Your own home is not only a personal fortress, but also a place where it is cozy and warm. For this to always be the case, a prudent owner must provide an uninterrupted supply of heat. The easiest way to do this is if you can connect to a centralized system.

However, this is not always the case, and many do not want to connect to an expensive service. In this case, it remains to consider the types of heating systems suitable for autonomous installation, and then choose the best option. And we will try to help you in this matter - our article discusses the features of water, air and infrared heating systems, listing their main pros and cons.

We have also provided useful recommendations for choosing the best option. The presented material was provided with visual diagrams, photographs and videos with reviews of these heating systems.

How to choose the best heating system?

There are many heating systems. They all have attractive sides and significant disadvantages. It is quite difficult for an unprepared person to navigate them and make the right choice. In order not to make mistakes, you need to know exactly what points you should pay attention to.

Firstly, it is the availability of fuel and its cost. This can be considered a key point. No matter how much you like the system, if the fuel for it is difficult to obtain, is supplied to the region intermittently, or is too expensive, you should consider another option. Otherwise, heating your home will cost a pretty penny and will be ineffective.

According to statistics, most owners of private houses choose heating systems with liquid coolant. This is a practical, reliable and quite economical option

The second point is the possibility of combining heating systems. In some cases, it may be very practical to use a primary and secondary system. This gives confidence that in the event of possible interruptions in energy supplies, the house will not be left without heat.

In addition, there is an opportunity to save money, since you can use the most economical heating method at the moment.

And finally, the financial side of the issue. It is necessary to determine how much the consumer can allocate for the purchase of equipment, its proper installation and subsequent regular maintenance.

Finally, about the scope of application

To avoid problems during operation, use single-pipe heating networks in suitable conditions:

- “Leningradka” works well in one-story dachas and small houses with an area of up to 150 m². If the quadrature does not exceed 70 m², one common ring for all batteries is sufficient, otherwise the system is divided into 2 circuits or a pipeline of a larger cross-section is laid.

- In a 2-story building, you can assemble an open-type gravity single-pipe circuit or a closed version with bottom wiring - your choice. In case of power outages, it is preferable to organize gravity flow and place the circulation pump on the bypass.

- Gravity flow with an accelerating manifold, used in one-story buildings, is characterized by inertia. Radiators warm up slowly, the water cools down greatly due to the low flow rate, and the boiler operates in extreme mode. It is better not to use this circuit at all; it is outdated and will not work normally without a pump.

- Feel free to divide the Leningradka into 2-3 separate floor loops with the optimal number of batteries on each. Do not combine the radiators of all floors into a single circulation circuit - the last devices will remain cold.

- The single-pipe Leningrad system is a suitable option for installing autonomous heating for a 2-3-room apartment.

Experts who prove the indispensability of single-pipe heating systems often refer to Soviet-built multi-story buildings, saying that they have 20 radiators per riser. But they forget to mention the pressure and performance of pumps from a centralized network, which is unattainable in private homes. Do not listen to would-be specialists and use the best system options - two-pipe, collector or associated.

Features of a liquid coolant system

Heating systems with coolant in the form of liquid are perhaps the most popular in our country. This is understandable, because they are familiar and quite effective. The basis of such a system is a closed-type heating circuit with a heating device, inside of which there is a heat exchanger. Liquid passes through it and heats up to the desired temperature.

Next, the coolant goes through the pipes to the heated rooms. Here it enters the radiators, where it gradually cools, giving off heat to the surrounding air. The cooled liquid moves towards the heating device, enters the heat exchanger and the cycle repeats.

Such a system is also called water heating, but this is not entirely correct, since various compounds can be used as a coolant - for example, antifreeze.

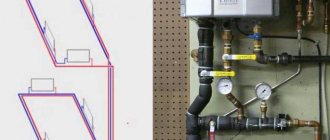

A liquid coolant system necessarily includes a pipeline through which water or antifreeze circulates, and heating devices installed in the premises

The undoubted advantage of such a system can be considered its variability. There are many different wiring schemes to ensure the most efficient heat supply for specific conditions.

There are water heating with forced and gravitational circulation. In the first case, a pump is used to supply the coolant, which makes it possible to implement circuits of varying complexity and length. The second option has many limitations, but is completely energy independent.

Heating systems with liquid coolant can be implemented in many options. This is, for example, what a two-pipe wiring diagram looks like: the coolant enters through one pipe, and out through the other

The system can be configured with one- or two-pipe wiring. The first is extremely simple and economical, but not effective enough for a large house. The second is more complex, but allows high-quality heating of buildings of any size. Depending on the type of system chosen, the set of equipment necessary for its installation also differs.

An integral element of any of them is the boiler, the type of which largely determines the operational characteristics of the system. Let's look at the most popular devices.

Option #1 - using gas equipment

A gas boiler is considered the most economical of all analogues. It works extremely simply. The gas enters the combustion chamber, where it burns, releasing heat, which is transferred to the coolant liquid through a heat exchanger.

The equipment is diverse and, accordingly, has different properties. Turbocharged equipment is considered the safest and most efficient.

It does not require the installation of a traditional chimney, does not take air from the room and has the highest efficiency.

Floor-standing varieties of gas boilers include models with maximum power. They are capable of heating 2-3-story cottages of any size

Devices with an open chamber are characterized by low efficiency and require high-quality ventilation and a traditional smoke exhaust system. At the same time, they are completely energy independent, and their cost is minimal. But it is important to install and connect the equipment correctly.

The advantages of heating with a gas boiler include the following features:

- Low fuel cost, it increases very slowly.

- High equipment efficiency.

- Possibility of full automation of the heating system.

- Cleanliness in the premises, since fuel combustion does not produce large amounts of ash and soot.

- Wide range of gas equipment.

Among the disadvantages, it is worth noting the potential danger of using gas. Great care is required when working with it. All maintenance and installation work may only be carried out by certified specialists.

In addition, special permission will be required to connect gas equipment. The cost of devices and their installation is quite high; the possibility of connecting to a gas main does not exist everywhere.

Option #2 - use of a solid fuel boiler

These are heating devices familiar to many. Their operation requires solid fuel: calibrated coal, firewood, peat, pellets, etc. The operating principle is similar to gas ones, they differ in the type of burner.

Modern modifications of long-burning are characterized by the fact that one load of fuel is enough to maintain the flame for half a day or more. The simplest models are non-volatile, require constant human control and have low efficiency.

Solid fuel boilers are not always easy to use. The simplest models require constant fuel loading, frequent cleaning and maintenance

Improved devices can be equipped with automated control and automatic fuel supply. True, the latter applies to pellet equipment. Such devices, when connected correctly, are quite effective and reliable.

The advantages of solid fuel equipment are:

- Simplicity and reliability of the design, which significantly extends its service life.

- The budget cost of the equipment and the possibility of carrying out its installation and subsequent maintenance yourself.

- There is no need to obtain special documentation for the installation of such a boiler.

- A wide selection of devices with different functionality and power.

The equipment also has significant disadvantages. First of all, this is the need to create a fuel reserve, which must be stored in proper conditions. Solid fuel boilers, especially their simplest modifications, are not very easy to use. There is a large amount of soot and soot, so very frequent cleaning of the device is required. In addition, you will also have to load fuel quite often.

Option #3 - using an electric boiler

You can also heat the coolant in the system using electric boilers. It is generally accepted that this is a very uneconomical method. However, this is not quite true. You need to understand that several types of electrical equipment with different characteristics are produced.

Heating element and electrode models

Heating element models are the simplest and most ineffective. They heat the coolant using tubular electric heaters lowered into it. The devices consume a large amount of electricity with a relatively low efficiency. At the same time, the heating elements in the liquid fail quite quickly.

Electrode boilers are more economical and reliable. In them, the coolant moves inside the boiler, where two electrodes are installed. When an electric current is applied, the liquid heats up very quickly.

Electrode boilers are compact and efficient. Thanks to their design, they are very durable and can last for decades.

Induction boiler type

The most efficient and economical type of electrical equipment is induction boilers. Thanks to the presence of two circuits, magnetic and thermal, they manage to heat the coolant liquid as quickly as possible.

The advantages of all types of heating devices include:

- Quick heating of the coolant and, accordingly, the room.

- Compact equipment.

- Simple installation, which is carried out without first obtaining permission.

- No chimney installation is required.

- Comfortable operation, possibility of equipping with automatic control.

- Complete safety and environmental friendliness.

Among the disadvantages, the rather high cost of operation is usually noted, which is a consequence of the high price of energy.

True, depending on the type of boiler and the presence or absence of automated system control, heating costs can vary significantly. Induction boilers, fully equipped with automation, are quite economical and pay for themselves quite quickly.

Combined heating boilers

On sale you can find combination heating boilers that can operate with several types of fuel. These are more expensive devices, the main advantage of which is the ability to provide the house with heat in conditions of interruptions in the supply of the main type of fuel.

A combined or multi-fuel boiler is a universal heating device, indispensable for areas where there are interruptions in the supply of different types of fuel

The common advantages of all heating systems with liquid coolant are low cost and availability, fairly high efficiency and many design options.

The disadvantages include not the most comfortable temperature distribution in the rooms. Warm air is at the top and cooler air is at the bottom.

In addition, water systems fail if the temperature in the building drops below freezing. Systems with antifreeze and saline solutions do not have this drawback. However, antifreezes are expensive and toxic, and salt solutions provoke rapid corrosion of the system.

Reviews from experts

Experts believe that installing a high-quality ventilation system in a city apartment will create a healthy atmosphere. In addition, if we take into account the fact that it is possible to install such structures yourself by turning to budget materials, then we can safely conclude that they are not only practical, but also profitable.

Experts also strongly recommend installing good quality supply ventilation in the apartment if condensation constantly accumulates on the windows of the home, and in hot weather it is very hot there.

Installing a properly selected system will help you get rid of such unpleasant problems. Date: September 25, 2022

Air heating of the building

This is another type of heating for a private home. Its main distinguishing feature is the lack of coolant. The air system is designed in such a way that air flows pass through a heat generator, where it is heated to the desired temperature.

Then, through special air ducts, which can have very different shapes and sizes, the air masses are directed to the heated rooms.

To heat a large private house, you can use air heating, while it is possible to create a comfortable microclimate in each room

According to the laws of convection, heated flows rise, cooled ones move down, where holes are mounted through which air is collected and removed to the heat generator. The cycle repeats.

Such systems can operate with forced and natural air supply. In the first case, a pump is additionally installed to force the flow inside the air ducts. In the second, air movement occurs due to temperature differences. It is clear that forced circulation systems are more efficient and powerful. We talked about arranging air heating with our own hands in the next article.

Heat generators also differ. They can run on a wide variety of fuels, which determines their performance characteristics. Gas, electric and solid fuel appliances are most in demand. Their disadvantages and advantages are close to similar water heating boilers.

The circulation of air masses inside a building can be carried out in different ways. This can be a closed cycle without adding air from outside. In this case, the indoor air quality is poor.

The best option is circulation with the addition of air masses from outside. An undeniable advantage of air heating is the absence of coolant. Thanks to this, it is possible to save the energy needed to heat it.

In addition, the installation of a complex system of pipes and radiators is not required, which undoubtedly also increases the efficiency of the system. The system does not have the risk of leaks and freezing, like its water counterpart. It is ready to work at any temperature. The living space heats up extremely quickly: literally, about half an hour passes from starting the heat generator to raising the temperature in the rooms.

A gas heat generator is one of the possible solutions for implementing an air heating project for a private house. But in practice such systems are rarely used

Another significant plus is the ability to combine air heating with ventilation and air conditioning. This opens up the widest possibilities for creating the most comfortable microclimate in the building.

The air duct system can be successfully used for air conditioning rooms in the summer. Installing additional equipment will make it possible to humidify, purify and even disinfect the air.

Air heating equipment lends itself well to automation. “Smart” control allows you to remove burdensome control over the operation of appliances from the homeowner. In addition, the system will independently select the most economical operating mode. Air heating is very easy to install and durable. Its average service life is about 25 years.

Air ducts can be installed during the construction phase of the building and hidden under the ceiling covering. Installation of such systems requires high ceilings

The advantages include the absence of pipes and radiators, which gives room for the imagination of designers who design the interior. The cost of such a system is quite affordable for most homeowners. Moreover, it pays off quite quickly, so its demand is growing.

Air heating also has disadvantages. These include a significant difference between the temperatures in the lower and upper parts of the room. On average it is 10 °C, but in rooms with high ceilings it can reach up to 20 °C. Thus, in the cold season, increased power of the heat generator will be required.

Another disadvantage is the rather noisy operation of the equipment. True, this can be mitigated by selecting special “quiet” devices. If there is no filtration system at the outlets, large amounts of dust may appear in the air.

Radiant wiring and heated floors

The radial scheme can also be used to install a “warm” floor system. With a well-designed project, taking into account all factors, you can abandon radiators, making the heated floor the main source of heating.

Heat flows will be evenly distributed throughout the room, without creating a convection effect, unlike radiators. As a result, there is no circulation of dust in the air.

Before you take on the idea of installing water-heated floors, it is important to consider the following features:

- a reflective screen with a layer of thermal insulation is laid on a concrete or wooden base;

- pipes are laid on top in a loop-like pattern;

- Before pouring concrete, a hydraulic pressure test of the system is carried out throughout the day;

- The finishing layer is screed or flooring.

The manifold of each circuit must be equipped with flow meters and thermostatic valves, which allow precise control of coolant flow and regulation of its temperature.

When routing pipes, you can use thermostatic heads and servos. These devices allow you to automate the operation of a heated floor. The system will respond to changes in room temperature, adjusting a comfortable mode for each room.

Radiant wiring for underfloor heating requires equipping the collector with several components that allow you to control, automate and manage underfloor heating to achieve maximum comfort and energy efficiency

During installation, it is extremely important to properly fix the pipes before filling everything with screed. To do this, you can use insulation with grooves, reinforcing mesh or staples

Before laying the pipeline, it is necessary to clearly define the route that the coolant will travel to heat the floor (do not allow pipes to cross). It is best to cut the pipe only after it has been completely laid and connected to the return and supply manifolds.

It is important that the pipeline is under pressure when filling. Until the concrete mixture hardens completely and three weeks have passed, coolant cannot be supplied at operating temperature

Only then we start with 25ºС and after 4 days we end with the design temperature.

Infrared heating system

This is a relatively new method of heating residential buildings. It is based on the use of infrared radiation. Scientists have found that infrared rays can have different lengths. Long-wave radiation, similar to what we receive from the Sun, is safe and even beneficial for humans. It is used in heating devices operating in the infrared range.

Infrared film heaters can be mounted on the ceiling. Then the radiation will fall down and reach the floor, which will begin to warm up

For heating premises, a special infrared film is used. A thin layer of carbon paste is applied to a non-woven base, which is activated under the influence of current and emits infrared waves. The resulting emitter is laminated on both sides with a film, which gives it strength and extends its service life.

The operating principle of infrared heating is as follows. The film is placed on the floor or on the ceiling. When the system is turned on, current is applied to the emitter and it produces infrared waves. They move and reach the first massive obstacle. This can be large furniture, household appliances, and most often the floor. Such objects are impenetrable to infrared rays; they are retained and accumulated in them.

Objects gradually heat up and release the resulting heat into the air, due to this the room warms up very quickly. In another article, we talked in more detail about installing infrared heating with our own hands.

It must be admitted that this type of heating is the most comfortable. Due to the fact that the floor is heated, the temperature distribution is as pleasant and beneficial for humans as possible. The lower part of the room is about 2-3 °C warmer than the upper part.

In addition, natural humidity and the amount of oxygen are completely preserved, and there are no convection currents that carry dust. There are no drafts either. Film heaters operate absolutely silently and are safe for humans.

If infrared heaters are placed under the floor covering, the radiation rises up, reaches the floor and heats its surface, and then the air in the room

Another advantage is fully automated system control. This allows it to operate in the most economical mode and at the same time provide the owner with complete comfort. Thanks to this, the film system has no heat losses and its efficiency is almost 100%.

The minimum service life of the equipment is 25 years, and the service life is twice as long. In this case, the system does not require maintenance.

The next advantage is compactness. The film is very thin and does not “eat up” the free space. No additional room is required for the heating unit; there are no batteries or air ducts. The film is very easy to install and connect. If necessary, dismantling and reuse is possible.

Among the disadvantages, it is worth noting that as the voltage drops, the amount of heat generated by the film decreases. In this case, the operating time of the heater increases, which leads to greater energy consumption. The film can be covered with a variety of finishing coatings, except putty, wallpaper and paint. The cost of equipment for installing infrared heating is quite high.

Basics of competent hydraulic calculation

Before starting work on the installation of heating structures, it is necessary to carry out a hydraulic calculation. For each building it will be individual, since it is carried out according to a previously completed “draft” heating scheme, including all elements of the system.

During calculations, the busiest pipeline ring is taken as the object being calculated and is divided into conditional sections. As a result, the homeowner receives:

- a value characterizing possible pressure losses in the circuit;

- optimal pipeline diameter;

- the area of batteries required for heating and, accordingly, the required number of heating devices.

There are many methods for carrying out hydraulic calculations. The most common can be considered:

- Calculations based on resistance characteristics and conductivity values. Allows you to obtain objective data on the temperature parameters of each element of the heating system and accurate water consumption.

- Calculation based on specific linear pressure losses. The result is a clear physical picture of the process, demonstrating the actual distribution of resistance in the heating circuit.

The result of the hydraulic calculation: exact parameters of the temperature regime and coolant flow in each section of the system, which are the basis for organizing the optimal heating plan for the house.

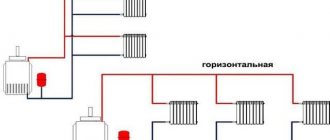

For a one-story house

The simplest single-pipe heating scheme, which has been used by developers for more than half a century, is Leningradka.

The figure shows a sketch of a modernized version of the Leningradka, with diagonal connection of radiators. The following elements are indicated in the figure (from left to right):

- Heating installation. Boilers operating on solid fuel, gas (natural or liquefied) and electricity are suitable for the implementation of this CO. Theoretically, liquid fuel boilers are also suitable, but the problem of storing fuel in a private home arises.

- A safety group, which consists of a blast valve set to a certain pressure in the system, an automatic air vent and a pressure gauge.

- Radiators connected to the system through shut-off ball valves. Needle balancing valves are installed in the jumper between the inlet and outlet of each radiator.

- A membrane expansion tank is installed on the return branch of the pipeline to compensate for the thermal expansion of the coolant.

- A circulation pump that creates forced movement of coolant through CO.

Now about what is not yet indicated in this sketch, but is a mandatory element for the reliable operation of this circuit. Only the pump was mentioned above, but its piping was not indicated, which includes three ball shut-off valves, between which a coarse filter and a pump are installed. Quite often, a pumping group with piping is connected to the CO through a jumper, thereby forming a bypass.

Often, developers ask whether a bypass is needed in a single-pipe heating system? The thing is that this CO scheme is self-sufficient and efficient. But in the event of a power outage, the circulation pump will stop and the movement of the coolant will stop. A bypass is optional, but it is better to build it to switch from forced to natural coolant circulation in the event of an emergency.

As for the pipeline: since the temperature at the boiler outlet can reach 80°C, it is recommended to use reinforced polypropylene pipes of the required diameter for the Leningradka circuit. Why reinforced? The thing is that polymer pipes are quite cheap and practical, they are easy to install and have a small weight. But, polymer pipes change their length when heated. Reinforced polymer does not suffer from such a “disease”.

Advice: despite the fact that this version of the CO has an automatic air vent, cases of airing of the circuit do occur. To solve this problem, it is recommended to use Mayevsky taps on radiators.