In Russia, the first effective devices for water heating of buildings were developed by the Russian scientist P.G. Sobolevsky in 1834–1841. He was the first to calculate the diameter of a heating pipe.

Nowadays, to create the most favorable living and working conditions for people, the most advanced methods of heating premises are being developed and implemented. At the same time, methods for calculating pipe diameters are being improved and simplified.

Water supply to the boiler: natural two-pipe heating in Leningrad

Gravity supply of water to the boiler is feasible with a centralized water supply to the area.

But if the developer receives water from the well individually, a circulation pump for heating is needed to supply and circulate the water. The heating system uses a circulation pump that optimizes the speed of the coolant and ensures that the cooled liquid is returned to the boiler. The pump simultaneously solves the problem of air pockets, which are simply washed away by the constantly flowing coolant. For the heating system of a private home, it is recommended to choose a self-regulating pump with a wet rotor, which during operation comes into contact with the coolant. This pump operates silently, is able to adapt itself to changes in the operation of the boiler, it is economical and durable. Its power and efficiency are sufficient for a cottage.

Pressure gauges allow you to control pressure.

Monitoring the pressure in the heating system is mandatory, since a failure can occur at any moment and you need to really understand the operating pressure

The optimal pressure for a home heating system should be one and a half to two atm. Pressure jump up to 3 atm. Can rupture boiler, pipes or radiators. And in order to avoid a sharp increase in pressure in the heating system due to increased water pressure, an expansion tank is installed at the outlet of the boiler.

Selection of pipe diameter for heating

This method is not based on calculations, but on a pattern that can be traced when analyzing a fairly large number of heating systems. This rule was developed by installers and is used by them on small systems for private houses and apartments.

The diameter of the pipes can be simply selected following a certain rule (click to enlarge size)

Most heating boilers come with supply and return pipes of two sizes: And ? inches. It is with this pipe that the pipe is routed until the first branch, and then at each branch the size is reduced by one step. In this way you can determine the diameter of the heating pipes in the apartment. Systems are usually small - from three to eight radiators in the system, maximum - two or three branches with one or two radiators on each. For such a system, the proposed method is an excellent choice. The situation is practically the same for small private houses. But if there are already two floors and a more extensive system, then you have to count and work with tables.

Pipes for private and apartment buildings

There are various heating systems, and in each specific case the pipes must correspond to the individual characteristics of the designed structure.

Individual construction

In Russia and the CIS countries, three types of heating systems are used, each of which has its own characteristics.

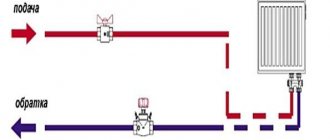

Leningradka

With its help, you can perfectly organize the heating of any home, significantly save on the purchase of materials and reduce the cost of installation work. This scheme allows you to regulate the temperature in each individual room, creating optimal living conditions.

The Leningradka heating system uses the following pipe diameters:

- Trunk: 20–25 mm (one-story house) and 30–40 mm (two-story house and above).

- For radiator connection: 13–16 mm.

To regulate the heat supply to each radiator, you can install a valve on the connection pipe.

Tichelman loop

This system is characterized by the following positive features: stability during operation and uniform heating of all radiators. This diagram for connecting heating devices is also called associated. The coolant supply ends at the last radiator. The return starts immediately from the first battery. The Tichelman loop can be used with equal effectiveness on large and small areas.

Dead end

In this system, the radiator closest to the boiler heats up more, and the latter receives less coolant than the others. For a dead-end circuit, the number of radiators in each arm is limited. The pipes used are the same as in Leningradka.

Heating system of an apartment building

Nowadays, a central heating system is usually used for an apartment building. Water comes into it from thermal power plants (or other suppliers). The system is designed in such a way as to ensure the same coolant pressure in the main pipes on all floors of the house .

Diameters of heating pipes in an apartment building:

- At the entrance, in the basement - 100 mm.

- Loungers that distribute the coolant along the entrances - 50–76 mm. The parameter depends on the size of the building, the distance to which the coolant is transported and how many branches the pipeline will have.

- The diameter of the risers is 20 mm.

The return is performed in increasing order - 20–50–76–100 mm. Various water circuits are used: single-pipe and double-pipe.

According to SNIPs and GOSTs, the heating system of an apartment building must ensure that the air inside all residential premises is heated to 20-22 degrees Celsius in winter.

Marking units

When selecting heating components, the standard unit of measurement is taken into account to determine the value and marking. The basic value that indicates the dimension is defined as a whole number or an inch. It is easy to convert inches into standard millimeters from the ratio: 1 inch equals 25.4 mm.

The size of the pipe is calculated using several indicators - the possible speed of fluid flow and some pressure loss over a one-meter section of the pipeline. Calculating the diameter based on pressure drop is economically feasible and consists of determining the balance sheet value between operating and major maintenance costs.

The larger the diameter, the higher the cost indicators, and in order to pump a certain amount of water where there is a narrowed diameter, much more energy will be required to operate the electric pump.

Metal-plastic pipes

This type of pipe is the most popular among consumers. Such products are available in a wide range of standard sizes and are ideal for installing heating systems. They have the following advantages:

- increased strength and durability (aluminum or fiberglass base coated with plastic generally creates a highly durable structure that does not collapse over time and is resistant to mechanical damage);

- resistance to corrosion processes (sealed outer coating does not allow air to pass through);

- minimal hydraulic resistance (such pipes are ideal for heating systems with natural and forced water circulation);

- have antistatic properties;

- simplicity and high speed of installation (installation does not require professional knowledge, just familiarize yourself with installation techniques on the Internet and purchase a special soldering iron);

- low cost of pipes of any diameters and components for them.

Reliable connection of the elements is ensured by special elements - fittings. If metal-plastic pipes need to be connected to metal pipes or shut-off valves, flanges or adapters for threaded connections are used.

When installing a heating system made of pipes and fittings reinforced with glass fiber, the operation of stripping these elements is not required, which significantly speeds up and simplifies the work.

Thus, metal-plastic pipes are the best option for self-installation of a heating system. The main thing is to choose the right number and diameter of pipes and components (fittings).

What to cook from eggs without harming your figure? Check out this interesting list of dishes that include eggs. These recipes will not harm your figure at all.

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don’t worry about the shape and length of their hair. It seems that youth is created for experiments with appearance and daring curls. However, already last.

These 10 little things a man always notices in a woman Do you think your man doesn’t understand anything about female psychology? This is wrong. Not a single little thing can be hidden from the gaze of a partner who loves you. And here are 10 things.

10 charming celebrity children who look completely different today Time flies, and one day little celebrities become adults who are no longer recognizable. Pretty boys and girls turn into...

9 Famous Women Who Have Fallen in Love with Women Showing interest in people other than the opposite sex is not unusual. You are unlikely to be able to surprise or shock anyone if you admit it.

Why do you need a tiny pocket on jeans? Everyone knows that there is a tiny pocket on jeans, but few have thought about why it might be needed. Interestingly, it was originally a place for storage.

Installation of a heating system with metal-plastic pipes

Metal-plastic pipes easily change shape and are quite convenient to install. An additional advantage is that there is no need for expensive tools; they have an attractive appearance, so painting the system is not required. You can even do without special scissors (replace with a hacksaw) and a pipe bender (a spring is enough).

In order to bend metal-plastic heating pipes, various pipe benders and external or internal springs (mandrels) are used. The bending radius depends on the outer diameter of the product, but cannot exceed four diameters.

Follow installation with detachable fittings

Detachable (threaded and compression) fittings are quite expensive, but without them it is impossible to create connections between pipes and devices. If necessary, these elements can be dismantled and installed again (in compression ones, the crimp ring must be replaced).

Regardless of the fitting used, you first need to cut a piece of pipe to the desired length, calibrate the end and remove the chamfer. When cutting, maintain perpendicularity to the axis. Both the presence of a chamfer and unevenness during cutting can lead to a violation of the tightness of the connection.

If the fitting is threaded (coupling, tee, cross), then it is enough to screw the pipes to its ends. If it is compression, then it is equipped with a special nut, which should be tightened with a wrench immediately after the pipe is inserted into the fitting. Both threaded and compression ones do not require the use of special tools during installation, but they must be monitored during operation, since such connections tend to relax. They are used for open installation, as well as for connecting to manifolds, installing radiators and connecting to valves.

Sequence with press fittings

If it is necessary to monolith metal-plastic pipes for heating, installation is carried out using press fittings that cannot be disassembled and do not require maintenance during operation. In this case, you cannot do without a press tool that compresses the sleeve around the fitting.

When installing a heating system, you can use fittings made of plastic, bronze and brass.

Metal-plastic heating pipes have not only advantages, but also disadvantages:

- the “layer cake” design is weakened by repeated deformations caused by temperature fluctuations;

- the cross-section of the fitting is narrower than the cross-section of the pipes;

- high-quality fittings are very expensive;

- counterfeit materials create problems during operation of the heating system;

- metal-plastic is unstable in relation to ultraviolet rays, mechanical and thermal influences.

The cost of high-quality metal-plastic cannot be less than 90 rubles per meter. This should be taken into account when purchasing. For example, metal-plastic pipes for heating rehau with a diameter of 16 mm cost 119 rubles per meter, with a diameter of 40 mm - 959 rubles per meter.

Installation of heating and water supply systems has become significantly easier with the advent of a new building material on the market - metal-plastic pipes. They have a number of advantages: they bend easily and reliably retain their given shape, are resistant to corrosion, do not require painting, have a lower noise level of liquid flow, are light in weight, and the flow area does not narrow during the entire period of operation.

Polyethylene is inert towards aggressive environments, and metal-plastic pipes are not subject to corrosion.

Regardless of what diameters of metal-plastic pipes are used in installation, the expansion coefficient of the material is always the same.

This ensures the reliability and durability of the pipeline

It is important that these products can come into contact with any materials, including concrete. They have proven themselves well in the Russian climate and can work without insulation at a temperature of -25°C

They are sold in coils and measured in linear meters. Flexible, allowing installation without the use of special tools.

How to choose the diameter of a heating pipeThis article tells you how to choose the pipe diameter for a metal-plastic and polypropylene pipe for a private house with an area of up to 300 sq.m. But you can also choose the diameters of other pipes, taking into account the internal diameter of the other pipeline.

How to choose the correct pipe diameter is shown in the examples below.

What diameter of pipes to choose also depends on the criteria of the heating system; this is also written below (see section Criteria for choosing diameters).

More about the program

Everything is very simple and you don’t even need to do a hydraulic calculation, which is written about here: Hydraulic calculation of a heating system

You can use the formula to find the diameter, or you can cut down on the calculation time and just select the diameter from the table below.

Formula for finding pipeline diameters

Coolant velocities are selected for a head loss of 150 Pa/m; below is an explanation of why this speed is chosen.

In the boiler branch, you can increase the coolant speed to the level of economic justification (for example, up to 1 m/sec.). Because on the boiler branch the cost of the fittings may be higher and the pressure losses may be exceeded, because this does not affect the even distribution of costs between the branched branches.

Selecting the pipeline diameter according to the table

Knowing only the power of heating devices (radiators) or the heat loss of the room, you can select the pipe diameter from the table below:

Diameters for polypropylene pipes

Diameters for metal-plastic pipes

Diagram for example of diameter selection

Description of an example of diameter selection

Each radiator is connected with an MP16 mm pipe, because the radiator power does not exceed 3200 W, indicated in the table for choosing diameters. (see table above). If the radiator exceeds the power of 3200 W, then select MP20 mm. If the radiator power is 4000 W, then choose MP20 mm.

Diameter of pipe section B-B

, marked in red letters. The section of pipe between the 2nd and 3rd radiator.

Pipe section B-B delivers coolant 3 and 4 to the radiator. The total power of these radiators is 2000 W + 2000 W = 4000 W.

For the B-B pipe section, MP20 mm is selected, because the power of the 4000 W pipe section is more than 3200 W and less than 6700 W. (see table above).

Diameter of pipe section A-B

Power of section A-B = sum of powers of 2,3 and 4 radiators = 2000 + 2000 + 2000 = 6000 W.

For pipe section A-B, MP20 mm is selected, because the power of a pipe section of 6000 W is more than 3200 W and less than 6700 W. (see table above).

Diameter of pipe section A-G

Total power of 1,2,3 and 4 radiators = 3000 + 2000 + 2000 + 2000 = 9000 W.

For the pipe section A-G, MP26 mm is selected, because the power of the 9000 W pipe section is more than 6700 W and less than 12400 W. (see table above).

Diameter of pipe section D-E

Total power of 6 and 7 radiators = 1500 + 1500 = 3000 W.

For pipe section D-E, MP16 mm is selected, because the power of a pipe section of 3000 W does not exceed 3200 W.

Diameter of the pipe section G-D

Total power of 5,6 and 7 radiators = 3000 + 1500 + 1500 = 6000 W.

For the G-D pipe section, MP20 mm is selected, because the power of the 6000 W pipe section is more than 3200 W and less than 6700 W.

Pipe diameters for boiler line

The calculation of diameters is selected based on the flow rate of the coolant, because economic calculations show that a lot of fittings are installed in the boiler line, which are more expensive than fittings of a smaller diameter. Also in the boiler circuit we can add hydraulic resistance, and this will not affect the flow rates between the radiators, because this is one main line in which flow balancing does not need to be done.

Power of all radiators = 3000 + 2000 + 2000+ 2000 + 3000 + 1500 + 1500 = 15000 W.

The power of the boiler circuit is selected at a speed of 0.7 m/sec.

We choose MP26 mm, because the power of a pipe section of 15000 W is more than 11700 W and less than 18500 W. (see table above for boiler circuit).

If it is problematic to use a large diameter, then you can limit yourself to a speed of 1 m/sec. For example, you use a metal-plastic pipe, and the diameter is 40 mm. no, then you can choose the diameter at a speed of 1 m/sec. There is also fittings with a diameter of 40 mm. may greatly exceed prices that will not pay off soon. It will be cheaper to buy a more powerful pump to compensate for these losses. It also happens that it is more profitable to spend more electricity than to buy expensive fittings that will pay for themselves for more than 20 years.

Diameter selection criteria

For which heating system are these diameters suitable:

House up to 300 sq.m. 10 x 10 meters. The perimeter of the house is 40 meters.

Heating system power up to 30 kW.

Two-pipe dead-end heating system for radiators only. No warm water floors.

The temperature difference of the radiators is 15-20 degrees.

The radiators have thermostatic (0.5 Kvs) and balancing (1.1 Kvs) valves. See Kvs in passports.

The length of the pipe from the boiler to the last radiator does not exceed 30 m.

Circulation pump wilo star 25/4 with an electric boiler with low hydraulic resistance.

With a gas wall-mounted boiler with its own pump up to 30 kW.

Explanation of the author who developed the diameter selection table

Looking through various circuits of radiator heating systems for a house of 200-300 sq.m. up to 30 kW. I realized that there is no universal approach to choosing diameters.

If you look at well-functioning circuits of heating systems and try to find features in diameters, then there is nothing particularly similar and there cannot be.

We look at the speeds, they range from 0.2 to 0.7 m/sec.

We look at the losses per meter of pipe, they also range from 20 to 250 Pa/m.

As you can see, there is nothing to grab onto. The speed and head loss ranges are too large.

On the boiler circuit from 0.7 - 1.0 m/sec. On the next distribution line from the boiler (tee, manifold) about 0.4-0.5 m/sec. This corresponds to 150 Pa/m. Of course, a forced reduction in the movement of coolant speed to 0.15 m/sec is allowed.

The radiator branch must have balancing valves up to 1.1 Kvs

You know that a 25/4 pump can charge a 30 kW radiator heating system.

If you buy a 25/6 pump, then over 10 years you will spend electricity approximately equal to 8 thousand rubles. Savings for small-diameter pipes may vary. A large diameter can pay for itself in 20 years. If you have a house of 250 sq.m. If you installed 2 25/6 pumps, then it’s clear you got something wrong with the diameters. Because you can heat a 250 sq.m. house with a 25/4 pump. m. if this applies only to the radiator heating system.

Where the branches begin, it is necessary to make a pressure loss in the pipeline of 150 Pa/m. In the boiler line, pressure losses can be neglected in favor of reducing diameters, which will not affect the uniform distribution of flow rates between the radiators. Also, a reduction in diameters leads to a significant reduction in the price of fittings on the boiler line.

In some short branches, a pressure loss of 250 Pa/m can be allowed. but in this case you need to make an accurate hydraulic calculation using a heating system simulator program

If you calculate 250 Pa/m. this may result in costs being less evenly divided between the radiators. In some cases, you may not be able to adjust the system with balancing valves. Large losses are also possible, which will lead to the selection of a more powerful pump.

Pressure loss of 150 Pa/m. predict diameters that make it possible to more evenly divide costs between radiators. Of course, with such a choice of diameters, it is necessary to install balancing valves on the radiators in order to adjust the flow rates between the radiators. It is possible to choose the diameters so as not to have to adjust the balancing valves, but in this case the diameters turn out to be very large and the heating system turns out to be expensive. The heating system simulator program will help you choose diameters to reduce the balancing setting

250 Pa/m. makes it possible to save on materials. But to save money, you need to make more accurate calculations, and this means time or money that you pay to the designer. It turns out that you can choose a large diameter, thereby saving time or money on hydraulic calculations.

If you already have a heating system installed and it is not working well, then you can test the heating system circuit in the program. Simply put, conduct an audit of the heating system in the heating system simulator program

Some plumbers or specialists say that low flow rates of the coolant in the pipes should not be allowed because the heating system may become airborne. They are partly right. But when it comes to the speed of movement, some plumbers are mistaken if they say that the speed should be at least 0.5 m/sec. I found reference books that indicate a speed of 0.2 m/sec. In order to remove air along the coolant flow. Take, for example, a warm water floor, they indicate a minimum speed of 0.15 m/sec. In a horizontal section of a warm water floor, airing does not occur at such a rate. In my experience, air was generally removed spontaneously in the air loops if there was not so much of it that there was circulation. There are cases, only at the first start-up it is not possible to start some branches due to air loops (where the pipe rises up and then falls down). Air loops cannot be made in the heating system. If you have air loops, then you will have to buy a more powerful pump in order to create pressure to expel the air from such air loops. I mean loops with a height of 250 mm up to 1.5 m.

There is one more feature: each increase in diameter leads to a doubling of power. You can look at the table and see this. In this case, the cross-sectional area of the internal diameter does not double.

I warn you that there may be errors in calculating the diameter from the tables

The table for choosing diameters has some error in choosing diameters. But the task was to give people an algorithm for choosing diameters without precise hydraulic calculations. And accurate hydraulic calculations can be performed in the simulator program.

More about the program

This article was written by a specialist in the field of calculations of heating and water supply systems with more than 10 years of experience. Developed and designed more than 100 heating system schemes. The specialist also has his own software for heating calculations: Read more about the program

Advertising of payment services

You can request services for calculating diameters for your heating system here: Submit a request for calculation

| Like |

| Share |

| Comments (+) [ Read / Add ] |

A series of video tutorials on a private house

Part 1. Where to drill a well?

Part 2. Construction of a water well Part 3. Laying a pipeline from the well to the house Part 4. Automatic water supply Water supply Water

supply for a private house.

Principle of operation. Connection diagram Self-priming surface pumps. Principle of operation. Connection diagram Calculation of a self-priming pump Calculation of diameters from a central water supply Water supply pumping station How to choose a pump for a well? Setting up a pressure switch Pressure switch electrical diagram Operating principle of a hydraulic accumulator Sewage slope of 1 meter SNIP Connecting a heated towel rail DHW recirculation diagram - the best solution! Heating schemes

Hydraulic calculation of a two-pipe heating system Hydraulic calculation of a two-pipe associated heating system Tichelman loop Hydraulic calculation of a single-pipe heating system Hydraulic calculation of radial distribution of a heating system Scheme with a heat pump and a solid fuel boiler - operating logic Three-way valve from Valtec + thermal head with remote sensor Why the heating radiator does not heat well in an apartment building How to connect a boiler to a boiler?

Options and connection diagrams DHW recirculation. Principle of operation and calculation You are not correctly calculating the hydraulic needle and collectors. Manual hydraulic calculation of heating. Calculation of a warm water floor and mixing units. Three-way valve with a servo drive for DHW. Calculation of DHW, BKN. We find the volume, power of the snake, warm-up time, etc. Heating temperature conditions 90-70, 80-63, 70-55, 60-50 Water supply and heating designer

Bernoulli's equation Calculation of water supply for apartment buildings

Automation

How servo drives and three-way valves work Three-way valve for redirecting the flow of coolant

Heating

Calculation of the thermal power of heating radiators Radiator section Overgrowth and deposits in pipes worsen the performance of the water supply and heating system New pumps work differently... Calculation of infiltration Calculation of temperature in an unheated room Calculation of the floor on the ground Calculation of a heat accumulator Calculation of a heat accumulator for a solid fuel boiler Calculation of a heat accumulator for storing thermal energy Where to connect the expansion tank in the heating system?

Boiler resistance Tichelman loop pipe diameter How to choose the diameter of a pipe for heating Heat transfer of a pipe Gravity heating from a polypropylene pipe Why don’t they like single-pipe heating? How to love her? Smart selection of diameters in a heating system Balancing heating radiators - a step-by-step guide Top 5 problems in designing heating systems Heat regulators

Room thermostat - operating principle

Mixing unit

What is a mixing unit?

Types of mixing units for heating Characteristics and parameters of systems

Local hydraulic resistance.

What is KMS? Bandwidth Kvs. What it is? Boiling water under pressure - what will happen? What is hysteresis in temperatures and pressures? What is infiltration? What are DN, Du and PN? Plumbers and engineers must know these parameters! Hydraulic meanings, concepts and calculation of heating system circuits. Flow coefficient in a single-pipe heating system. Hydraulic paradox in a heating system. Riddle No. 4 Video

Heating Automatic temperature control Simple replenishment of the heating system Heat engineering.

Walling. Warm water floor Combimix pump mixing unit Why choose underfloor heating? Water heated floor VALTEC. Video seminar Pipe for heated floors - what to choose? Warm water floor - theory, advantages and disadvantages Laying warm water floor - theory and rules Warm floors in a wooden house. Dry heated floor. Warm water floor cake - theory and calculation News for plumbers and engineers Plumbers Are you still doing hack work? The first results of the development of a new program with realistic three-dimensional graphics Thermal calculation program. The second result of the development of Teplo-Raschet 3D Program for thermal calculation of a house through enclosing structures Results of the development of a new program for hydraulic calculation Primary secondary rings of the heating system One pump for radiators and underfloor heating Calculation of heat loss at home - wall orientation? Regulatory documents

Regulatory requirements for the design of boiler houses Abbreviations

Terms and definitions

Basement, basement, floor Boiler houses

Documentary water supply

Sources of water supply Physical properties of natural water Chemical composition of natural water Bacterial contamination of water Requirements for water quality

Collection of questions

Is it possible to place a gas boiler room in the basement of a residential building ?

Is it possible to attach a boiler room to a residential building? Is it possible to place a gas boiler room on the roof of a residential building? How are boiler rooms classified according to their location? Personal experiences in hydraulics and heating engineering

Introduction and introduction.

Part 1 Hydraulic resistance of a thermostatic valve Hydraulic resistance of a filter flask Video course Calculation programs

Technotronic8 - Program for hydraulic and thermal calculations Auto-Snab 3D - Hydraulic calculation in three-dimensional space

Useful materials Useful literature

Hydrostatics and hydrodynamics

Problems in hydraulic calculations

Pressure loss along a straight section of a pipe How does head loss affect flow?

Miscellaneous

Do-it-yourself water supply for a private house Autonomous water supply Scheme of autonomous water supply Scheme of automatic water supply Scheme of water supply for a private house

Privacy Policy Answers to questions Client 1 Client 1. Boiler efficiency

Boiler and circuit power

In private houses or apartments, heating of the interior is carried out by gas or electric boilers.

The calculation of the required thermal power is carried out depending on the size of the heated area. It is believed that high-quality heating of 1 m2 will require 0.1 m kW of thermal energy. Depending on climatic conditions and gentle operating conditions, this figure increases to 1.3 kW/m2. Factors affecting the power of a heating boiler:

- Type of building material for the enclosing wall structures of a house. The high thermal conductivity of the material in combination with the insufficient thickness of the external walls greatly increases heat losses and then the operation of the boiler with the highest power will be inefficient and unsatisfactory.

- Using a second circuit to heat water. If such an option is provided in advance, a more powerful heat generator is selected.

- Type of fuel. A gas boiler is considered more economical, but it can only be used in areas where there is a gas pipeline.

Water circulation in the system is ensured by a pump designed to optimize the speed of hot water and its return. At the same time, the problem of air pockets squeezed out by a constant flow of coolant is solved.

Views: 255

Where can I get the tables?

Everything is simple here. Usually, all detailed tables with all the necessary data can be viewed (or downloaded) on the websites of pipe manufacturers. But it happens that there are still no tables. You can get out of this situation as follows. If there are no tables for the outer diameter, then take the one for the inner diameter and calculate according to it. Yes, there will be inaccuracies, but, as experience shows, for forced circulation they are completely insignificant and acceptable.

Having analyzed a huge number of already installed and perfectly working systems, experts noticed a certain pattern in the choice of pipe cross-section. It is mainly suitable for small-sized autonomous systems.

In private houses, the pipes that come out of the boiler are most often one-half and three-quarters in size. This diameter of the pipe for heating a house is used until the first fork, and at each subsequent fork the cross-section is reduced by exactly one step. But this method is applicable only for apartments and one-story houses; for high-rise buildings, alas, everything will have to be calculated very carefully.

How to calculate the cross-section of pipes for heat supply

Before you begin to determine the diameter of the pipeline, it is worth understanding in detail the very concept of “diameter”. When applied to heating pipes, it is customary to talk about several interpretations of this term:

- External diameter. A parameter required when designing a system. It is made up of the internal diameter and wall thickness.

- Inner diameter. Determines the throughput of the pipeline.

- The nominal value of the pipe bore. An indicator used for labeling plastic products.

Quite often, pipe diameters are indicated in inches. Converting them into millimeters that are more familiar to us is simple - one inch contains 25.4 mm.

Calculation of system thermal power

For small standard heating systems it is quite possible to do without complex calculations. Here it will be enough to follow a few simple rules:

- For circuits with natural circulation, the optimal pipe diameter will be 30-40 mm.

- In systems with forced circulation of coolant, pipes of a smaller diameter should be preferred. This will ensure optimal fluid flow speed and pressure.

- Q – thermal power, kW/h,

- V – volume of heated room, m3,

- ∆t – average temperature difference indoors and outdoors, ⁰С,

- K – heat loss coefficient,

- 860 – constant correction factor for converting calculated indicators into kW/h format.

All multipliers can be easily calculated with a reasonable degree of reliability. Only the determination of the K coefficient may raise some questions.

Its value depends on the level of thermal insulation of the house or room for which calculations are being made.

The numbers could be like this:

- K=3-4. A building with a minimum level of thermal insulation.

- K=2-2.9. Facade facing with brick.

- K=1-1.9. Average level of thermal insulation.

- K=0.6-0.9. High-quality insulation with modern materials.

After determining the thermal power of the heating system, you will need to use a special table to determine the diameter of the pipes.

Tables may vary depending on the type of pipe (polypropylene, steel, cast iron, copper, etc.) and even the manufacturer. It is more correct to take these tables directly from the websites of manufacturers. Most often, the table indicates the thermal power and the expected temperature delta. At the intersection of these parameters, the required pipe diameter will be indicated.

If you cannot find a table for a specific type of pipe, you can use the table of correspondence between different types of pipelines.

Here, for each pipe diameter (meaning the internal diameter), corresponding models made from other materials are described. Of course, there will be some error, but for small heating systems it is quite acceptable.

Speed of fluid movement in the system

The speed of movement of the coolant through the heating system determines the uniform distribution of thermal energy across all radiators or radiators.

The diameter of the pipe, meanwhile, has a direct impact on the speed of movement of the liquid - the smaller the cross-sectional area of the pipeline, the higher the speed (all other things being equal) the coolant will move through it.

When determining the diameter of the pipes, it is worth choosing the speed value so that it falls within the range:

- On the one hand, the water flow rate should not be too high. This, of course, will increase the efficiency of the system, but will invariably be accompanied by additional noise.

- On the other hand, at speeds below 0.3 m/s there will be large heat losses. In addition, low pressure will make air vents and Mayevsky taps useless, since air pockets simply will not reach these elements.

- The optimal speed value is considered to be in the range of 0.36-0.7 m/s.

What data do you need to take into account for the calculation?

The calculation will be considered using the example of a system with forced circulation, which is ensured by the operation of a pump.

For the calculation the following data is required:

- Delta temperature of the coolant at the entrance to the system and at the return;

- coolant speed;

- heating system power;

- general heat loss of the room (house, apartment);

- pipeline length;

- radiator power in each room;

- wiring method;

- pipe material.

Example of heating system calculation

As a rule, a simplified calculation is performed based on such parameters as the volume of the room, the level of its insulation, the flow rate of the coolant and the temperature difference in the inlet and outlet pipelines.

The diameter of the heating pipe with forced circulation is determined in the following sequence:

the total amount of heat that needs to be supplied to the room is determined (thermal power, kW), you can also rely on tabular data;

Thermal power value depending on the temperature difference and pump power

Having set the speed of water movement, the optimal D is determined.

Calculation of thermal power

As an example, a standard room with dimensions of 4.8x5.0x3.0m will be used. The heating circuit is with forced circulation; it is necessary to calculate the diameters of the heating pipes for distribution throughout the apartment. The basic calculation formula looks like this:

The following notations are used in the formula:

- V is the volume of the room. In the example, it is equal to 3.8∙4.0∙3.0 = 45.6m 3 ;

- Δt is the difference between the temperature outside and inside. In the example, 53ᵒС is taken;

Minimum temperatures by month for some cities

K is a special coefficient that determines the degree of insulation of the building. In general, its value ranges from 0.6-0.9 (effective thermal insulation is used, the floor and roof are insulated, at least double-glazed windows are installed) to 3-4 (buildings without thermal insulation, for example, change houses). In the example, an intermediate option is used - the apartment has standard thermal insulation (K = 1.0 - 1.9), K = 1.1 is accepted.

The total thermal power should be 45.6∙53∙1.1/860 = 3.09 kW.

You can use tabular data.

Table for calculating heat flow

Diameter determination

The diameter of the heating pipes is determined by the formula

Where notations are used:

- Δt – difference in coolant temperatures in the supply and discharge pipelines. Considering that water is supplied at a temperature of about 90-95ᵒС, and it has time to cool down to 65-70ᵒС, the temperature difference can be taken equal to 20ᵒС;

- v is the speed of water movement. It is undesirable for it to exceed 1.5 m/s, and the minimum acceptable threshold is 0.25 m/s. It is recommended to stay at an intermediate speed value of 0.8 - 1.3 m/s.

Note! An incorrect choice of pipe diameter for heating can lead to a drop in speed below the minimum threshold, which in turn will cause the formation of air locks. As a result, work efficiency will become zero.

The value of Din in the example will be √354∙(0.86∙3.09/20)/1.3 = 36.18 mm

If you pay attention to the standard sizes, for example, of a PP pipeline, you will see that there is simply no such Din. In this case, simply select the closest diameter of propylene pipes for heating

In this example, you can choose PN25 with a diameter of 33.2 mm, this will lead to a slight increase in the coolant flow rate, but it will still remain within acceptable limits.

Features of heating systems with natural circulation

Their main difference is that they do not use a circulation pump to create pressure. The liquid moves by gravity, after heating it is forced upward, then passes through the radiators, cools and returns to the boiler.

The diagram shows the principle of circulation pressure

Compared to systems with forced circulation, the diameter of pipes for heating with natural circulation must be larger. The basis of the calculation in this case is that the circulation pressure exceeds friction losses and local resistance.

Example of wiring with natural circulation

In order not to calculate the value of the circulation pressure each time, there are special tables compiled for different temperature differences. For example, if the length of the pipeline from the boiler to the radiator is 4.0 m, and the temperature difference is 20°C (70°C in the outlet and 90°C in the supply), then the circulation pressure will be 488 Pa. Based on this, the coolant speed is selected by changing D.

When performing calculations yourself, a verification calculation is also required. That is, the calculations are carried out in the reverse order, the purpose of the check is to determine whether friction losses and local resistance do not exceed the circulation pressure.

How does pipe diameter affect the efficiency of a heating system?

Calculating the diameter of the pipes will help to avoid unnecessary heat loss and energy costs for heating the room. The process allows you to determine the dimensions that should be taken into account when planning the design of the premises.

Even if during the construction of a residential building, industrial building, or structure the most modern thermal insulation materials are used, but miscalculations are made in choosing the diameter of the pipes, then maintaining the required temperature in the premises will become unprofitable for the developer. In some cases, the entire system may fail or fail.

To achieve the highest possible system efficiency, design must be approached holistically. The selection of each link - boiler, pipes, radiators, circulation pump - is carried out taking into account all the features of each individual project.

Calculation of the diameter of heating pipes

Then, when the material for the heating system is selected, it is the turn to calculate the diameter of the pipe. You can do this yourself or trust the professionals. Moreover, you need to take as a basis the following characteristics, which can help you correctly calculate the diameter of the pipeline:

- drag coefficient;

- heating system wiring system;

- amount of heat given off;

- speed mode of coolant movement;

- internal section of the pipe;

- diameter of inlet and outlet openings in the boiler system;

- calculation of coolant cooling in the radiator.

If your heating system is highly complex (many radiators) or a mixed option (warm floors and radiators), then it is advisable to use the help of specialists and entrust them with making a design calculation of the diameter of the pipeline, because it will be quite difficult to calculate everything correctly on your own.

If you perform the calculation incorrectly, you may need a lot of effort and material costs in the future to correct all the shortcomings.

Rules for calculating diameter

The following indicators are considered standard:

- calculation of coolant cooling (T), the difference can be 15-20 degrees when leaving the boiler and returning back;

- the coolant movement speed (V) cannot be more than 1.5 m/s;

- the diameter of the inlet and outlet openings of the boiler is indicated by the manufacturer;

- the resistance coefficient is indicated by the manufacturer;

- water consumption C=0.86Q/T;

- the amount of heat released (Q) is the total power of the heated floor or radiators.

The heating system is calculated in this way. The boiler inlet and outlet is the main point. The initial pipe of the heating system, even when choosing polymer pipes, is made of metal (approximately 1.5 meters from the outlet), the corresponding section is attached to the first branch of the system. Afterwards, the pipeline branches are laid out. In this case, the diameter of the pipeline depends on the length, but, as a rule, each subsequent branch is installed an order of magnitude smaller than the previous one. The calculation for connecting the cold water pipeline system is the same, only it is connected to the inlet of the boiler system.

Heating pipe slope

When organizing an autonomous water heating system, do not forget that it must be on a slight slope, which helps its proper operation. This is especially true for a heating system where the coolant naturally moves through the pipeline. How to choose the slope of heating pipes?

To preliminary calculate the angle of inclination of heating pipes, you can use a water level - a hydraulic level or a spirit level.

In systems that use forced movement of coolant using a pump, a slope is not necessary. As a rule, in these systems the pipes are laid horizontally or with a slight slope towards the outlet shut-off valves of a few millimeters. This helps to drain the coolant from the pipes during repair work or to prevent pipe rupture if the system has not been used for a very long time in the winter.

A horizontal outlet for connecting to heating radiators from vertical pipe systems with a length of more than 50 centimeters is installed with a slope of 10 millimeters in the direction of movement of the coolant. If this bend is smaller, it is not necessary to make a slope.

Calculating the heating system in an apartment or country house is quite difficult, since the result depends on various factors. They all need to be taken into account and calculated. The efficiency and even normal performance of the entire heating system will depend on the correct calculation of indicators. This is one of those basic elements that make up the entire system in general. Therefore, the determination of this parameter must be taken very seriously. And only in this case will your apartment or private house be cozy and warm in winter.

If all the questions seem incomprehensible and quite complicated to you, then you should not waste time, and, probably, energy, and immediately turn to professionals for help. Their knowledge and experience are often enough to calculate and completely install a heating system at the highest level in a short period of time, taking into account all the necessary standards and indicators. And you can enjoy the results of professional installation.

Features of calculating the cross-section of metal pipes

For large heating systems with metal pipes, heat loss through the walls must be taken into account. The losses are not that great, but over a long distance they can lead to the fact that the temperature on the last radiators will be very low due to the wrong choice of diameter.

Let's calculate the losses for a 40 mm steel pipe with a wall thickness of 1.4 mm. Losses are calculated using the formula:

q = k*3.14*(tв-tп)

Where:

q is the heat loss per meter of pipe,

k is the linear heat transfer coefficient (for this pipe it is 0.272 W*m/s);

tw — water temperature in the pipe — 80°C;

tп — room air temperature — 22°С.

Substituting the values we get:

q = 0.272*3.15*(80-22)=49 W/s

It turns out that almost 50 W of heat is lost per meter. If the length is significant, this can become critical. It is clear that the larger the cross-section, the greater the losses will be. If you need to take these losses into account, then when calculating losses, add losses in the pipeline to reduce the thermal load on the radiator, and then, using the total value, find the required diameter.

Determining the diameter of heating system pipes is not an easy task

But for individual heating systems these values are usually not critical. Moreover, when calculating heat loss and equipment power, the calculated values are most often rounded upward. This gives a certain margin, which allows you not to make such complex calculations.

An important question: where to get tables? Almost all manufacturers' websites have such tables. You can read it directly from the site, or you can download it for yourself. But what to do if you still haven’t found the necessary tables for the calculation. You can use the diameter selection system described below, or you can do it differently.

Despite the fact that different values (internal or external) are indicated when marking different pipes, they can be equated with a certain error. Using the table below you can find the type and marking for a known internal diameter. You can immediately find a corresponding pipe size made of a different material. For example, you need to calculate the diameter of metal-plastic heating pipes. You did not find a table for MP. But there is one for polypropylene. Select sizes for PPR, and then use this table to find analogues in MP. Naturally, there will be an error, but for systems with forced circulation it is acceptable.

Correspondence table for different types of pipes (click to enlarge size)

Using this table, you can easily determine the internal diameters of the heating system pipes and their markings.

Calculation for a two-pipe system

There is a two-story house with a two-pipe heating system, two wings on each floor. Polypropylene products will be used, operating mode 80/60 with a temperature delta of 20 °C. The heat loss of the house is 38 kW of thermal energy. The first floor has 20 kW, the second 18 kW. The diagram is shown below.

Two-pipe heating scheme for a two-story house. Right wing (click to enlarge)

Two-pipe heating scheme for a two-story house. Left wing (click to enlarge)

On the right is a table from which we will determine the diameter. The pinkish area is the zone of optimal coolant movement speed.

Table for calculating the diameter of polypropylene heating pipes. Operating mode 80/60 with a temperature delta of 20°C (click to enlarge)

- We determine which pipe needs to be used in the area from the boiler to the first branch. The entire coolant passes through this section, therefore the entire heat volume of 38 kW passes through. In the table we find the corresponding line, follow it to the pink-tinted area and go up. We see that two diameters are suitable: 40 mm, 50 mm. For obvious reasons, we choose the smaller one - 40 mm.

- Let's look at the diagram again. Where the flow is divided, 20 kW goes to the 1st floor, 18 kW goes to the 2nd floor. In the table we find the corresponding lines and determine the cross-section of the pipes. It turns out that we are dividing both branches with a diameter of 32 mm.

- Each of the circuits is divided into two branches with equal load. On the first floor there is 10 kW each to the right and left (20 kW/2=10 kW), on the second floor 9 kW each (18 kW/2)=9 kW). Using the table, we find the corresponding values for these areas: 25 mm. This size is continued to be used until the heat load drops to 5 kW (as seen in the table). Next comes a section of 20 mm. On the first floor we go 20 mm after the second radiator (look at the load), on the second - after the third. At this point there is one amendment made by accumulated experience - it is better to switch to 20 mm at a load of 3 kW.

All. The diameters of polypropylene pipes for a two-pipe system are calculated. For the return, the cross-section is not calculated, and the wiring is made with the same pipes as the supply. We hope the methodology is clear. It will not be difficult to carry out a similar calculation if all the initial data is available. If you decide to use other pipes, you will need other tables calculated for the material you need. You can practice on this system, but for an average temperature mode of 75/60 and a delta of 15 °C (the table is located below).

Table for calculating the diameter of polypropylene heating pipes. Operating mode 75/60 and delta 15 °C (click to enlarge)

Determination of pipe diameter for a single-pipe system with forced circulation

The principle remains the same, the methodology changes. Let's use another table to determine the diameter of pipes with a different principle for entering data. In it, the optimal zone of coolant movement speeds is colored blue, the power values are not in the side column, but are entered in the field. That's why the process itself is a little different.

Table for calculating the diameter of heating pipes

Using this table, we calculate the internal diameter of the pipes for a simple one-pipe heating circuit for one floor and six radiators connected in series. Let's start the calculation:

- 15 kW is supplied to the system input from the boiler. We find values close to 15 kW in the optimal speed zone (blue). There are two of them: in a line measuring 25 mm and 20 mm. For obvious reasons, we choose 20 mm.

- On the first radiator, the thermal load is reduced to 12 kW. We find this value in the table. It turns out that it goes further from it of the same size - 20 mm.

- On the third radiator the load is already 10.5 kW. We determine the cross section - still the same 20 mm.

- Judging by the table, the fourth radiator is already 15 mm: 10.5 kW-2 kW = 8.5 kW.

- On the fifth there is another 15mm, and after that you can already put 12mm.

Scheme of a one-pipe system with six radiators

Please note again that the table above defines internal diameters. Using them you can then find the markings of pipes made of the desired material.

It seems that there should be no problems with how to calculate the diameter of the heating pipe. Everything is quite clear. But this is true for polypropylene and metal-plastic products - their thermal conductivity is low and losses through the walls are insignificant, therefore they are not taken into account when calculating. Another thing is metals - steel, stainless steel and aluminum. If the length of the pipeline is significant, then the losses through their surface will be significant.

Problems in choosing heating pipes

Some may find that determining the required diameter of pipes for a heating system is not at all a difficult task. It would seem, what requirements can be presented to a pipe, the only task of which is to deliver coolant to the radiators.

Meanwhile, an incorrectly selected pipe (or collector) diameter can negatively affect the operation of the entire heating system. The movement of liquid through a pipeline is accompanied by numerous complex processes, for the description of which there is a special branch of physics - hydrodynamics.

Without delving into the scientific jungle, it is nevertheless possible to determine a number of fundamental characteristics that directly depend on the diameter of the pipeline:

- Velocity of fluid propagation. Affects the optimal distribution of heat across heating radiators, preventing the coolant from cooling below the minimum temperature value. In addition, the noise level of the operating heating system will directly depend on the speed of propagation.

- Coolant volume. On the one hand, increasing the diameter of the pipes will help reduce losses from friction of the liquid on the inner surface of the pipeline. On the other hand, as the cross-section of the pipe increases, the total volume of coolant in the system will increase, and its heating will require more energy.

- Hydraulic losses. Occurs at the joints of pipes of various diameters. The more transitions there are in the thermal system, the more losses of this kind will result in the end.

Bottom line

If we have a private house or apartment, autonomous heating for no more than 5-8 radiators and 2-3 forks, we can easily calculate everything ourselves. We need to know how powerful each heating point is, the heat loss in the room and a good table for selecting the pipe diameter.

However, as has already become clear, trust experienced specialists to calculate a complex multi-level system with numerous junctions and forks. Well, if you still decide to do everything yourself, then at least read articles like ours and consult with experts.

Finding relevant data

As for finding the optimal reference data, almost all websites of manufacturers of heating system components provide this information. In cases where suitable values have not been found, there is a special system for selecting diameters. This technique is based on calculations, and not on average patterns based on processing data on a huge number of heating systems. Calculation of the coolant by pipe cross-section was developed by plumbers with practical experience in installation work, and is used for arranging small circuits inside homes.

In the vast majority of cases, heating boilers are equipped with two sizes of supply and return pipes: ¾ and ½ inches. This size is taken as the basis for wiring up to the first branch. In the future, each new branch serves as a reason to reduce the diameter by one position. This method allows you to calculate the cross-section of pipes in an apartment. We are talking about small systems with 3-8 radiators. Typically such circuits consist of two or three lines with 1-2 batteries. Small private cottages can be calculated in a similar way. If there are two or more floors, you have to use reference data.

Where can I get the tables?

All boiler pipe manufacturers offer them on their websites. If you cannot find the table you need, you can choose one of these actions:

- Apply the following principles for selecting diameters.

- Another solution.

Typically, when marking pipes, manufacturers indicate external or internal parameters. With some error they are equal. If you know the internal diameter, you can calculate both the type and markings using the proposed table. Here the parameter of a pipe made of other material is determined.

Example: the task is to calculate the diameter of metal-plastic pipes for a boiler. No table found for this material. There is data on polypropylene. Parameters for it are being selected. The table calculates analogues for metal-plastic. There is an error. But if the network has forced circulation, this error is acceptable.

Table on pipes made of different materials.

The main task of choosing heating system elements

Usually, when choosing heating pipes, the following questions most often arise: which pipes are best to choose, what material to choose, what diameter is needed and how to calculate it correctly? To get the correct answer, you first need to decide what is most preferable for you: the total cost of the entire heating system or compliance with the standards that apply to the diameter of the pipeline? First, let's decide on the material. All pipes that are used in heating systems are divided into several types:

- polymer (metal-plastic, polyethylene, polypropylene, PVC);

- metal (stainless steel, ferrous metal, brass, copper, bronze).

Even professionals will not tell you the best heating material, because each of the above has its own advantages and disadvantages. The only material that absolutely cannot be used as a heating pipeline is PVC, because it cannot withstand elevated temperatures in the heating system. Polypropylene is less susceptible to elevated temperatures, however, it is not recommended for installation in heating. That is, you need to select one of the following materials. In order to calculate the length or weight of the pipe depending on the material of manufacture, you can use a calculator.

Copper pipes

are in no way inferior to metal-plastic products

Experts say that copper is an ideal material for heating; the service life of this heating system is more than 100 years. But the disadvantages include high thermal conductivity (which is not a disadvantage when installing a heated floor system), as well as a rather high price.

Why is this necessary?

But in fact, why is it necessary to calculate the diameters of heating pipes? Why not simply take pipes that are obviously oversized? After all, in this way we will protect ourselves from excessively slow circulation in the circuit.

Unfortunately, this approach has several serious drawbacks.

- Material consumption and, accordingly, the price per linear meter increases in proportion to the square of the diameter. The costs will not be cheap.

Please note: to maintain the same operating pressure, when the pipe diameter increases, the wall thickness must be increased, which further increases material consumption.

- What is equally important, the increased diameter of the pipeline means an increase in the volume of coolant and, accordingly, an increased thermal inertia of the system. It will take longer to warm up and take longer to cool down, which is not always desirable.

- Finally, if thick heating pipes are laid openly, they will not really decorate the room, but if hidden, they will increase the depth of the grooves in the walls or the thickness of the screed on the floor.

It is much more difficult to hide thick pipes in grooves.