To carry out bath procedures according to all the rules, you must solve the issue of heating water for washing. Owners who remain true to traditions do not think much about this and, even at the design stage of the bathhouse, include a heater in it. However, you can avoid the labor-intensive work of heating it if you choose a modern solution - an electric boiler. True, there are difficulties here too.

You will have to choose a suitable heater model with a heat exchanger. But you can save money if you decide to make it yourself. But in order for this device to perform its functions well, it would not hurt you to first learn about the purpose of the heat exchanger and the rules for its installation.

Why do you need a heat exchanger in a bathhouse?

In the steam room, the heat comes from the stove and the stones on it, which accumulate heat and release it. In other rooms, heat comes from special structures that partly resemble a heating system.

The sauna heating system is based on water. The heat exchanger can be of different sizes and shapes. It can be a water tank, which is heated directly from the stove, or a water jacket made of pipes through which liquid circulates.

The main tasks of the heat exchanger:

- Heating of rooms other than the steam room;

- Energy saving;

- Creating a cozy atmosphere;

- Creation of warm and hot water for a bath.

Important! In a bathhouse, hot water is usually needed in a larger volume than in a regular home. So it is required for washing, to create cleanliness in the room, for the operation of vats with herbs, steam barrels and other original devices. Therefore, the heat exchanger must be designed for the required amount of water and its turnover.

Video description

The video will show what a sauna stove with a heat exchanger is:

Siphon type

Quite effective, but not very popular method. A storage tank is installed at some elevation from the surface of the furnace. From its bottom, at an angle, a pipe with a sealed end goes into the hearth. In this case, you cannot do without boiling.

It starts at the end of a sealed pipe. The water turns into steam bubbles, which begin to rise to the top. In a cold environment, they burst and heat the surrounding water. Additional heating also occurs due to the usual convention of warm water rising to the surface and cold water taking its place.

Types of heat exchangers

Heat exchangers differ both in their appearance, and in the material from which they are made and in the type of construction.

Now manufacturers offer stoves that are already equipped with ready-made heat exchangers. It is convenient and very economical. But the downside here is that the heat exchanger has a predetermined design and shape.

There are different forms of heat exchangers:

- A coil is when a pipe comes out of the furnace that makes many bends. This option is usually designed for one room.

- Flat version in the form of two or three flat disks that are built into the oven. They have greater heat transfer than conventional pipes.

- A samovar-shaped design on a chimney pipe that works like a boiler.

The heat exchanger is selected depending on the area of the bathhouse and the number of rooms in it.

Select an option

You can, of course, install an ordinary electric boiler in the wash compartment by running cold water to it. But what's the point of wasting electricity when you're going to heat the bathhouse anyway?

According to the location of the tank

The tanks produced by our industry differ in their future location. They all have their advantages and disadvantages.

According to manufacturing materials

A lot depends on what material the pipe bath tank is made of. This includes the speed of heating water, the time it takes to keep water warm, and the durability of the product.

Built-in or homemade design

Some stoves are sold with already built-in heat exchangers. This is a convenient and compact option that is quite easy to install in the bathhouse. But it is designed only for small rooms: steam room and wash room.

Features of the built-in heat exchanger:

- The water tank is pre-integrated into the combustion chamber;

- Heat loss is minimal, and water heating is at a high speed;

- The capacity has limited volumes;

- In the built-in heat exchanger, due to the high temperature of the water, additional, increased pressure arises, which forces water to circulate throughout the entire circuit;

- In any case, installation of additional pipes is required.

Built-in tanks and pipes are usually made of different metal alloys. They have a pre-limited design. However, they can always be supplemented with an external heat exchanger or boiler.

An external heat exchanger can complement the internal one or be welded to a stove that is not equipped with such devices.

Features of external heat exchanger:

- Can have any volume;

- May have an additional boiler;

- Poorly suited for heating the entire room circuit;

- Heated by a stove or chimney, or has a combined heating method;

- The coolant is more designed to generate hot water for washing;

- It has a more complex design and requires the installation of additional pipes, elbows and taps.

It is ideal to combine the built-in and additional heat exchanger with external equipment. But this option will be the most expensive and time-consuming.

Material

More often, a device to prevent heat loss is usually made of stainless steel. The material must be food grade, austenitic, and have greater ductility. Products made from this steel are able to withstand high temperatures for a long time. At the same time, their performance is not reduced and their service life is not shortened. Austenitic stainless steel contains nickel, which promotes the formation of a special thin layer on the surface of the pipeline. The resulting film is highly resistant to environmental influences.

Stainless steel

The heat exchange system pipe is made of galvanized steel. When heated to a temperature of 200 degrees, the zinc contained in the metal evaporates. At a temperature of 500 degrees, a large amount of released substance accumulates in the air, which becomes hazardous to health.

When using galvanized steel, it is important to monitor the temperature to avoid unpleasant consequences.

External samovar-type heat exchanger

With this option, the liquid storage tank is usually installed around the chimney pipe. At the outlet, the smoke has a temperature of about 800-600 degrees, so the water in the container will heat up very quickly to 85-150 degrees.

However, this is significantly less than the temperature inside the oven. In this case, the heat exchanger will also have the additional function of cooling the pipe.

The design of a container with a pipe can have different shapes:

- A tank through which the pipe passes through;

- A thin pipe that goes around the chimney;

- The pipe that runs next to the chimney.

Structures in the form of tanks can also serve as boilers where hot water is stored. Due to their external similarity, such heat exchangers are often called samovars.

The material of such a product can be anything: from steel to copper. The copper option transmits heat best, but is more expensive.

Everything you need to make a wooden gate

The most common option is a wooden gate. It’s quite easy to make with your own hands. Its cost is low, even when using high quality boards. If you purchase less expensive coniferous boards, the gate will be even cheaper.

Wooden gate

For a wooden gate you will need:

- 10-11 boards measuring 200x14x2 cm;

- two boards measuring 200x15x5 cm;

- door handle and latch, gate awnings;

- fastening material – about 40 screws;

- antiseptic for wood processing;

- wood primer and varnish;

- cement, sand and water for making concrete mortar.

Tools you will need:

- plane, chisel, hammer, hand drill;

- screwdriver, drill, pencil, tape measure, building level and sanding material (numbers 25-16 for the first stage, and 10-9 for the final stage of processing).

Installing a heat exchanger in a sauna stove

When choosing a heat exchanger, you should, first of all, take into account the volume and power of the furnace combustion chamber. A powerful furnace will most likely already contain a heat exchanger.

However, such water is best suited for heating the circuit. Since it has a high outlet temperature, which creates a pressure difference that forces the water to move through the pipes. The internal heat exchanger is not capable of producing large quantities of hot water.

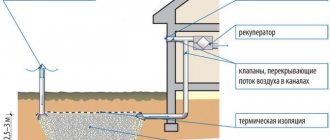

- A solution to the problem can be a remote samovar tank. It should be taken into account that the smoke in a stove with an internal heat exchanger has a lower temperature than in a conventional stove. The difference can be 50-100 degrees. Therefore, the additional heat exchanger here must have a small volume of 20-80 liters.

- The tank for the pipe of a unit without an internal heat exchanger can be much larger - up to 150 liters.

- Manufacturing and installation of external tanks does not require additional effort. For this, metal sheets or ready-made tanks are used. They are installed simultaneously with the creation of the pipe. In this case, the pipe itself may have a shorter length, since at the outlet into the wall or roof the temperature in it will be significantly lower than usual.

- The difficulty in installing built-in heat exchangers is not associated with them themselves, since they are completely integrated into the stove, but with the installation of the heating circuit.

If an additional pump is not planned here, then the length of the pipes should not be more than 10 meters. For longer circuit lengths, forced circulation pumps should be installed.

Important! The unit with a built-in heat exchanger cannot be operated continuously without water. Since the design of the furnace is designed for cooling by water. Without it, the metal in the combustion chamber will overheat and deform.

When choosing and installing a heat exchanger, you should also not forget that any water containers require maintenance and regular descaling. Operating tanks in this regard is much easier.

Each owner chooses for himself how to make the bathhouse more comfortable and high-tech. But it will always be reasonable to combine several methods at once, and family and guests will certainly appreciate it.

Pipeline installation

We have already mentioned that for pipelines it is better to use pipes with a diameter of 3/4″; this diameter is most often used in all heating systems and is suitable in all respects for a bathhouse heat exchanger.

Pipe diameter 3/4″

Pipes can be metal or plastic. You can also use flexible corrugated hoses, but you need to keep in mind that they have a significantly smaller nominal diameter, and this negatively affects the speed of water flow.

Flexible corrugated pipe for heating and water supply

Corrugated pipe for heating

Corrugated pipes

Cut using a special tool.

Let's give some tips on installing pipelines.

- Try to reduce the length of the pipelines as much as possible; do not make many turns or bends in the pipe. Your task is to create the most favorable conditions for water circulation.

Metal pipes for connecting a remote tank

- When using plastic pipes, do not allow them to overheat at the junction with the heat exchangers.

The presence of water inside will prevent their complete breakthrough due to loss of strength caused by heating, but deformation is possible. Connecting the heat exchanger to the sauna stove with plastic pipes - Don't forget to place the drain valve in the lowest place.

If the bathhouse is not used for a long time, then in winter you need to drain all the water from the system. Diagram showing the position of the drain valve - When connecting pipelines, provide for the possibility of dismantling them to perform repair or routine maintenance work.

- Try to keep the length of horizontal sections of the pipeline to a minimum. Install all such sections at an angle of at least 10°. Such measures have a positive effect on the speed of water flow.

Prices for flexible corrugated stainless steel tube

flexible corrugated stainless steel tube

Photo heat exchanger for sauna stove

Gas heating system

When connected to a gas main, heating a bathhouse with gas is the fastest and most efficient option for the system.

The system has two implementation options:

- traditional heater equipped with a gas burner;

- gas boiler with installation of heating radiators and water pipes.

The undoubted advantage of such heating is the absence of unpleasant odors, the formation of soot and soot. At the same time, gas equipment has a compact body, low weight and does not require much space during installation. The power of a standard boiler reaches 45 kW, which is enough to heat a room up to 280 square meters. m.

Power calculations

All calculations will always be approximate; in each individual case it is difficult to determine the power that will be required to heat a room, steam room, etc.

It is generally accepted that no more than 5 kW is enough to heat an ordinary bathhouse. For example, 1 sq. m of heat exchanger (its area) is equal to 9 kW of the furnace. Keep in mind that the power will be significantly reduced after the furnace or boiler goes out, so the calculation must be made based on the surface of the furnace heat exchanger. Therefore, when calculating, try to take into account the maximum area of the heat exchanger to ensure sufficient temperature even with a one-time fire.

The shape in this case practically does not matter; it can be as different as you like. A register made of stainless steel pipes is considered the most optimal, but gradually its place is taken by a welded manifold made of two channels. A heat sink of this shape is considered less easily produced, but it does not require a lot of material for its installation and installation.

Also, do not forget to take into account the type of chimney itself; it is quite difficult to install a high-quality heat exchanger on brick chimneys, unlike metal ducts. Therefore, when giving preference to independent work, proceed from convenience.