According to environmentalists, up to 40% of heat and electricity generated in the northern hemisphere is spent on heating residential, industrial and other facilities. For this reason, high-quality insulation of buildings brings tangible benefits in terms of financial savings and living comfort. One of the most popular heat insulators is polystyrene foam (expanded polystyrene, EPS).

Which polystyrene foam is better for insulating the outside of a house?

Which polystyrene foam is better for insulating the outside of a house? Let’s look at this question in detail.

Is polystyrene foam safe?

In Europe, PPP has been widely used for more than half a century. During this time, no material was found that would surpass foam plastic in terms of environmental friendliness, efficiency and thermal insulation characteristics. Europeans use PPS everywhere: as insulation for buildings and utility lines, packaging material for food products and any other goods.

Styrofoam

In Russia and the CIS countries there is a certain prejudice towards this material. It is based on information about the environmental friendliness and fire hazard of polystyrene foam. The veracity of this information can be verified using documents that contain the results of tests and examinations carried out in relation to the teaching staff.

The eco- and fire safety of this material is confirmed by many official researchers, including:

- Research Institute named after Erisman (expert opinion No. 03/PM8);

- State Institution “Republican Scientific and Practical Center of Hygiene” (Republic of Belarus);

- SP 12-101-98 (SNiP for construction heating engineering);

- Research Center for Fire Safety VNIIPO of the Ministry of Internal Affairs of the Russian Federation;

- According to the BREEM environmental safety scale, PPP is classified as class A +.

The products of each foam manufacturer must undergo a certification stage. The presence of an appropriate conclusion confirms the suitability of this material for use in everyday life, construction and for other purposes.

Certificates of Conformity

Certificates for foam plastic

Hygienic characteristics of products

You need to know: the most important information about the percentage of harmful substances and their list is on the back of the hygiene certificate, which is rarely paid attention to.

After reviewing the documentation, we can conclude that the opinion about the dangers of polystyrene foam is greatly exaggerated and is based not on facts, but on myths and rumors. If there are any doubts about the rationality of using this material, it is worth considering that it will be located not inside, but outside the premises, since the technology of insulation of the facade, and not living rooms, is being considered. Therefore, PPS can be safely chosen as the main heat insulator for the external walls of a house.

Foam plastic, test results according to GOST 15588-86

Expanded polystyrene (foam) is a panel material that occupies the highest positions in sales volumes

Internal and external insulation

Before you start insulating the walls, you need to decide on the insulation method. Laying insulation outside or inside is an individual preference. Each method has its own advantages and disadvantages . The features of each insulation method must be studied at the time of building design.

Insulation from the inside

Internal wall insulation is characterized by the following features:

- the cost of insulation from the inside is less than that of external insulation;

- season and weather do not affect the choice of time for work;

- there is no need to build additional scaffolding for insulation work.

Negative factors for internal insulation are:

- significant reduction in living space;

- the outer wall is insulated from heating from the room;

- the likelihood of fungus forming inside the wall increases, since the dew point is formed precisely in the inner part of the structure;

- when the heating is turned off, the walls quickly cool down due to the low inertia of the insulation;

- the junction of the ceiling with the external wall cannot be equipped with insulation, which leads to the formation of cold bridges.

The method of insulating walls from the outside is more popular despite the fact that the cost of labor and materials for performing the work is significantly higher than the method of internal insulation.

Dew point

Insulation from outside

The advantage of insulating walls from the outside is:

- in winter and in cold weather, heat is retained in the wall for a long time;

- the design area of the room is preserved;

- external thermal insulation protects internal walls from dampness.

In addition, the external walls are additionally protected from weather conditions, which significantly increases the service life of the structure.

The main disadvantages of external thermal insulation of a structure are:

- restriction of work in accordance with weather conditions;

- increase in costs for materials used.

Which side of the wall to insulate with polystyrene foam?

It is advisable to insulate walls with expanded polystyrene from the outside, since the material does not allow air to pass through, which can lead to the formation of condensation inside the wall during internal insulation, and also inside the room the material can emit a specific odor.

Exploitation

The raw material called expanded polystyrene is in great demand and this is due to its low price. Mainly, the building material is used for insulation work and during construction and repair work. It is also used as a heat insulator in some types of household appliances and industrial installations. It is used in the development of refrigerators, thermal vans, and containers. Another area where expanded polystyrene has found application is the packaging process.

As for insulation work for external and internal wall surfaces, preference is given to polystyrene foam of the PSB-S brand. It is characterized by different densities, as well as a high level of breathability, which cannot be said about the extruded version of the foam. The use of PSB-S foam plastic is an excellent opportunity to create a comfortable climate inside residential buildings.

For external insulation of wall structures, it is advisable to use PSB-S slabs.

If ceiling finishing is needed, then preference is given to polystyrene foam boards. As a rule, their dimensions are 500.0×500.0 millimeters. The raw materials delight with a rich color palette.

The operation of PPP in the process of construction manipulations allows you to achieve the following results:

- reduce the price of work, as well as the time it takes to complete insulation work;

- expand the usable area of a residential building by reducing the thickness of the external walls;

- increase the environmental performance of the structure;

- reduce space heating costs.

Insulation of the attic Source re-home.su

Advantages and disadvantages of expanded polystyrene

The polystyrene foam material is a porous, air-containing raw material , used in most cases as a heat-insulating material.

In industry, the material can also be used as electrical insulating and packaging material.

The material has become widely used due to its quality indicators:

- low level of water absorption;

- low thermal conductivity;

- ease;

- biological stability;

- durability;

- compressive strength;

- not affected by temperatures;

- ease of installation;

- low price of material.

Comparison of insulation materials

Despite the impressive list of positive indicators, polystyrene foam has disadvantages that must be taken into account during installation:

- low sound insulation;

- instability to solvents and many chemicals;

- afraid of fire. When burned, it releases harmful toxic substances;

- poor resistance to ultraviolet radiation;

- easily susceptible to the influence of rodents and insects, which, by making holes in the material, provoke its destruction;

- low vapor permeability;

- fragility.

IMPORTANT!

Expanded polystyrene is sometimes compared in terms of characteristics and external indicators with another similar material - polystyrene foam.

However, the production technology of these materials is different : polystyrene foam is produced by extrusion, when the granules melt when combined into a single structure, polystyrene foam is produced by gluing granules with dry steam.

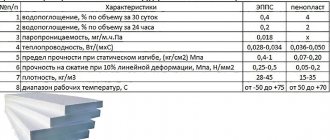

Specifications

Non-flammability, environmental friendliness and how long does it last?

Construction raw materials called polystyrene foam serve for a long period of time. It does not lose its original characteristics. Various tests have confirmed that it can be used repeatedly, and the quality does not decrease as a result. Expanded polystyrene contains special components. They are called fire retardants. Due to this composition, the material has a low flammability rate. But to say that it does not ignite at all would be wrong.

Insulation of a house from the outside Source realstroyservice.kiev.ua

Types of expanded polystyrene

Expanded polystyrene is classified according to the method of production of the material and the inclusion of various additives in it:

- pressed polystyrene foam . Produced by pressing;

- pressless polystyrene foam . Produced by removing moisture by drying and then foaming at high temperatures;

- extruded polystyrene. Not much different from pressless; an extruder is additionally used in production. The best and optimal option for thermal insulation of walls.

There are other types of polystyrene foam (extruded, autoclaved), but they are not used as insulation materials because they have different characteristics.

In addition to types of expanded polystyrene, there are also various types of insulation, such as:

- mineral wool;

- penofol;

- penoizol;

- penoplex;

- polyurethane foam.

Criteria for choosing modern thermal insulators

The first thing that is taken into account is the characteristics of thermal insulators. Their task is to preserve the brick walls and warmth inside the house, and make it presentable.

Main criteria:

- Heat conductivity indicator (the number indicates what heat loss will be per 1 m2 in 1 hour with a masonry thickness of 1 m.).

- Absorption of moisture (condensation).

- Flammability (best G1, means the ability to go out on its own).

- Density. Optimally low, so as not to put additional load on the foundation, but the strength of the final product is low.

- Soundproofing.

- Environmentally friendly.

Be sure to pay attention to the final weight of the structure. The brick wall itself creates a large load on the foundation, so even at the stage of its construction they make a decent margin of safety.

To insulate walls yourself, you need to choose a material that requires a minimum set of related parts and tools.

Wall pie when using insulation - polystyrene foam on the outside

A wall pie refers to layers of materials that are laid in a certain order, each of which performs its own functions to ensure a normal microclimate in the room.

When thermally insulating brick walls with polystyrene laid outside, the wall pie looks like this:

- interior plaster;

- outer wall;

- adhesive solution for gluing polystyrene foam;

- insulation (expanded polystyrene);

- adhesive solution for gluing the next layer;

- fiberglass mesh;

- adhesive composition;

- primer;

- finishing plaster.

NOTE!

When arranging a wall using polystyrene foam, it is necessary to lay the layers in strict sequence.

Internal and finishing plaster can be replaced with other finishing materials that are provided for in design solutions.

Wall cake "wet"

How to calculate the thickness of insulation

Calculation of material thickness is carried out according to a two-step scheme:

- First, the thermal resistance of the wall is determined . This refers to the general value, together with the insulation. If there are many layers of the pie, all are taken into account. The value is standard, determined according to SNiP tables for a given climate zone.

- Then the thickness of the PPS is determined - the product of the thermal resistance of the wall and the thermal conductivity coefficient of the material.

It should be borne in mind that theory is largely corrected by practice, since it’s all about subtle effects, which are individual in each case and cannot be taken into account in calculations.

Therefore, during private construction, they do not go into complex theoretical research , being content with generally accepted standards for a given region.

If in doubt, you can always use an online calculator (preferably several) to find out the desired value. You just need to substitute your data into the required columns of the attached table and get the finished result.

Wall pie device

Issues of vapor barrier and waterproofing

An important requirement during the construction and improvement of a house is the correct implementation of all work to ensure ventilation and waterproofing, since it is the incorrect installation of these components that significantly reduces the performance of the structure.

When insulating walls with polystyrene, waterproofing is not needed . It should be taken into account that if there is a high passage of groundwater under the building, it is necessary to waterproof the basement and foundation.

Since polystyrene foam does not allow air and water to pass through, there is no need to lay a vapor barrier layer when insulating walls from the outside.

Wall insulation cake under siding

Other benefits

Insulating the wall allows you to move the dew point outside the facade.

Thus, freezing of facades and the formation of mold in this case are excluded; A building finished with extruded polystyrene foam can be called a thermal stabilizer. In other words, temperature changes during the day and evening are not scary for him. The indoor climate will remain the same; Thermal insulation of the wall outside does not take up space inside the building.

Sealing cracks and preparing sheathing

Installing polystyrene foam on the sheathing is the most labor-intensive process among the insulation options. Most often, sheathing is done in the case of finishing siding.

Sealing cracks

If you plan to install siding on the wall of a house made of beams, you must first seal the seams properly, clean the surface of dust and debris, and seal the cracks with sealants, polyurethane foam, or a mixture of sawdust and PVA.

If the wall is concrete, brick or foam blocks, then the cracks in such houses are cleaned of sand, treated with a primer, then sealed as follows :

- if there is a small gap . Using a prepared mixture of cement and sand with the addition of PVA, seal the gap with a spatula;

- if the gap is medium in size . Make holes for dowels at a distance of 20 cm. Using screws and washers, pull the metal mesh over the gap and seal it, pressing it into the mesh with plaster. Next apply the finishing layer;

- for a large crack . Seal the gap with polyurethane foam, cut off any irregularities and seal it with two layers of plaster.

Large cracks can be repaired using anchors:

- knock down the plaster, seal the cracks with polyurethane foam;

- install a channel in the opening and attach a reinforcing mesh to it;

- you can use staples made of reinforcing mesh;

- apply plaster;

- putty.

Sealing cracks

When the wall is prepared for laying insulation, you can install the sheathing.

Preparing the sheathing

The sheathing for siding can be made from metal profiles and wooden beams . In humid climates, it is advisable to install metal slats.

Before you begin installing the sheathing, you should determine the location of the siding:

- with horizontal siding . The beam or metal profile is installed perpendicularly;

- with vertical siding . Frame boards or metal profiles are installed in a horizontal position.

The pitch of the sheathing is determined by the width of the polystyrene foam sheet: in width it should fit tightly between the sheathing slats and not form gaps.

The order of work is determined in steps:

- treat the wall with special mastic;

- frame boards are secured around the entire perimeter of the walls using galvanized screws and plastic dowels;

- if holes form between the timber and the wall, these gaps are sealed with pieces of polystyrene foam by gluing them to the wall.

When the sheathing is installed, then proceed to the installation of polystyrene foam panels.

CAREFULLY!

If the sheathing is made of wood, the boards must be pre-treated with antiseptic agents.

Lathing does not require special skills, but it should be noted that the choice of materials should be made based on climate conditions.

Lathing for siding

Wooden sheathing

Myth No. 4. A facade insulated with foam plastic “does not breathe”

By the way, the concept of a wall that “breathes” as such does not exist in the technical environment. This term, torn from scientific journalism, was picked up by builders, after which it happily went to the people. The fact is that the wall as such cannot “breathe”; ventilation performs this function in the house. The share of “breathing” of the walls accounts for from 0.5% to almost 3% of the entire ventilation system of the house. Therefore, no wall can replace ventilation. If we take specifically the popular concept of “breathing walls,” it means the following: the insulation itself cannot “breathe” at all, that’s why it is a heat-insulating material, the system “breathes.” The design of the facade, thanks to the upper air gaps between the facade, foam plastic and side joints, provides a high-quality (necessary for this type of structure) air flow for ventilation of the facade, thereby eliminating the possibility of condensation.

Technology of wall insulation with polystyrene from the outside

Before you begin insulating the wall with polystyrene foam, you should dismantle the gutters, decorative elements, clean and prime the wall. Next, insulate the sills and window slopes.

Now let's talk about the thickness of polystyrene foam.

NOTE!

When insulating walls with extruded polystyrene, sheets are used whose thickness ranges from 80 to 100 mm or more.

You can also use thinner sheets 30-40 mm thick if they are laid in two layers.

Let's start installing insulation on the walls with our own hands:

- a profile is installed at the bottom of the wall to hold polystyrene foam;

- the adhesive mixture is applied to the wall over the entire area in spots and onto the insulation sheet (amply on the center and edges of the sheet);

- tightly attach the sheet for gluing to the wall;

- Use dowels to secure the panel so that the dowel penetrates the wall at least 50 mm. The dowels are placed in the center of the panel and at the joints. It is recommended to use plastic nails;

- if gaps form (up to 2 cm), then they are sealed with polyurethane foam , if the gaps are larger, then they are first sealed with pieces of insulation, and then foamed. Excess foam is cut off;

- The heads of plastic nails are cleaned and puttied.

After installing the insulation, a reinforcing mesh is applied to the façade . You should cut strips of mesh at the corners and slopes and glue them with a spatula using an adhesive composition. An adhesive composition is applied to the mesh along the wall so that it penetrates 0.1 cm through the mesh onto the polystyrene foam. If an overlap occurs, separate strips of mesh are placed on it and additionally glued.

Sectional view of the device

Fastening slabs with dowels

Application of assembly adhesive

After the surface has completely dried, it is leveled with fine granulation sandpaper.

Next, the surface of the walls is covered with putty and a finishing decorative coating . External insulation with polystyrene foam, when installed correctly, will provide comfort and warmth in the house.

Rules for working with material

Most often, extruded polystyrene foam is used to insulate foundations, floors, walls and ceilings of residential and commercial buildings. For example, for insulating the walls of a loggia/balcony or the walls of a residential apartment from the inside.

But those who decide to use this material to insulate their own building should remember a few rules.

If the wall is sufficiently smooth and rough, the EPS will adhere perfectly to the adhesive mass. But most often, due to the geometry of the walls, it is more advisable to install polystyrene foam slabs using special dowels. This method is also chosen because it is more budget-friendly.

What are EPS boards placed on?

Extruded polystyrene foam slabs are easily attached to a flat and dense vertical surface using special types of glue. It can be Penoplex FASTFIX, TechnoNIKOL or dilutable adhesive mixtures such as Ceresit CT 83.

If you don’t want to bother with glue, or the surface structure does not allow it, you can resort to fasteners such as special dowels. In general, before insulation, it is advisable to level the surface of the walls with at least rough plaster and place the slabs on both of the mentioned fasteners at once - both on glue/cement mortar and on dowels.

The Ceresit CT 83 adhesive mixture, according to the developers, can be used at temperatures from 0 degrees Celsius. It is also claimed that it is very economical and environmentally friendly

Insulation of foundations and floors

In the case of foundations, all external sides are covered with EPS slabs, after which the newly made thermal insulation layer is covered with a layer of waterproofing. Often homeowners decide to insulate even the blind area.

In this case, a layer of concrete is formed over a layer of expanded polystyrene, which, in turn, rests on a bed of sand and gravel mixture.

The concrete floor screed is also erected on top of evenly laid EPS slabs.

EPS is also used as one of the methods for insulating wooden floors. We talked about this in more detail in the next article.

A blind area insulated with polystyrene foam will help protect the upper part of the foundation from freezing. Plus, a layer of such material will also work as an additional water-repellent layer.

Cutting expanded polystyrene boards

Since the density of extruded polystyrene foam is an order of magnitude higher than that of regular polystyrene, a number of small problems arise with this. For example, this type of material can still be cut with a knife, but firstly, the blade must be extremely thin and strong, since a thick blade can cause the slab to discolor and crack.

And secondly, the creaking and grinding noise that will accompany such an “event” will be an order of magnitude higher than in the case of ordinary polystyrene foam. Therefore, before starting the procedure, it is recommended to lubricate the knife blade with machine oil.

Some people use a grinder equipped with the thinnest metal wheel to cut EPS blocks. Cutting, in this case, is efficient, but the whistle is so loud that it is better to put plugs in your ears. Among other things, this method is the most “unclean”. It will leave a huge amount of garbage behind.

If you decide to use a grinder to cut polystyrene foam, we recommend that you familiarize yourself with the rules for using this equipment.

You can easily make a machine or machine for cutting polystyrene foam yourself. To do this, you just need to get some nichrome and a powerful transformer. By connecting the opposite ends of the nichrome wire to the wires coming from the power source, we get a kind of polystyrene foam knife. To make the cut as even as possible, the nichrome wire in the device should be kept taut

The most effective and simplest method is considered to be cutting with hot wire. Take two nails, between which a nichrome wire is stretched. Voltage is applied to the nails through a transformer, the wire becomes hot and the process begins. Using this method, you can cut out the most precise blocks and shapes of a high degree of complexity.

But this method is also the most harmful. As already mentioned, phenol vapors released during the cutting process can cause significant harm to the human body, and therefore, this procedure should be performed in the open air, preferably in a draft or using a special respirator, or even a gas mask.

Few people know, but polystyrene foam makes an excellent formwork for foundations. The material lends itself perfectly to cutting, drilling, etc., and therefore anyone, showing a certain amount of ingenuity and resourcefulness, is able to make a wonderful insulated foundation for their structure

Fire safety measures

When working with extruded polystyrene foam, you must adhere to strict fire safety measures, otherwise extinguishing the fire will be much more difficult than it seems.

That is why, in case work is being done nearby using an open fire, for example, there is a furnace with which bitumen is melted, etc., you should always have a water supply hose, a fire extinguisher, or, at worst, a barrel of water and a bucket at the ready .

It is recommended to do the same when carrying out welding work in close proximity to the EPS. Moreover, it is advised to either shield the material from sparks and scale flying from welding, or pre-moisten nearby polystyrene slabs with water; it is better to do both at the same time. Only in this case will you protect both yourself and your building from fire.

Most fire hazards at construction sites occur precisely because of neglect of safety precautions. If welding work is carried out near work carried out using flammable materials, always expect disaster. To prevent this disaster from happening, you should always keep at least a fire extinguisher on hand.

Myth No. 8. Decorative plaster over insulation is not necessary - just paint is enough

The protective properties of painting can be defined as follows: good protection against temperature changes and chemical influences. However, this cannot be compared with the protective properties of reinforcing layers and plaster. The reinforcing mesh will first ensure the strength of the system and prevent further cracking of the plaster, and the plaster itself will protect the foam from ultraviolet radiation and mechanical damage. The facade will retain its attractive appearance for many years. In addition, you can paint and repaint it in any color.