Are you building a new house or renovating an old one, and it comes to the heating system? Don't know what type of wiring is best to choose? A correctly designed heating scheme from a gas boiler in a two-story house is the key not only to warmth and comfort in the winter, but also to the uninterrupted operation of the equipment.

A competent heating project takes into account many factors - from climate and financial capabilities, to the need for spot adjustments and aesthetic issues. In this article we will analyze in detail all possible types of heating systems, present and compare ready-made schemes with the most successful set of parameters for different cases, and also indicate the possibilities of their modification.

Horizontal layout

The horizontal type of pipe routing, in turn, is divided into:

- beam (collector);

- consistent.

The collector circuit, which, as the most popular, will be described in more detail below, is characterized by the presence of a separate supply for each radiator.

The sequential method implies the existence of a single branch extending from the riser, running along the perimeter of all floors and containing supply and return pipes.

Advantages of horizontal wiring:

- high level of hydraulic stability;

- the ability to automatically set and maintain the temperature in each individual room;

- when using the scheme, it is allowed to install separate heat meters, either two or more;

- Wiring of this type can be placed discreetly without spoiling the appearance of the rooms with pipeline parts.

Disadvantages of wiring:

- a complicated heating startup scheme: to ensure uninterrupted operation, gently release the air from it first;

- on all radiators it is required to install taps to release air pockets;

- the cost of a project involving a collector is quite high, since more building materials need to be purchased for the arrangement.

Selection of pipe sections

Below is a table, using which you can easily cope with the selection of pipe sections. The data in the table is specifically for the above floor heating connection diagram:

| Number of TP collectors | Number of TP loops | MP/PP pipe of the section “boiler - mixing unit” | MP/PP pipe of the “mixing unit - collector” section | MP pipe loops TP |

| 2 | Up to 8 | 26/32 | 20/25 | 16 |

| 2 | Up to 16 | 26/32 | 26/32 | 16 |

| 3 | Up to 8 | 32/40 | 20/25 | 16 |

| 3 | Up to 16 | 32/40 | 26/32 | 16 |

Abbreviations in the table: TP - warm floor; MP - metal-plastic and PP - polypropylene pipe, respectively, through the fractional line in the third and fourth columns, the diameters of these pipes, depending on which one you chose for the section “boiler - mixing unit” and “mixing unit - manifold”.

So, we looked at the heating floor connection diagrams, consisting of two and three circuits. But if this is not enough, then another contour is added in the same way, and another. how much do you need.

heated floor connection diagram, heated floor on two floors

Installation of a two-pipe heating system

Vertical two-pipe system. Click on photo to enlarge.

There is horizontal and vertical two-pipe wiring. In a vertical system, all heating devices are connected to a vertical riser. Its installation is more expensive, but during operation there will be no air pockets in the system. In two-story houses, two-pipe heating is most often done according to this scheme.

The horizontal system is installed in one-story houses that have a large area and length. For a two-story house, such wiring is not recommended, since a tall building may not fully warm up.

Both types of heating circuits have excellent thermal and hydraulic stability. Only systems of the first type require balancing of vertical risers, and the second type requires balancing of horizontal loops.

Let's consider the installation of a vertical two-pipe heating system of a two-story house.

- heating boiler;

- circulation pump;

- car air vent;

- balancing valve;

- safety valve;

- thermostatic valve;

- expansion tank;

- thermomanometer;

- valves;

- supply and return collectors (in collector-type systems);

- supply pipe;

- return pipe;

- heating radiators.

Selecting heating radiators. It is better to purchase batteries with greater heat dissipation (aluminum). We install the boiler. Coolant circulation will be better if it is installed below the level of the incoming pipes. According to fire safety standards, the boiler must be located at a distance of more than half a meter from the nearest wall. It is advisable to install it in the basement. Indoor walls, floors and ceilings are made of non-combustible materials. The boiler room must be equipped for air exchange with a special ventilation duct or window with a window.

Let's move on to pipe routing. First, we install the return pipeline from the boiler. The “return” must be located below the supply. We need branches for heating devices. If a circulation pump is provided, we install a bypass with the pump in the return pipeline and install three taps in this area.

We install radiators under the windows, having previously secured special metal fasteners to the walls. The distance from the battery to the base of the floor should be 10 cm or more, and from the protruding parts of the window sill - 12 cm. After this, the pipes are connected.

After completing installation of the heating system, it is necessary to flush it. To do this, you need to disconnect the supply and return pipes. You need to put clean water into the supply pipe and fill the system. We drain the contaminated water into the sewer through a hose, which we attach to the return pipe. It is necessary to flush the heating system until clean water appears at the outlet of the system.

Before the heating season, it is necessary to check the installed heating system by filling it with hot water. The water needs to be heated to 95°C, fill the system and keep it at this temperature for an hour. When filling the system, it is necessary to get rid of air pockets and, if a leak appears at the connection points, repair it.

As a result, you get a closed heating system that always maintains a comfortable temperature and creates a cozy atmosphere in your two-story house.

Installation diagram on a concrete base

Scheme of a water heated floor on a concrete base

Installation of water heated floors with concrete screed

Installing water heating on a concrete base contains several “layers of the cake”.

Thermal insulation layer

It is laid on a cleaned base; if it has large irregularities, then a screed must be made first. It is advisable to use foam concrete, it reduces unproductive heat losses. The thickness of the thermal insulation must be more than three centimeters, the density of the thermal insulation must be at least 35 kg/m3.

It is recommended to use polystyrene foam or pressed mineral wool of increased physical strength in the design. There are special mats for water floor heating systems; they have installed clamps that make the process of laying pipes much easier. If the room is large, the thickness of the insulation increases.

Pipe laying

Fastening underfloor heating pipes

On average, per square meter of room you will need approximately five linear meters in increments of 20 cm. These figures may vary taking into account the design power of the heating system.

Practical advice. It is advisable to provide for installation in two streams in the diagram. In this case, the connection should be made in such a way that the hottest pipes of the primary circuit alternate with the cooled pipes of the second circuit. This scheme ensures uniform heating of the entire floor.

After connecting all sections, it is imperative to carry out hydrotests for the tightness of the connection. To do this, plug one end of the pipe and connect a water pump to the other. The water pressure during testing should be twice the operating pressure. Such tests will allow timely detection and elimination of leaks.

Damper tape for heated floors

Damper tape and insulating film

A damper tape is provided along the contour of the room, which compensates for thermal expansion of the upper cement screed. The diagram provides a layer of waterproofing between the pipe contour and the screed. For these purposes, you can use cheap polyethylene film with a thickness of at least 30 microns.

A metal or plastic mesh for reinforcement is laid on top of the waterproofing.

Insulation film and mesh

The thickness of the screed is 3–10 cm above the surface of the pipes. The screed is done in the usual way; you can use wet or semi-dry material. After cooling, the final floor covering is installed.

Screed over water heated floor

The diagram shows all the layers of the heated floor, indicating the materials of manufacture and linear parameters.

The simplest scheme

The main difficulty in installing a heating system is the need to supply coolant to the second floor of the building. And the main advantage of single-pipe networks is their simplicity and low cost of installation. Regardless of the wiring method - top or bottom - they can significantly save on materials and components, reducing the total length of the pipeline. If necessary, different types of heating systems can be combined with each other, thereby increasing their efficiency.

The design of a single-pipe system is very simple. One pipe leaves the boiler, to which radiators are connected. Having passed through all elements of the heating network, the pipe returns to the heating unit. As a result, the coolant passes in a vicious circle, repeating this cycle over and over again.

The peculiarity of single-pipe schemes is the difference in coolant temperature in different parts of the network. When leaving the boiler, the water is at its maximum temperature. As it passes through a closed circuit, it gradually cools down, giving off its heat to each of the installed radiators. They, in turn, give it to the air space of the premises.

The operating principle of such a system determines its technical features:

- There can be a strictly defined number of radiators in a network.

- The system cannot be scaled or changed during operation.

- Radiators located at a distance from the boiler heat up less and, as a result, heat the room worse.

- The scheme is not suitable for large houses with a large number of heated rooms.

These features determine the disadvantages of single-pipe systems, as well as restrictions on their use. On the other hand, if you correctly install the heating network in a two-story private house and select effective heating equipment, you can ensure comfort, coziness, an optimal microclimate and a temperature regime favorable for humans.

Single-pipe systems also have advantages, which determines their popularity. The most important advantage is the low cost of installation due to the reduction in the number of pipes and time.

Important! This scheme is suitable for houses of different heights and with different layouts. Regardless of the architectural features of the house, it will completely cover all rooms

During installation, it is allowed to lay the deck chair in the floor screed. For underfloor heating systems, a single-pipe design is the ideal choice. The pipeline can also be laid on the floor surface. In this case, it is necessary that the sun lounger goes as low as possible.

Expansion tanks, open and closed systems

Single-pipe open type heating system with forced circulation. The expansion tank should be at the highest point.

When creating heating in a two-story private house with your own hands, you need to think about the location of the expansion tank. If you plan to create an open system, then the tank is installed at the highest point of the heating system. Most often it stands on the tops of vertical sections - this ensures effective removal of air bubbles. Sometimes it is also installed on the return pipe, but this scheme does not ensure air removal and forces the installation of additional pipes.

In closed heating systems the following are used:

- Sealed expansion tanks;

- Air vents;

- Safety valves;

- Thermomanometers.

Sealed tanks are hollow metal structures with a flexible internal partition. This partition bends and takes on part of the coolant that expanded when heated. The heating system remains completely sealed. Air is removed through a special air vent, and if excess pressure is detected, it will be relieved via a safety valve.

Open heating systems do not require the installation of air vents and safety valves, but they do require the installation of a tank at the very top. As for closed systems, here the tank is placed near the heating boiler, along with a “safety group”. As a result, the cost of creating heating in a two-story private house increases, but residents have the opportunity to create heating with a non-freezing coolant.

In open heating systems, the use of coolants other than water is quite problematic. Therefore, we opt for closed systems, the installation of which will not cause huge additional costs.

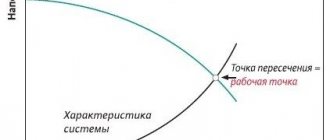

Balancing

The point of this operation is to balance all branches of the system and regulate the water flow in each of them. To do this, each branch must be correctly connected to the mains, that is, special balancing valves must be installed on the tie-in. Also, control taps or thermostatic valves are installed on the connections to all radiators.

It is not so easy to carry out accurate balancing with your own hands; you need to have the appropriate instruments (at least a pressure gauge to measure the pressure drop across the balance valve) and perform calculations for pressure losses. If there is none of this, then after testing you need to fill the system, bleed the air and turn on the boiler. Next, balancing of the two-pipe system is done by touch, according to the degree of heating of all batteries. Devices located next to the heat generator must be “pressed” so that more heat goes to those further away. The same goes for entire branches of the system.

Systems with natural and forced circulation, which is better?

The difference between these two types of circulation is the way water moves through the CO. To implement a forced scheme, it is necessary to install special equipment, in particular a circulation pump; for a natural scheme there is no such need.

The EC is characterized by a number of advantages:

- absence of noise and vibration during system operation;

- simplicity of installation and maintenance;

- long service life.

Installation of a natural circulation system

At the same time, COs with natural circulation start up quite slowly; the water in the pipes of such systems can freeze at sub-zero temperatures outside. Another disadvantage is the need to install large cross-section pipes (they are more expensive and more difficult to install).

Nowadays such systems are used quite rarely. Users prefer a more modern and efficient heating scheme. This is forced circulation CO, which has the following important advantages:

- the possibility of constructing wiring of any length in a private house;

- independence of heating quality from coolant temperature indicators;

- simple adjustment of operating modes.

CO with forced circulation

In versions with forced circulation, hot water flows through pipes due to the operation of pumping equipment. The water comes from the boiler, in which it is heated, under the action of a special pump (it is called a circulation pump).

With such a heating scheme, Mayevsky valves and taps are installed on each radiator. The first make it possible to select the heating temperature of a specific battery. Valves can be automatic or manual. And the Mayevsky valve allows you to remove unnecessary air from the system.

Mayevsky valves and taps

Experts advise installing CO in two-story cottages with a double-circuit boiler and forced circulation. Then it will be very easy for you to install a “warm floor” in your house, install heated towel rails and always control the operation of the CO, setting the most comfortable temperature for yourself.

Additional equipment - advantages and disadvantages

Any heating circuit can be improved by adding thermostats to adjust the operation of each battery, thermostats, a hydraulic needle, a circulation pump for each circuit, and other additional devices.

Mayevsky taps and air vents at the top of each riser are required in systems with a closed expansion tank. Each additional device makes the system more efficient, more economical, and allows for more precise and convenient settings.

Use only the necessary components, because the fewer units, the lower the likelihood of one of them failing and stopping the system.

Is it worth installing it yourself?

As can already be understood from all of the above, the Tichelman Loop heating has a fairly simple design. In any case, it will not be more difficult to assemble than a regular dead-end system. However, it is worth considering that the Tichelman loop is most often installed in very large houses. The assembly of heating systems in such buildings in itself has a lot of nuances. In addition, the calculation of communications for such an object should be made as accurate as possible. In this case, simply taking average values (10 kW boiler per 1 m2 of room, pipe diameters 26 and 16) will not work. It will be quite difficult to make correct calculations using tables and even using appropriate programs on your own. Therefore, it is still worth hiring specialists to design and install the Tichelman Loop system in a large house.

Our ancestors slept differently than we do. What are we doing wrong? It’s hard to believe, but scientists and many historians are inclined to believe that modern man sleeps completely differently than his ancient ancestors. Initially.

These 10 little things a man always notices in a woman Do you think your man doesn’t understand anything about female psychology? This is wrong. Not a single little thing can be hidden from the gaze of a partner who loves you. And here are 10 things.

7 Body Parts You Shouldn't Touch with Your Hands Think of your body as a temple: you can use it, but there are some sacred places that you shouldn't touch with your hands. Research showing.

20 photos of cats taken at the right moment Cats are amazing creatures, and perhaps everyone knows this. They are also incredibly photogenic and always know how to be in the right place at the right time.

15 Cancer Symptoms Women Most Often Ignore Many signs of cancer are similar to symptoms of other diseases or conditions, which is why they are often ignored.

Pay attention to your body. If you notice

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don’t worry about the shape and length of their hair. It seems that youth is created for experiments with appearance and daring curls. However, already last.

Preparatory stage

Before calculating a water heated floor, decide on the desired temperature for a given room

It is the same for all underfloor heating schemes. You need to start by calculating the power of the system, taking into account the area of the room, the optimal temperature, and actual heat losses. The power of heated floors should be increased for rooms located on the first and last floors, if the facade walls do not have insulation in accordance with the requirements of existing standards, if the finishing coating is made of natural stone or ceramic slabs.

Necessary conditions for high-quality operation of water floors

Old flooring should be removed and the base leveled if necessary. The height difference across the entire area of the room cannot exceed five millimeters, otherwise the load on the pump increases significantly. In addition, there is a high risk of air locks forming and difficulty in removing them.

Existing single-pipe system schemes in a private house

To heat a private house, both vertical and horizontal single-pipe heating schemes can be used.

For one-story buildings, the horizontal version, usually with a closed contour, has found the greatest use. To supply heat to a two-story house, both of these schemes can be used.

Horizontal single-pipe heating system for a private house

This heating scheme involves the sequential installation of radiators connected to one main pipeline. In this case, the supply and removal of coolant to the heating devices can be carried out diagonally (the supply is organized in the upper part of the radiator, and the return is in the lower) or in a lower version (both the supply and return are located at the bottom of the devices). The most widely used option for heating a one-story private house is the second option, called “Leningradka”.

Figure 2 – Horizontal diagram of single-pipe heating

In the general case, a horizontal single-pipe heating system is structurally simple: the main line is laid from the heat source along the entire perimeter of the building and returns back. As a rule, the supply line is located below (above or below the floor), and the required number of radiators is connected to it.

With this option, coolant circulation can be provided naturally (by gravity) or forcefully (using a circular pump). In the first case, during installation it is necessary to observe the slope of the supply line in the direction of water movement. Radiators should be located at the same level.

It is known that the coolant, passing successively through all heating devices, gradually cools. Therefore, with natural circulation, the temperature in the radiators will decrease more and more as you move away from the heat source.

This drawback can be eliminated either by increasing the temperature of the coolant, which is not always advisable, or by increasing the speed of its movement, for which purpose a pump is installed in the system.

In the case of using a horizontal circuit with natural circulation for heating a two-story house, a vertical riser is provided, which should be cut into the main pipe on the ground floor and preferably up to the first radiator. The coolant will first be supplied to the second floor, pass through all the devices installed there, then go down to the lower level and, having passed through the remaining radiators, return to the boiler.

It is clear that in this case the temperature on the second floor of the house will be higher. But if the boiler’s power is not enough, it will not be able to supply water upward, and the system will stop functioning. This drawback is eliminated by installing a circular pump, a return riser, as well as installing taps between the supply riser and the first heating devices, which allow you to regulate the heat supply and the required temperature at each level of a two-story building.

Figure 3 – Horizontal diagram of single-pipe heating of a two-story house

Vertical single-pipe heating system for a private house

This heating scheme is often used to heat a two-story house. In the general case, a vertical single-pipe system provides for overhead distribution, so the main heating pipes are laid in the attic. Risers extend from them, supplying coolant to radiators, which must be installed on different floors, one below the other.

Water circulation can also be carried out either forcibly (using a pump) or naturally (by gravity). In the latter case, installation requires compliance with the slopes of the inlet and outlet lines, as well as the use of large-diameter pipes.

Figure 4 – Vertical diagram of single-pipe heating

Designations: I – flow riser; II, III – risers with offset and axial closing sections; IV, V – flow-regulated risers: 1 – coolant supply line; 2 – heating device; 3 – flow faucet; 4 – double adjustment valve; 5 – axial closing section; 6 – the closing section is displaced; 7 – bypass section; 8 – air vent; 9 – expansion tank; 10 – main riser; 11 – return line; 12 – heat exchanger; 13 – circular pump

What is the best heating scheme for a two-story house?

If to heat a small one-story private residential building you can use an ordinary stone or brick stove, then for heating large houses and cottages, all kinds of water heating schemes for a two-story house, designed for the use of gas or solid fuel heating boilers, are more effective.

In order to study this issue in more detail, this article will present a brief overview of instructions in which I plan to consider the three most common heating schemes for a two-story house using water radiators and underfloor heating systems.

Option 1. Single-pipe connection diagram

The most stable, but at the same time the least effective, is the single-pipe heating system for a two-story house, which is a chain of heating radiators installed in different rooms, which are connected in series with each other using metal or plastic water pipes.

Options for connecting radiators in a two-story house using a two-pipe and one-pipe scheme

This type of connection allows you to minimize the amount of materials used and work performed, however, it has some significant disadvantages.

- Heated water, passing through pipes and radiators, gives off its heat unevenly, and as it moves to remote rooms of the house, it gradually cools down.

- To compensate for this phenomenon, in order to increase the heat transfer area, it is necessary to install more water radiators in remote rooms.

- With this connection option, it becomes impossible to independently adjust the optimal temperature for each individual room in a residential building.

Single-pipe heating circuit

Option 2. Two-pipe connection

More efficient, but at the same time more expensive, is a two-pipe water heating scheme for a two-story house, the installation of which requires the consumption of more materials and labor costs.

With this connection, each water radiator is individually connected with an inlet pipe to the direct heating circuit, and an outlet pipe to the return circuit of the heating system.

Connecting the first and second floors using a two-pipe scheme

For two-story houses, this connection option is considered the most optimal, as it has the following advantages:

- Thanks to uniform heat transfer, equal heating of all rooms of a residential building is ensured, regardless of their relative location relative to the heating boiler.

- Separate connection of each section makes it possible to independently regulate the required temperature for each specific room or room of a residential building.

- More efficient heat distribution leads to increased energy efficiency of the entire system, and accordingly to significant fuel savings.

Two-pipe heating scheme in a two-story house

Among other things, a two-pipe connection allows you to remove the main forward and return pipelines from prying eyes by placing them under the finished floor or behind decorative wall decoration elements.

Option 3. Combined connection diagram

When designing and building a residential building with a heated floor system, the most rational would be a combined heating scheme for a private two-story house, combining both a single-pipe and a two-pipe connection.

Heating system design with a combined circuit

In this case, parallel to the forward and return pipelines, a separate manifold for the coolant is connected through a three-way valve. This, in turn, is sequentially connected to a warm water floor system.

This connection has all the advantages of a two-pipe circuit. In addition, this option allows you to separately turn on heating radiators and a heated floor system, which makes it possible to more flexibly regulate the required temperature in the room.

Schematic diagram of the combined connection of underfloor heating and water radiators

In parallel with the water collectors of the underfloor heating system, you can also connect water heaters and heated towel rails located in the bathroom, shower room or kitchen.

Single-pipe or double-pipe

As the name suggests, these systems differ in the number of main pipelines supplying coolant to the radiators. In a single-pipe scheme, all connections from the batteries are connected to one common pipeline; it is both supply and return. A striking example of such a system is the famous “Leningradka”, shown in the figure below:

Despite the apparent ease of installation and savings in materials, the single-pipe system has one serious drawback. Since each battery discharges cooled water into a common line, the coolant arrives at the next radiator at a lower temperature, and so on, until the end of the branch. Because of this, the latest heating device may be barely warm. What does it mean?

The room still needs to be heated, which means you will have to increase the heat output of the battery, that is, increase the number of sections. It turns out that we saved on pipes and fittings, but spent money on additional sections. Add here the difficulties with regulation in two-story houses and the impossibility of natural circulation.

The only disadvantage of a two-pipe system is that its assembly requires more materials, since in this case the supply and return manifolds are separated. That is, the coolant comes to all batteries through one pipe and leaves through another. This scheme for the heating system of a private house has many advantages, and therefore is the most popular. This is a reason to opt for a two-pipe system.

Conclusions and useful video on the topic

You can see how a two-pipe scheme is implemented in practice in a 2-story building in this video:

You can find out about the arrangement of a combined system with radiators and heated floors here:

And this video will be useful for those who are planning to install heating with gravity or mixed circulation:

To summarize, we can say that there is no ideal and universal heating scheme: in each specific case, many factors must be taken into account and priorities must be set. We tried to describe to you all the available options to make the choice easier and more correct.

What is the heating scheme in your house? How satisfied are you with it and what would you like to change? Join the discussion below.

Source

General operating principle

The operation of any heating system is to convert the energy of burned gas, solid (liquid) fuel or electricity into heat. Heated water (antifreeze) flows through pipes into radiators, where it releases heat into the space.

Gravity system

Pipe slope during natural circulation in the heating system

The operation is based on the laws of physics. If the contours provide for the natural movement of water, then such a scheme is called gravitational.

It is extremely difficult to create a heated floor circuit in gravity systems without the use of additional pumps. A difference of several millimeters in the pipes in the floor leads to airing and cessation of coolant movement.

The density of the heated coolant is lower than that of the cold one. Due to the difference in density, water/antifreeze from the boiler rises upward along the supply riser (diameter 60 - 80 mm). An open or closed expansion tank is installed at the top of the entire system.

The upper circuit of the wiring is laid along the perimeter of the second floor premises. A pipe with a diameter of 40-50 mm is installed with a slope of 2-3 cm per meter of length. In places where radiators are installed, pipes with a diameter of 16 - 25 mm are welded into the wiring. The liquid flows through them into the radiators. The coolant then enters the radiators on the ground floor.

At the level of the boiler or slightly lower, along the perimeter of the building, a lower circuit (return) is laid, into which the cooled water is collected.

The circuit is used in places where the electricity needed to operate the pumps is often cut off. Gas boilers in this case are equipped with non-volatile safety devices.

The same scheme is needed for systems with solid fuel boilers. In the event of a power outage, circulation stops, and wood/coal continues to heat the water. You can stop the operation of a solid fuel boiler only by quickly removing the burning fuel, which is extremely problematic. Increased pressure occurs, which can destroy pipes and radiators.

Basic system requirements

There are a number of important requirements that must be taken into account when designing a heating system.

- In general, the heating design of a two-story house must correspond to the architectural design of the building. The placement of the boiler requires certain structural and design conditions of the room in which it will be located. The installation locations of radiators, as well as the pipeline routes, should not violate the architectural rules for the arrangement of residential and technical premises. All this means that a qualified designer must draw up a plan for the heating system, based on the finished architectural design of the house.

- During operation, the system must provide all internal and external surfaces with the temperature required by building codes and regulations (SNiPs).

- The system must be quite economical to operate. If heating your home requires too much energy consumption, you should contact a specialist: perhaps some parts or components can be unified.

- The pipeline should have a minimum of bends and turns. If during its installation you need a large number of fasteners in different sizes, it means that the heating circuit is poorly designed.

It is always necessary to draw up and evaluate a preliminary scheme Source tapiart.ru

- During use, the system must be reliable, safe, convenient and silent. A good system allows home owners to easily control heating appliances and, if necessary, easily repair them.

- The aesthetic side is also important. Radiators and pipes connected to them must have a neat, attractive appearance. The less noticeable the heating elements are, the better.

What does forced circulation provide?

All the advantages of water heating systems, where the coolant circulates with forced impulse, are provided by one simple element - the pump. It is placed on the supply or return pipeline directly next to the boiler, as a result of which the speed of water movement through the pipes significantly increases. If during gravity flow the coolant speed is 0.1–0.3 m/s, then after installing the pump it increases to 0.7–1 m/s. This provides a lot of benefits.

So, let’s look at all the advantages of a forced circulation system:

- the speed of water has increased - its flow rate has increased, which means that the diameter of the pipe can be reduced;

- the warm-up time of all radiators is reduced, there is no inertia;

- large length of branches and highways, choice of a convenient method for laying them. The main thing is that the pump develops the required pressure;

- The slopes of the routes can be kept to a minimum. They are only needed to empty pipelines;

- when a closed type system is installed, the expansion tank can be placed in the boiler room.

The list of other advantages is very extensive; there is no need to list them all. Is it worth mentioning an important point: a forced circulation system allows you to install a type of heating such as heated floors in private homes. But there are only 2 shortcomings, but one of them plays an important role. This is the dependence of building heating on the availability of electricity. They turned it off - the pump stopped - the batteries cooled down.

There is also a worse case scenario. After a power outage, a solid fuel boiler will quickly overheat and boil, and then there will be an explosion. Therefore, forced circulation must always be provided by uninterruptible power supplies or a generator so that the heating system continues to function normally.

The second disadvantage is that the running pump consumes a small amount of electricity and sometimes makes noise. But these nuances are insignificant compared to the number of options for heating schemes that forced movement of the coolant allows you to implement. Here is their list:

- single-pipe;

- two-pipe;

- collector (radial);

- water heated floors.

How does heating work without a pump?

To understand how a forced circulation system works, it is worth understanding how buildings are heated using natural coolant circulation. As the latter, various special compounds and water can be used. For a one-story house, water heating is most often chosen.

The movement of water through pipelines is carried out according to the laws of physics. Having heated up in the boiler to a given temperature, it begins to rise up the riser. Due to this, all pipes and radiators of the system are gradually heated. The newly incoming hot water gradually displaces the cold water down to the boiler.

After the cooled coolant heats up again in the boiler, it will begin to rise up the riser to displace the cooled down. This cycle will be repeated as long as the boiler operates. Obviously, the larger the diameter of the pipe, the more coolant will pass through its cross section per unit time.

That is why, with natural circulation, the diameter of the pipeline and the dimensions of the mounted radiators are of great importance. If the area of the latter is insufficient, it will be difficult to warm the room to a comfortable level.

Features of installation of a single-pipe heating system

Traditionally, installation work begins with choosing a location and installing a heating source. Depending on the type, it can be mounted on the wall (electric or gas boilers) or on the floor (gas or solid fuel equipment). In the latter case, a mandatory chimney installation is required.

At the next stage, the main lines are laid at each level of a one- or two-story building, not forgetting to install tees at the points of connection with heating radiators and bypasses (if any).

Next, a circular pump is installed.

After this, they begin to install the expansion tank, which should be placed at the highest point of a one- or two-story house. In this case, the minimum height of its location is 3 m.

At the next stage, the radiators are installed. As a rule, they should be located under windows. To do this, first make markings for mounting heating devices, taking into account the requirements for maintaining distances to structures (floors, walls, etc.), and then install brackets and hang batteries on them.

When connecting radiators to the main line, you should adhere to the selected connection diagram, avoiding unnecessary pipe bends. After this, plugs, Mayevsky taps and shut-off fittings are installed.

After connecting the heating system to the boiler, it is pressurized with compressed air. Then it is filled with coolant and a test run is performed and, if necessary, adjustments are made.

To allow draining and replenishing the system with water, it is recommended to install a special unit.

Flue gas problem

When burning any type of fuel, combustion products are formed, which must be removed outside the premises.

In traditional boilers, combustion products are discharged through a chimney, in which natural draft is present. The principle of operation of the chimney is simple - lighter hot gases tend to rise, obeying the buoyancy force. The higher the temperature of the gases, the better the thrust. If there is insufficient draft in the chimney, normal operation of the heating device is not guaranteed. Modern boilers have protection against lack of draft - the equipment automatically turns off. Gas boilers come in two types - with open and closed fireboxes. In the former, combustion products always exit through natural draft. Such boilers are also called atmospheric boilers. In the second case, it is always forced. This is the so-called turbocharged boilers.

The chimney of atmospheric gas boilers cannot be shorter than 4 m, and for liquid fuel boilers - shorter than 5 m. It is often difficult to meet these requirements when the boiler is located in the attic, since from the boiler outlet to the roof surface is usually no more than 2 m. It turns out that the height of the chimney above The roof slope must be at least 2 m for a gas atmospheric boiler, and such a long chimney does not always fit into the architecture of the cottage.

Boilers with a closed combustion chamber do not have the disadvantages of atmospheric engines. They do not depend on chimney draft, weather conditions and wind direction. Combustion products are discharged through a coaxial pipe, which also serves to supply fresh air to the firebox. Exhaust gases are removed due to excess pressure created by a built-in fan. The specificity of this solution allows the use of not only vertical, but also horizontal chimneys, along their entire length. The only limitation is that they cannot be longer than 5 m. The coaxial pipe of a boiler with a closed combustion chamber is most often routed through the wall and ends with a special tip on the outside. If necessary, exhaust gases can be discharged through the roof. Special ceramic or steel chimneys are designed for this purpose. As a rule, this is a pipe within a pipe, where gases are discharged through the internal channel, and air is taken in through the external one.

Gas boilers are either convection or condensation . Convection - these are the already described atmospheric ones with an open firebox. Condensing boilers have a closed firebox and are designed to remove residual heat from combustion products. In such boilers, gases are removed forcibly, since their temperature is much lower than the level that would provide natural draft in an atmospheric chimney.

When exiting a horizontal coaxial pipe through a wall, two conditions are met:

- the height of the outlet from the ground is at least 2.5 m;

- the minimum shortest distance to the nearest window is 0.5 m.

Natural and forced circulation

Single-pipe systems can be installed with natural or forced circulation of coolant. The scheme is always chosen based on the layout and architectural features of the building. For 1-story houses, natural circulation of water in the main is preferable. This scheme is also suitable for two-story private houses. You just need to take into account the planning features of the building.

Forced circulation

The performance of the heating system is determined by the correct installation location of the expansion tank. In one-story houses, it is often necessary to take it out into the attic, which risks freezing during the cold months of winter. In a two-story building, this problem disappears by itself. The expansion tank can be placed anywhere on the second floor. This arrangement will ensure the necessary coolant discharge.

Systems with natural circulation are most often installed with top wiring, when the coolant enters the radiators from above. The main advantage of this method is the most uniform heating of heating devices. To ensure the gravitational movement of water in the pipes, they are laid at a slope of 3–5 degrees. The pipes are selected in such a way that their diameter increases as the return line is supplied to the boiler. The result is an efficient, easy-to-use and reliable system.

Despite its advantages, a system with natural circulation in two-story buildings is not installed very often. The main reason for this is the limitations on the area of the room where such communications can be created. The pressure of the coolant moving naturally through the pipes is sufficient to heat a house of no more than 130 square meters. meters. The number of floors of the building does not matter. A significant temperature delta in the supply and return pipes also has a negative impact on operation.

A single-pipe forced circulation system is more efficient. It is better to use a scheme in which two branches extend from the boiler - one for each floor. When using such a connection, it is necessary to install shut-off valves at the pipe inlet.

The operation of the system looks like this: The coolant leaves the boiler through the supply pipe and diverges along two branches. Each branch has radiators heated by the passage of warm water. Next, the coolant enters a single return pipe, which leads to the boiler. Installing shut-off valves allows you to heat not the entire room, but only half of it, since if necessary, one branch can be easily turned off.

But such a solution is energy-dependent, and in the event of a power outage, the house will be left without heat. After all, the circulation pump will stop working.

Automatic control system for gas contamination and gas leakage protection

Dangerous properties of gas fuel:

- the ability of gas to form fire-explosive mixtures with air;

- suffocating power of gas.

The components of gas fuel do not have a strong toxicological effect on the human body, but at concentrations that reduce the volume fraction of oxygen in the inhaled air to 16%, they cause suffocation.

When gas burns, reactions occur that produce harmful substances, as well as products of incomplete combustion.

Carbon monoxide (carbon monoxide) is formed as a result of incomplete combustion of fuel. A gas boiler or water heater can become a source of carbon monoxide if the air supply and flue gas removal system is faulty (insufficient draft in the chimney).

Carbon monoxide has a highly targeted mechanism of action on the human body, including death. In addition, the gas is colorless, tasteless and odorless, which increases the risk of poisoning. Signs of poisoning: headache and dizziness; there is tinnitus, shortness of breath, rapid heartbeat, flickering before the eyes, redness of the face, general weakness, nausea, and sometimes vomiting; in severe cases, convulsions, loss of consciousness, coma. Concentrations in the air of more than 0.1% lead to death within one hour. Experiments on young rats showed that a CO concentration of 0.02% in the air slows down their growth and reduces activity compared to the control group.

Gas alarm - gas leak sensor

and carbon monoxide gas alarms in residential buildings and apartments containing gas boilers, hot water heaters, stoves and other gas equipment

The methane gas alarm serves as a leakage sensor for household natural or liquefied gas from gas equipment. The carbon monoxide alarm is triggered in the event of malfunctions in the smoke exhaust system and the entry of flue gases into the room.

Gas sensors should be triggered when the gas concentration in the room reaches 10% of the LPR of natural gas and the CO content in the air is more than 20 mg/m 3 . Gas alarms must control high-speed shut-off valves installed at the gas inlet into the room and shut off the gas supply based on a signal from the gas sensor.

NCPRP and VKPRP are the lower (upper) concentration limit of flame propagation - the minimum (maximum) concentration of a flammable substance (gas, flammable liquid vapor) in a homogeneous mixture with an oxidizer (air, etc.) at which it is possible for a flame to spread through the mixture to any distance from ignition source (open external flame, spark discharge).

Natural circulation system

The principle of its operation is based on the convective movement of water. The hot coolant leaving the boiler has less density and weight than the cooled water coming through the return line. The latter tends to go down and displace the lighter heated coolant. Due to this, natural circulation occurs. For normal operation of the system, several conditions must be met:

- due to the low speed of fluid movement, the diameters of the pipes must be increased to ensure the required coolant flow;

- the difference in the densities and masses of water at different temperatures is small, therefore the heating circuit with natural circulation should be installed with large slopes of horizontal sections;

- The pipeline network is under natural pressure; creating excess pressure is unacceptable, otherwise the flow of liquid will stop. This means that the expansion tank can only be of the open type and must be installed above the entire system;

- In order to withstand all the slopes, the boiler often has to be placed in a small recess.

What does such a heating distribution scheme give us in a two-story house, where compliance with all conditions requires careful calculations and leads to high consumption of materials and complexity of installation? The answer is simple: a gravitational circuit, operating in conjunction with a conventional solid fuel or gas boiler, makes the water heating of a two-story house independent of electricity. Sometimes this is a very important factor, for example, in areas with unreliable power supply. This is the scope of application of gravity systems.

Horizontal systems

This is a closed two-pipe system in which, instead of vertical risers, horizontal branches are laid, and a certain number of heating devices are connected to them. As in the previous case, branches can have upper, lower and combined wiring, only now this happens within the same floor, as shown in the diagrams:

As can be seen in the figure, a system with overhead wiring requires laying pipes under the ceiling of the premises or in the attic and will be difficult to fit into the interior, not to mention the consumption of materials. For these reasons, the scheme is used infrequently, for example, for heating basements or when the boiler room is located on the roof of the building. But if the circulation pump is correctly selected and the system is configured, then it is better to run the boiler pipe from the roof downwards, any homeowner will agree with this.

Combined wiring is indispensable when you need to install a two-pipe gravity system, where the coolant moves naturally due to convection. Such schemes are still relevant in areas with unreliable power supply and in houses of small area and number of floors. Its disadvantages are that there are many large-diameter pipes running through all the rooms, making them very difficult to hide. Plus the high material consumption of the project.

And finally, a horizontal system with bottom wiring. It is no coincidence that it is the most popular, because the scheme combines a lot of advantages and has almost no disadvantages. The connections to the radiators are short; the pipes can always be hidden behind a decorative screen or embedded in the floor screed. At the same time, the consumption of materials is acceptable, and from the point of view of work efficiency it is difficult to find a better option. Especially when a more advanced passing system is used, shown in the diagram below:

Its main advantage is that the water in the supply and return pipelines travels the same distance and flows in the same direction. Therefore, hydraulically, this is the most stable and reliable scheme, provided that all calculations are carried out correctly and installation features are taken into account. By the way, the nuances of systems with associated coolant movement lie in the complexity of the design of ring circuits. Often, pipes must cross doorways and other obstacles, which can increase the cost of the project.

Simplified floor heating connection diagrams

As in previous articles, I will first present simplified diagrams - containing only large devices.

Connection diagram for heated floors on two floors

Compared to the “single-story” scheme, check valves have been added to each heated floor circuit:

The presence of check valves in such systems is mandatory for proper coolant circulation.

Note. On the ground floor there is a check valve on the return line in front of the mixing unit. On the second floor - on the supply side, after the mixing unit. This just means that it doesn’t matter where you install the check valve, as long as it is directed in the right direction (there is an arrow on the valve body for this).

Connection diagram for heated floors on three floors

In the next picture, another outline of the heated floor has simply been added, resulting in a “three-story” diagram:

In this diagram, the check valve is on the supply side, but in front of the mixing unit. In general, I think I got the idea across: we install the valve where it is more convenient for us.

Dual-circuit heating

Installing a two-pipe heating system increases the comfort of living in a two-story house. This design, unlike a single-circuit one, allows you to regulate the temperature of the radiators in each room. This significantly saves resources and reduces the cost of paying for them. For a two-pipe circuit, two lines are installed:

- one supplies water or antifreeze to the radiators;

- the other brings the coolant back.

Each radiator has two pipes and a thermostatic valve that allows you to regulate the temperature. With its help, you can reduce heat transfer or shut off the flow of coolant completely. The advantages of such heating:

- pressure loss is significantly reduced;

- you can get by with a medium and low power pump;

- the temperature is maintained the same for all radiators;

- Various thermal devices can be used within the system;

- repairs and replacement of parts can be carried out without stopping the entire system.

Modular scheme on a wooden base

Provides for the use of ready-made OSB boards with sawn grooves for pipes and metal plates. The thickness of the slabs is at least 22 mm; in the diagram, the installation of thermal insulation is provided in the ceiling. The variety of modules in configuration allows them to be placed in the desired sequence according to the developed scheme. Depending on the pitch of the plastic pipe, it is possible to use strips measuring 130–280 mm. They have convenient latches for fixing pipes. Sizes 150 mm, 200 mm and 300 mm. After assembling the pipes and checking them for leaks, the circuit is covered with gypsum fiber boards.

Warm floor on a wooden base

Photo of laying heated floor pipes