In what ways is a water-heated floor inferior and superior to other home heating systems? Are there any restrictions in application that are important to consider when choosing materials? This article addresses these and other questions. We asked Miralex specialists to tell us more about the benefits of water heated floors.

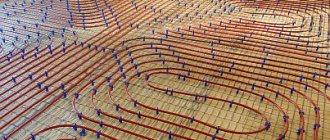

Before installing the floor covering, a water-heated floor looks like this Source pol-exp.com

Water heated floor

Water heated floors are the most common system for heating an individual home. Its important component is pipes made of polypropylene or metal-plastic. The system also includes a circulation pump, a manifold-mixer, and three-way valves (according to the number of water circuits).

Here's how this system works: the heated liquid moves along the heating circuit and transfers its heat to the screed. The cooled water goes back, flows into the boiler, heats up again - the cycle repeats. Limiters built into the system prevent the floor from heating above the set temperature.

Pros and cons of a water heated floor system in a private house

| Flaws | Advantages |

| Difficult installation. If using a concrete screed, you need to wait at least a month until it dries completely. Need a boiler room. | Compatible with different types of floor coverings. |

| The initial costs will be several times (3-5) more expensive than an electric floor. | Very effective system. The temperature of the circulating fluid is 35-50 degrees, this greatly reduces heating costs. |

| When this is the only way to heat a house, complex calculations are needed. | May be the only SO at home. |

| In case of leakage, complete dismantling of the covering and removal of the screed will be required. | Does not generate an electromagnetic field. |

| A wide variety of floor coverings are compatible with hydronic heated floors, and you can lay a carpet on it. | Does not dry out the air in the room. |

Water floors are divided according to the type of installation: usually the pipes are poured into a screed, but there are also flooring systems, wooden or polystyrene.

sly2kFORUMHOUSE Member

A 50 mm board is placed on top of the logs, recesses for laying tubes are milled into it, then foil is laid into the recesses (as waterproofing and for better heat distribution), and metal-plastic pipes are laid. All this is covered with boards (20 mm pine), the boards are coated with polyurethane varnish on both sides.

Each type of water heated floor is good in certain conditions.

Lightweight and quickly warmed up, the flooring system is considered an ideal solution for panel houses.

The polystyrene system is recommended for wooden floors.

The concrete system is chosen for capital, powerful buildings. It, as already mentioned, is more expensive, but it is an indispensable element of an energy-efficient home.

Installing a hot water system is an extremely important task: a leak will mean repairing the subfloor, covering and finishing.

Health effects

Is it enough to analyze the information on the query “water heated floor advantages and disadvantages” to make a final decision, especially if people with poor health live in the home? On the one hand, if the difficulties do not frighten you, but the advantages captivate you, it is worthwhile to critically evaluate them again.

The fact is that the very main feature and advantage of this type of heating, namely, a constant elevated floor temperature, which allows you to “keep your feet warm” all the time, can also have a downside.

Namely, it has a negative impact on the vascular system of the legs, because blood constantly rushes to the “warm” legs, putting a constant load on the veins and expanding them.

Therefore, it is recommended to install a water or electric floor in rooms with periodic and short-term presence of people there, or to limit the time they walk on the floor or stay on it.

The question of whether heated water floors are harmful to the general physical condition and well-being cannot be answered unambiguously. The air in the room is not too dry, there is no improper mixing of the layers, but in the case of heated floors, natural ventilation is difficult. In order to avoid air staleness, it is necessary to ventilate the room more often and take care of forced ventilation.

Electric heated floor

Electric heated floors are divided into:

- Cable. The heating element in them is a resistive heating cable with a conductive core protected by a sheath.

- Heating mats – cable on a mesh backing.

- Infrared film floors – film with carbon stripes.

- Infrared rods. The heating element is a carbon rod.

The most important plus

Warm floors have a significant difference from heating using conventional radiators. The most important advantage of a heated floor is that the distribution of thermal energy in the case of the operation of just such a main or additional heating system is ideal for a person. The temperature of a heated floor is evenly distributed over the entire area of the room, unlike radiator heating, where the main heat flow is concentrated near the radiators. Here the heat is radiated evenly, whether near a window, near a cozy chair, or near a work desk. That is, the human body feels warmth throughout the house, and not in its individual places. An important plus is that the higher it is, the cooler the temperature in the room becomes. This is due to the fact that the heat comes from below in a warm floor, and not at body height.

A warm floor is usually heated to 22-25°C, and at head level the air will be heated to 19-20°C. This temperature regime corresponds not only to the recommendations of scientists, but also to the well-known folk proverb that it is advisable to keep your head cool and your feet warm. A radiator heating system does the opposite - it creates a high temperature at the top, and the floor warms up worse than all other parts of the building. When heating from radiators or radiators, the temperature is distributed unevenly. The difference between it near the battery and away from it is not a few degrees, as in underfloor heating systems, but up to 8°C. All this is due to the strong upward movement of heated, lighter air under the influence of the physical phenomenon of convection. Along with the movement of air, the radiator heating system pulls dust from the floor, carpet and things upward. Warm floors do not create such convection and therefore the air in houses equipped with warm floors is cleaner.

Cable floor

Electric cable flooring is usually installed in city apartments and country houses as part of a combined heating system. It is good where minimal screed or tiles with glue are planned (that’s why it is so often installed in the kitchen or bathrooms).

This heated floor in the house is not suitable for main heating, but it is good, for example, for heating in the off-season.

SubnusFORUMHOUSE Member

A cable to the floor is not heating, but additional heating with all that it implies.

An electric floor may use resistive or self-regulating cable. Resistive can be single-core or two-core (the method of laying a heated floor depends on this; two-core is much more convenient), self-regulating - only two-core.

| Variety | Advantages | Flaws |

| Single-core resistive cable. The unheated end is connected to the temperature regulator, the main cable is placed in a “snake” under the floor, the second unheated end is pulled into the initial connection and also connected to the thermostat. | The maximum heating temperature is several times higher than that of a two-wire one. Consumes little electricity. It's inexpensive. | A resistive cable has uniform heat transfer in all areas; overheating of the floor covering under the furniture is possible and the system may fail. It is better that there is no heating cable under large furniture - this will have to be taken into account during the design. |

| Two-core resistive cable. It is enough to connect it to the thermostat at one end. This is convenient for large areas and complex house layouts. | Easy to install, you can lay a highly complex heating channel. The voltage that passes through the wire does not affect the electromagnetic pulses. | |

| Self-regulating cable (two conductive cores are in contact with a matrix made of a special polymer material). | Depending on the temperature in the room, it independently changes the heating power. Well protected from mechanical impact. It cannot overheat due to the design features. It lasts a long time and almost never needs repairs. Compatible with any surface and under any furniture. You can make contours of different sizes (and less than 1 sq.m). Easy installation of heated floors. | Expensive. Special ballasts are required. Provides a comfortable temperature only on the floor surface and is not able to quickly warm up the room. |

When installing a resistive cable floor, it is important:

- calculate cable length

- pay attention to the material (brass, nichrome or copper). They have different properties and electrical resistance indicators

- strictly observe the permissible distance between heating elements specified by the manufacturer (usually no more than 12 cm)

- perform the calculations correctly - it is impossible to remove or add part of the wire at the installation stage

When making calculations, they usually rely on the following data (per square meter of room):

- Bedroom – 100-150 W/sq.m;

- Kitchen, hallway, corridor - 150 W/sq.m;

- Bathroom - 150 W/sq.m

- Balcony -200 W/sq.m

Technical capabilities

The design of a heating system when using heated floor technology is never (even in its simplest design) limited to the working pipeline. In this case, each of the used components of the “pie” is important, from the supporting base to the finishing coating.

The technology for laying water mains can differ radically depending on its design. The basis can be either a concrete screed or dry structures (prefabricated screeds and frame structures are used with high efficiency). But it is worth noting that the second option is practically not used in practice, since it is distinguished by the complexity of its design and the lower performance characteristics of a water heated floor.

The optimal thickness of the screed is determined based on the balance of the strength of the resulting structure and the heating rate of the slab. The recommended thickness is 5 centimeters. If there is a possibility of subsidence, a metal reinforcing mesh is used, but with the installation of rigid insulation, such a need disappears.

Warm floors under tiles: heating cable mats

Heating cable mats are the best heated floor for laying under tiles, because they can be laid directly into a layer (up to 1 cm) of tile adhesive. Thin cables can also cope with this task, but their range on sale is usually limited.

kjr11FORUMHOUSE Member

Manufacturers prefer to glue thin cables onto mats and sell them at a higher price.

The mats are suitable for all finishing coatings. Compared to a simple cable floor, they are much faster and easier to install - the cable is already fixed to the polymer mesh, and you just need to roll it out on the floor. The mats use both single-core and double-core cables, and with the same power, single-core cables are about 15% cheaper. So the difference is only in price and the magnitude of the electromagnetic field - for single-core ones it is much stronger. If this factor is important, it is better to overpay and buy heating mats made from a two-core cable.

Another big plus is that if any part of this system breaks, the rest will work.

There is only one minus, but a big one - quite high cost.

Comparative assessment of both systems

It is impossible to answer unequivocally which type of heated floor is better.

We can only draw a few general conclusions:

- The cost of arrangement - components and installation of systems is approximately the same. It all depends on the type and operating characteristics of the system. In some cases, an electric floor can benefit from lower component costs.

- The cost of operation for water systems is much lower than for electric ones. Especially when the coolant is heated by a gas boiler.

- Design restrictions . Water systems are not used in the construction of multi-storey buildings.

- Dependence on power supply - electrical systems are dependent on the presence/absence of electricity, water systems will work regardless of this.

- Maintainability . It is cheaper and easier to repair electrical systems. Water-based ones, with the exception of floor options, are difficult and expensive to repair.

In general, both types of underfloor heating have proven themselves well. They warm up rooms evenly and quickly enough, are reliable, and with proper use can last for decades.

When calculating the costs of installing a particular system, you need to remember that before installing a water floor on the first floor of an apartment building, you will need to obtain permission. This means additional costs for collecting documents.

The choice of the type of heating system is also influenced by the type of flooring; more details can be found in the articles:

- Which heated floor to choose for laminate: a comparative analysis of the best options

- Which warm floor is better for tiles: pros and cons of various solutions + review of the best manufacturers

Infrared carbon floors

Infrared floors consist of heating elements filled with a carbon mixture and fixed to a polypropylene base. When exposed to current, carbon emits heat waves with a length of 8–14 microns; the waves pass through the floor covering and warm up the objects in the room (the air only slightly). A room heated by an infrared carbon floor is always very comfortable - there is no dry air, which is why we suffer so much in winter.

RavaFORUMHOUSE Member

It heats up objects: tables, stairs, walls, that’s the whole point. You open the windows wide, ventilate, and when you close everything, it’s warm again. Because not only the air is warm, but everything around it.

Infrared floors are not afraid of frost: you can come to a cold country house in winter for the weekend after a week of hellish minuses, turn on the system and it will work normally, and a comfortable temperature will be established very quickly (the system enters operating mode in 5-7 minutes, but it also cools down such a floor immediately).

Film and rod floors have their own characteristics.

| Film floor | Rod floor |

| Installed without wet processes, on a dry, flat surface under the finishing coat. Installation is quick, with the ability to dismantle the system and use it again. | Laying is carried out in a screed or a layer of tile adhesive (2 cm) with mandatory thermal insulation of the rough base. Foil materials are not allowed for the coating substrate. |

| It is not recommended under carpet, carpet tiles, linoleum on felt - these coatings reduce the heating efficiency several times. Parquet and solid boards are possible if the operating temperature of the system is not higher than 28 degrees. | Self-regulating system: if the floor temperature rises in the area under the furniture, the power consumption of the heating elements decreases. And vice versa. |

| It can be cut into pieces and placed arbitrarily - this allows you to heat only some local areas of the room: passages, places where children play, etc. | A core floor can be installed in any room; large furniture and equipment can be placed on top. |

| If any section breaks, the floor will work as before - you won’t even notice it. | Thanks to the parallel connection scheme, the system will operate stably even if several heating elements fail. |

Heating coatings of this type are used to heat stairs and porches in private homes, to prevent the formation of ice.

All about water systems

Before choosing one of the two popular systems, you should get acquainted with the features of each.

Operating principle and design features

A water-type heated floor is very easy to install. Under the finishing floor covering, pipes are laid in the form of a closed loop, through which the coolant is run. Depending on the type of heating system, this may be an antifreeze solution or water, etc.

Considering that the length of such a circuit is usually quite large, a circulation pump must be present.

It will provide the liquid with the necessary circulation rate. Two methods can be used to heat the coolant.

Option number 1 . Receiving hot water from a centralized system. You must understand that this can only be done by obtaining permission from the heat supply company, with the installation of additional equipment. For illegal connections, heavy fines are imposed and dismantling is carried out.

A warm water floor system is a liquid heating circuit installed under the floor covering. It is preferable to choose plastic pipes for installation

In practice, this option is used extremely rarely. In addition, it is only permissible in the first floors of multi-storey buildings due to the impressive weight of the floor with screed, for which the floors were not designed, and because of the likelihood of leaks and an overly costly, complex emergency response plan.

Option number 2 . Connecting the system to the heating boiler. There are subtleties here too. SNiPs prohibit heating floors above 30ºС, so the coolant temperature cannot be higher than 35ºС.

Standard boilers heat the liquid to higher temperatures, on average up to 65-95ºС. Therefore, additional equipment will be required to reduce the coolant temperature.

For these purposes, a so-called mixing unit is used, in which the hot liquid is mixed with the cold liquid coming from the return pipe.

An exception is condensing type boilers. These devices are capable of heating the coolant to small values, which is ideal for heated floors. In this case, installation of a mixing unit is not required.

The coolant for a water floor is most often heated by a boiler. In this case, the installation of additional equipment is required - a mixing unit. Here the heated liquid will mix with the cool “return”, otherwise the floor will overheat (+)

For comfortable operation of the water floor, a temperature regulator is provided, working in conjunction with temperature sensors. The latter are placed in a heated room at a certain height. The information received from them is analyzed by a thermostat, which in turn controls the degree of heating of the coolant.

A more convenient option is to equip each of the collector inputs with thermostatic regulators.

Nuances of system installation

A water-type floor can be arranged in several ways. Each of them is quite complex and expensive.

Option number 1 . The most common method is to use a screed. In this case, it is assumed that thermal insulation is first installed on a leveled base. This is a mandatory point; if it is ignored, some of the heat will go down, heating the basement.

Thus, the heating fee will be higher than necessary. The insulation thickness is calculated individually for each room.

Be sure to use additional insulation around the perimeter of the room. Damper tape or tape insulation is placed here. This is necessary to prevent heat loss through the walls and prevent the appearance of cracks due to thermal expansion.

Traditional technology for installing a water floor involves laying it in a screed using the so-called “wet” method. The resulting heated floor “pie” should look something like this (+)

The pipes are laid directly on the thermal insulation. There are several mounting options: on a mesh reinforcing screed, on fastening tapes, on a special substrate. Next, the solution is poured. This is concrete to which additives have been added to increase thermal conductivity.

The thickness of the screed should be such that there is at least 3 cm of compound above the pipes. Next, it takes time for the concrete to dry and gain strength. On average, this is at least 28 days. During this time, using heated floors is prohibited.

Among the disadvantages of this method of arranging the system, the most significant can be identified:

- large mass , which puts a significant load on the carriers;

- low maintainability - in case of a leak, you will have to dismantle the floor covering and break the screed;

- significant height - on average, taking into account the insulation, the water floor has a height of about 9-10 cm, which significantly reduces the height of the room.

Option number 2 . The so-called flooring system. In this case, the pipes are laid without using a screed. Special plates are used to form the structure. They can be made of polystyrene or wood.

Grooves are formed on the sheets into which it is convenient to lay pipes. Considering that the material has low thermal conductivity, the plates must be supplemented with metal elements.

A flat-type water floor is easier to install, especially if you use polymer mats for laying pipes. They must be equipped with metal elements to increase the thermal conductivity of the base

The topcoat can be applied directly to wood sheets. In the case of polystyrene, an additional solid base for finishing will be required.

This installation method is less labor-intensive and expensive. An additional plus is that the flooring system can be laid on wooden floors, since its weight is low. In general, installation of water heating is quite complicated.

Why choose a water floor

In general, heated floors are a very effective way to heat a home. The temperature distribution with such heating is very favorable for humans. The air warms up evenly, with the warmest zone being formed in the lower part of the room, and a little cooler at head level.

There are no convective currents characteristic of the use of spot heating devices that carry dust and microorganisms.

Water floors can be used as an additional or as the main source of heat. For relatively warm regions, the second option is preferable. For areas with harsh climates, the first choice is the best choice. The main thing is to pre-calculate the system, correctly determine the diameter of the pipes and the laying pitch.

In addition to high efficiency, it allows you to significantly save on heating. If two heating circuits are laid from the boiler, the heated liquid will first go to the radiators.

One of the best options for using underfloor heating is when there are both radiators and a water circuit under the floor. This is the best option for heating in cold regions

After it has cooled a little, it is served on a warm floor, where it will cool even more. After this, the coolant is sent to the boiler. As a result, the user receives maximum heat output in one heating session. The room will be heated as quickly and efficiently as possible.

In addition to undeniable advantages, a water floor also has disadvantages. The most significant is the high costs of setting up the system.

The cost of components is high, and the cost of installation, given all its complexity, is also high. However, these costs are fully recouped during its use. Water floors are effective, their efficiency is quite high. All this makes the cost of their operation minimal.

To be fair, it is worth noting that the cost of heating the coolant depends on the type of boiler used. The minimum costs will be for a gas-powered device.

If the need for repairs arises, it will be easier to work with decking systems. It will be enough to dismantle the floor covering, after which access to the pipes will appear. In this case, we can talk about relatively inexpensive and simple work.

In the case of a screed, repair will most likely be impossible. To implement it, you will have to dismantle the screed itself, which is very expensive and labor-intensive. It will be easier to install a new system.

What type of floor should I choose for my apartment?

If you decide to install it in an apartment, then water ones should be immediately rejected.