Siding is a non-flammable PVC facade material used for cladding the walls of a building. Siding as a façade cladding material is already familiar to many, mainly because today the use of siding is the simplest and easiest way to cover any type of façade and make it attractive to the eye. Facade panels are used both for the reconstruction of an old house and for creating a unique image of a new house.

Vinyl siding performs 2 main functions:

1. Decorative – siding adds an element of novelty and uniqueness to the appearance of the facade. At the same time, the time spent on installation is reduced to 1-2 days of work;

2. Protective – siding panels are an excellent protection for insulation from the effects of external destructive factors (snow, rain, wind, dust).

You can learn more about the range and types of Fasiding siding by looking at the “About the Product” section.

Advantages of using siding:

service life - more than 50 years; installation - facade panels are easy to install, and the time spent on installing siding is minimal; high sound insulation; not subject to combustion; high vapor permeability; high strength of the material;

high color fastness.

You can see detailed instructions for installing Fasiding panels in the “Installation” section.

In this article we would like to draw your attention to a set of products for a suspended ventilated facade, such as thermal insulation, membrane and lathing, and also focus your attention on some installation features. We will tell you which insulation for siding is best to choose and how to install it so that the service life of the facade corresponds to the period declared by the manufacturer.

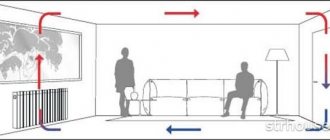

The entire “siding + thermal insulation” design belongs to the type of so-called “ventilated facades” - quite popular today and one of the most durable options for finishing a house. A ventilated facade is a facade that has between the external facade material (siding, panels, cladding) and thermal insulation there is a ventilated gap. The air gap ensures the removal of excess steam, which enters the insulation, passing through the walls of the building, and then exits to the outer surface of the windproof membrane. To remove excess moisture and organize proper ventilation, it is necessary to ensure air flow that occurs due to different temperatures - high inside the gap and low (outside), which will be directed upward.

Building façade insulation scheme

1. Load-bearing wall 2. Lathing 3. Thermal insulation 4. Air gap 5.

Membrane6. Exterior finishing1. Wall. The load-bearing wall can be made of: brick; block; wooden beams / logs; adobe; stone.2. Lathing. A lath (made of wood, metal) or sheathing is a system of elements with which thermal insulation and a membrane are attached to the wall.

The lathing can be: 1st lathing: from wooden blocks, from U-shaped suspensions, from a homemade fastening element; 2nd lathing: from a wooden block; from profile CD 60.3. Insulation. mineral wool foam4. Wind barrier membrane; Euro barrier.5. Air gap. The gap is made due to: additional sheathing; U-shaped profile; length of a homemade fastening metal element.6. Exterior finishing Some options for external cladding of the facade: siding; slabs; blockhouse. When choosing insulation for siding, you should pay attention to the characteristics of the material: thermal conductivity; vapor permeability; fire resistance; service life/service life; naturalness. Materials such as mineral wool can be used under plastic panels, glass wool, foam plastic.

Let's consider the advantages and disadvantages of the above materials. Disadvantages of polystyrene foam: susceptible to combustion, that is, toxic and quickly spreads fire; short service life; low vapor permeability; susceptible to fungus and mold. Advantages of using glass wool: - use for surfaces of almost any shape and design; - high chemical resistance; - ability to retain still air; - during cold periods, does not allow cold to pass through and retains heat in the room; - high vapor permeability; - high water-repellent qualities; - high sound insulation qualities; - not subject to combustion. Recommended thermal insulation material - ISOVER.ISOVER - glass wool of the highest quality, most optimally suited for private construction among other mineral wools. Produced by a world-famous European company - the Saint-Gobain concern, France, ISOVER thermal insulation at international exhibitions and in major projects using environmentally friendly materials for the home has proven its safety and the highest class of material in providing high-quality thermal insulation for the home. ISOVER mineral wool is used in pitched roofs, for insulating interior partitions, for ventilated facades, coping well with any mechanical and wind loads. A few tips.

Siding installation options. Economical option. Depending on the siding you have chosen, a frame in a vertical or horizontal design is mounted on the wall. The frame can be made of wood or metal. The step between the frame elements should be no more than 30cm. In this facade design, mainly roll insulation made of soft wool 50 or 100 mm is used.

It is cut into pieces of the required width without opening the packaging, then the cut pieces are released from the packaging, rolled out and mounted into a frame, slightly compressed in volume so that in the frame itself the cotton wool takes on its previous volume and tightly fills the entire space. Recommended thermal insulation materials: sound and thermal insulation rolls ISOVER Classic. Optimal option. Just like in the first option, a metal or wooden frame is mounted on the load-bearing wall, but the pitch between the frame slats in this case can be increased to 60 cm. Mineral wool is used as insulation in this design in slabs (semi-rigid positions). They are inserted into the frame lattice by surprise, so that the slabs fit tightly into place and, due to the pressure on the slats, hold tightly. To effectively insulate the house and achieve minimal heat loss, experts recommend making two-layer insulation of the facade.

This is an option in which another sheathing is mounted on top of the first layer of thermal insulation, located perpendicular to the load-bearing frames of the first frame. Then a second layer of thermal insulation is laid in the frame, which helps to avoid cold bridges in the first layer. Recommended thermal insulation materials: heat and sound insulating boards ISOVER Pitched Roof, ISOVER Frame, ISOVER Profi rolls. Hydro- and vapor barrier materials should not be placed between the thermal insulation and the wall of the building , because

they create an additional bridge of cold due to the absence of ventilation under the film in such a design and the condensation of moisture on it, which will ultimately remain in the walls. To ensure that steam from the house is removed outside without obstacles and does not remain either in the walls or in the thermal insulation, it is strongly recommended to use windproof superdiffusion membrane. This is the same mandatory working layer of the entire structure as thermal insulation. The superdiffusion membrane is attached to the sheathing using galvanized brackets. The membrane roll is rolled out so that the panel is directed vertically from bottom to top.

The membrane is installed with an overlap of 10-15 cm. To provide a ventilation gap between the siding panels and the thermal insulation, counter-lattice bars 50-60 mm thick are placed on the sheathing. The final gap between the siding panels and the top layer of thermal insulation must be at least 50mm. Such a gap will provide sufficient air flow to erode moisture, which through active diffusion is removed to the outer side of the membrane, leaving the walls and thermal insulation dry. The final stage of insulating the house is installing siding on the installed sheathing. Tips: storing the insulation in the open air is extremely undesirable; the pitch of the sheathing should be 10-15mm smaller than the width of the rolls/slabs; use of personal protective equipment - glasses, mittens, respirator. Conclusion: What you cover your house with is an entirely individual decision. You can choose siding, facade panels or composite materials.

It is important to remember that wall insulation will help you save on heating your home, as well as maintain comfort in the interior. Correctly and competently installed thermal insulation and a high-quality facade are the key to a comfortable indoor microclimate, as well as a guarantee of a long service life. When choosing facade insulation for siding, it is necessary to evaluate the material’s compliance with the following requirements: low thermal conductivity; resistance to temperature changes; low level of hygroscopicity ;environmental friendliness;fire safety;density and resistance to deformation;possibility of choosing the thickness of the material that provides the required level of insulation. Facade insulation for siding is sold at reasonable prices in Moscow. From us you can order high-quality mineral wool from the manufacturer Isorok.

Features of the material

Mineral wool is suitable for insulating walls lined with metal or plastic siding. As a facade insulation for siding, it is better to use mineral wool not in rolls, but in semi-rigid slabs, which are easier to install. To avoid the formation of dust from mineral wool, it is recommended to use a vapor barrier film.

This type of facade insulation, installed under siding, is characterized by high sound and heat insulating properties.

Thanks to its loose fibrous structure, the material absorbs different types of noise well: airborne, impact and structural. These are environmentally friendly products. Mineral wool is easy to give the required shape, and during operation it is characterized by durability.

For the optimal choice of insulation for walls under siding based on price, technical and operational characteristics, call our qualified specialists.

They will advise you on installation technology, recommend a material with certain parameters, depending on the operating conditions and the requirements for thermal insulation. We will answer questions regarding the application features and subtleties of installing mineral wool. To clarify the terms of purchase, contact our managers.

Review of leading manufacturers

As already written above, in the construction market of our country, both domestic and foreign companies are represented in the segment of materials intended for insulating a house under siding. Among them, the most popular brands are:

- mineral wool - “Rockwool” (Denmark) and “Paroc” (Finland), “Isover” (France) and “Knauf” (Germany), as well as “URSA” (Spain), “IZOVOL” and “Beltep” (Russia) ;

- polystyrene foam – “RosPenoplast”, “PARAPLEX”, “Penoplast PSK” (Russia);

- glass wool - “Isover” (France) and “Knauf” (Germany), “URSA” (Spain) and “IZOVOL” (Russia);

- penoplex - “URSA” (Spain) and “TechnoNIKOL” (Russia).

For your information! All foreign companies operating in the domestic market have their production facilities and representative offices in our country.

Using polystyrene foam to insulate a frame house

Prices for insulation for siding

Name Dimensions (mm) Cost (RUB/m3) Min slab P-75 1000*500*50-1001730.00 PP-601000*500*50-1001670.00 Min slab P-125 1000*500*50-1002230.00 PP-801000* 500*50-1002170.00Izolight L (40) 1000*600*50-1001230.00Izolight (50) 1000*500*50-1001450.00Isovent L (80) 1000*500*50-1002530.00Isovent (90) 1000* 500*50-1002720,00PP-601000*500*40-100,120,140,1501550,00PP-801000*500*50-100,120,1501900,00

Today, the problem of energy saving has affected not only large enterprises and cities, but has also become extremely relevant for the average cottage or summer house developer.

Therefore, when choosing a wall structure for a future home or preparing to renovate the facade of an old building, you must first choose the right insulation.

We will not dwell on traditional types of finishing, such as plaster or stone cladding, but will consider the issue of insulating walls that will be covered with siding.

Is insulation needed for siding? This is a rhetorical question, since the answer is obvious to a specialist.

Not a single house made of brick or large-sized blocks without additional external insulation today passes strict heat transfer resistance standards.

The situation is similar with wooden houses. Despite the fact that wood is a warm material, the standard thickness of rounded logs or timber (180-200 mm) used for the construction of log houses is not enough for the economical consumption of gas, coal or firewood for heating.

The siding used for cladding the base and facade is optimally combined with insulation in the design of a ventilated facade. Therefore, it would be extremely unwise to refuse this option.

Therefore, the discussion should not be about whether insulation for siding is needed or not, but about the correct choice of this material.

It is not difficult to answer which insulation for siding is best, since the choice here is quite narrow. Mineral wool, ecowool, polystyrene foam - this is the entire list of materials used for insulation of ventilated facades with siding.

Technology examples

Laying insulation in an aluminum frame

The choice of method for laying the material is made based on the composition of the base, thickness and configuration of the insulation.

In private construction, the following options are possible:

- Single-layer laying in a frame cell. It is used for finishing buildings made of foam concrete, brick and wood, the walls of which themselves have good thermal insulation.

- Two-layer styling. Used in cold climates and for insulating buildings with thin walls. To accommodate the material, a cross lattice is made into which slabs and mats are laid in a checkerboard pattern.

- Frameless option. It is used when insulating a building with polystyrene foam or polyurethane foam. Only the siding frame is attached to the walls and the insulation is already attached between them.

Before deciding on insulation methods, it is recommended to consult with specialists.

Polystyrene foam - fast, but not always good

Let's consider insulating the facade under siding using polystyrene foam. This material is easy to install. It is light and quite rigid, so it is firmly glued to the walls or attached to them using disc-shaped dowels.

However, this is where its advantages as a wall insulation end. In terms of price, this material in the first years of its appearance on the market was cheaper than mineral wool, but today their cost is almost the same. So the factor of saving money can be discarded. There is a lot of debate about the durability of polystyrene foam, but objectively this material cannot last more than 10-15 years, because, like all polymers, it quickly ages and deteriorates. The vapor permeability of polystyrene foam is very low.

Therefore, by insulating the walls with it, we are deprived of natural air exchange and voluntarily enclose our house in an impenetrable thermos. Excess moisture can only be removed with the help of ventilation or mechanical ventilation, releasing precious heat along with it into the street. Talk about foam being a good sound insulator is a common advertisement by manufacturers of this material. Moreover, foam plastic, rigidly fixed to the outer wall, under certain conditions, works as a sound amplifier, since it falls into the resonant frequency of sound vibrations - 70 - 7000 Hz (speech range). Digression from our topic, we note that foam plastic is best suited for insulating engineering communications (water supply, sewerage) and concrete floor screeds, since in this case such qualities as minimal water absorption and low thermal conductivity are in demand.

Mineral wool and ecowool - high-quality insulation of the facade

It is better to choose insulation for siding, considering the advantages and disadvantages of mineral wool and ecowool.

Mineral wool is suitable for insulating any walls: wooden, large-block and brick. It is optimally combined with plastic or metal siding.

You just need to buy not rolled mineral wool for siding, but semi-rigid one in the form of slabs measuring 0.5 by 1 meter. Rolled mineral wool is more difficult to attach. In addition, over time it can slide down the wall, exposing certain areas.

Semi-rigid slabs attach and hold better. To prevent mineral wool from generating dust, it is protected with a vapor barrier film before facing it with siding. It not only protects the atmosphere from small particles of cotton wool, but also does not create obstacles for water vapor penetrating from the walls of buildings into the ventilation gap. Siding with ecowool insulation is better than mineral wool in terms of environmental friendliness. Despite the fact that ecowool is made from cellulose, due to the introduction of safe additives (borax and boric acid) into it, it does not rot or burn.

Unfortunately, ecowool is not yet available in the form of rigid panels that can be fixed to the wall using vapor-permeable glue or disc dowels. Therefore, to attach it, you need to use special equipment that applies ecowool to the walls.

Ecowool then firmly adheres to the surface and does not shrink over time. In terms of heat and sound insulation characteristics, both mineral wool and ecowool are equivalent materials. Their loose fibrous structure absorbs all types of noise well: structural, impact and airborne. When comparing prices for polystyrene foam, mineral wool and ecowool, it should be taken into account that for the latter type of thermal insulation, the cost of application must be taken into account. It is quite high, therefore, for example, at a price of 1 m3 of ecowool at 1,300 rubles, the final price of insulation taking into account the work (wet method) reaches 4,900 rubles. If we compare the cost indicators of the listed insulation materials that can be installed under siding, then the lowest price is for ecowool ( 1350-1500 rub./m3).

This is followed by semi-rigid slabs made of mineral wool and facade foam - 1650 and 1900 rubles per 1 m3, respectively. Useful video on the topic from one of the insulation manufacturers: Comments: Rating: 85 It is common for every person to strive to make their home comfortable and cozy. However, despite the general warming of the climate, not a single brick, wooden or large-sized house is capable of providing its residents with comfortable living conditions without additional heating of its premises using firewood, coal or gas. Mineral wool is an ideal insulation material, suitable for almost everyone wall materials: panels, brick, wood and blocks. But if you cannot do without heating the house, then you can minimize heat loss. To do this, it is enough to wrap the house in a kind of fur coat, consisting of finishing material and insulation. Recently, siding has been gaining popularity as a finishing material.

This is due to its durability, ease of installation and beautiful appearance. But since the finishing of external walls with siding is carried out according to the principle of a ventilated facade, the air layer remaining between the wall and the siding will not add heat to the house, but the moisture accumulating on the wall is fraught with big problems, up to the destruction of the wall. The insulation laid between the wall and the finishing serves a kind of thermos, not letting the heat out of the house in the winter, and not letting the heat in in the summer. Therefore, the question of whether it is necessary to insulate the walls when finishing with siding is purely rhetorical. What insulation is better for siding?

Requirements for insulation under siding

There are few such requirements for insulation used when finishing a house with siding, but neglecting at least one of them threatens to result in serious problems during the operation of the house. Therefore, when choosing insulation for siding, you need to pay attention to the following characteristics:

Installation diagram of siding with insulation.

- low thermal conductivity - the lower its coefficient, the more heat will remain inside the house; low hygroscopicity - the less the insulation absorbs moisture, the better it retains its shape and thermal insulation properties; high vapor permeability - moisture from the house should freely come out and not settle on the walls and on the inside of the insulation; environmental friendliness - the insulation material must be environmentally friendly, otherwise health problems for the residents of the house cannot be avoided; fire safety - the lower the class of the insulation, the better; the ability to withstand environmental influences for a long time; the ability to retain the original shape and density - deformation of the insulation sheet causes the appearance of cold bridges, through which some of the heat leaves the room.

Based on these requirements, the list of materials that can be used as insulation for siding is small: polystyrene foam, polystyrene foam, ecowool and mineral wool.

Criterias of choice

The main selection criteria are price and free time. If the construction budget allows, then ecowool would be the best choice. This is especially true for wooden houses, since the seamless method allows you to close the smallest cracks.

On the other hand, you can insulate the building yourself with basalt wool, the difference will be insignificant, and you will save a good amount. Therefore, in matters of insulation, two factors are always important: money and free time.

It is imperative to pay attention to vapor permeability. The seller can easily describe this property as both negative and positive. Moreover, in any of the judgments he will be right. However, vapor permeability is necessary and it is better to choose materials that can “breathe”.

Foam and polystyrene

Polystyrene foam is one of the most popular insulation materials. It has a low thermal conductivity coefficient, is slightly hygroscopic, quite rigid and retains its shape for a long time. However, it is not the best choice as insulation for external walls.

Scheme of wall insulation using polystyrene foam.

Despite advertising, the service life of polystyrene foam as insulation does not exceed 10-15 years. Foam plastic belongs to the family of polymers and, like any polymer, quickly ages and loses its properties. Also, the statement about the good soundproofing properties of polystyrene foam is not entirely true.

It is a good internal sound insulator, but, having a rigid mount on the outer wall, it can become a kind of resonator of sounds, amplifying them. This especially applies to the howl of the wind. In addition, the foam burns well.

But the main disadvantage of polystyrene foam as wall insulation is that it is vapor-tight. Fixed to the walls, it places the house in a kind of thermos, sealing not only heat, but also moisture. Excess moisture can only be removed using forced ventilation, removing a significant part of the heat from the room.

Polystyrene, having all the advantages of polystyrene foam, is also non-flammable and, due to its structure, has better sound insulation properties compared to foam plastic. But, like polystyrene foam, polystyrene foam has low vapor conductivity, and is also much more expensive than polystyrene foam.

Mineral wool and ecowool

Mineral wool as insulation for siding is suitable for any wall material: wood, brick, panels and blocks.

To insulate walls, it is better to use mineral wool not in rolls, but in the form of semi-rigid slabs. The slabs are easier to lay, they stick well to a vertical wall, and they also hold their shape better than their rolled counterpart. Rolled mineral wool can slide down, exposing sections of the wall, but such a problem will not happen with slabs.

Scheme for insulating a wall under siding with mineral wool.

The main difficulty when working with mineral wool is the large amount of dust contained in it.

In addition, if even a small amount of moisture gets inside the mineral wool, its thermal insulation properties deteriorate significantly. Therefore, when used as insulation for walls, it must be protected with a vapor barrier film. The film performs two tasks: it does not release mineral wool dust into the atmosphere and protects the mineral wool from moisture getting into it.

Ecowool is the cheapest insulation material today.

However, it is not yet available in the form of panels or rolls. It is sprayed onto the wall surface using special equipment, while ecowool firmly adheres to the wall surface and retains its shape for a very long time. However, the total cost of ecowool, equipment rental and spraying work is 2.5-3 times higher than performing the same work with other insulation materials.

Ecowool takes first place in terms of environmental friendliness. And although its basis is ordinary cellulose, factory-treated ecowool with special additives practically does not burn and does not rot even in high humidity conditions. This allows you to use it without installing additional vapor barrier.

As insulation and sound insulators, mineral wool and ecowool are equivalent materials.

Having studied all the advantages and disadvantages of the insulation used, you need to decide which insulation for siding will be best for your home individually for each case.

Good luck!

.

Preparing the wall surface

Preparing the wall surface with your own hands for attaching insulation to it is as follows:

- All protruding objects are removed from the wall.

- The surface is leveled. To do this, it should be taken into account that the depth of the depressions and protrusions should not be more than 20 millimeters.

- If required, the wall surface should be treated with a primer and leveled with a plaster solution. The primer should be chosen for external use.

Then the insulation is prepared.