at ambient temperatures above +50C. We use electrodes with a thickness of 2.5 mm or 3 mm. We weld the seam from the side of the drum 2-4 mm larger than from the pipe. The welding direction is from the middle of the crack to the edges using two welding machines simultaneously.

- We clean the seam until it shines and look at its quality. If necessary, we eliminate deficiencies: uncooked areas and shells.

- We test the boiler.

Fire-tube water-heating boilers are used in boiler houses, for heating private households, in industry and other areas. Sometimes in the construction of fire-tube boilers, due to improper operation, it becomes necessary to replace the damaged section.

For these purposes, the gas-flame method is used. In this case, the dimensions of the damaged part must be at least 200 mm or the diameter of the pipe. First, they localize the area, then cut it out with a grinder until the thickness and properties of the metal are preserved, after which they clean and weld a patch made of steel of the same composition. Fire-tube water heating boilers are used in boiler houses, for heating private households, in industry and other areas. This is due to their high heating efficiency and economical fuel consumption, reliability and ease of operation. The design of fire tube boilers is relatively simple, so they can be easily repaired even independently without the involvement of specialists.

Operating requirements

When connecting a three-way valve to a boiler that runs on solid fuel, you must strictly follow the operating rules of the system:

- Periodically conduct a thorough inspection of the system to ensure its stable operation.

- Do not allow the equipment to be used for purposes other than its intended purpose.

- All equipment for the heating system must correspond to the technical capabilities of the heating boiler.

- Shut-off valves must not be installed between the expansion tank and the heating system.

- In order for the boiler to comply with the rules for safe use, the heating system is equipped with an emergency relief valve, which is activated urgently when it is necessary to reduce the pressure in the heating system.

- For ease of installation, the direction of movement of the coolant with a three-way thermal mixing or distribution valve is shown on the device body with arrows or letters. The device should be installed in the heating system only in the indicated directions. Failure to comply with this rule may cause a breakdown of the entire system and even an explosion of the boiler.

Installation of a three-way thermostatic mixing valve for a solid fuel boiler is also done in the case of simultaneous connection of several heating circuits with different temperature indicators. A fairly popular esbe three-way valve, which is very reliable and practical to use.

All of the above requirements must be strictly observed in order to increase the service life of all heating system equipment and ensure safe and efficient operation.

Principle of operation

The valve that protects the boiler has a simple device and operates on a principle that is understandable even to a schoolchild. The device consists of a straight fitting with a 90-degree outlet and a spring-loaded seal that closes the side passage. When the pressure in the system increases due to overheating, exceeding the pressing force of the spring holding the valve in a stationary position, it rises up and opens the side hole.

Excess liquid begins to pour out from the side and is sent to a container, drainage or sewer system. After bleeding part of the coolant, the pressure in the system and on the valve weakens, the spring puts it in place, closing the side pipe.

Two final recommendations

Since we have presented a simplified method for calculating and selecting a 3-way valve based on capacity, we strongly advise you to consult knowledgeable people on this matter. If this is not possible, purchase a valve with a reserve, regardless of the price. There is another option: agree with the seller about a possible replacement of the product in case it does not fit.

If you need to install water heating in a large cottage, heated by a radiator network and heated floors, and you plan to provide hot water from an indirect heating boiler, then you will not be able to do it without the help of experienced specialists. You will have to make from 4 to 10 adjustable branches, for each of which you need to calculate and select a three-way valve, and then balance their work as a whole.