Pelletron is a leading domestic brand involved in the development and production of heat-generating equipment, taking into account modern demands for the production of quality products, characterized by good functionality and ergonomics. Engineers design equipment in accordance with the trends of modern world standards, using innovative technologies.

Heating with pellets has long been used in the countries of the European Union and is quickly gaining popularity in our country, especially in regions where there is no main gas supply. Homeowners are increasingly paying attention to a pellet boiler for heating a private home. Today, such boiler equipment is presented as devices operating on specially prepared fuel granules - pellets.

For the combustion process of pellets, a special pellet burner is accordingly required. We invite you to read and study the operating instructions for the Pelletron pellet boiler. Its design is based on a Pelletron pellet burner - a well-deserved pride of the enterprise. In conclusion, we will read some reviews from happy owners who will share with us their experience and operating features of Pelletron equipment.

At the end of the 10s of this century, NPP "Pelletron" presented the pellet burner "Pelletron 15" of its own design. An acceptable price, reliable design and warranty did their job and as a result, the Pelletron pellet burner gained great popularity among owners of solid fuel boilers. Soon, the company launched the production of solid fuel pellet boilers, which used the already proven pelletron burner.

Pellet burner Pelletron

Vast experience in production experiments helped to develop a burner for burning fuel pellets in autonomous mode with a high degree of efficiency. The company successfully offers three main burners on the market:

PELLETRON-MA - If you are tired of servicing your boiler every two hours, then pay attention to this miracle. Guaranteed operation in autonomous mode, with a supply of fuel pellets of 34 kg. up to two days continuously. The produced power of 10-15 kW allows you to heat a house from 80 to 150 sq.m.

PELLETRON-M - the manufacturer guarantees the absence of soot formation; the combustion process is accompanied by minimal release of resin and no smoke. Capacity 5, 10 and 15 kW. makes it possible to heat a house up to 150 sq.m. The volume of the pellet hopper is 56 liters. The Pelletron 15 burner is very popular; according to reviews, its power is enough to equip a suitable boiler and install a heating system.

PELLETRON-MB is a convenient tool that allows you to flood the bathhouse in the evening, and at dawn, in the frost, into a hot bathhouse! The company assures that 10 hours of continuous operation and 15 kW of power is enough to warm up 15 cubic meters. m. Can be used in conjunction with brick heaters! The fuel used is white granules

The power is regulated using a mechanical regulator; the combustion intensity changes over a wide range. By changing the burner performance it is possible to set the optimal - comfortable temperature regime in the heating system.

A distinctive feature that the pelletron pellet burner can boast of is its economical parameters during operation. A pelletron combustion burner is capable of producing 1 kW/h of energy, spending no more than 200 grams of resources. The device requires regular cleaning, depending on the ash content of the fuel pellets; the intervals between preventive maintenance can range from 1 to 3 days. The package includes a 56-liter hopper that can hold up to 34 kg. pellet

The easiest way is to install the burner yourself, without resorting to after-sales services, so you will save on paying for the work of specialists. The burner is designed in such a way that it fits most boiler models. For a video review of installing a burner on a Kupper wood-burning heating boiler with a water circuit, see the instructions on the YouTube channel:

What are pellets?

Pellets are compressed cylindrical granules that are made from wood waste, bark, and sawdust. To ensure that the wood does not crumble, the composition also includes a special binding element, lignin. The size of the pellets is length from 6 to 70 mm, and diameter 5-9 mm.

The room where they are stored must have low humidity, as they can swell. They are often made from pine needles, but deciduous trees are considered more efficient. Their use is the most environmentally friendly and safe; when burned, they do not harm the environment, since they are recyclable materials.

However, if you look from the point of view of economy, heating a house with gas is almost 3 times cheaper, but to install gas equipment you will need to collect a very large number of documents and permits, and the cost of this is quite high. By burning 10 kg of pellets you get 50 kW per hour, however, this value may vary depending on the device used.

You can make a pellet boiler yourself. Instructions are in this article.

Pelletron boiler

The company presents three models with power modifications, from household to industrial units. We will look in more detail at a domestic boiler, since it is this type that is most often in demand in the heating system of a private home.

VECTOR 25/36/50 is a vector pelletron boiler, as the manufacturer’s slogan says: turn it on and forget it. The boiler turned out to be economical. Requires little maintenance time. Works in automatic mode. The vector pellet boiler serves as a heating device with the possibility of supplying hot water (DHW). The boiler performance varies within three modifications and reaches a maximum of 50 kW. Able to cope with heating in a room up to 500 sq.m.

V-100 / V-200 line of powerful industrial units. The pellet boiler Pelletron – V can be operated automatically, according to programmed parameters. Enlarged bunker receiver with a size of 5 cubic meters. Used in heating industrial facilities with the possibility of installing a hot water supply system. The line is represented by two models, with a power from 100 to 200 kW. The heated area reaches 4000 sq.m.

COMPACT 20/40 - Pelletron compact, the most affordable model, operating in semi-automatic operating conditions. The Pelletron Compact pellet boiler is used only for heating. Available in two power options: 20-40 kW. Heats an area of 100-400 sq.m. Parameter adjustment and control is carried out manually.

general description

Pellets are small granules of plant origin. They consist of ground, compressed remains of wood, bark, corn, straw, sunflower, and other plants. The average length of one is about 4 cm. This type of heating material is environmentally friendly and hypoallergenic.

Pellets burn more efficiently, more productively, and safer, since they cannot self-ignite.

On a note! If we compare different fuels in terms of efficiency, then for wood it is about 37%, for natural gas - 85%, for pellets - over 90%.

To burn such material you need a special burner. Pelletron pellet boilers are based on a special model. This is a unique development of the enterprise, which has a long service life and high reliability. It is made of stainless, heat-resistant materials.

Pelletron pellet boilers are available in different capacities and are capable of heating rooms of different sizes. Their hoppers are located on the side, which ensures simple, easy loading of fuel material.

Boiler hopper

Pellet boiler Pelletron Vector

The most popular because it is designed to work from burning pellets. The boiler was not converted from a solid fuel boiler by installing a pellet burner, but was developed from scratch.

Thanks to technical solutions, the time interval for boiler operation from one load of granular fuel was increased. In addition, it was possible to reduce pellet consumption and reduce maintenance time, which ultimately added positive reviews to the pelletron boiler collection.

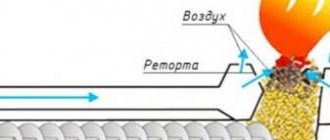

The Pelletron Vector torch burner is designed in such a way that it is possible to use granules of “gray” pellets containing bark. The burner is equipped with a movable grate; moving in a reciprocating direction, it loosens the sintered ash and it freely falls into the ash receiving tank.

Pelletron deserves another good review in its collection, since the use of gray pellets significantly reduces operating costs. In addition, it is easier to find a pellet seller with low prices.

Technical characteristics of boilers Vector

Boiler structure Vector

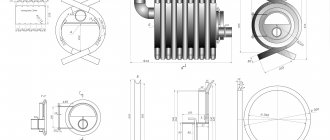

The vector solid fuel unit is made on the basis of a proprietary burner. It includes the following main elements: a bunker capacity for fuel reserve, a combustion chamber equipped with a pellet burner, a heat exchanger made of metal pipes with the possibility of three-way movement of the coolant, an air blower and an ignition heating element.

- Removal of combustion products,

- upper rotating chamber of the heat exchanger,

- three-way shell-and-tube heat exchanger,

- torch firebox,

- lower rotating chamber of the heat exchanger,

- ash collection box,

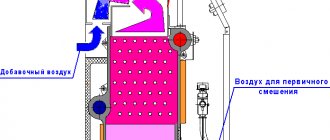

- combustion air supply,

- fuel resource.

Structural features

- The combustion chamber has a horizontal design, made for flare combustion. At the end of the firebox there is a hinged door with a built-in Pelletron M burner. The solution to increase the heat removal area is to place the combustion chamber inside the water jacket, which surrounds it in a circle.

- At the rear of the pellet boiler there is a vertical heat exchanger made of steel pipes. Hot streams of flue gases passing through it participate in heat exchange with maximum efficiency and share their heat energy.

- The upper section of the heat exchanger is equipped with a smoke exhaust pipe and a smoke suction motor. The turbofan creates forced draft and removes combustion products to the street, which decompose during the process of photosynthesis.

- The reserve of pellets is provided by the bunker, with their subsequent supply to the combustion burner. Granules from the hopper enter the burner, where they are mixed with air and burned, releasing heat. The volume of the bulk bunker is determined according to the boiler power characteristics. The bunker should be kept clean, avoiding clogging with foreign matter.

The Vector pellet boiler is declared as a device with continuous operation for up to 4 days according to the set mode. During operation, the required coolant temperature is maintained. Regulation of heat output from heating devices (radiators, heated floor systems, etc.) occurs by changing the flow rate or adding coolant.

The power characteristics of the device are adjusted automatically by the control unit. The Vector pellet boiler is equipped with multifunctional sensors that provide protective blocking of equipment operation in the event of:

- excessive heating of the feeder;

- exceeding the specified temperature conditions for the coolant;

The unit is equipped with the necessary complex for organizing a fire extinguishing system. The equipment is connected to the electrical network according to the wiring diagram attached to the operating instructions. A mandatory condition for operation is the use of a circuit breaker and a residual current device. Grounding of the unit is also a mandatory requirement.

Parameter table

The Pelletron company presents 4 models of heating boilers. Their characteristics are discussed in the comparative table.

They are different in size and power. Capable of heating different types of rooms. The reliable design of each works smoothly and lasts. Each boiler has a proprietary burner that heats continuously and economically.

Pelletron boiler - pros and cons

In heating equipment stores, pellet boilers are increasingly being offered for sale, from the most popular ones, such as the Korean Kiturami pellet boiler, which is a reliable but expensive device, to the simplest models. The Pelletron boiler, operating on fuel pellets, is considered a strong mid-range boiler with a simple design equipped with a water circuit.

The Pelletron unit is easy to use and convenient to operate; the price attracts with its competitiveness in comparison with imported analogues.

In addition to the traditional advantages of using automatic pellet boilers, known to consumers as: long-term autonomous operation in the absence of main gas or automatic control with high efficiency values, we suggest paying attention to the positive aspects characteristic of the Pelletron Vector device:

Advantages

Convenient loading of the hopper.

As a rule, third-party models have the loading hopper located on top. Perhaps this approach saves space, but greatly complicates the loading process. A simple solution by engineers came in handy in the design of the Pelletron boiler; the bunker was located on the side, with a height of 1 meter above ground level, which made laying the reserve a simple procedure. It is not necessary to wait until the bunker is completely empty, since fuel pellets can be filled in at any time while the boiler is operating.

Easy maintenance.

Routine maintenance work on the Pelletron boiler involves periodic cleaning. Due to the fact that all surfaces are accessible, you do not have to spend a lot of time and effort on cleaning. Cleaning of the supply channel is carried out as it becomes dirty.

Untimely cleaning impairs the stability of the fuel supply to the burner, which can lead to its complete stop. When the device is operating at low power, the supply channel will have to be cleaned a little more often. The work will not take more than 30 minutes per week.

Pelletron pellet boiler - reasonable price.

It is no secret that purchasing a pellet boiler will require significant initial financial investments. The management of the Pelletron company has done everything possible so that the consumer can buy an effective device at the best price. The price of Pelletron is two or more times less than equipment manufactured in the Eurozone.

Application of a short chimney

Thanks to the built-in smoke exhauster, the boiler can operate with a short chimney flue. Engineers designed the Pelletron with equipment to create artificial thrust. The product is equipped with a motor with a special exhaust fan. This solution eliminates the need to build a large and bulky chimney with natural draft. A sufficient condition will be the construction of an exhaust pipe leading through the wall of the boiler room.

Flaws

Noting the disadvantages that the Pelletron boiler has, we can limit ourselves to standard reviews about the high cost of equipment, dependence on the electrical network, and the use of pellets for heating, without the possibility of switching to another type of fuel.

Reviews from customers and owners

Equipment owners share their impressions and features of using Pelletron pellet units with us:

Grigory Vasilievich, Yaroslavl

I bought a Pelletron boiler last year and it worked for the first winter. The farm is not large, but the house is two-story with a total heating area of 135 m². The first floor, at the request of my wife, was heated using underfloor heating. The second floor is smaller; radiators were installed there.

Additionally, we bought an indirect heating boiler, which also heats the water using a common system. I’ll tell you right away that I only use pellets during the day. In the evening I have a night tariff on the meter, so I use electric convectors. The house warms up well during the day, and the convectors are quite enough to maintain a normal temperature.

As soon as the boiler was started, it started smoking a little at first. After experimenting with the draft and installation height of the grate, the problem went away in one of the options. 3.5 tons of pellets were enough for the season. I took expensive white birch granules. In the first season, I decided to use high-quality ones, because I was afraid that the gray ones would cake, and I didn’t want to get the new boiler dirty.

Dmitry Evgenievich, Samara

I thought for a long time about what kind of system to build at the dacha. I weighed everything for a long time and settled on the Pelletron boiler. I was persuaded that there is a pellet production nearby, and from time to time I know someone can buy it cheaper, but I can buy substandard ones at half the price. I don’t come to the dacha often in winter; I heat the boiler only during the winter holidays and several more times during the season, but no more than 20-30 days during the winter. It's still early in the spring and a little in the fall.

Upon arrival, the cold dacha warms up very quickly; I have a 100mm diameter pipe around the house - instead of radiators. The operation is very simple - there are no complex and finicky electronics. I clean the boiler in 15-20 minutes and it is ready for use again.

I encountered the problem of pellets hanging in the bunker, but quickly realized that this directly depends on the quality of the pellets. I had to dry the pellet granules, after drying the problem went away, but now I only buy dried pellets with good density.

Sergey Ivanovich, Syktyvkar

I already had a Kupper heating device in my system. I was interested in the possibility of long burning. In short, I read a lot of reviews and installed the Pelletron 15MA pellet burner on my device, the power was 15 kW, my house is 120 square meters, it’s enough with a reserve.

I did the entire installation myself, there is a detailed description of the steps in the operating instructions (instructions on our resource here - editor's help), there were no problems. If you order, do not forget to order from the manufacturer a door with a hole that is attached to the bottom. By the way, there is even a video of the installation of the burner on YouTube.

Then install the entire set one by one: burner, hopper. You buy pellets, fall asleep, light them and that’s it! Then you just add granules and adjust the power. I highly recommend it. Next year I’m thinking of increasing the sides of the pellet container so that it lasts longer, I’ll post later how it turned out.

Ilya Lukoyanov,

I kindly made a video review on how to correctly remove the grate and clean the Vector 50 and Vector V36 pellet boilers. The removal and installation of the grate block was filmed in detail on the video, which we bring to your attention:

Let's sum it up

With the growing popularity of equipment operating on pellets, more and more families are installing pellet boilers in their households. Perhaps very soon the moment will come when they will become the main alternative to heating with wood or coal.

Moreover, the development of the region is increasingly involving business participants in the development and production of heating pellets. Which is good news, since as a result of healthy competition, the price of pellets is falling.

In turn, the market is increasingly offering models of devices that run on fuel pellets. A good example to follow is the Pelletron boiler, which stands out noticeably for its excellent characteristics. Pelletron, due to the lack of complex automation, remains a boiler whose price is affordable for most domestic consumers.