In modern heating systems, more advanced equipment is used to minimize economic costs and increase the efficiency of installations. An induction boiler for a private home is an excellent alternative to classic models with heating elements.

The main advantage of induction boilers is the rapid heating of the coolant, so these models, in addition to heating, are used for heating water.

Boiler design VIN

Vortex induction heaters (VIN) are not produced in the city of Izhevsk. These devices became known and popular in the CIS countries. Apparently, due to its simplicity of design and reliable operation.

The boiler consists of:

• Metal body.

• Induction coil, it is located in the inner chamber of a hollow cylinder. A metal pipe is inserted into the hole of the cylinder, acting as a core.

• Two pipes for cold water inlet and hot water outlet.

• Quartz sand.

• Control cabinet.

• Temperature sensor.

• Safety system.

Advantages and disadvantages of installing VIN

As mentioned earlier, induction boilers, compared to their predecessors, heating elements, are characterized by greater efficiency. The monetary costs of heating with induction heaters are not only lower than when using heating elements, but also do not change during operation. An automatic control system controls the air temperature in the room and, if necessary, turns off the heater, so the boiler operating time per day is no more than 8 hours. The efficiency of tubular heaters subsequently decreases significantly and increases the cost of electricity.

Economics of VIN use

VINs belong to electrical safety class 2 devices, having reinforced insulation. An induction boiler does not require grounding or additional ventilation in the room. Fire safety is ensured by the absence of connecting sections and electrical contacts exposed to high temperatures.

Not only water can act as a coolant, but also any liquid non-freezing materials that do not need to be removed from the system with the onset of cold weather. This is true for rooms not used during such a period - the boiler can simply be turned off. No additional technological preparation of the carrier is required. In addition, even when using “hard” technical water, there is no problem of scale, since magnesium and calcium ions, due to the influence of powerful eddy currents, do not settle on the walls of the pipe, but are removed with a stream of hot water.

To install a VIN, no special approvals are required from regulatory authorities (Rospotrebnadzor), unlike gas heaters. The design can be easily integrated into an existing heating system.

The main disadvantage of induction boilers is their high cost. Their use is also impossible in open heating systems. It is also not always possible to mount the heater on a wall.

Unlike a heating element, an induction boiler will last for 30, and when used in a residential area - 40 years, or more than 100,000 hours. The equipment does not require inter-seasonal checks, preventive maintenance is kept to a minimum. When carrying out work on installing boilers, there is also no need to involve qualified workers. In addition, induction boilers are silent during operation.

Durability, compactness, autonomy and the absence of the need for frequent maintenance make VIN a profitable alternative to uneconomical tubular heaters and gas boilers that require high initial costs.

Boiler marking

The plant produced several modifications of boilers that use electromagnetic induction for their operation. They all have different powers.

The numbers after the abbreviation indicate the boiler power. A boiler with a minimum power of 3 kW is capable of heating an area of 40 square meters, a device consuming 80 kW will create heat in a building of 900 m2.

Equipment options

Almost all manufacturers offer induction boilers in the power range from 3 to 80 kW in two types of configurations:

- standard. Includes equipment for controlling the boiler (cabinet measuring 20x40 cm and a remote control that allows contactless control) and a temperature sensor.

- improved (VIP). In addition to the standard set, it contains a coolant flow sensor, a circulation pump and shut-off and control valves. The kit includes a boiler safety group - structural elements that protect against excess pressure in the system. Most often this is a system of a pressure gauge, a valve for releasing excess coolant and an air vent.

Vortex induction boiler VIN – 5

The boiler is used to heat private houses. Consumes 5,000 W. The body is metal, the thickness of the core walls is 10 mm, the coil is made of copper. Operates on 220 volts.

The boiler easily heats a room of 60 meters. The pipes have a diameter of 25 millimeters. Weight is 27 kilograms. Dimensions 675 x 133. The first number is the height, the second is the diameter.

Specifications

The induction boiler is universal and connects to a regular 220 V electrical network supplying alternating current (frequency 50 Hz). There are models operating from a 380 V network.

Thermal performance depends on the power of the heater and varies from 2500 to 67400 Kcal/hour for various configurations. An increase in power, and, consequently, the potential size of the heated room, affects the price of the VIN. Boilers with a power of over 7 kW are a system of three heaters arranged in series.

Dimensions for single heaters (VIN-3, -5, -7/220 V) are most often indicated as structure height x diameter. A typical boiler with a diameter of 13.3 cm has a height of about 62 cm. The weight of the device is 25-30 kg. More powerful boilers can weigh up to 185 kg, which imposes certain restrictions on their wall placement.

The diameter of the inlet and outlet pipes is the same and, depending on the characteristics of the VIN and the manufacturer, is 23-32 mm.

Myths about induction boilers

One of the most popular myths is created by sales representatives selling induction electric boilers. The bottom line is that these boilers are supposedly 20-30% more efficient than other heating electrical installations, especially heating elements. This information is not true, since all heat generators that convert electricity into heat operate with an efficiency of at least 96% in accordance with the physical law of conservation of energy. The only undeniable fact is that heating elements heat up the coolant a little longer due to their multilayer structure. The tungsten spiral first heats the quartz sand, then the tube material, and then the water. In this case, energy is not lost anywhere, and the efficiency of the heating element unit is 98%, the same as the vortex unit.

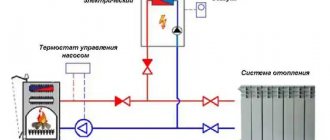

Example of a heating system

Another myth is that an induction electric boiler requires no maintenance at all, since the alternating magnetic field prevents deposits from settling on the heating elements. This question depends on the quality of the water and scale appears on the coil core in the same way as in heating element heaters if the coolant is not desalted. Therefore, at least once every 2 years, the heat generator itself and the heating system must undergo a flushing procedure.

Contrary to the assurances of the sellers, the water heater cannot be installed in any room. There are two reasons: the danger of electric shock and the presence of an electromagnetic field around the device. It is better to place it in a technical room with limited access (boiler room).

Principle of operation

The work is based on the principle of electromagnetic induction:

- After the device is started, an electromagnetic field is generated. In this case, the core warms up to a temperature of 75 degrees.

- Water is supplied through the inlet pipes to the core heat exchanger.

- The coolant heated to a given value is supplied to the pipe system through the outlet pipes.

For heating large and multi-storey buildings, the presence of a circulation pump in the system is mandatory.

Induction heating is the fastest of all currently available.

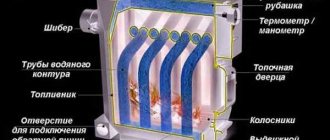

Models consist of three main nodes (layers):

- Internal - directly the core. Manufactured in the form of steel pipes.

- Insulation. Necessary to reduce heat loss to the unit.

- Outer – body. Made of metal.

The coolant used is water or antifreeze.

Induction boilers type SAV

They are used for autonomous and combined heating systems, hot water supply systems, backup heating sources, maintaining a given temperature in industrial installations (reactors).

The advantage of SAV boilers is the possibility of remote temperature control and complete automation of the heating process.

They consist of an inductor, a system of short-circuited channels and pipes and a heating element - a core. Heating of the coolant occurs due to the formation of an electromagnetic field and the conversion of electrical energy into thermal energy.

Important! Due to the branching of the installation system, the efficiency is approaching 100%.

Boiler units are produced in three types:

- Low-power. 2.5-10 kW. For small private and country houses.

- Medium power. 15-60kW. For administrative and multi-storey residential buildings.

- Great power. 100-500 kW. Used in industrial installations.

Water heaters type "VIN"

The heart of the unit is a coil consisting of a large number of turns of insulated wire, and placed vertically in a cylindrical housing in the form of a vessel. A metal rod is inserted inside the coil. The housing is hermetically sealed at the top and bottom with welded lids, and the terminals for connection to the electrical network are brought out. Cold coolant enters the vessel through the lower pipe, which fills the entire space inside the body. Water heated to the required temperature goes into the heating system through the upper pipe.

Coolant heating circuit

Due to its design, when connected to the network, the heat generator constantly operates at full power, since it is irrational to supply the heating installation with additional voltage regulation devices. It is much easier to use cyclic heating and use automatic shutdown/on with a water temperature sensor. You just need to set the required temperature on the display of the remote electronic unit and it will heat the coolant to this temperature, turning off the water heating induction element when it is reached. After the time has passed and the water has cooled by a few degrees, the automation will turn on the heating again, this cycle will be repeated constantly.

Since the heat generator winding provides a single-phase connection with a supply voltage of 220 V, induction-type heating units are not produced with high power. The reason is that the current in the circuit is too high (over 50 amperes), it will require laying large cross-section cables, which in itself is very expensive. To increase power, it is enough to put three water heating units in a cascade and use a three-phase connection with a supply voltage of 380 V. Connect a separate phase to each device in the cascade; the photo shows a similar example of the operation of induction heating.

Heating with induction boilers

Design features of heaters of the “Sibtekhnomash” type Using the same effect of electromagnetic induction, another company develops and produces water heating devices of a slightly different design that deserves attention. The fact is that the electric field created by a multi-turn coil has a spatial shape and spreads from it in all directions. If in VIN units the coolant passes inside the coil, then the Sibtekhnomash induction boiler device provides a spiral-shaped heat exchanger located outside the winding, as shown in the figure.

The winding creates an alternating electric field around itself, eddy currents heat the turns of the heat exchanger pipe in which water moves. Coils with coils are assembled in a cascade of 3 pieces and attached to a common frame. Each of them is connected to a separate phase, the supply voltage is 380 V. The Sibtekhnomash design has several advantages:

- induction heaters have a separate, collapsible design;

- in the zone of action of the electric field there is an increased area of the heating surface and a larger amount of water due to the spiral circuit, which increases the heating rate;

- Heat exchanger piping is accessible for cleaning and maintenance.

An example of connecting an induction boiler

Despite the differences in the design of the heat generator, its operating efficiency is 98%, as in heaters of the “VIN” type, this efficiency value is declared by the manufacturer itself. The durability of the units in both cases is determined by the performance of the coils, or more precisely, by the service life of the winding and electrical insulation; manufacturers set this indicator within 30 years.