A solid fuel boiler with a hob resembles a conventional stove in its structure. It is easy to operate, does not require high fuel costs and can help out the owners of those suburban areas that cannot be supplied with gas or centralized heating.

Such devices do an excellent job of their duties; they not only maintain a comfortable temperature in homes, but also provide the ability to cook food and heat water.

Features of boilers with a stove

Traditional solid fuel boilers with a hob have a fairly simple design and are modular in design. These devices consist of a set of important parts placed in a durable and fire-resistant housing. For its manufacture, corrosion-resistant sheets of steel or cast iron are usually chosen.

Pyrolysis models have a similar structure, but are distinguished by high efficiency and long-lasting fuel combustion. This effect occurs due to the afterburning of wood gas resulting from the combustion of firewood.

Device

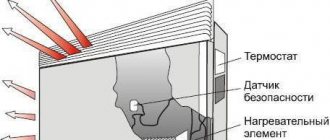

The main parts of such a device can be called:

- The heat exchanger is an important element of the device; it transfers energy to the coolant using flue gas. The process itself and the speed of gas passage are regulated by a smoke exhauster. The service life of these parts is 15-25 years and depends on the metal used in their manufacture. When choosing a boiler, it is worth remembering that models with cast iron heat exchangers will cost more, but will not fail longer. Cheap cast iron options wear out quite quickly and are not highly resistant to corrosion.

- The combustion chamber is designed to accommodate and burn fuel. It is equipped with a loading door.

- The grate is made of an alloy of iron and graphite (gray cast iron), so it survives strong heat well and is not afraid of rust. This part is designed to distribute fuel evenly and also helps combustion products enter the ash pan.

- The thermostat can be mechanical or automatic. It performs protective functions and controls the degree of heating of the coolant.

- The hob is heated by direct exposure to fire. To prevent the tile from deforming during operation, only cast iron is used for its manufacture.

Boilers can also be equipped with additional elements designed to make their use comfortable and safe. For example, expensive units usually have safety valves to prevent overheating, draft regulators, and even gas burners for igniting wood.

Principle of operation

A solid fuel unit with a hob combines three useful functions:

- The heating device increases the temperature in the room using a coolant (most often ordinary water plays this role) or heated air.

- Providing domestic hot water supply - a device with a water circuit is connected to the pipes and works like a regular water heater. One bucket of liquid reaches a comfortable temperature in about 20 minutes.

- Cooking - a hob equipped with burners eliminates the need for a conventional stove. More expensive models can also be equipped with an oven designed for baking food.

Most boilers presented in stores have a so-called “summer mode”. It allows you to cook food without starting the heating system. Some devices can also play the role of decorative fireplaces.

Such design features allow consumers to significantly save on fuel, and the device itself takes up little space. Modern options are not only multifunctional, but also miniature, and some can even decorate the interior of the house.

Most units of this kind operate on the principle of top combustion.

The installation operates according to the following algorithm:

- Fuel is loaded into the combustion chamber and placed on the grate.

- Then they set it on fire and close the chamber door.

- Pull back the damper on the chimney to open the air supply to the device.

- Oxygen is evenly distributed in the combustion chamber and promotes gradual and layer-by-layer combustion of wood. This allows you to save fuel and control the process.

Each heating device is unique in its own way; even budget devices can maintain heat thanks to slow smoldering for up to 10-12 hours.

Advantages

Solid fuel heaters equipped with hotplates help provide heat, hot water and the ability to cook food for homeowners without access to a gas main.

The advantages of such useful devices include:

- Economical. High-quality long-burning units require low fuel consumption. From this we can conclude that such systems bring lower costs than gas or electric heaters.

- Environmental friendliness. Most types of solid fuel are renewable and do not emit combustion products hazardous to the environment.

- Ease of use and no installation difficulties. Many craftsmen will be able to independently assemble and install such devices in their homes.

- Multifunctionality. An ordinary solid fuel heater can be adapted for heating water and cooking food by equipping it with several additional parts during assembly.

- Availability. Many models are capable of operating on any type of solid fuel, so its choice depends only on the desires of the consumer.

- Autonomy. The performance of the unit is not subject to interruptions in the supply of gas or electricity. To light the boiler, you can always use sawdust, wood chips or branches cut down on your site, and even dry manure.

Flaws

For all their advantages, units with hobs still have disadvantages, like other solid fuel boilers.

Among them it is worth highlighting the following points:

- To store and place fuel, you need to allocate a place, for example, equip a pantry or build a shed.

- Budget models are not as easy to use as expensive ones. They get dirty faster and require frequent cleaning.

- If problems arise with smoke removal, you will have to equip the device with additional elements for forced draft.

- The combustion chamber must be filled manually.

- Cooking and heating units are characterized by lower heat transfer and have low efficiency in contrast to classic solid fuel devices.

Design and principle of operation of a solid fuel boiler with a hob

By their design, solid fuel boilers resemble wood stoves.

The solid fuel boiler with a hob has the following technical features:

- Heating the room with heated air or using a coolant.

- As we indicated at the beginning of the article, cooking is another important function and characteristic for such a boiler. And some models also have ovens for baking.

- Boilers with a water circuit are connected directly to the hot water supply system. Water heating is carried out using a flow method. If the unit does not have a hot water supply circuit, it is possible to heat the water on the hob.

Many models have a “summer” mode. It makes it possible to cook food without turning on the heating system.

A solid fuel boiler-stove includes a heating device and a hob. It is possible to equip it with a fireplace. This allows you to save money on fuel, as well as room space (since there is no need for additional installation of a fireplace). Some boilers can fit perfectly into the interior design and look aesthetically pleasing.

Construction of a boiler with a Zota Master stove

The surface of the boiler is heated by direct fire, so all models have a cast iron hob. The heat exchanger is made of high-temperature resistant cast iron or steel.

| Steel heat exchanger | Cast iron heat exchanger |

|

|

When choosing such a unit, buyers are guided primarily by financial capabilities and frequency of use of the boiler.

Plate and heat exchanger material

The boiler body is made from various materials, the main thing is that they have thermal and corrosion resistance. The bodies of industrial versions are smelted from cast iron and steel; homemade stoves are often made of brick or constructed from metal barrels.

Heat exchanger made of cast iron

Cast iron heat exchangers are considered the most reliable and durable, but many domestic companies have abandoned the use of this material in their devices. The fact is that working with it is quite labor-intensive and requires expensive production, since cast iron parts are created by casting.

The main advantages of such heat exchangers are slow cooling after heating and a long service life (up to 35 years) if operating rules are followed.

Steel heat exchanger

Such parts are light weight and low cost. The weight of 40 kW boilers with steel heat exchangers is about 130-150 kilograms, which greatly simplifies the installation and connection process.

Although heat-resistant steel is used for their manufacture, the parts still cannot boast of reliability and long service life. Such heat exchangers tend to deform over time and are susceptible to corrosion.

Advantages and disadvantages

Let us note a few more advantages of solid fuel heating boilers with a stove:

- They create comfortable heating in places where there is no possibility of gas or electricity.

- The fuel for such a boiler is clean materials: peat, wood waste, etc.

- Variability in fuel choice.

- A variety of prices for boilers, which allows you to choose a unit for any budget.

- Easy to install. To use it in a private home, you will not need to perform complex actions and additional costs.

Boiler-stove Wirbel TEMY 15

The disadvantages of the boiler are as follows:

- Despite the ease of installation, storage of solid fuel will still require a certain area, possibly a separate building or utility room. And for the efficiency to be as high as possible, certain conditions will be required.

- The second disadvantage of a solid fuel boiler is that if you purchase a cheaper model, the comfort of use will be somewhat reduced: constant cleaning, soot and soot. Regular care.

- Any boiler of this type requires independent manual loading of fuel.

- The efficiency in long-burning boilers is 70%.

Methods for cleaning a solid fuel boiler.

Clover Smart

Criterias of choice

The modern market offers a wide range of solid fuel boilers with hobs. Such devices have long been popular among consumers, as they are multi-functional and affordable, and do not require large expenses. However, the choice of heater should be taken seriously, since some models presented in stores have an outdated design and not all manufacturers can be trusted.

The main criteria for choosing solid fuel appliances with cooking capabilities:

- Hob material . The tile must be made of durable and heat-resistant metal, since it directly interacts with fire, which can cause it to become deformed and quickly fail.

- Type of fuel. The ideal option for kindling with wood would be a cast iron model, while coal is more efficient when using devices made of high-alloy steel.

- Loading chamber volume . This parameter affects the amount of fuel that can be loaded at one time and how often this will have to be done.

- Weight and volume of the boiler . A steel appliance is lighter and will take up less space than a cast iron appliance of similar power. That is, the cost of its installation and delivery will be lower, and it will also be easier to do.

- Efficiency Cast iron devices cool slower than steel ones, but have a lower efficiency. And the thermal output of the device, as well as fuel costs, depend on it.

- Cost-effective and easy to maintain. When choosing, you should pay attention to how much wood is required to light the boiler. It is also important to find out from the seller how often you will have to clean the device and how much its maintenance and installation will cost.

- Durability. The average service life of such units is 10 years. However, if you use it correctly and do not neglect safety measures, this figure can be increased.

We also must not forget about the possibility of burns and injuries and the degree of safety of the structure. Most steel boilers are produced by well-known and respected companies in the market. They have several levels of protection, and the equipment used to make devices from steel is considered expensive, so such devices are created in small quantities, while there are an order of magnitude more cast iron models in stores. They are cheaper, but their degree of safety is lower.

How to choose a solid fuel boiler for a private home

Direct, long burning or pyrolysis

First of all, the choice depends on the budget. Direct combustion is used in traditional solid fuel boilers: inexpensive, mechanical and easy to operate, do not require connection to the electrical network and are unpretentious in the type and quality of fuel.

If the budget is very limited, it is optimal to focus on classic TT boilers and not consider others. Despite the fact that their efficiency is low, and the owner is required to be regularly present in the boiler room to control combustion and load a new portion of fuel (every 2-4 hours), this is still the optimal and most popular option for both temporary and permanent residence in the house. This is explained by the simplicity, practicality of the design and, of course, affordable cost, starting from 12-13 thousand rubles. (low-power Teplodar Kupper Praktik 8, Karakan 8TPE 3 8 kW).

If the budget is not so limited, then there are two options: long-burning boilers using the “top-down” principle and pyrolysis boilers. When choosing the first option, you can count on a practically autonomous and, in most cases, non-volatile system with simple mechanical control. The efficiency of such boilers is higher, and fuel economy is correspondingly higher (on average by 10-15%). The burning time of one stack of firewood is on average 10-12 hours, but in some models it can reach 20-24 hours. Coal burns out on average in 24-40 hours in standard popular models (Stropuva S15U, Heiztechnik Q Alfa 15, TIS PRO 11), but there are models with a burning duration of up to 7 days (Stropuva S20U, WEEK KO-60). Therefore, it is advisable to heat them with coal. Prices for this category of TT boilers start from 55-60 thousand rubles.

Pyrolysis solid fuel boilers, unlike the previous ones, are more suitable if you plan to use firewood as fuel. And the efficiency of this technology is the highest today, saving on average from 20 to 25%. When choosing this option, you can get a practically autonomous heating system, but most often it is volatile, with automated electronic control, and remote control via a mobile application is possible. On average, the cost of pyrolysis models is higher than top-down long-burning models, but prices still start at 60 thousand rubles for mechanical options (Burzhuy-K Modern-12, Trayan TB-10-2KT).

Poll: what budget do you have for the purchase of a solid fuel boiler?

Heat exchanger material

Cast iron sectional heat exchanger using the example of Viadrus U22.

The primary heat exchanger is the main element of the boiler, which is the walls of the combustion chamber. A coolant (usually water) circulates in it, accumulating heat from the fuel burned inside the combustion chamber. The cost of the boiler, its practicality, service life and acceptable types of fuel depend on the material of the heat exchanger. Two versions are possible:

- Steel heat exchanger . The most common due to its low cost and lightness, invulnerability to temperature changes, and practicality. Typically used in boilers of low and medium price segments. Often, steel heat exchangers are not designed for burning coal, and never anthracite, since they burn out or melt at combustion temperatures of 800-1000°C. But the most significant disadvantage of steel heat exchangers is their vulnerability to corrosion (even despite special anti-corrosion coatings); under its influence, the service life of steel structures averages 12-18 years. We recommend choosing models with a heat exchanger wall thickness of at least 4 mm, ideally 5 mm.

- Cast iron heat exchanger . Much heavier and more expensive, but corrosion resistant and durable. The service life of cast iron heat exchangers is more than 30 years, and they can withstand temperatures above 1000°C, which means that they can fire any type of coal, incl. anthracite. The only disadvantages that can be noted are the difficulty of transportation, increased requirements for flooring (cast iron boilers can weigh from 100 to 600 or more kg), as well as fragility and vulnerability to sudden temperature changes. If the difference in the temperature of the supply and return lines is over 50-55°C, standard gray cast iron can crack, so when installing in the heating system of a large private house, where such a difference is possible, it is necessary to take care of a three-way valve. Connecting the supply and the mains, he mixes the last heated water, reducing the temperature difference. The cost of cast iron models starts from 30,000 rubles, but it is better to choose just such a boiler.

Important differences between cast iron solid fuel boilers for heating a private home

Single-circuit or double-circuit

Construction of a double-circuit solid fuel boiler using the example of the Wirbel ECO SKB model with a built-in storage tank.

Single-circuit boilers are designed exclusively for heating the heating circuit. Double-circuit ones are equipped with an additional DHW circuit, which is not directly connected to the heating circuit, so sanitary water in it does not mix with technical water in the heating circuit. The cost of dual-circuit models is only 30-50% higher, so this is the cheapest way to organize hot water in the house. However, in the case of solid fuel boilers, unlike gas boilers, we do not recommend double-circuit models: it is better to organize the system using a heat accumulator (buffer tank).

Firstly, the conversion of thermal energy in classic solid fuel boilers is a cyclical process: first the fuel flares up, then a peak heat release occurs and the combustion dies out. With such work, it is extremely difficult to ensure a stable temperature of sanitary hot water using only the functionality of the boiler. Secondly, when organizing a heated floor circuit, you will need a heat accumulator in any case, otherwise the floors will overheat, and the system will be unsafe, with a high probability of an accident. And thirdly, it is simply impossible to find double-circuit models of long-burning solid fuel boilers, only among the classic ones.

A good buffer tank is equipped with both a second DHW circuit and outlets for underfloor heating circuits. The use of a double-circuit solid fuel boiler for hot water supply at home is justified only if you are living in it temporarily.

Efficiency

The efficiency factor shows the efficiency of burning solid fuel; accordingly, the higher it is, the less fuel will need to be burned to accumulate the required amount of heat. Of course, to ensure the efficiency declared by the manufacturer, it is necessary to organize a chimney in accordance with the norms and requirements, configure the boiler, control the quality of the fuel, and also timely service the boiler. Nevertheless, it is quite possible to achieve the specified parameters even with fuel that is not the most ideal in terms of calorific value.

In general, you should pay attention to the efficiency indicator after deciding on the parameters described earlier when choosing between specific models. We recommend starting from values of 75% and above for classic solid fuel boilers and 82-85% and more for long-burning boilers. Indicators below these limits in 2020 indicate technical imperfections in the design and a large waste of thermal energy.

Automation

Inexpensive TT boilers are not equipped with automation, but are controlled exclusively mechanically. Models in the highest price segment are equipped with systems that can increase the efficiency of fuel combustion, significantly reduce cycling, increase the burning time of one load, and provide automatic ignition. You can install the automation kit yourself, the price is 7-11 thousand rubles, so if you understand all the processes of the boiler and have certain skills, you can save a lot. The set consists of two separate elements:

- boost fan – mounted on the front door of the boiler, on the ash pan or on the ash pan. The fan provides the combustion chamber with oxygen and, unlike a mechanical door, is able to regulate the air volume automatically, in real time.

- controller – a control unit that controls the fan rotation speed. The controller can also control the circulation pump, if available, a smoke exhauster, and a three-way valve. Advanced models can be connected to a room thermostat, have weather-dependent functionality, and be equipped with a GSM module.

Functions, best kits and cost of automation for solid fuel boilers

Separately from the previous ones, it is worth mentioning the automatic fuel supply system, which is mainly equipped with pellet boilers, but sometimes also with coal-fired boilers (in such systems, the main thing is to maintain the proper coal fraction). Such a system is not cheap, but it allows you to achieve maximum autonomy; the regularity of reloading is reduced to once every 5-8 days, and in some cases up to two weeks.

Are pellet boilers with automatic fuel supply worth the money?

Minimum required power

Despite its importance, we left this criterion to the very last, since modern models of solid fuel boilers have many power variations. This allows you to first decide on the model and then select the appropriate power.

For all solid fuel boilers, generalized calculations of the minimum required thermal power are sufficient. Therefore, in practice, the standard is used: to heat a standard weakly or moderately insulated house with a masonry of 2 bricks and a ceiling height of 2.7-3 m, 1 kW of power is sufficient for every 10 m2 of heated area. We also recommend setting aside + 20-25% reserve for unexpected frosts and house features. If you plan to install a heat accumulator or a dual-circuit model, an additional 20-30% reserve must be included in the calculation.

For example, for the above-described house in the climatic zone of the Moscow region with an area of 150 m2, the minimum required boiler power is (150/10) * 1.2 = 18 kW, if it is planned to connect a heat accumulator - 18 * 1.25 = 22.5 kW. It is always necessary to round up the indicator.

Review of popular manufacturers

Different boiler models differ from each other in power, suitable fuel, possible efficiency, combustion chamber volume and other characteristics. It is also worth considering that the heating time most often depends on the type of material used for kindling (peat briquettes, coal, firewood or sawdust). And the power of the device affects the area of the room that it can heat.

Before purchasing, it is recommended that you read the review of popular models from well-known manufacturers of heating systems with hobs.

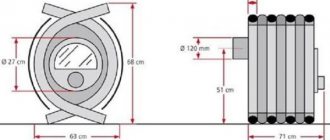

Wirbel Temy

The Austrian company Wirbel Temy offers a wide range of such units. Some of them have built-in heating elements and an oven, drawers for storing dishes and even a lever for switching operating modes.

All models are equipped with fireboxes made of high-quality steel 5 mm thick, and the hob is made of 6 mm sheets.

Such stove-boilers are designed both for heating and for cooking hot dishes. Thanks to the convection heat transfer method, the devices quickly and efficiently fill houses with an area of up to 280 square meters with heat.

It is worth noting that the units from this manufacturer have an elegant and decorative design, and are also very easy to use. Due to the special design features, their glass doors always remain clean, which makes cleaning the boiler easier. If the heating function is not needed, you can turn it off and use the boiler only for cooking.

Models marked L have additional heating elements, that is, such devices can operate not only on solid fuel, but also on electricity.

| Model | power, kWt | Price in online stores, ₽ |

| Wirbel TEMY | 10-25 | from 69 000 |

| Wirbel TEMY L | 10-25 | from 75 000 |

| Wirbel TEMY Plus | 12-30 | from 85 000 |

| Wirbel TEMY Plus L | 12-30 | from 100,000 |

| Wirbel TEMY Plus P | 25 | from 120,000 |

Karakan

A company from Russia produces boilers for residential premises; their models can provide heat to homes with an area of up to 200 m2. Brown and black coal, wood, and peat are used as fuel.

| Model | power, kWt | Heated area, m2 | Price in online stores, ₽ |

| 8TPE-3 | 8 | 40-80 | from 13 870 |

| 9TEG-3 | 9 | 90 | from 16 750 |

| 10TPEV | 10 | 100 | from 19 800 |

| 11TPE | 11 | 110 | from 17 000 |

| 12TEGV | 12 | 120 | from 18 080 |

| 20TEGV | 20 | 200 | from 21 604 |

Siberia

Sibir offers consumers five models of boilers with a built-in stove. They are made from steel, but some parts are made from cast iron. Such stoves are perfect for placement in private and country houses. The goal of creating this line was to obtain comfortable, economical and versatile heating systems.

| Model | power, kWt | Heated area, m2 | Price in online stores, ₽ |

| KVO 10 TPE | 10 | 100 | from 15 600 |

| KVO 12 TPE | 12 | 120 | from 18 043 |

| KVO 15 TPE | 15 | 150 | from 16 500 |

| KVO 20 TPE | 20 | 200 | from 18 499 |

| KVO 25 TPE | 25 | 250 | from 20 135 |

User reviews

Which solid fuel boiler you choose depends only on you. However, initially it should be noted that the advantages and disadvantages of purchasing one type or another depend on the conditions: room area, level of thermal insulation, absence or presence of central communication systems.

User reviews confirm their wide range from a large number of manufacturers. Standard boilers with a tiled surface have the ability to cook food and, moreover, operate on different solid fuels: peat, wood, coal... Having purchased this type of boiler, you will no longer depend on either electricity or gas.

Prices depend on the manufacturer. On the Russian market, the price varies from 20 to 60 thousand rubles. There are premium boilers.

Users have already seen their high quality and reasonable price.

What fuel can be used

Most solid fuel boilers operate on the following types of fuel:

- firewood;

- coke;

- granules;

- brown coal;

- anthracite;

- peat.

In rare cases, they can even be drowned with dry manure. It is worth remembering that the efficiency of the heating system depends on the choice of raw materials for kindling. Most often, manufacturers indicate in the operating instructions which fuel a certain model of device operates best on. Read our article for a heating diagram for a two-story house with forced circulation.

Fuel prices for brown coal boilers

brown coal fuel for boilers