The Korea Star gas boiler is a product of the South Korean company of the same name, not inferior in quality to the best European analogues. At the same time, Korean boilers are 20–30% cheaper than their competitors. KoreaStar is not the only gas equipment manufacturer in South Korea.

In Russia, people willingly buy heaters from various South Korean brands - Daewoo, Navien, Olympia, etc. They are united by a high level of production technology, affordable cost and adaptability to difficult Russian conditions. Coreastar is no exception - domestic consumers have managed to evaluate the endurance and reliability of the company’s boilers.

About company

KoreaStar is an enterprise founded in 2003. It has been on the Russian market since 2004. The company produces a variety of household and industrial equipment. One of the areas of activity is the production of gas heaters, which are sold all over the world. The brand supplies several dozen models of different designs and power to Russia. During assembly, Korean and European components are used that comply with ISO 900 standards. Korean Star works closely with the German company Wilo. The latter supplies circulation pumps to its eastern partner.

Design Features

- 10–20 kW devices are equipped with a 24 kW copper heat exchanger, so when the DHW circuit is turned on, they are not afraid of extreme loads. Their water productivity is 13.6 l/min.

- Thanks to double protection of the heat exchanger, it does not overheat and its service life is extended.

- The combustion chamber is available in two versions - closed (PREMIUM E) and open (PREMIUM A).

- Economical fuel consumption.

- Equipped with LCD screen. Self-diagnosis.

- Modulated fire intensity.

- Equipped with a WILO pump (German production), an anti-blocking system.

- Frost protection system.

- Connecting a remote control, room thermostat.

Advantages of Korean equipment

- Does not respond to pressure changes in the gas line.

- High efficiency value, efficient fuel combustion.

- Wide range of models, there are wall and floor models, with one and two circuits.

- Stylish design. Compactness.

- Equipped with built-in fuses that guarantee the safety of the equipment in case of emergency situations.

- Convertible to liquefied gas, the kit includes jets.

- They can provide the house with hot water.

- Possibility to select the operating mode. Setting the temperature.

Selection rules

When choosing a boiler, you first need to calculate how much power is required to service your home. The roughest method is based on area: it is assumed that for every 10 square meters, 1 kilowatt of energy is needed. To achieve greater accuracy of calculations, it is necessary to take into account the climatic characteristics of the region where the home is located, the material of the walls and the influence of various sources of heat loss. The manufacturer indicates what room dimensions a particular model with a certain power value is designed to work with.

Products equipped with a bithermic heat exchanger heat the liquid faster, but do not last as long as options with two insulated coils. Heating a living space of 300 m2 requires 3 cubic meters of gas per hour. With smaller premises, consumption will be lower. Using the economy mode cuts your expenses by almost half.

Features of operation

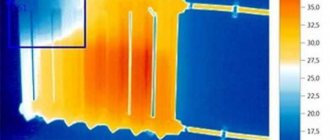

KoreaStar boilers, being productive and reliable, have advantages and disadvantages characteristic of any equipment with a closed firebox:

- Noisy. The reason is the operation of the fans. With their help, air is pumped and removed from the coaxial chimney. A distinctive feature of all forced-air burners is noisy operation. It is advisable to install such heaters away from living rooms.

- The water in the hot water supply is heated separately from the coolant. A three-way solenoid valve increases the heating speed and ensures a uniform supply of water at any pressure in the water pipes.

- When the coolant cools down to +5 °C, the boiler automatically starts, preventing defrosting of the heating system.

- Energy dependence. The instructions for use of KoreaStar heaters say that they are capable of operating under voltage surges of up to 15% of the nominal value. But in practice there are problems, the controller board fails. Installing an uninterruptible power supply will help prevent breakdowns.

- Before connecting the device, you need to obtain permission and order design documentation from the gas service.

Basic error codes

Error a01 – there is no signal about the presence of a flame. Gas does not flow or the gas valve or ionization electrode ignition is faulty. The control board may not be working correctly.

It is necessary to check all shut-off valves and, if necessary, bleed air from the water supply. Check the gas pressure on the valve - it should be 20 mbar (2 kPa), as well as the gas valve itself (replace if necessary).

Check the electrode for contamination, as well as the gap between it and the burner. It should be 3 mm ± 0.5 mm.

Error a02 - the signal about the presence of a flame is false. The control board or ignition electrode is faulty. Check for mechanical damage on the electrode itself; it is possible that it is touching the burner. Also set the required gap between the burner and ignition/ionization - 3.5 ± 0.5 mm. Replace the control board if it fails.

Corestar boiler ignition electrode

Error a03 - the boiler is overheating. The bimetallic overheat sensor (or it is also called an emergency thermostat) blocks the operation - the threshold temperature is about 90 degrees. Air has entered the heating system and/or there is insufficient water circulation in the heating system.

It is necessary to cool the boiler and restart it. Replace the sensor if necessary. Remove air from the circuit. Check the pump - open all shut-off valves, check the pump blades for contamination and the supply of voltage to its contacts. Replace the pump if necessary. If a03 appears again, the control board should be replaced.

Error a08 - the exhaust air overheating sensor is faulty. The temperature limiter gives an erroneous value. Check it for open or short circuit and replace if necessary.

Error f05 - a failure has occurred in the smoke removal system. The fan or air relay is not working correctly or is faulty. The chimney is clogged.

Boiler fan Corestar

Check the correct connection of the connectors to the air relay contacts and make sure that the air diaphragm does not stick. Replace the relay if necessary.

Error f11 – the NTC extract air temperature sensor is faulty. Open circuit or short circuit of the device. Check the resistance of the semiconductor - it should be 10 kOhm. There may be no signal between the control board and the temperature sensor. Disconnect the sensor and then reconnect it. Replace if it is faulty.

Error f37 – NTC DHW temperature sensor. Open circuit or short circuit of the corresponding device. With such an error, the burner will not be able to light up only in DHW mode. The boiler itself will be able to continue its work. Check the resistance of the sensor and the quality of the connectors. Replace parts if necessary.

The same code indicates low pressure in the heating system. The exhaust pressure sensor is faulty or the circuit pressure has dropped below 0.8 bar. Check the sensor, replace if necessary, and also find leaks. Fix the problem and replenish with water.

Error f41 - heat exchanger is overheated. Poor circulation of the heat exchanger or air has entered. Remove air and check the pump according to the procedure described in the instructions, with the shut-off valves open. If necessary, replace the circulation pump.

Heat exchanger for Corestar boiler

Error f50 - the control board has failed. Control board faulty. Check that there is no “breakdown” on the case, grounding, and if it fails, replace the board.

Power setting

After starting the device, you need to press and hold for 5 seconds. buttons to adjust the temperature to enter the setting mode. Adjust the gas pressure by decreasing and increasing the pressure using the DHW adjustment buttons. While the setup is in progress, a number will appear on the screen. This board designation is the minimum power value in percent: 44–54. When the pressure gauge shows the required pressure value, press the RESET button, the parameters will be saved.

When setting the operating power, set the gas pressure using the buttons that regulate the heating agent temperature. The power percentage will appear on the screen: 0–99. Having set the required value, press RESET, save the parameters, exit the settings mode.

Installation

Before installing the device, you should make sure that it runs on natural gas. If you plan to use liquefied gas, you need to readjust the heater - this should be done by a specialist. A power supply with parameters of 220 V/50 Hz must be supplied to the installation site of volatile models. Deviation of parameters from the norm leads to decreased performance and reduced service life.

It is prohibited to connect other electrical appliances to the boiler power source. It is also prohibited to use extension cords and adapters when connecting. Violation of safety standards may result in a fire.

Premises requirements

The room in which gas equipment is to be installed should be equipped with fresh ventilation. Moreover, door and window openings cannot be classified as such if they do not have devices that ensure constant air flow - fans, holes in the door leaf, etc. When the heater is put into operation, it is prohibited to carry out construction work in the room that could change the ventilation design, thereby affecting the volume of incoming oxygen.

In the boiler room it is prohibited:

- Store flammable substances and materials.

- Store chemically active substances - chlorine, ammonia, acids, etc.

- Place heating devices and air conditioners near the boiler.

- Install equipment near stairs, in wall openings, near windows and emergency exits.

Model overview

KoreaStar ACE

The series is represented by 2-circuit heaters Atmo and Turbo, which differ in the design of the firebox. “Atmo” - a - turbocharged. In the first, oxygen for combustion comes from the room in which the equipment is installed, in the second, street air is pumped in. The atmospheric version is equipped with standard pipes with thermal insulation made of mineral wool, the turbocharged version is equipped with a coaxial chimney.

Atmo and Turbo have similar characteristics, the same power range - 10,000–32,000 W. Equipped with pressure gauges, manual control units, Wilo pumps, and an anti-blocking system. If necessary, you can connect a thermostat and remote control. The body color is white or silver. The heat exchanger material is copper. Equipped with bypass. Two levels of overheating protection. The cost is about 30,000 rubles.

As an example, here are the characteristics of a double-circuit device with a closed firebox (“Turbo”) Ace-24K:

- Heating capacity - 24,000 W.

- Efficiency - 91.2%.

- Area - 240 m².

- Volatile. There is automatic ignition.

- Gas consumption - 2.79 m³/h.

- Weight - 30.5 kg.

- Price - 30,000 rubles.

- Dimensions - 742x440x235 mm.

Turbo advantages:

- Work on different types of fuel.

- Anti-blocking 3-way valve.

- The special design of heat exchangers is “pipe in pipe”. Treated with anti-corrosion coating.

- Fire modulation.

The Ace Turbo 10–20 kW modifications have a secondary circuit power (DHW) of 10,000–20,000 W. And Atmo has 24,000 watts. Work guarantee - 2 years.

KoreaStar Premium

This is the most popular series. Wall mounted equipment with classic design. Equipped with two heat exchangers, a circulation pump, a closed firebox, a safety group, and an automatic bypass valve. Full adaptation to Russian conditions. Heating capacity from 16 to 40 kW. Capable of heating an area from 160 to 400 m². Protection is the same as Ace models. Controlled by an electronic unit.

There are 4 positions in the Premium line:

- Atmo - what distinguishes them from “Ace Atmo” is the LCD screen. 10,000–40,000 W.

- Turbo - equipped with a Wilo pump (white and silver).

- Turbo-K - equipped with a KoreaStar pump (white). Equipped with a powerful fan to remove combustion products. The devices were developed for apartments.

- Turbo-C - KoreaStar pump (white).

For example: an attachment with two circuits, a closed firebox, and a power of 24 kW. Heats a room up to 240 m². Characteristics and design features of Premium-24E TURBO:

- Efficiency - 91.2%.

- The copper heat exchanger is the primary one. Steel is secondary.

- DHW water heating is 35–55 °C.

- The capacity of the DHW circuit is 13.6 l/min.

- Equipped with an expansion tank and circulation pump.

- White body.

- Weight - 31.5 kg.

- Dimensions (HxWxD) - 742x440x235 mm.

Senator

The series is presented in two versions, both with floor installation and open fireboxes:

- Senator-D. Volatile.

- Senator-TP. Does not require power supply. Equipped with European automatic equipment. Heater material is cast iron. Power range - 10,000–60,000 W.

Equipped with electric ignition. If desired, connect an indirect heating boiler. Weather-compensating automatic equipment has been installed. Works in winter and summer modes. The screen displays information about current settings and error codes. The intensity of the fire is smoothly modulated. 9 powers - 25,000–60,000 W. 5 years of service guaranteed. The cost depends on the thermal power, estimated prices are 58,000–80,000 rubles.

Characteristics of Senator TP 25:

- Floor installation.

- One circuit.

- 21,000 W.

- Efficiency - 90%.

- Fuel consumption - 2.4 m³/h.

- Weighs 99 kg.

Buran

Only one model. This is a floor-standing, single-circuit, non-volatile device. Equipped with a steel heat exchanger, atmospheric burner and Italian automation. Efficiency - from 88%. Equipped with a draft stabilizer and a smoke temperature sensor. The coolant can be water that complies with GOST 21563-93. Maximum heating of the coolant is 95 °C. Can be converted to liquefied gas. The heat exchanger has a cylindrical shape and is equipped with turbulators. Power range - 7.5–100 kW. Moderate price - from 17,000 to 47,000 rubles.

If during ignition the coolant temperature is below 30°C, condensation may appear, which provokes corrosion processes. To avoid this, you need to ensure that the water temperature in the circuit does not drop to critical values.

Characteristics of Buran 35:

- Heating capacity - 35,000 W.

- Efficiency - 90%.

- Heats up to 350 m².

- Gas consumption - 3 m³/h.

- Weight - 104 kg.

- Dimensions (HxWxD) - 930x500x630 mm.

Bravo

A series of boilers equipped with an LCD display and two heat exchangers - copper for heating and steel for hot water. A range of powers - 10, 13, 16, 20, 24 kW. Hot water capacity - 13.6 l/min. Equipped with a 3-speed energy-saving circulation pump. The body is white. There is anti-blocking of the pump, protection against freezing and against water hammer. Characteristics of Bravo-10E:

- Heating capacity - 11,000 W.

- Two circuits.

- Heats up to 88 m².

- Heating/water supply temperature: 30–90°C/35–55°C.

- Efficiency - 91.2%.

- Maximum fuel consumption is 1.19 m³/h.

- Expansion tank - 6 l.

- Weighs 34.6 kg.

- Dimensions (HxWxD): 742x440x262 mm.

Design and principle of operation of Corestar boilers

Despite the name, Koreastar gas boilers have nothing in common with Korea. These are European boilers, designed specifically for Russian conditions.

Wall-mounted boilers Koreastar (Korea Star) have a classic design - a circulation pump, two heat exchangers, a closed combustion chamber, an automatic bypass valve, and safety groups. These devices can easily withstand voltage surges of 15% and have a flow capacity of about 13.6 liters per minute (DHW). They are designed to heat rooms up to 240 square meters.

Many models have copper double-circuit heat exchangers, which are made according to the “pipe-in-pipe” principle and, thanks to the anti-corrosion coating, are resistant to heat.

The models are equipped with built-in functions aimed at preventing freezing, as well as a pressurized burner, which is of a modulating type.

Anti-blocking systems for the gas valve and pump protect the combustion chamber from water hammer. Boiler productivity reaches 32 kW. Koreastar gas boilers are quite noisy. This is due to the working forced-air burner, so it is recommended to install it away from housing.

Hot water is heated independently of the heating system. Thanks to the presence of an electromagnetic three-way valve, the heating speed is significantly increased, and a uniform supply of heated water is ensured regardless of the system pressure.

Motorized 3-way valve

Reviews

Premium 24E: Raisa P., Dedovsk

I liked it for its capabilities and affordable price. Worked well, kept the temperature at the set level. But in the second year of operation, the pressure switch broke and was impossible to find. And it’s good that it wasn’t winter, otherwise we would have had to freeze.

Premium-24E Turbo: Leonid Zh., Kostroma

Works for two years. During this time, it showed an error twice - operation failure. It was fixed by rebooting. Before the start of the heating season, the hot water flow sensor broke, so they could not turn on the boiler: information about the hot water supply was constantly displayed on the screen. The repairman arrived two days later - due to workload - and replaced the spare part free of charge, under warranty. Pros: compact, hangs on the wall and doesn’t bother anyone. No need to build a chimney. Consumes little electricity. The downside is that it depends on the electrical network. It is difficult to regulate the water temperature with low pressure. There is a shortage of specialists; you have to wait a long time for a specialist.

The efforts of the manufacturer and its marketers were crowned with success - KoreaStar products have won their niche in the Russian market. Consumers are attracted by the affordable cost and reliability of Korean boilers. There are usually no problems with the operation of the equipment, but there are problems with maintenance and repair. This is due to insufficient coverage of the territory of the Russian Federation by service providers.

Gas boilers Koreastar Senator

This line includes two floor-standing models: Senator-D and Senator-TP. They differ not only in design, but also in their operating principle. In fact, these are completely different devices. Thus, Senator-TP is equipped with an open combustion chamber. This unit does not rely on electricity. The operation of the heater is controlled by automation from SIT and Honeywell. The boiler is made of Viadrus cast iron. Power from 10 to 60 kW. Can work in both sealed and gravity systems.

Electronic automation.

The Senator-D boiler is available with an open combustion chamber, but is already dependent on the electrical network. Characteristics of the Korea Star boiler from the instructions:

- electric ignition;

- possibility of connecting an indirect heating boiler;

- weather-compensated automation;

- summer/winter mode;

- pipe for the boiler pump and three-way valve;

- turbocharger pipe.

To prevent the walls of a house made of logs and timber from blowing into the cracks, jute inter-crown insulation in rolls or in the form of a cord is clogged.

How effective felt insulation is for floor insulation is written here.

The boiler display shows all information about its operation and errors. From the display you can make settings for the operation of the indirect heating boiler. Electronic smooth modulation of the flame is provided. There are nine power options from 25 to 60 kW. The cast iron boiler has a 5 year warranty. There are service centers throughout the Russian Federation, so there are no problems with servicing the equipment.